Nanocrystalline thermal deformation rare-earth permanent magnet material with high coercivity and preparation method of nanocrystalline thermal deformation rare-earth permanent magnet material

A high coercive force, rare earth permanent magnet technology, applied in the direction of magnetic materials, inorganic material magnetism, magnetic objects, etc., can solve the problems of poor comprehensive magnetic properties of magnets, reduction of residual magnetism, etc., to improve coercive force and coercive force Improvement, easy operation and industrialization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a method for preparing a high-coercivity nanocrystalline heat-deformed rare earth permanent magnet material, which comprises the following steps:

[0026] S1, providing alloy powder and high melting point additives respectively, wherein the high melting point additives are at least one of refractory carbides, nitrides, and oxides;

[0027] S2, uniformly mixing the alloy powder and the high melting point additive to obtain a mixed magnetic powder, wherein the mass ratio of the high melting point additive in the mixed magnetic powder is greater than or equal to 0.01 and less than or equal to 10%; and

[0028] S3, performing hot-press forming and heat-deformation forming on the mixed magnetic powder in sequence to obtain a high-coercivity nanocrystalline heat-deformable rare earth permanent magnet material.

[0029] In step S1, the chemical formula of the alloy powder is Re by mass percentage x Fe 100-x-y-z m y B z , where Re is one or more of Nd...

Embodiment 1 to 9

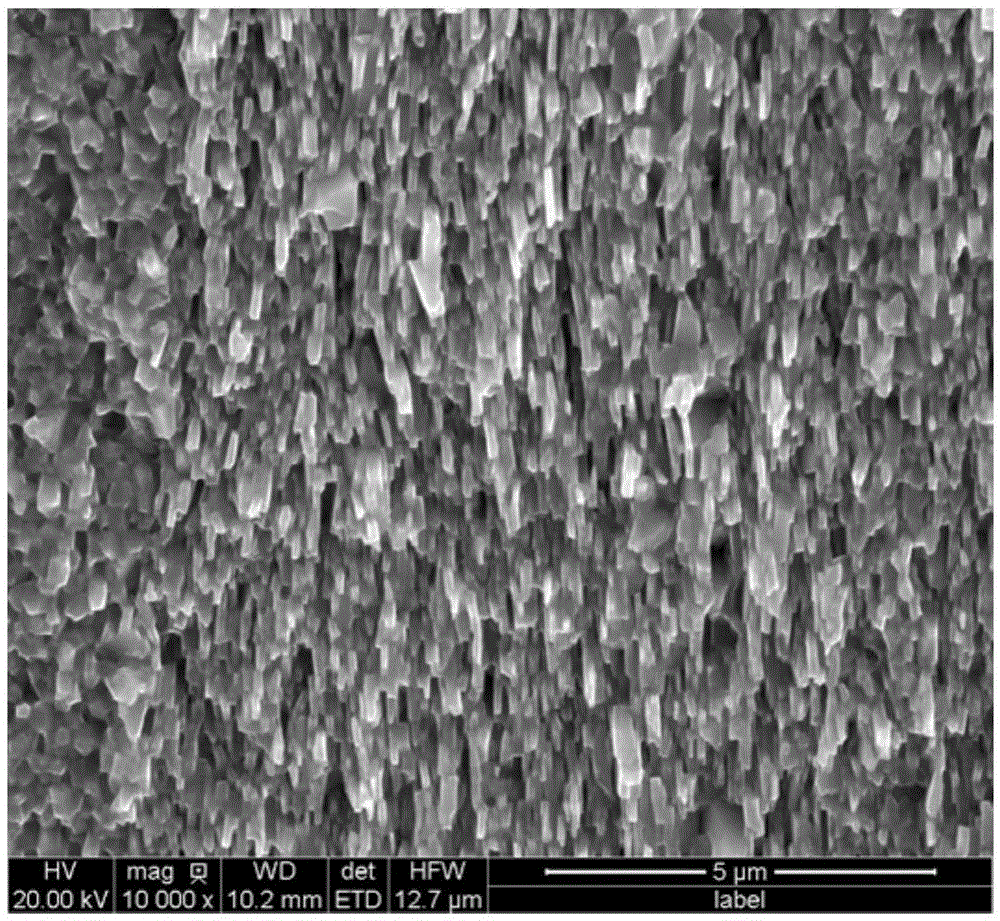

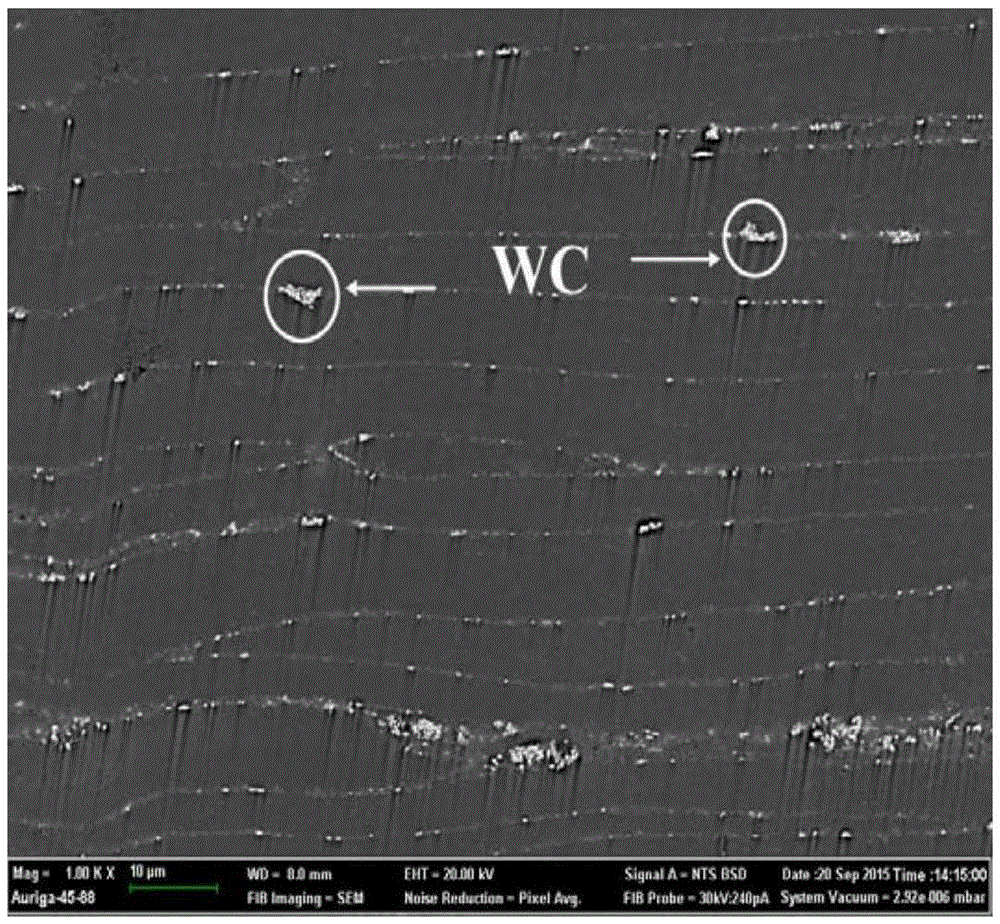

[0044] In composition Nd 30 Ga 0.5 Fe bal. co 4 B 1 Add high melting point additives with a particle size of 10 nanometers to 50 nanometers to the alloy powder and mix them uniformly. Please refer to Table 1 for the amount and type of high melting point additives.

[0045] Inductively heat the mixed powder in a vacuum environment. When the temperature rises to 200°C, the first pressure is applied to the first mold, and the maximum temperature is controlled to 670°C to obtain a hot-pressed magnet, in which the temperature rises from room temperature to the maximum temperature The time is 5 minutes to 6 minutes, the first pressure is 150MPa, and the vacuum degree during the hot pressing process is not lower than 5×10 -2 Pa.

[0046] Put the hot-pressed blank into a second mold with a larger diameter, and inductively heat the hot-pressed magnet in an argon atmosphere, so that the hot-pressed magnet is deformed with a deformation degree of 70%. When the temperature reaches ...

Embodiment 10 to 14

[0049] The thermally deformable magnets of Example 1, Example 2, Example 3, Example 5, and Example 6 were respectively placed in a vacuum environment, and tempered at 700° C. for 2 hours. After cooling, the magnetic properties of the magnet were measured according to the method of Example 1, and the results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com