Free-piston type internal combustion engine power generating system

A power generation system, piston type technology, applied in the field of internal combustion engine power generation system, free piston type internal combustion engine power generation system, can solve the problems of complex devices and great influence on fuel economy, and achieve the effects of improving thermal efficiency, avoiding losses, and reducing harmful emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

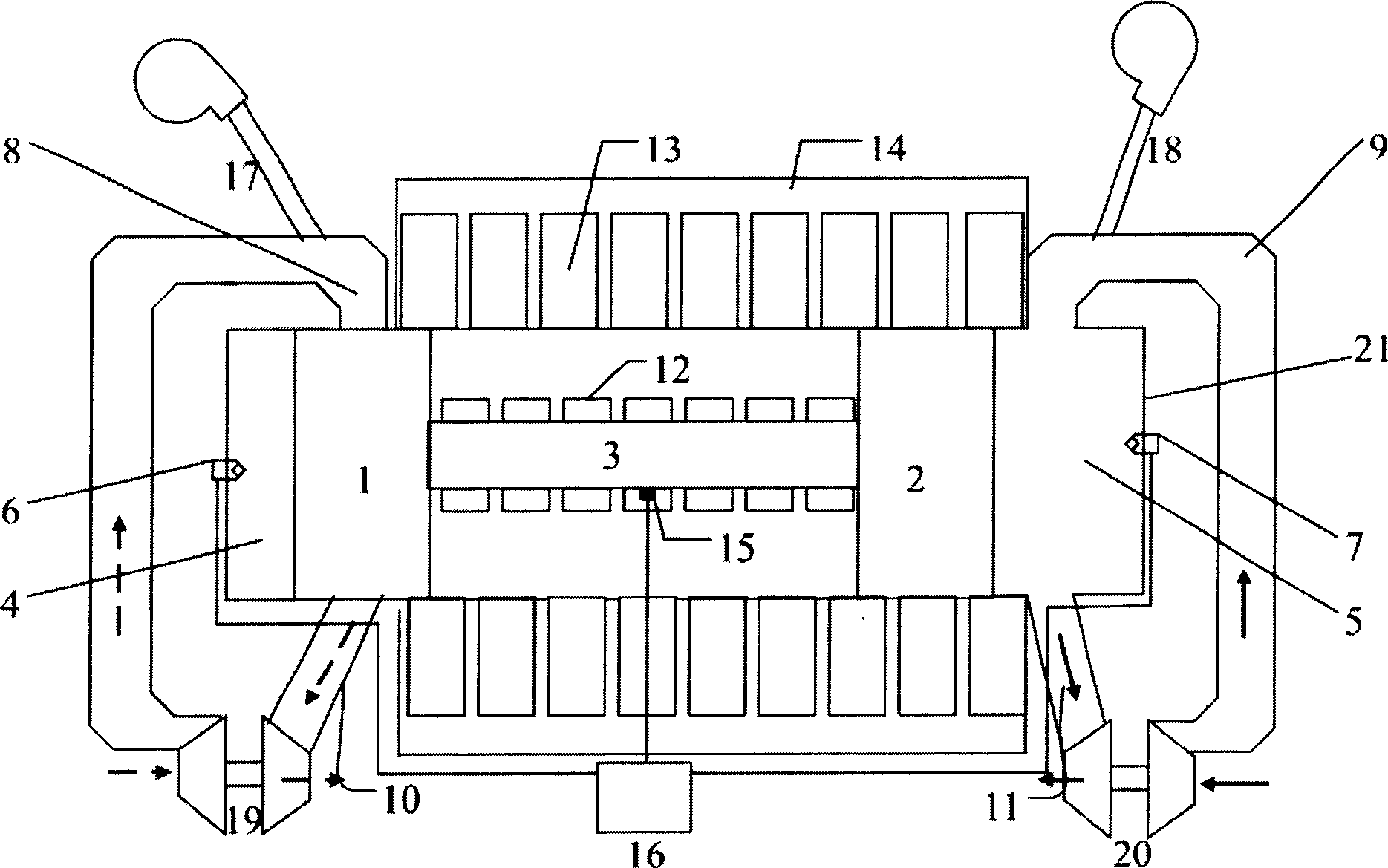

[0014] like figure 1 As shown, the present invention includes: a first piston 1, a second piston 2, a connecting rod 3, a first combustion chamber 4, a second combustion chamber 5, a first fuel nozzle 6, a second fuel nozzle 7, a first air inlet 8. Second air inlet 9, first air outlet 10, second air outlet 11, permanent magnet 12, coil 13, iron core 14, piston position sensor 15, electronic control unit 16, first high-pressure starting pump 17 , the second high-pressure starting pump 18, the first turbocharger 19, the second turbocharger 20, and the cylinder 21.

[0015] The first piston 1 and the second piston 2 form an opposing whole through the connecting rod 3 in the middle, and the connecting rod 3 is arranged with a permanent magnet 12, which reciprocates left and right in the cylinder 21 together with the opposing structure. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com