Determining one or more proportional particle group shares in flue gas of a recovery boiler

A waste heat boiler, flue gas technology, applied in furnace components, furnaces, furnace control devices, etc., can solve the problems of corrosion, reduce the availability of waste heat boilers, reduce the recovery of recyclable chemicals and steam production, and achieve short measurement time, The effect of fast burning disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The following is a detailed description of embodiments of the invention, examples of which are illustrated in the accompanying drawings. The following detailed description together with the accompanying drawings is intended to describe examples, not to represent the only ways of implementing or utilizing the provided examples. The following highlights an example activity and a series of phases / actions to assemble and use the example. However, the same or equivalent activities and stages / operations can be performed by other examples as well.

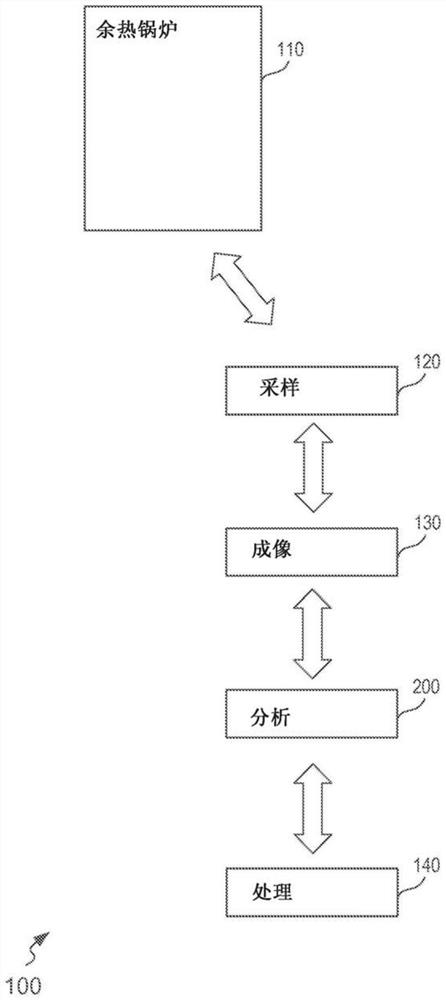

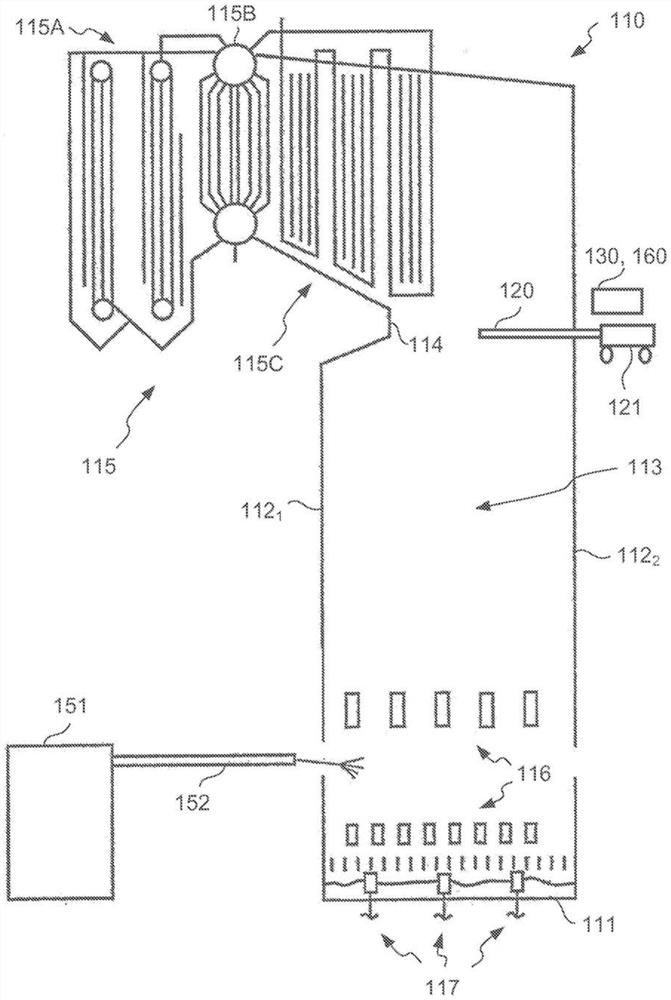

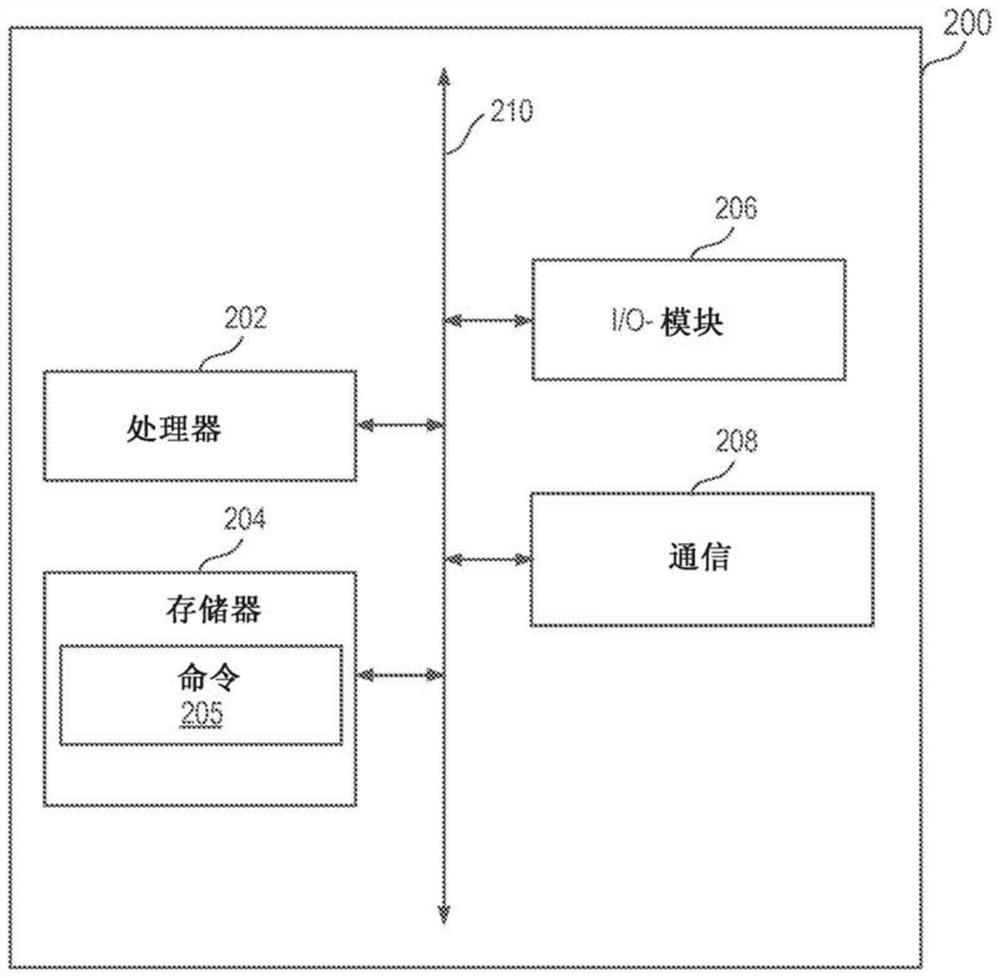

[0051] As an example, FIG. 1 depicts components of a system 100 in which different embodiments of the invention may be implemented in accordance with the invention. Figure 1A The example in represents a waste heat boiler 110, a sampler 120, means for generating a digital frame from a sample of particles contained in the flue gas (or in short, a flue gas sample) taken from the waste heat boiler 110 via the sampler 120 130. A compute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com