A Novel Adaptive Gas Fuel Control System

A gas fuel and control system technology, applied in engine control, combustion engine, internal combustion piston engine, etc., can solve problems such as high modification cost, inconvenient operation, and hidden safety hazards of misoperation, and achieve low cost, convenient use and maintenance, and hardware. simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

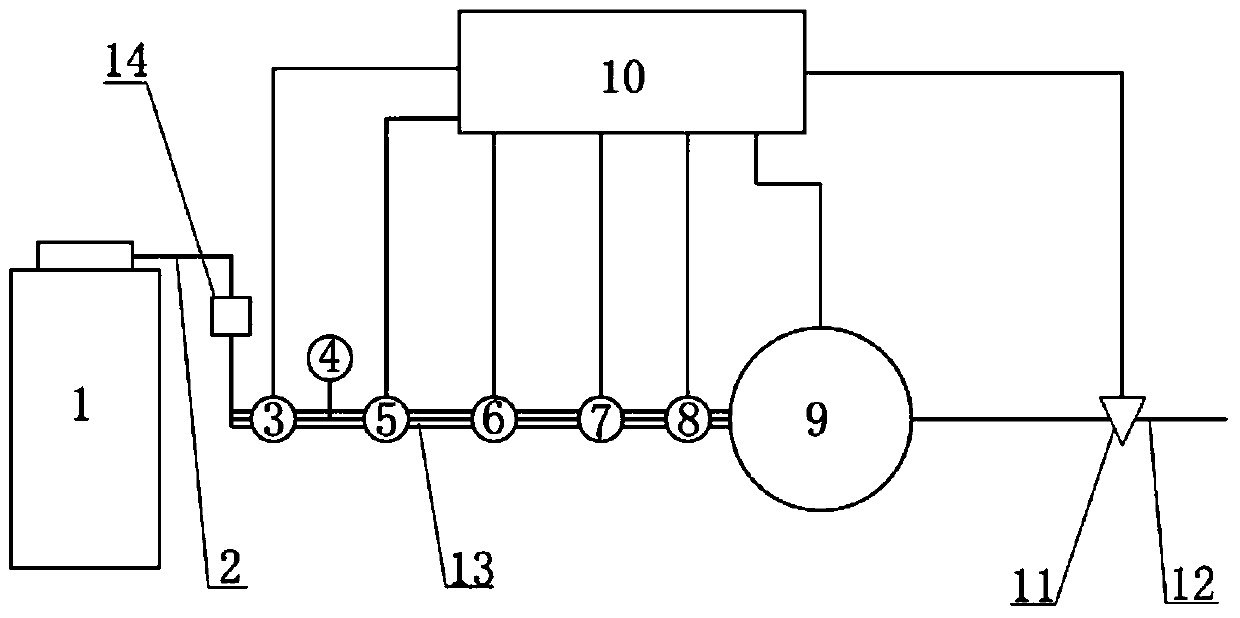

[0022] The second embodiment, this embodiment is partly the same as the above-mentioned embodiments, except that the exhaust pipe 12 is provided with an air-fuel ratio sensor, and the air-fuel ratio sensor is a common air-fuel ratio sensor in the prior art. The combustible gas concentration sensor 7 is an alkane combustible gas detector in the prior art, and the combustible gas detector is used to detect the concentration of alkane gas.

[0023] The gaseous fuel stored in the gaseous fuel tank 1 in this embodiment is a mixture of natural gas and hydrogen, wherein the volume fraction of hydrogen is 1-50%, and the rest is natural gas. However, the gaseous fuel provided does not have accurate hydrogen and natural gas. Ratio, in the process of combustion, it is necessary to control the system to respond to different hydrogen and natural gas ratios and different air pressure conditions, and specifically adjust to adapt to the best energy supply effect under the current ratio, so the...

no. 3 example

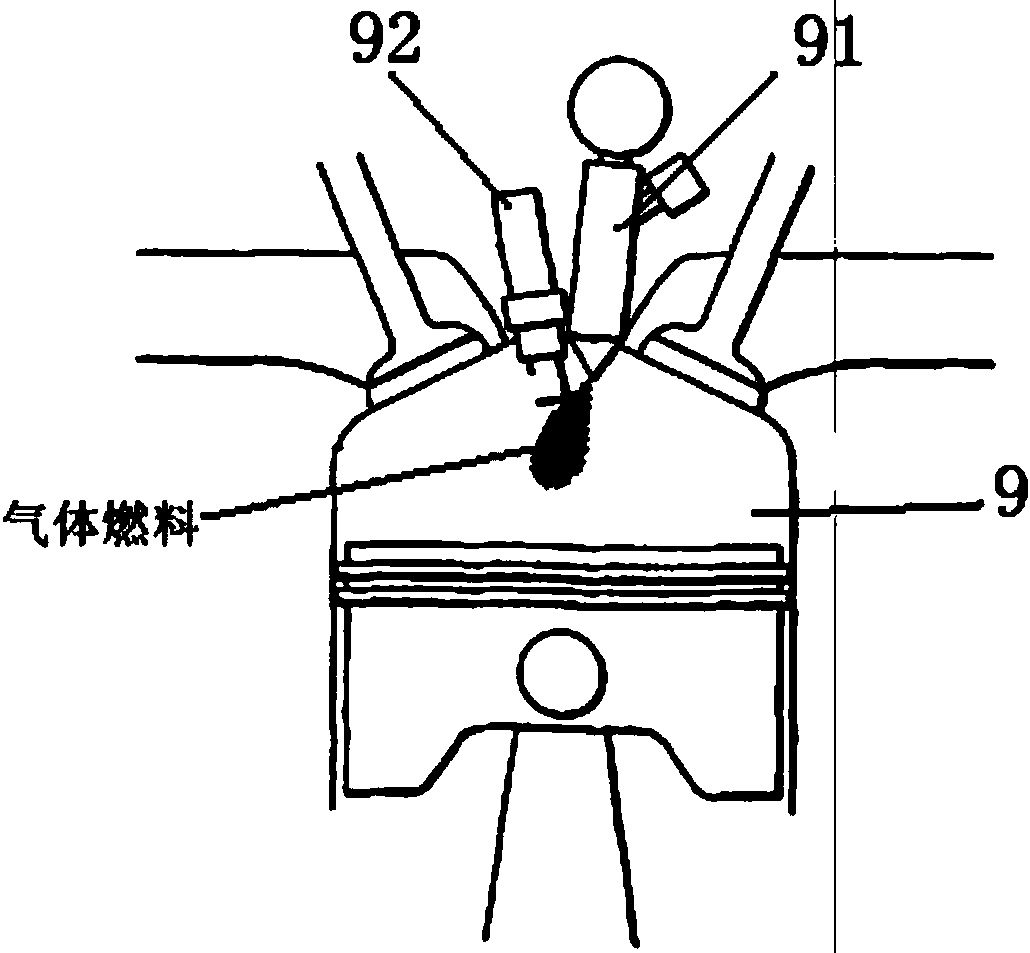

[0025] The third embodiment, this embodiment is partly the same as the above-mentioned embodiments, except that the internal combustion engine 9 is provided with an injection valve 91 and a brake spark plug 92, and the gas fuel is injected through the injection valve in the internal combustion engine 9, simultaneously causing The moving spark plug 92 can directly ignite the gaseous fuel. In this case, the gaseous fuel is diffused and mixed with air and continues to burn, which is a diffusion combustion method. At the same time, another combustion method is to fill the internal combustion engine 9 with natural gas through the injection valve 91- After the air mixture is activated, the spark plug is activated to achieve pre-mixed combustion, and the excess air ratio is calculated by judging the amount of natural gas supplied and the amount of intake air, and when the internal combustion engine can be operated at the air excess ratio equal to or greater than 1.5 When working in th...

no. 4 example

[0026] The fourth embodiment, this embodiment is partly the same as the above-mentioned embodiments, the only difference is that a nano-promoting layer 13 is provided on the side of the inlet pipeline 2, and a nano-promoting material is provided in the nano-promoting layer 13 , the nano-promoting material includes a nano-powder accelerator, a binder, an expansion coefficient regulator and a mixing aid; the nano-powder accelerator: binder: expansion coefficient regulator: mixing aid=40-60:5 -8: 20-30: 10-15; the above ratios are weight ratios.

[0027] The nano-powder accelerator includes 40-80 parts by weight of nano-silicon carbide powder, 30-60 parts by weight of nano-copper oxide, 5-30 parts by weight of zirconia powder, 5-10 parts by weight of chromium oxide powder and 1-10 parts by weight of silicon powder , wherein the particle size of the nano-silicon carbide powder is 100-200nm; the particle size of the nano-copper oxide is 200-300nm; the particle size of the zirconia ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com