Installation structure for fuel injection valve and fuel injection system

A fuel injection system and fuel injection valve technology, which are applied to fuel injection devices, low-pressure fuel injection, and low-pressure fuel injection, etc., can solve the problems of insufficient fuel combustion and increase in fuel consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

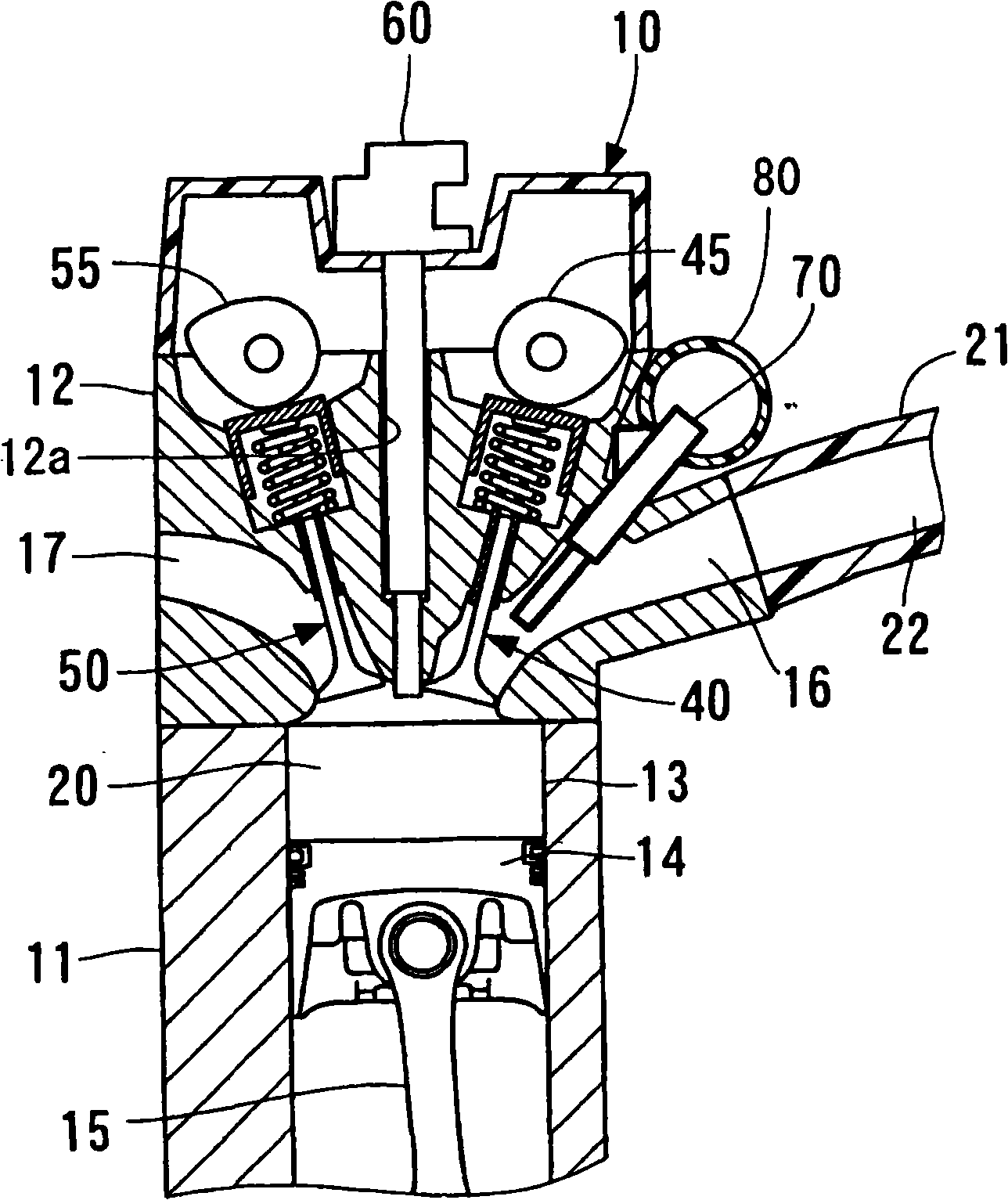

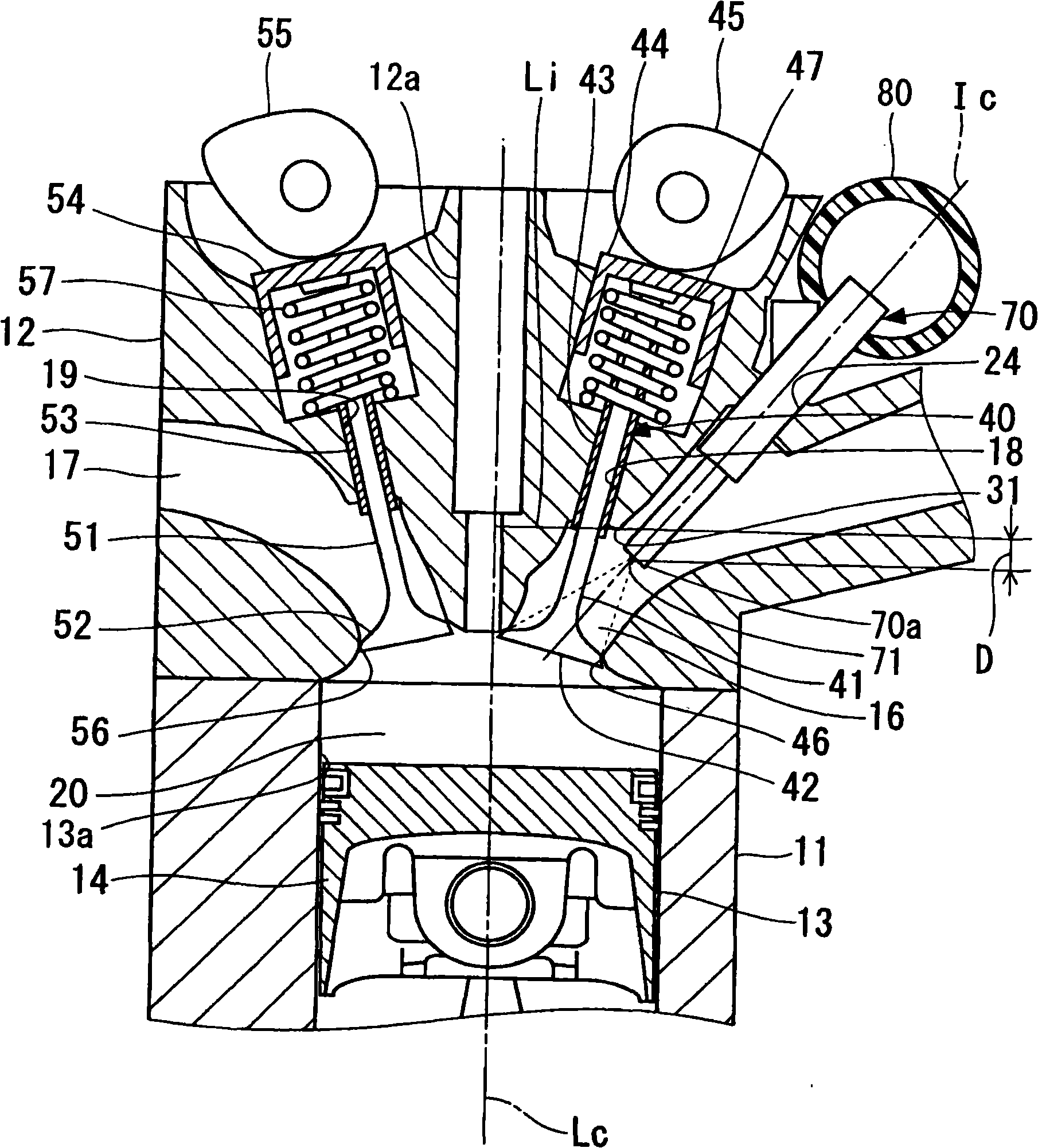

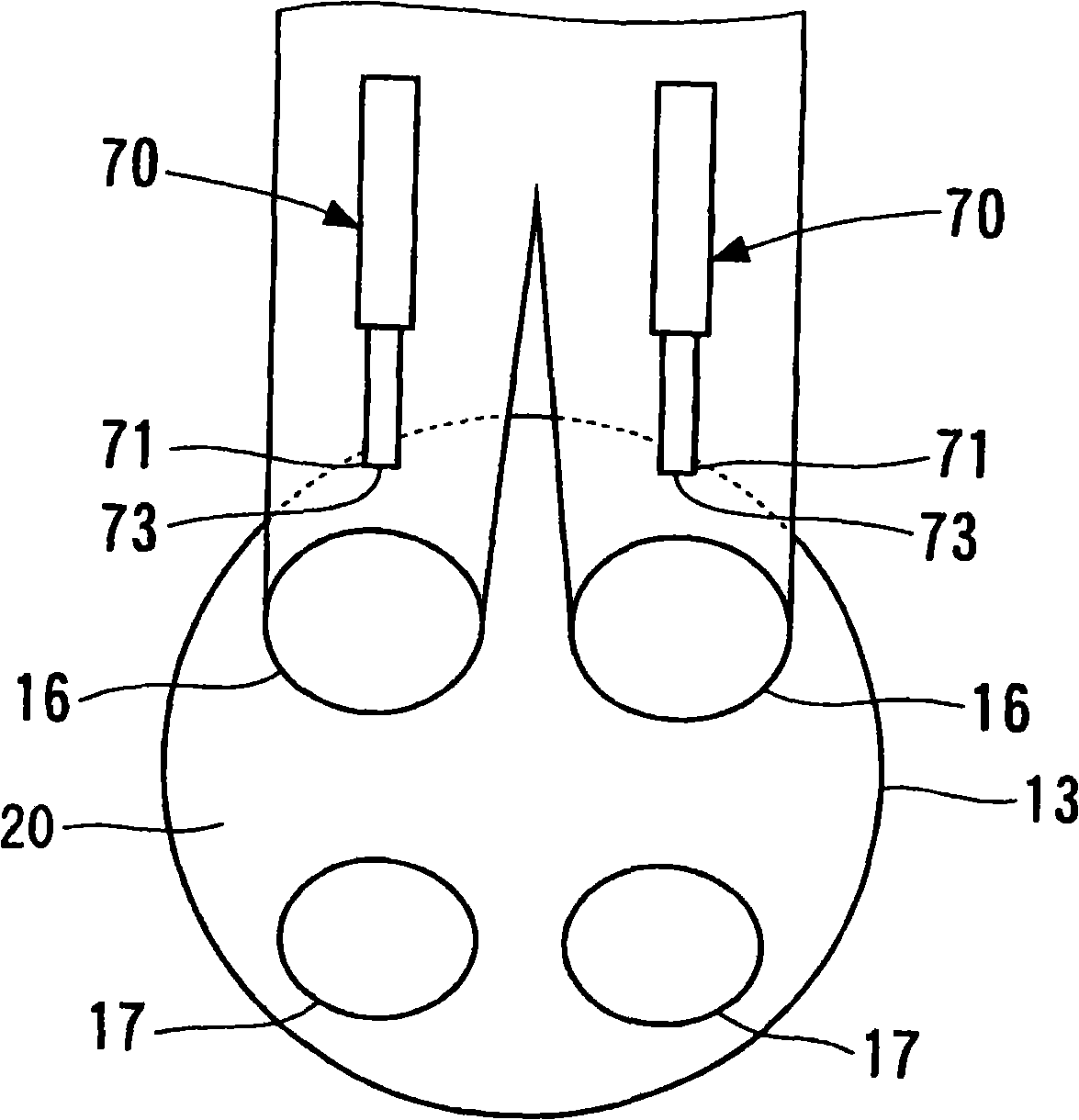

[0052] Hereinafter, the mounting structure of the fuel injection valve and the fuel injection system according to the first to fourth embodiments of the present invention will be described.

[0053] In the mounting structure of the fuel injection valve and the fuel injection system according to the first to fourth embodiments, the end portion of the fuel injection valve is a wall surface through which the intake valve protrudes out of the wall surfaces forming the intake port, and is located at an angle perpendicular to the The position overlaps with the imaginary plane of the central axis of the cylinder, or protrudes toward the combustion chamber side from the imaginary plane. Accordingly, it is possible to suppress the fuel injected from the fuel injection valve from adhering to the wall surface forming the intake port. As a result, insufficiently atomized fuel is suppressed from flowing into the fuel chamber. Thereby, the fuel injected from the fuel injection valve is suf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com