Patents

Literature

55 results about "Cubic centimetre" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A cubic centimetre (or cubic centimeter in US English) (SI unit symbol: cm³; non-SI abbreviations: cc and ccm) is a commonly used unit of volume that extends the derived SI-unit cubic metre, and corresponds to the volume of a cube that measures 1 cm × 1 cm × 1 cm. One cubic centimetre corresponds to a volume of 1/1,000,000 of a cubic metre, or 1/1,000 of a litre, or one millilitre; thus, 1 cm³ ≡ 1 mL.

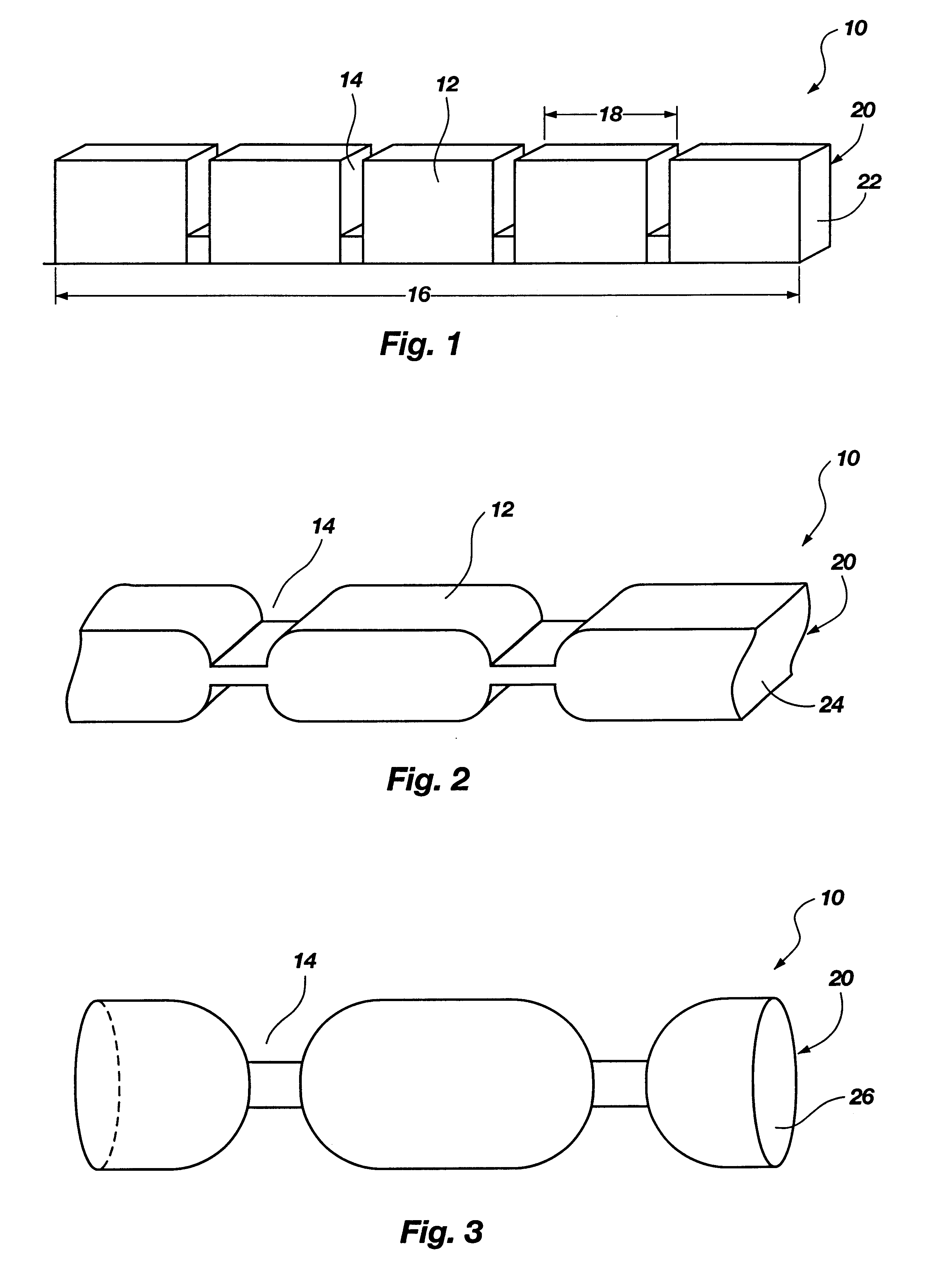

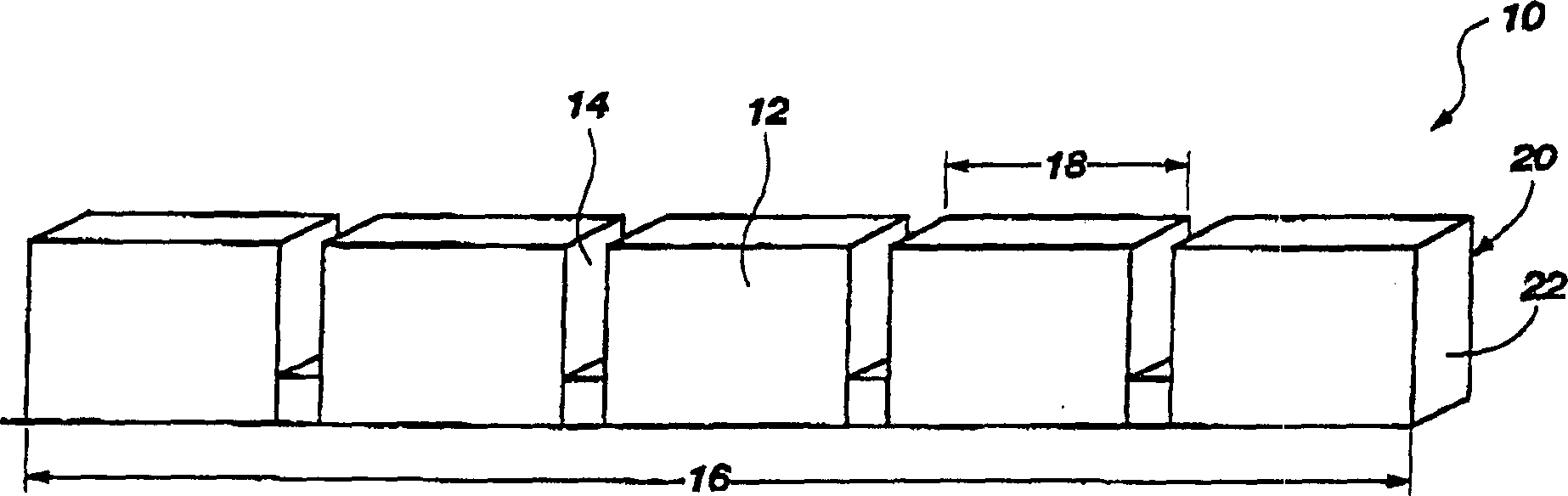

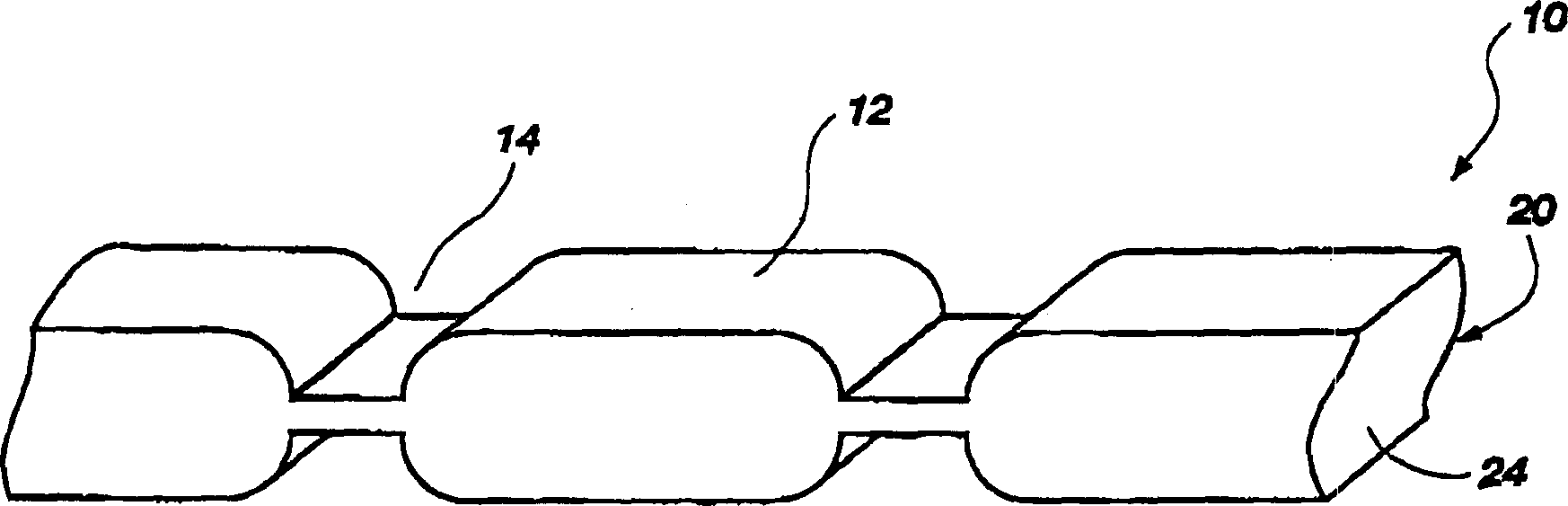

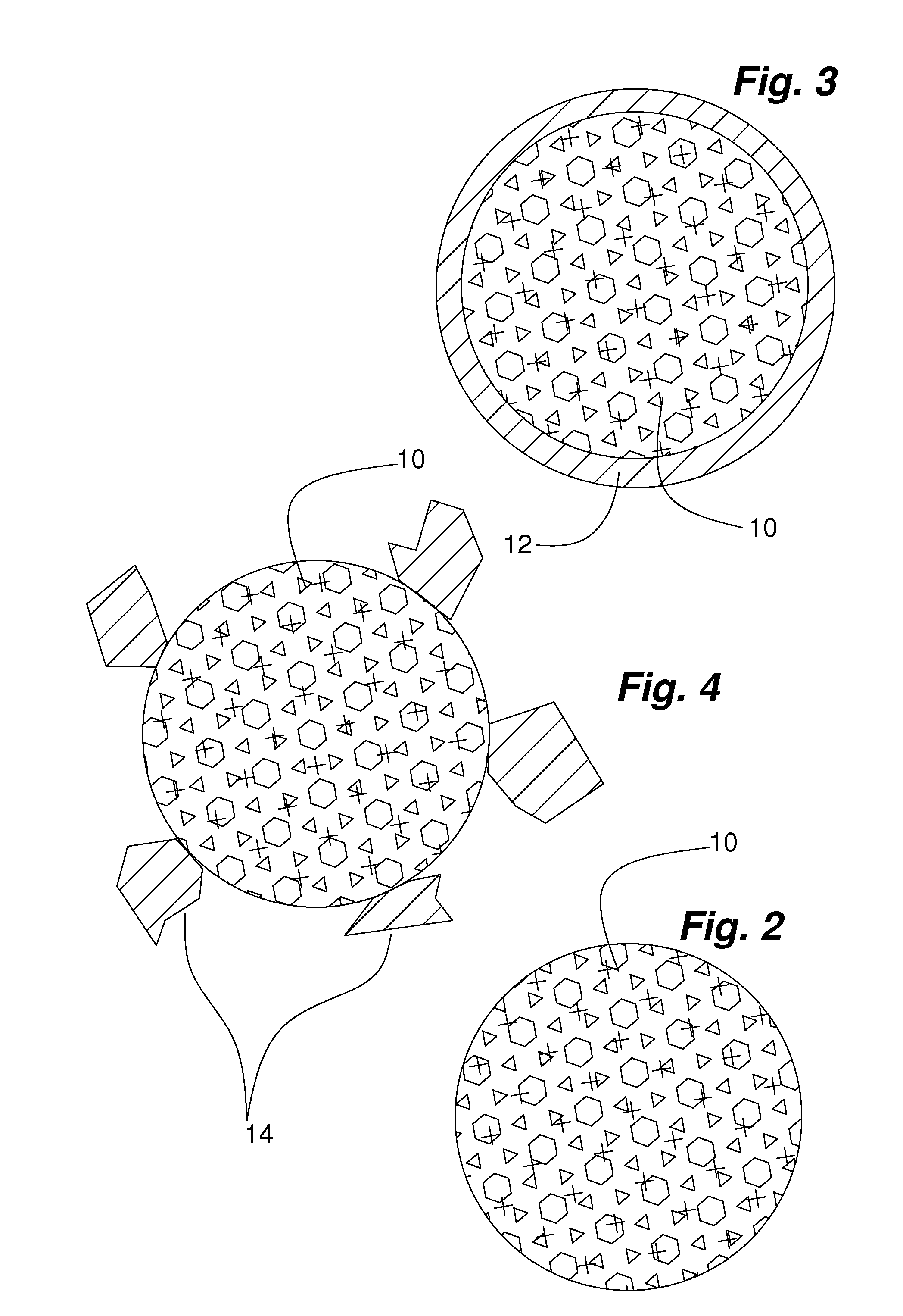

Edible thermoplastic and nutritious pet chew

The present invention relates to an edible thermoplastic made from about 30 to 50 wt. % protein comprising a mixture of plant and animal derived protein, about 20 to 50 wt. % starch about 10 to 20 wt. % water, about 1 to 10 wt. % edible fiber, and about 0.5 to 3 wt. % metallic salt hydrate. When molded, the thermoplastic has good strength and stiffness and other physical properties. The edible thermoplastic may be molded in a variety of shapes including a segmented nutritional pet chew with a plurality of segments separated by a plurality of scores. The scores serve to structurally weaken the pet chew so that it may be broken into smaller pieces. When molded the edible thermoplastic has a density of about 1.2 to 1.5 g / cubic centimeters.

Owner:BISMUTH INVESTMENTS

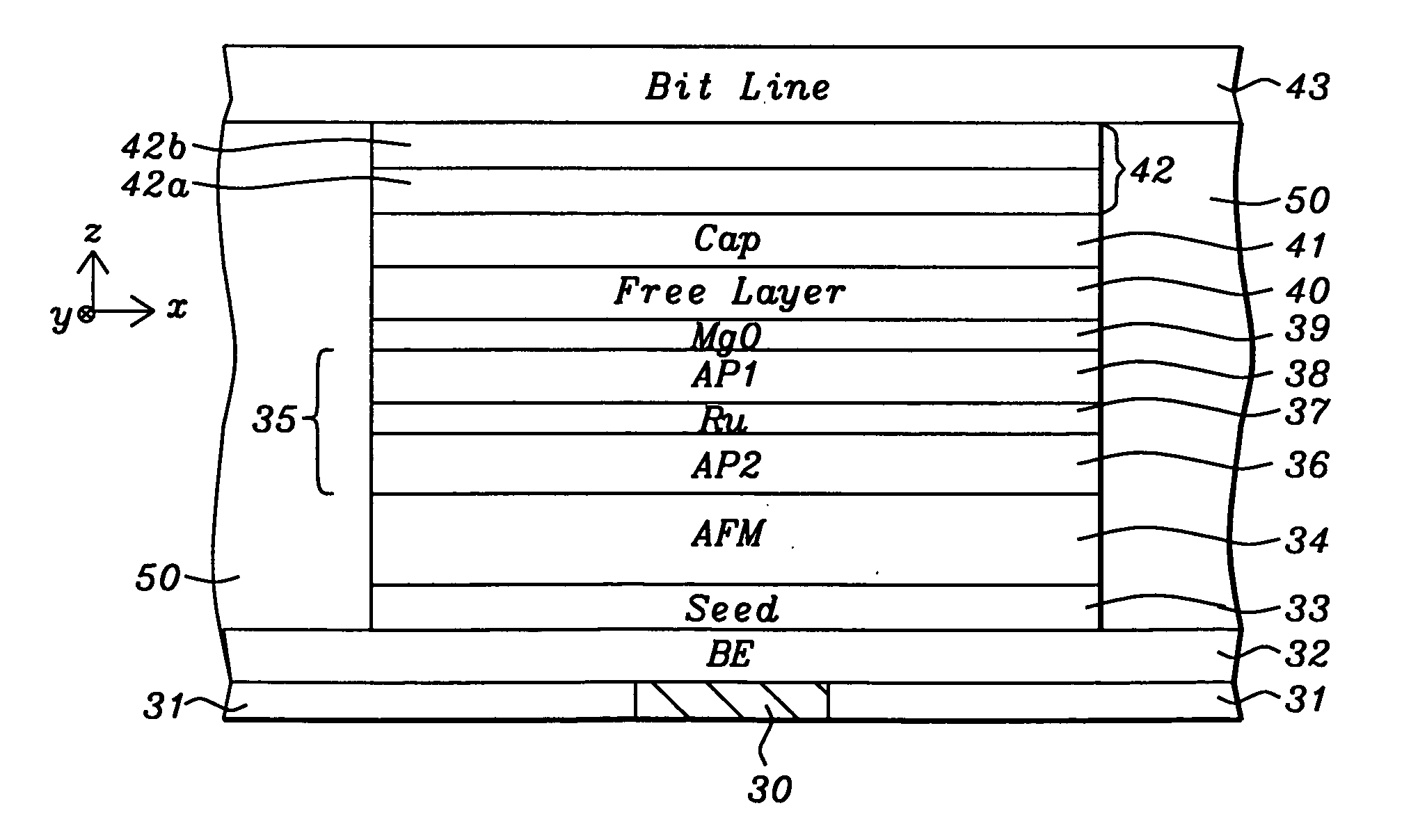

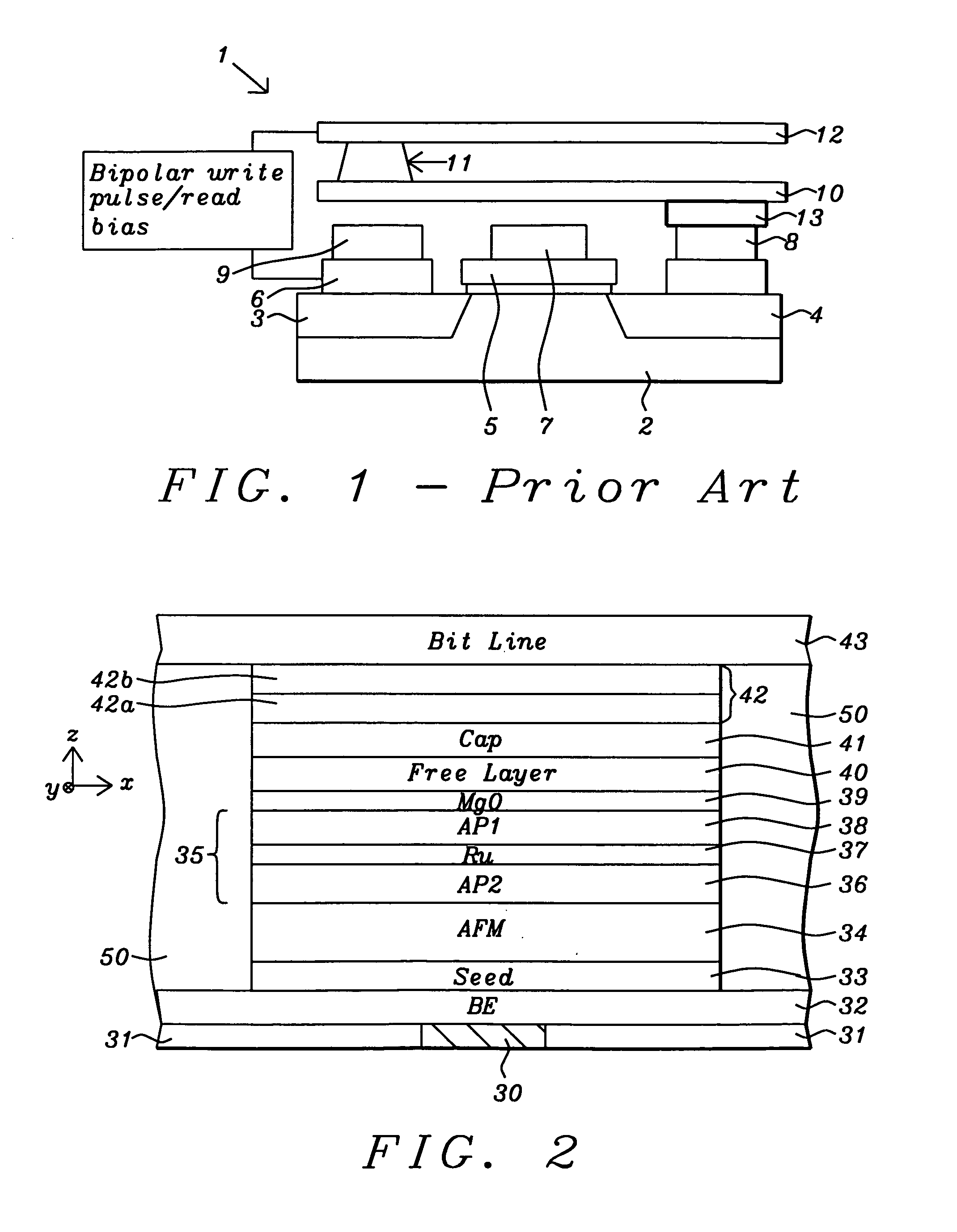

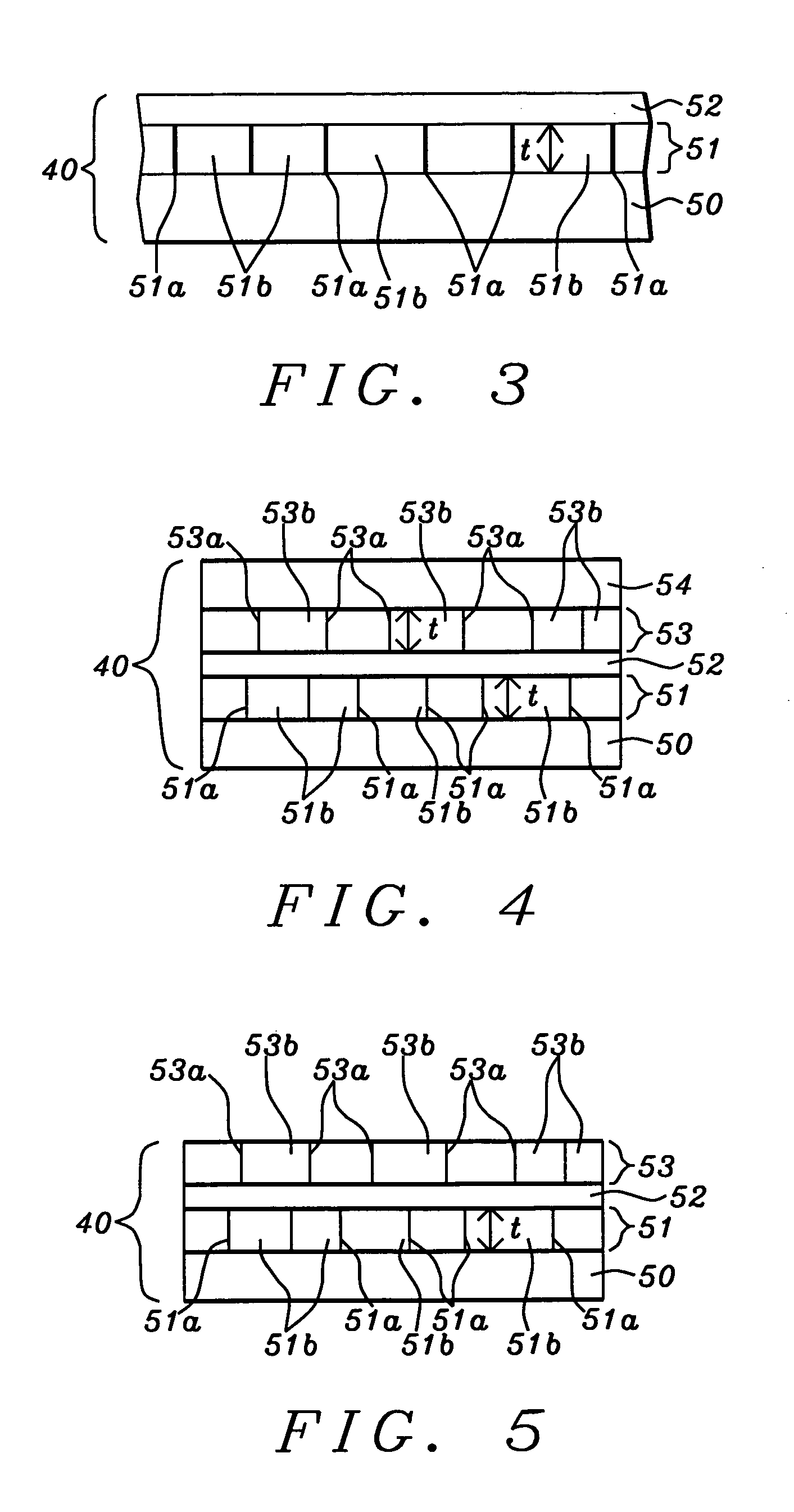

Structure and method for enhancing interfacial perpendicular anisotropy in CoFe(B)/MgO/CoFe(B) Magnetic Tunnel Junctions

ActiveUS20120135273A1Magnetic materials for record carriersVacuum evaporation coatingSwitched currentPerpendicular anisotropy

A STT-RAM MTJ is disclosed with a MgO tunnel barrier formed by natural oxidation process. A Co10Fe70B20 / NCC / Co10Fe70B20, Co10Fe70B20 / NCC / Co10Fe70B20 / NCC, or Co10Fe70B20 / NCC / Co10Fe70B20 / NCC / Co10Fe70B20 free layer configuration where NCC is a nanocurrent channel layer made of Fe(20%)-SiO2 is used to minimize Jc0 while enabling higher thermal stability, write voltage, read voltage, Ho, and Hc values that satisfy 64 Mb design requirements. The NCC layer is about 10 Angstroms thick to match the minimum Fe(Si) grain diameter size. The MTJ is annealed with a temperature of about 330° C. to maintain a high magnetoresistive ratio while maximizing Hk⊥(interfacial) for the free layer thereby reducing Heff and lowering the switching current. The Co10Fe70B20 layers are sputter deposited with a low pressure process with a power of about 15 Watts and an Ar flow rate of 40 standard cubic centimeters per minute to lower Heff for the free layer.

Owner:TAIWAN SEMICON MFG CO LTD

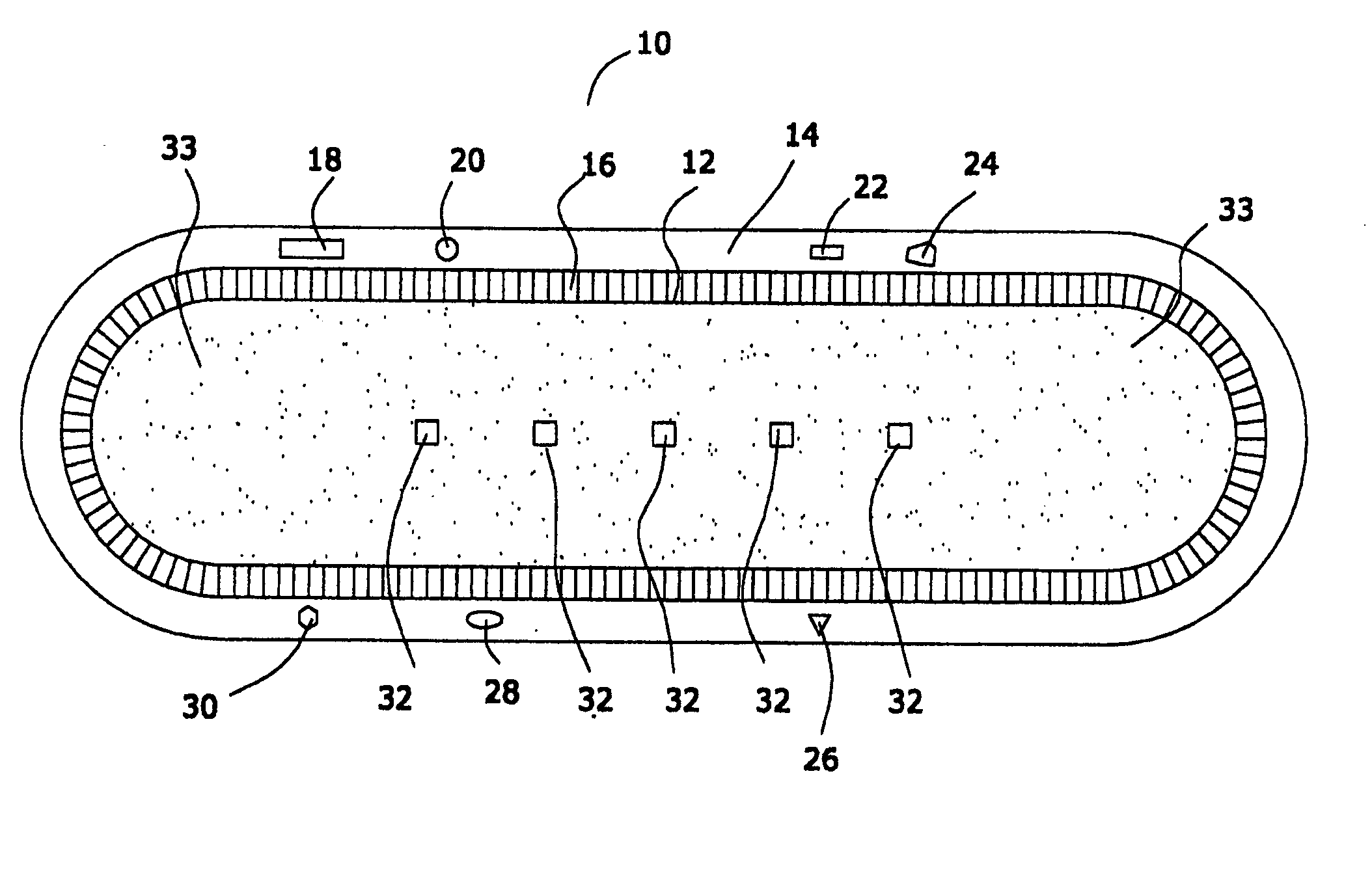

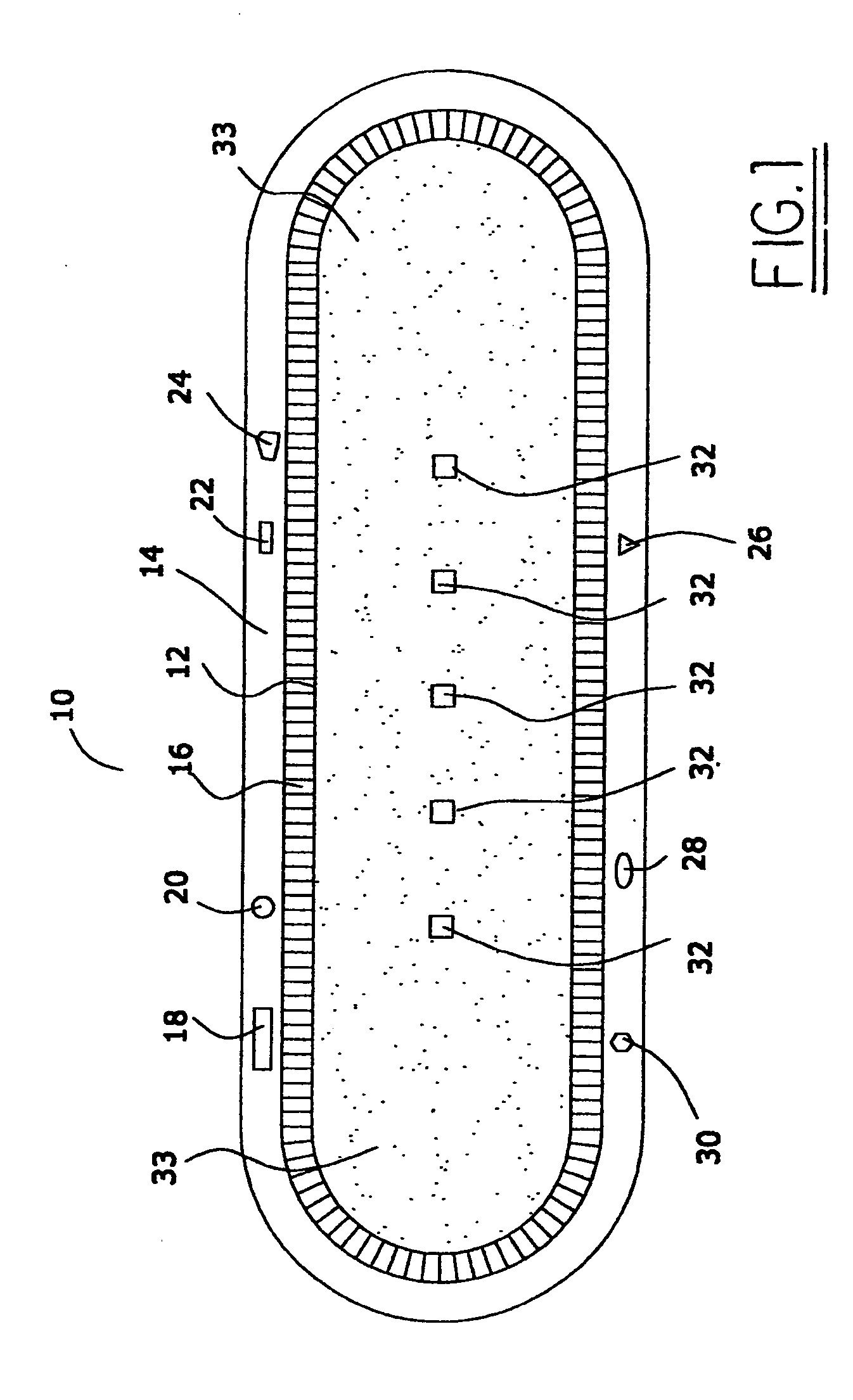

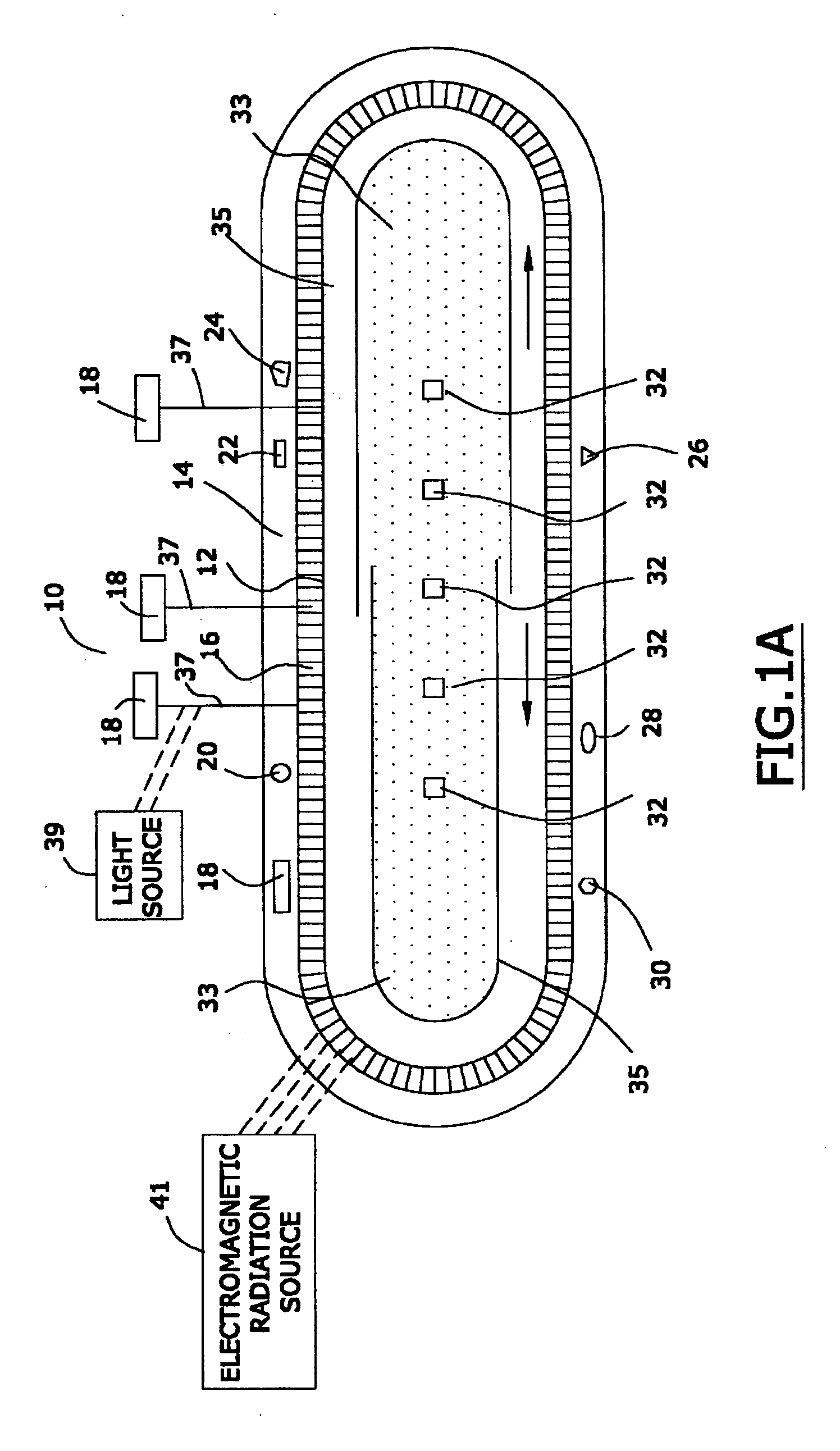

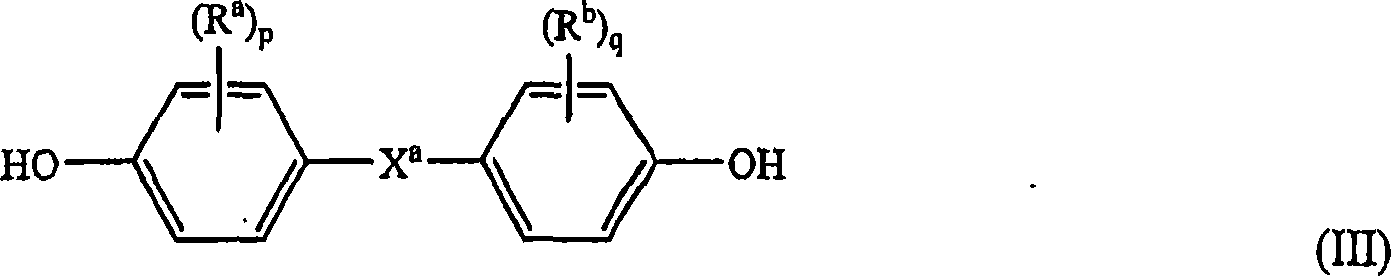

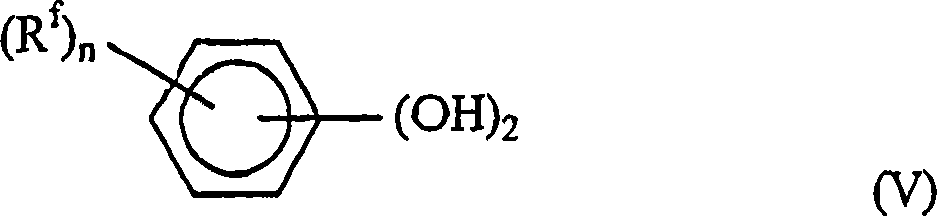

Coated substrate assembly

Owner:BIOPHAN TECH

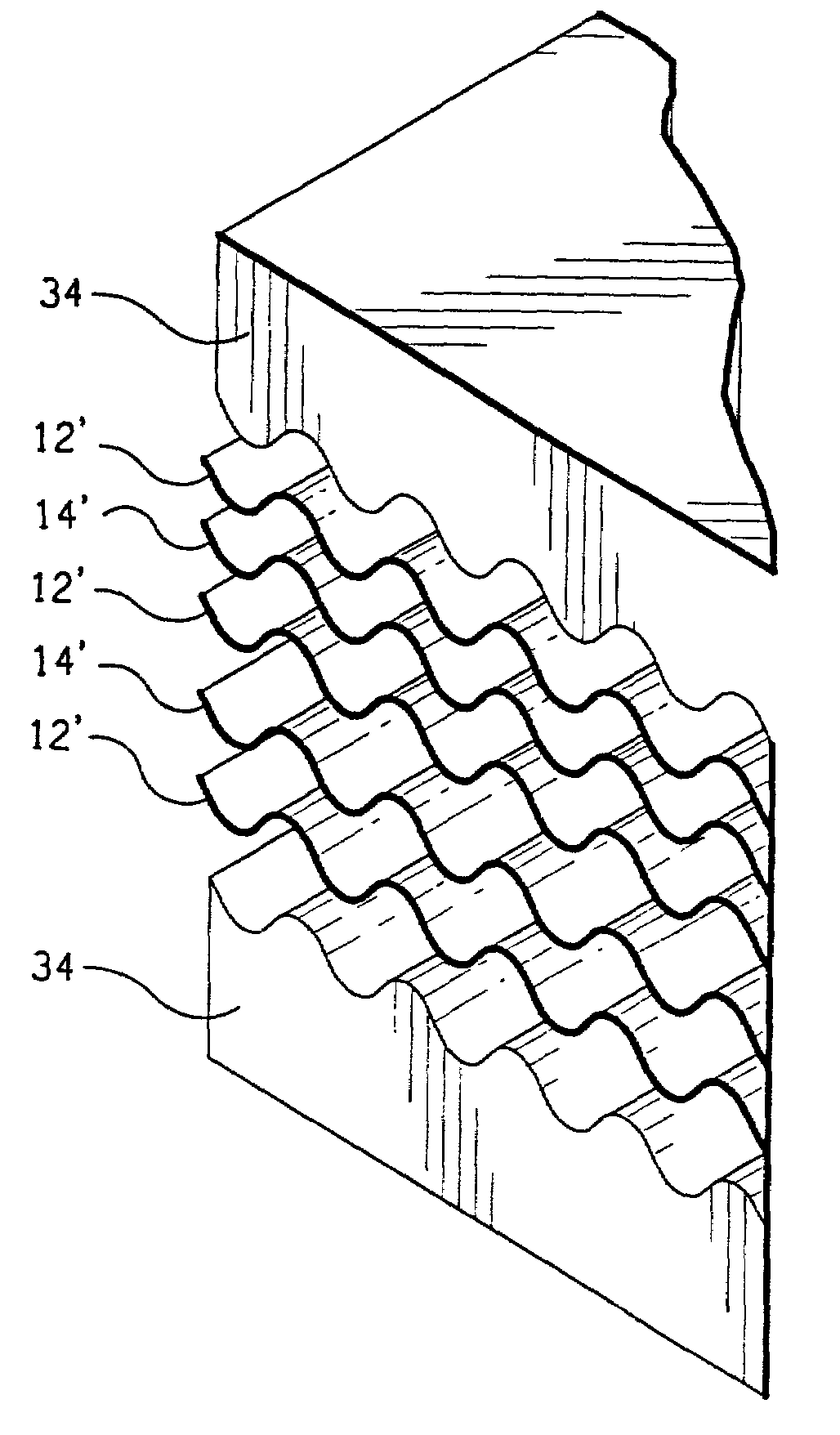

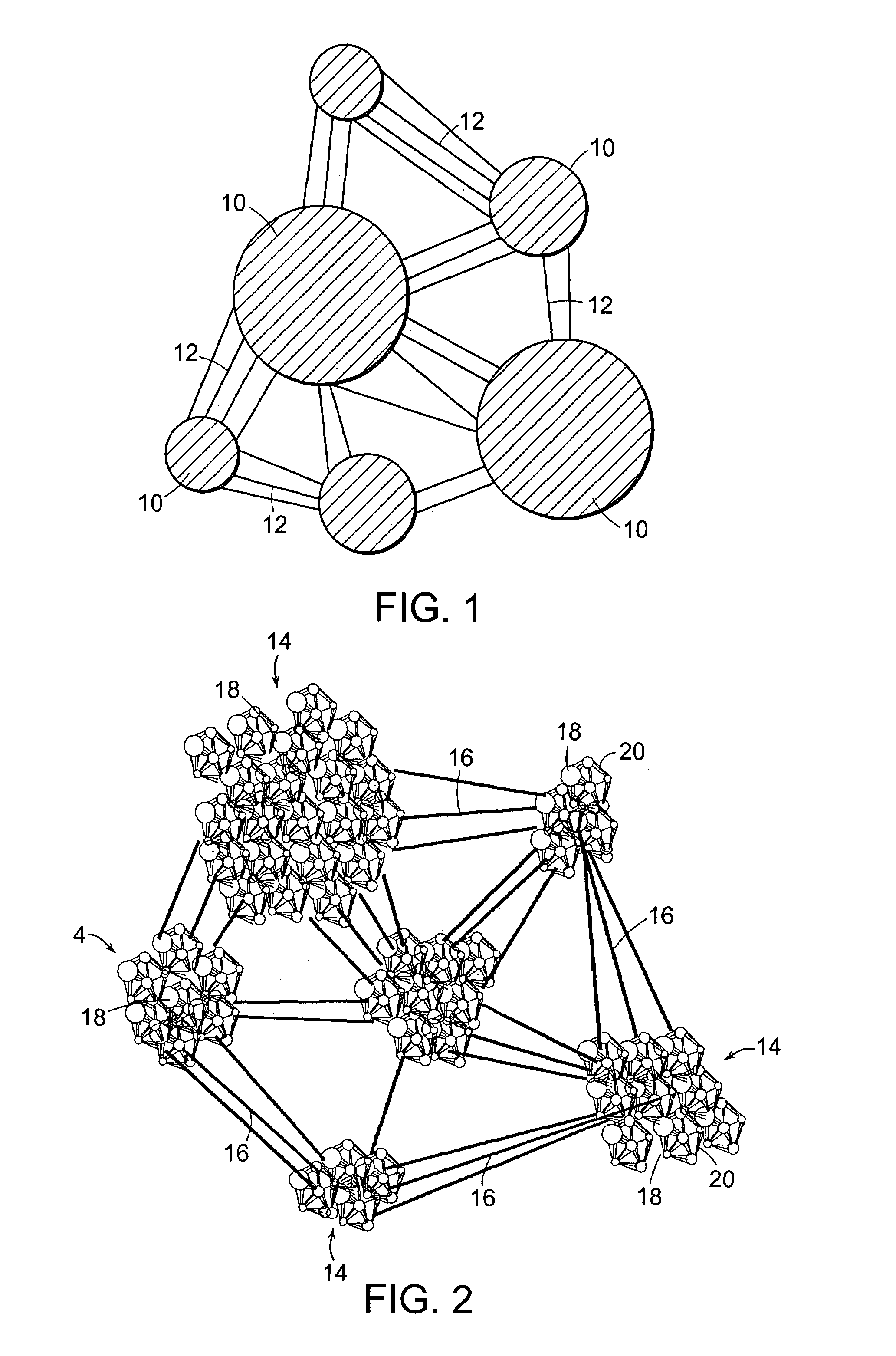

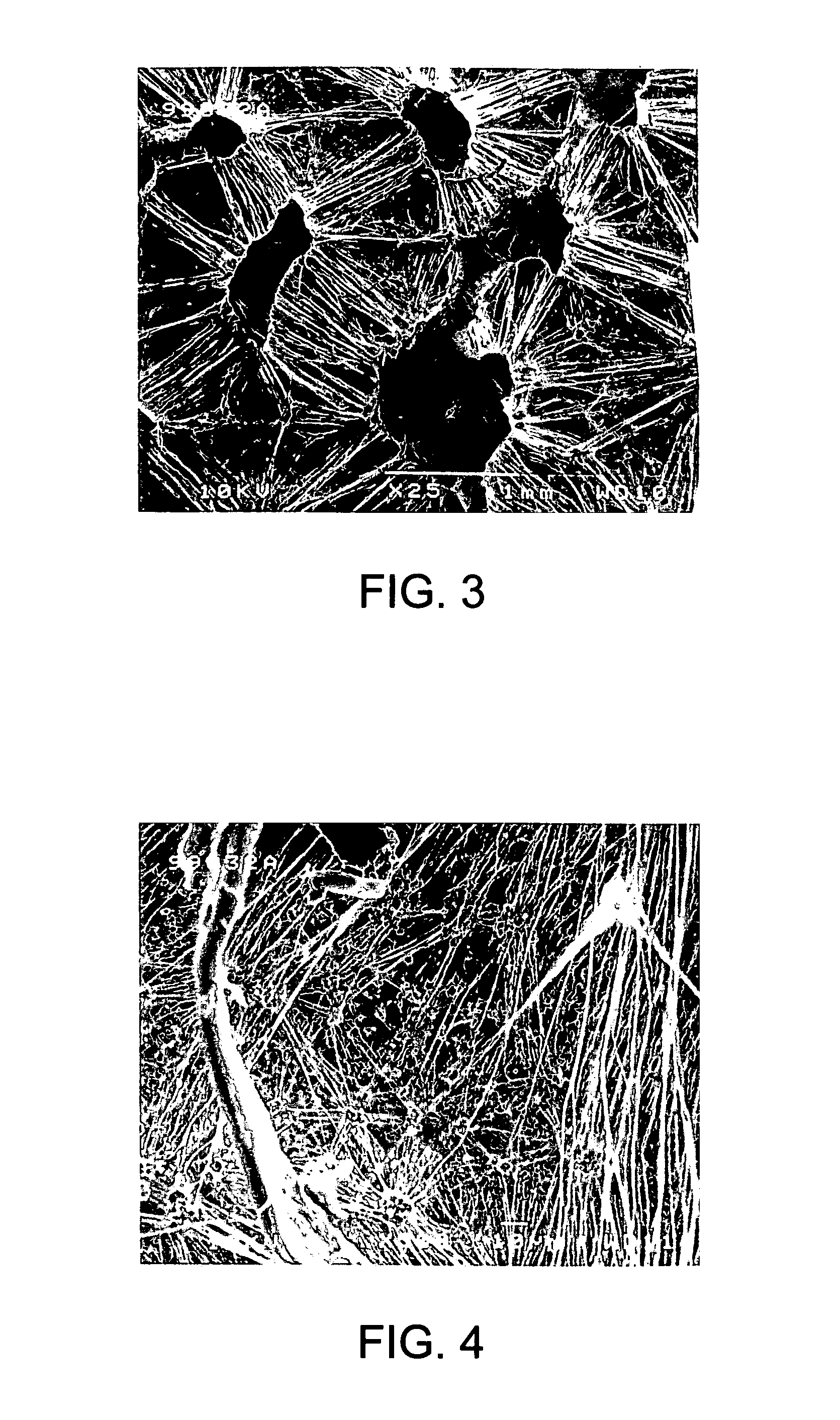

Fabrication of interleaved metallic and intermetallic composite laminate materials

InactiveUS7188559B1Well formedLimit cracking and fracturingWeapon componentsDomestic articlesGramComposite laminates

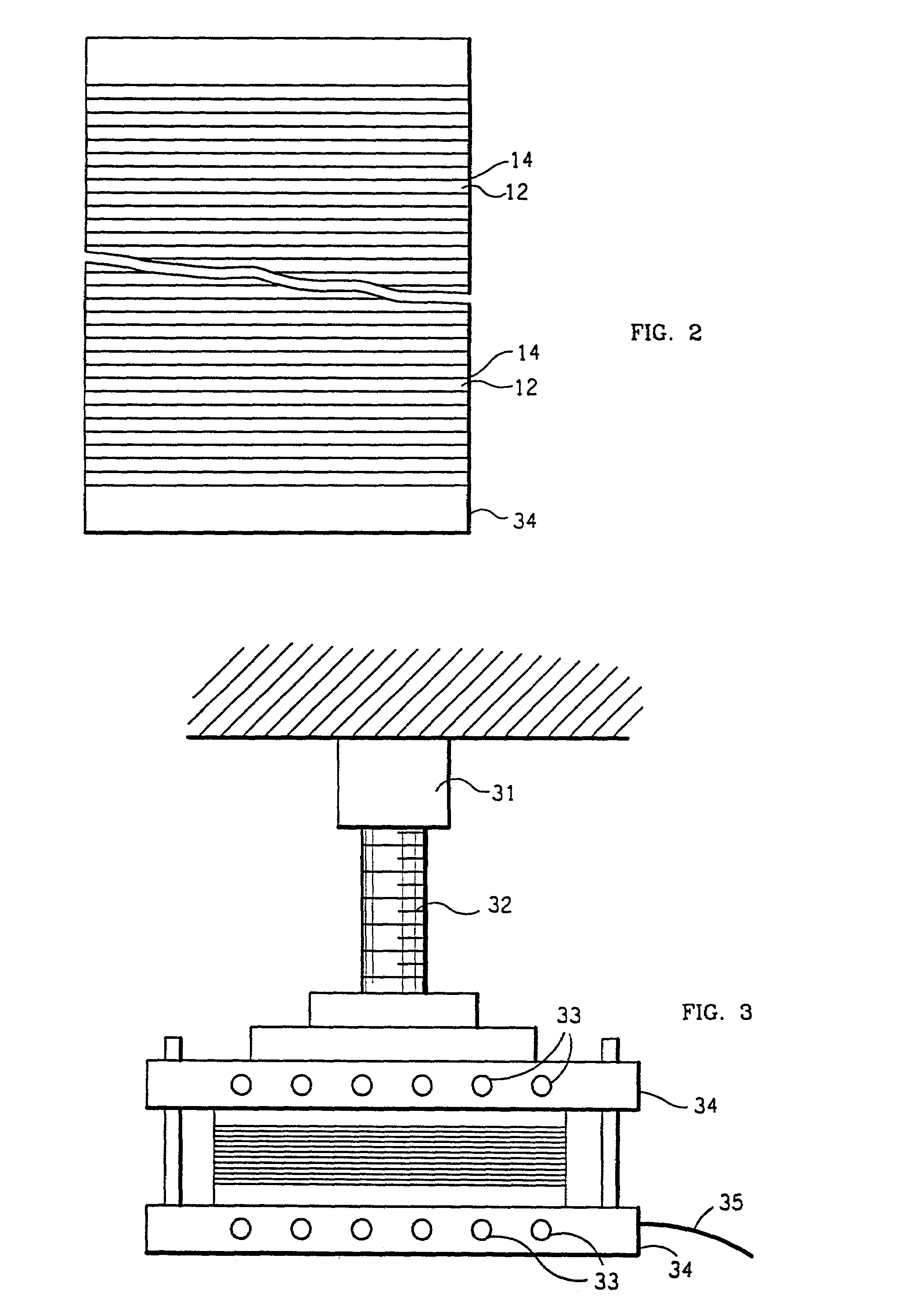

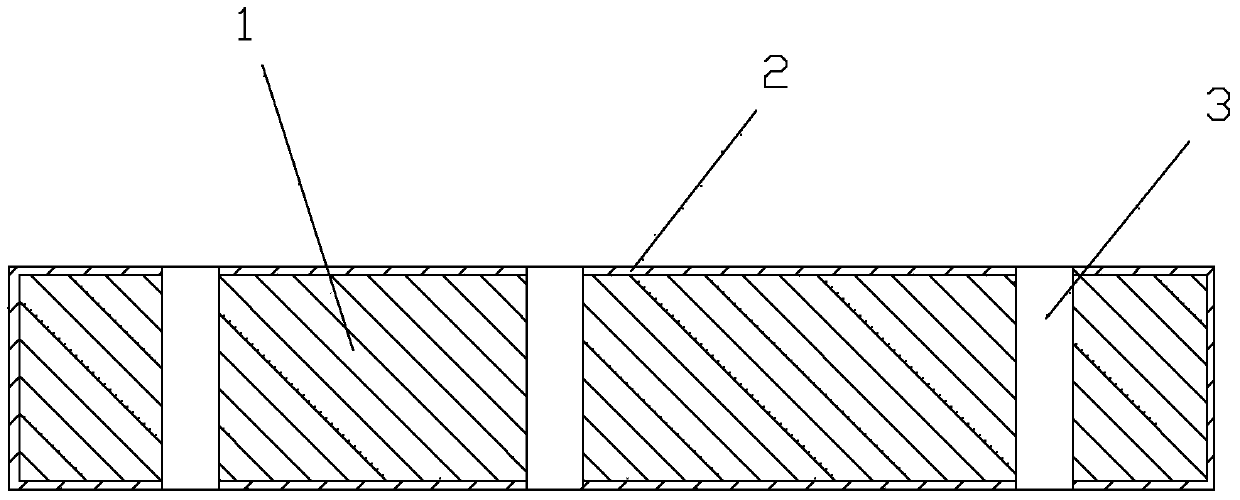

Typically 20–40 films of a tough first metal, normally 0.1–1.0 mm thick films of titanium, nickel, vanadium, and / or steel (iron) and alloys thereof, interleaved with a like number of films of a second metal, normally 0.1–1.0 mm thick films of aluminum or alloys thereof, are pressed together in a stack at less than 6 MPa and normally at various pressures 2–4 MPa while being gradually heated in the presence of atmospheric gases to 600–800° C. over a period of, typically, 10+ hours until the second metal is completely compounded; forming thus a metallic-intermetallic laminate composite material having (i) tough first-metal layers separated by (ii) hard, Vickers microhardness of 400 kg / mm2+, intermetallic regions consisting of an intermetallic compound of the first and the second metals. The resulting composite material is inexpensive, lightweight with a density of typically 3 to 4.5 grams / cubic centimeter, and very hard and very tough to serve as, among other applications, lightweight armor. Upon projectile impact (i) the hard intermetallic, ceramic-like, layers are confined by the tough metal layers while (ii) cracking and fracturing is blunted and channeled in directions orthogonal to the axis of impact.

Owner:RGT UNIV OF CALIFORNIA

Method for producing powder metal materials

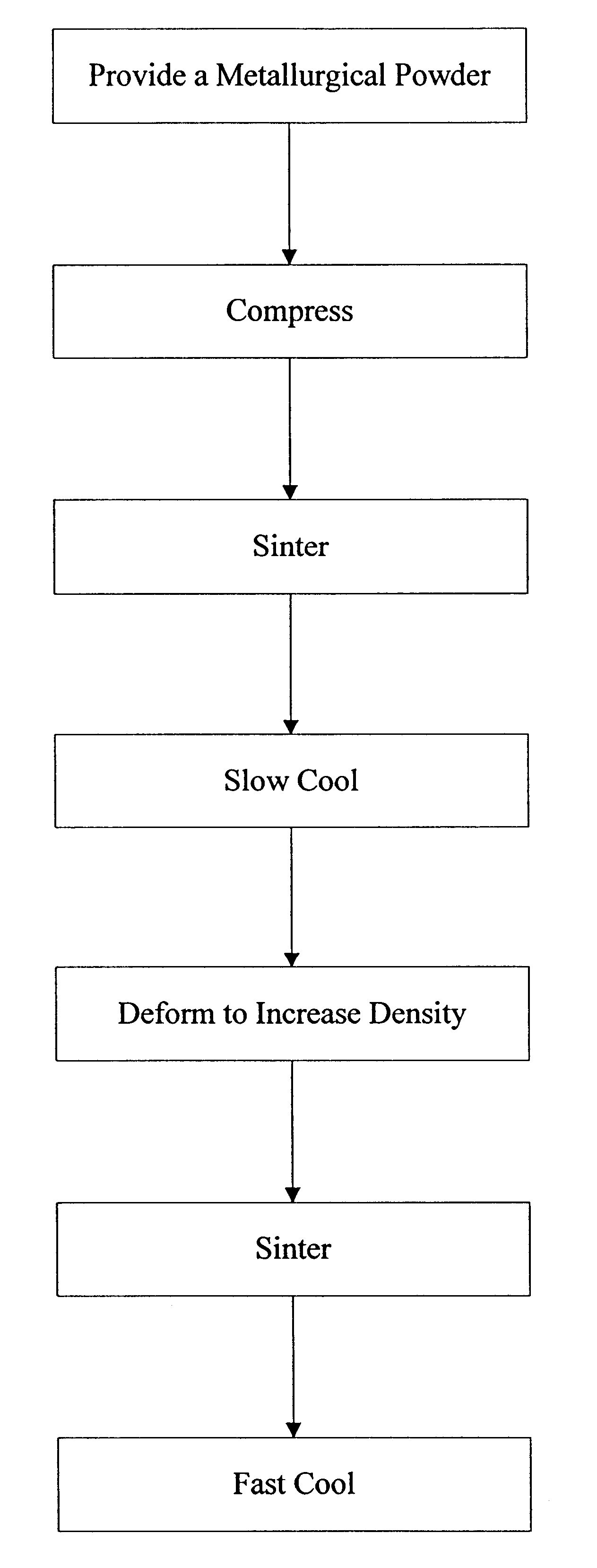

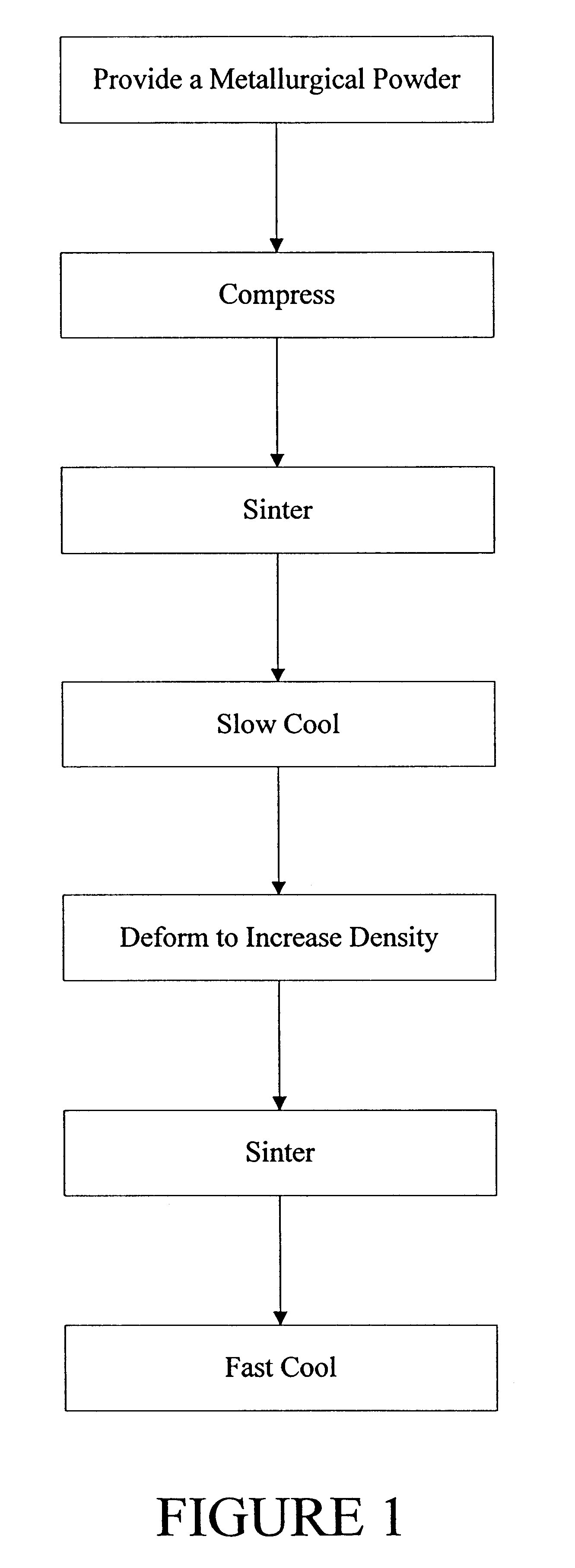

A method for producing a material includes providing a metallurgical powder including iron, 1.0 to 3.5 weight percent copper, and 0.3 to 0.8 weight percent carbon. At least a portion of the powder is compressed at 20 tsi to 70 tsi to provide a compact, and subsequently the compact is heated at high temperature and then cooled at a cooling rate no greater than 60° F. per minute to increase the surface hardness of the compact to no greater than RC 25. The density of at least a region of the sintered compact is increased, by a mechanical working step or otherwise, to at least 7.6 grams / cc. The sintered compact is then re-heated to high temperature and cooled at a cooling rate of at least 120° F. / min. so as to increase the surface hardness of the compact to greater than RC 25, and preferably at least RC 30. Material made by the method of the invention also is disclosed.

Owner:KEYSTONE INVESTMENT CORP

Lightweight concrete compositions containing antimicrobial agents

InactiveUS20070027224A1Decrease health care costReduce areaSolid waste managementCeramicwareCompressive strengthUltimate tensile strength

A lightweight concrete composition containing from 10 to 90 volume percent of a cement composition, from 10 to 90 volume percent of particles having an average particle diameter of from 0.2 mm to 8 mm, a bulk density of from 0.03 g / cc to 0.64 g / cc, an aspect ratio of from 1 to 3, and from 0 to 50 volume percent of aggregate, where the particles contain an antimicrobial agent; where the sum of components used does not exceed 100 volume percent, and where after the lightweight concrete composition is set it has a compressive strength of at least 1700 psi as tested according to ASTM C39 after seven days. The concrete composition can be used to make concrete masonry units, construction panels, dining tables, counter surfaces, bench tops, and / or examination tables as well as other articles.

Owner:SYNTHEON

Cable semiconductive shield compositions

InactiveUS20020032258A1Special tyresPower cables with screens/conductive layersAliphatic unsaturated hydrocarbonGram

A composition comprising: (a) one or more copolymers selected from the group consisting of (I) a copolymer of ethylene and vinyl acetate containing about 10 to about 50 percent by weight vinyl acetate and having a melt mass flow rate of about 1 to about 100 grams per 10 minutes; (II) a copolymer of ethylene and ethyl acrylate containing about 10 to about 50 percent by weight ethyl acrylate and having a melt mass flow rate of about 1 to about 100 grams per 10 minutes; and (III) a copolymer of ethylene and butyl acrylate containing about 10 to about 50 percent by weight butyl acrylate and having a melt mass flow rate of about 1 to about 100 grams per 10 minutes, and based upon 100 parts by weight of component (a): (b) about 55 to about 200 parts by weight of a linear copolymer of ethylene and an alpha-olefin having 3 to 12 carbon atoms, the copolymer having a melt mass flow rate of about 0.1 to about 30 grams per 10 minutes and a density of 0.870 to 0.944 gram per cubic centimeter; (c) about 5 to about 50 parts by weight of polypropylene having a melt mass flow rate of about 0.5 to about 30 grams per 10 minutes and a density of 0.900 to 0.920 gram per cubic centimeter; (d) about 2 to about 50 parts by weight of an organopolysiloxane having the following formula: R1xR2ySiO(4-a-b) / 2 wherein R1 is an aliphatic unsaturated hydrocarbon group; R2 is an unsubstituted or substituted monovalent hydrocarbon group excluding aliphatic unsaturated hydrocarbon groups; x is equal to or greater than 0 but less than 1; y is greater than 0.5 but less than 3; x+y is greater than 1 but less than 3; a is greater than 0 but equal to or less than 1; and b is equal to or greater than 0.5 but equal to or less than 3; (e) about 10 to about 350 parts by weight of carbon black; and (f) optionally, up to about 2 parts by weight of an organic peroxide.

Owner:NIPPON YUNIKAA

Lightweight concrete compositions

A lightweight concrete composition containing from 10 to 90 volume percent of a cement composition, from 10 to 90 volume percent of particles having an average particle diameter of from 0.2 mm to 8 mm, a bulk density of from 0.03 g / cc to 0.64 g / cc, an aspect ratio of from 1 to 3, and from 0 to 50 volume percent of aggregate; where the sum of components used does not exceed 100 volume percent, and where after the lightweight concrete composition is set it has a compressive strength of at least 1700 psi as tested according to ASTM C39 after seven days. The concrete composition can be used to make concrete masonry units, construction panels, road beds and other articles.

Owner:SYNTHEON

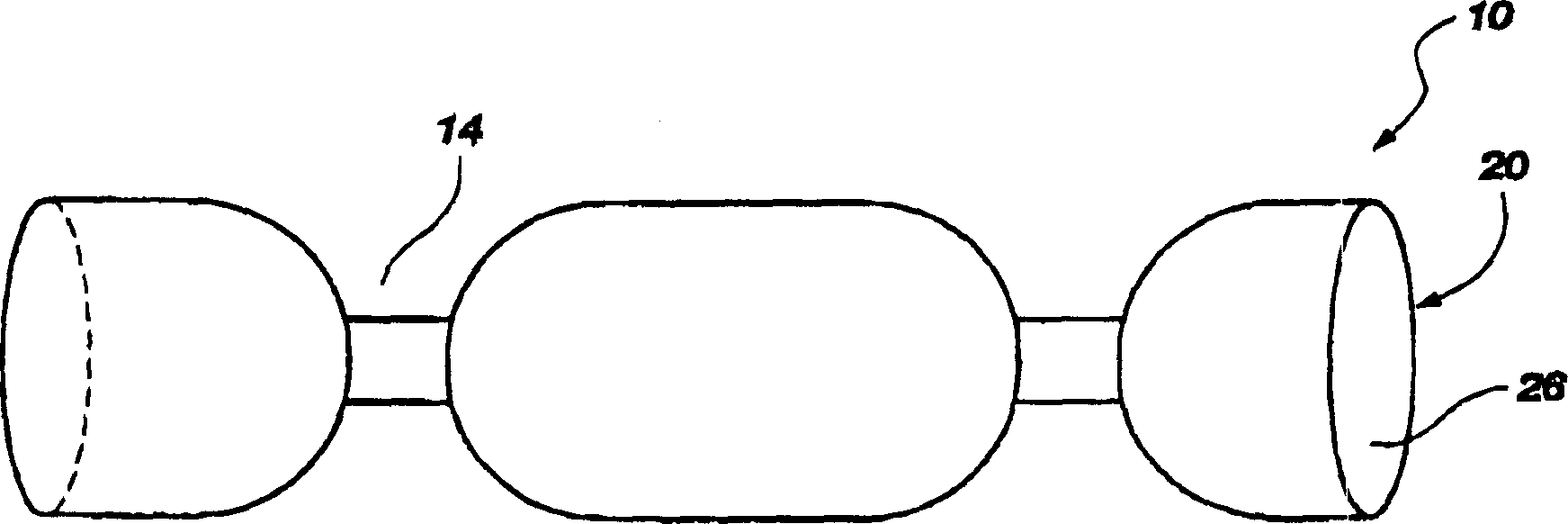

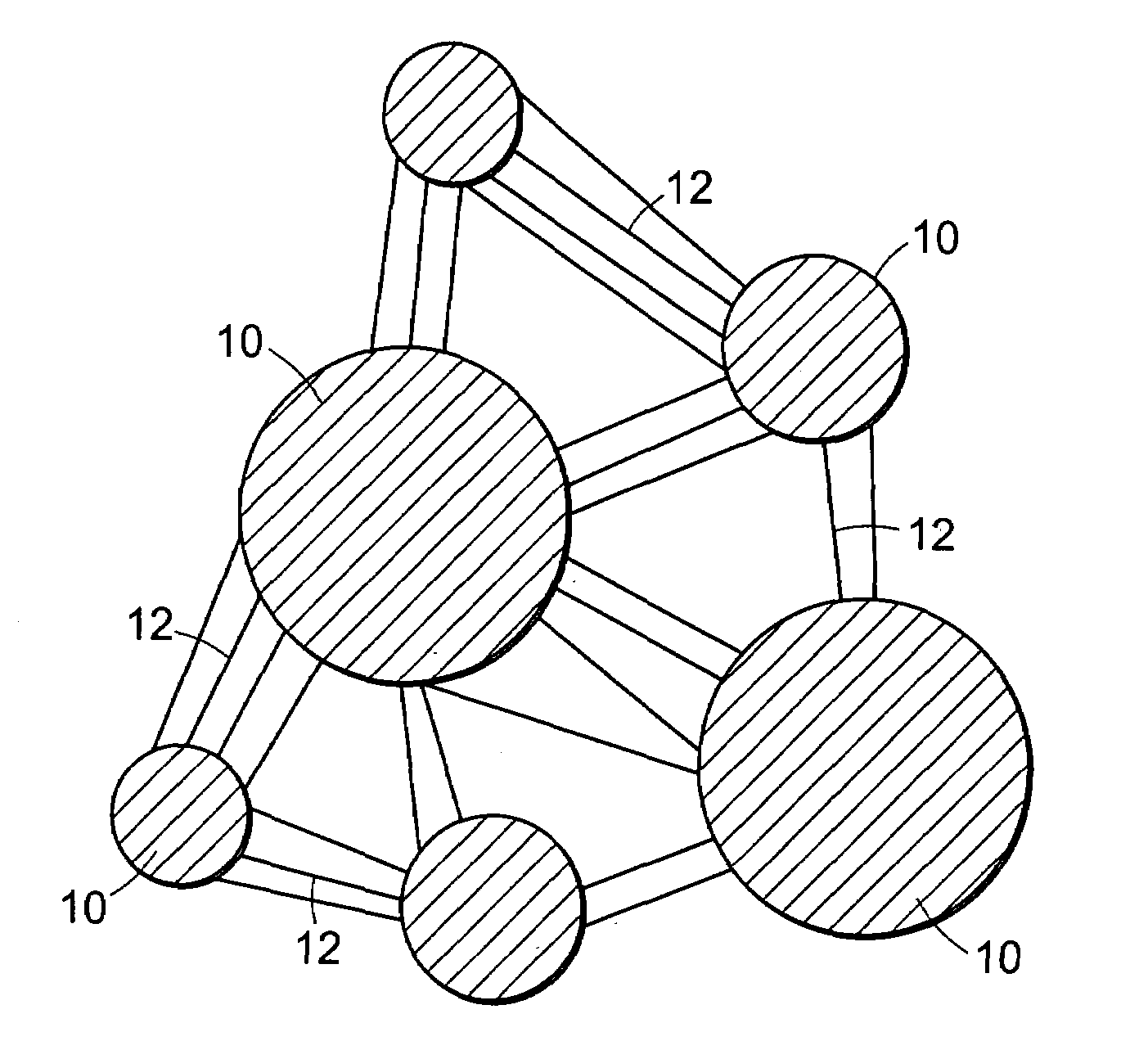

Edible thermoplastic and nutritious segmented pet chew

The present invention relates to an edible thermoplastic made from about 30 to 50 wt. % protein comprising a mixture of plant and animal derived protein, about 20 to 50 wt. % starch about 10 to 20 wt. % water, about 1 to 10 wt. % edible fiber, and about 0.5 to 3 wt. % metallic salt hydrate. When molded, the thermoplastic has good strength and stiffness and other physical properties. The edible thermoplastic may be molded in a variety of shapes including a segmented nutritional pet chew with a plurality of segments separated by a plurality of scores. The scores serve to structurally weaken the pet chew so that it may be broken into smaller pieces. When molded the edible thermoplastic has a density of about 1.2 to 1.5 g / cubic centimeters.

Owner:NATURAL POLYMER INT CORP

PTFE material with aggregations of nodes

InactiveUS7306841B2Improve acceleration performanceLow expandabilitySynthetic resin layered productsThin material handlingFiberFibril

Owner:BRIDGER BIOMED

Multi-component liquid explosive composition and method

InactiveUS6960267B1Extended shelf lifeLoomsNitroparaffin explosive compositionsNitromethaneSquare meter

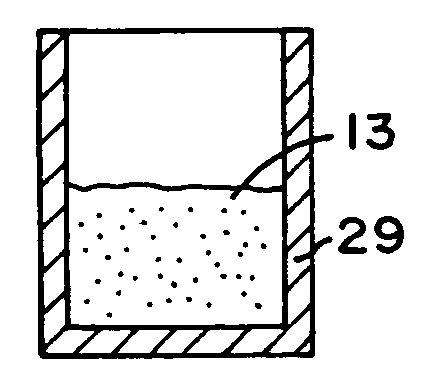

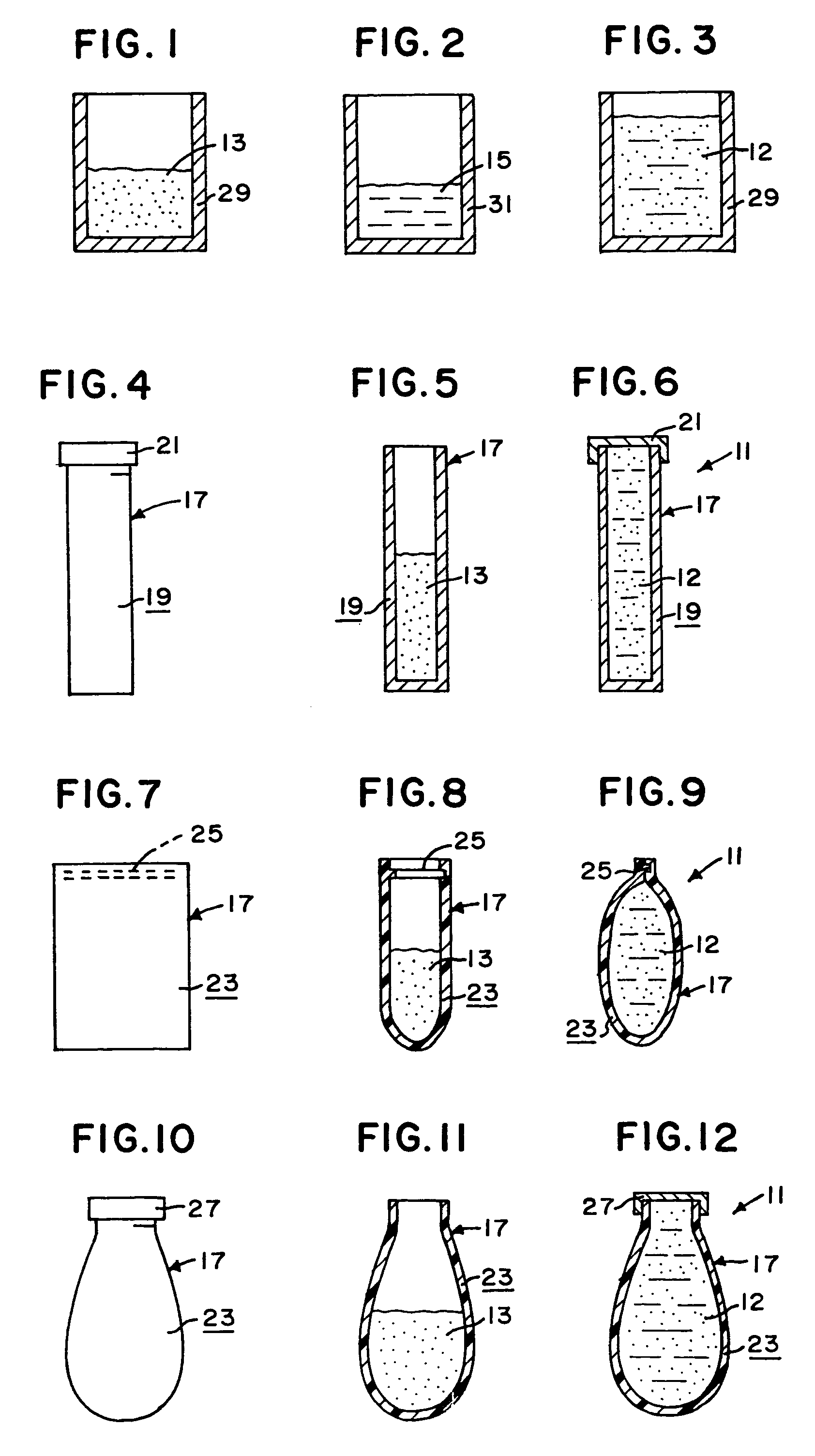

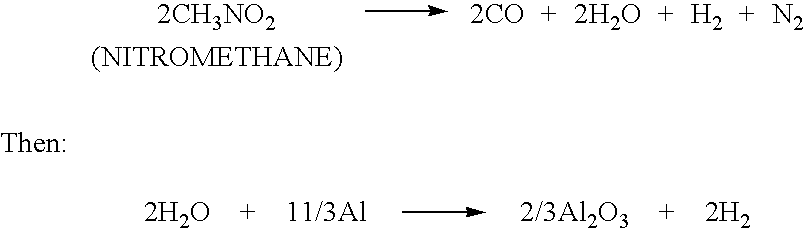

A multi-component liquid explosive composition and method of mixing thereof. The steps include (a) providing a powder consisting of aluminum preferably having an average particle size of 5 to 50 microns and a surface area of 0.5 to 2 square meters per cubic centimeter containing 0.1 to 5% stearic acid by weight; (b) providing a liquid consisting of nitromethane; and (c) mixing said aluminum powder with the nitromethane to form a liquid explosive formulation detonable at a wide range of temperatures and diameters with a standard commercial number 8 blasting cap.

Owner:NIXON III WILLIAM P

Cable semiconductive shield compositions

InactiveUS6706791B2Special tyresPower cables with screens/conductive layersAliphatic unsaturated hydrocarbonGram

A composition comprising:(a) one or more copolymers selected from the group consisting of (I) a copolymer of ethylene and vinyl acetate containing about 10 to about 50 percent by weight vinyl acetate and having a melt mass flow rate of about 1 to about 100 grams per 10 minutes; (II) a copolymer of ethylene and ethyl acrylate containing about 10 to about 50 percent by weight ethyl acrylate and having a melt mass flow rate of about 1 to about 100 grams per 10 minutes; and (III) a copolymer of ethylene and butyl acrylate containing about 10 to about 50 percent by weight butyl acrylate and having a melt mass flow rate of about 1 to about 100 grams per 10 minutes, and based upon 100 parts by weight of component (a):(b) about 55 to about 200 parts by weight of a linear copolymer of ethylene and an alpha-olefin having 3 to 12 carbon atoms, the copolymer having a melt mass flow rate of about 0.1 to about 30 grams per 10 minutes and a density of 0.870 to 0.944 gram per cubic centimeter;(c) about 5 to about 50 parts by weight of polypropylene having a melt mass flow rate of about 0.5 to about 30 grams per 10 minutes and a density of 0.900 to 0.920 gram per cubic centimeter;(d) about 2 to about 50 parts by weight of an organopolysiloxane having the following formula: R<1>xR<2>ySiO(4-a-b) / 2wherein R<1 >is an aliphatic unsaturated hydrocarbon group; R<2 >is an unsubstituted or substituted monovalent hydrocarbon group excluding aliphatic unsaturated hydrocarbon groups; x is equal to or greater than 0 but less than 1; y is greater than 0.5 but less than 3; x+y is greater than 1 but less than 3; a is greater than 0 but equal to or less than 1; and b is equal to or greater than 0.5 but equal to or less than 3;(e) about 10 to about 350 parts by weight of carbon black; and(f) optionally, up to about 2 parts by weight of an organic peroxide.

Owner:NIPPON YUNIKAA

Low density oriented polymer composition with inert inorganic filler

An oriented polymer composition containing thirty to 95 weight-percent inert inorganic filler and a continuous phase of at least one orientable polymer contains void spaces due to cavitation and has a density of less than 0.8 grams per cubic centimeter, a flexural modulus of 1.4 gigapascals or more, cross section dimensions all greater than 1.5 millimeters, a delamination force value of 44.5 Newtons (ten pounds force) or more and little or no blowing agent.

Owner:EOVATIONS

Polyethylene and polypropylene blends for liquid packaging films

ActiveUS20080090062A1Good low temperature sealing propertyInsufficient thermal resistanceSynthetic resin layered productsBagsButeneCrack resistance

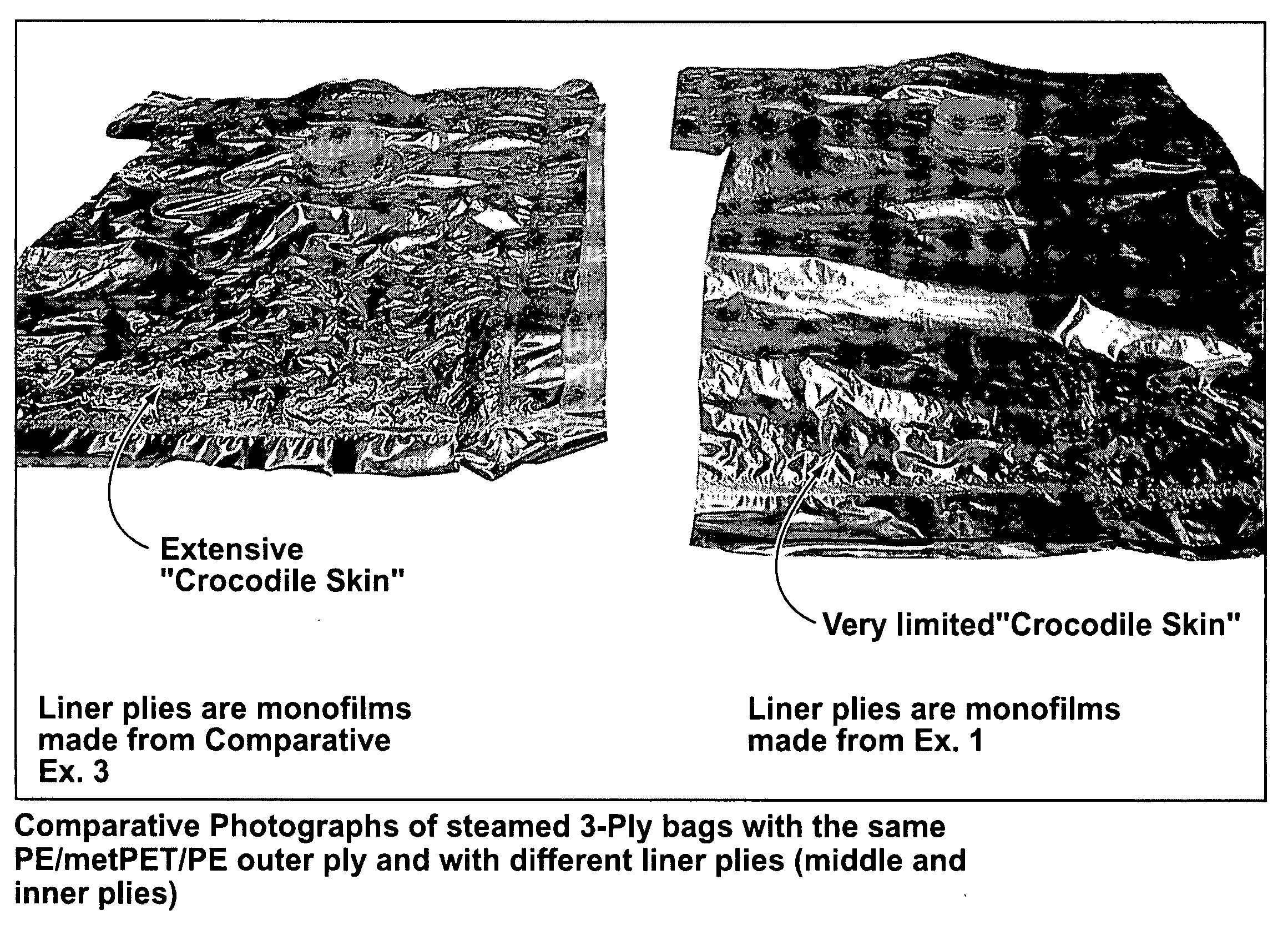

There is disclosed a flowable material packaging film comprising at least a resin blend of (a) from about 33 wt % to about 80 wt % of at least one ethylene-C4 to C10-α-olefin interpolymer having a melt index of from 0.4 to 1.5 g / 10 min (190° C., 2.15 kg), a density of from 0.900 to 0.916 g / cc; and (b) from about 67 wt % to about 20 wt % of at least one heterogeneous interpolymer of propylene with ethylene or ethylene and butene comprising from about 71 mol % to about 86 mol % propylene and from about 29 mol % to about 14 mol % ethylene or ethylene and butene, the interpolymer having an overall weight average molecular weight (MW) of at least about 400,000, a xylene soluble phase of not less than 30% (wt), with the xylene soluble phase having a MW of at least about 275,000 and said heterogeneous interpolymer of polypropylene has a density of from 0.875 to 0.91 g / cc; and the film has a Hot Tack Initiation Temperature in the range of from about 100° C. to about 140° C. and a Hot Tack Strength of not more than about 5 N / inch in the temperature range of about 100° C. to about 150° C., when fabricated at a thickness of about 50 microns and tested using a JB Instrument Hot Tack Tester set at a 0.5 second dwell, 0.2 second delay time, 40 psi seal bar pressure and 250 mm / second peel rate; and the film has a flex crack resistance such that it develops 5 or less pinholes per 300 cm2 in 10,000 cycles of Gelbo Flex testing as measured according to ASTM F392. The film exhibits flex crack resistance and thus is useful in the manufacture of pouches and bags made from such films. Processes for making such pouches and bags which may include aseptic conditions are also described.

Owner:LIQUI BOX

Highly moisture proof film and method of manufacturing the same

ActiveUS7501176B2Increased compact structureExcellent oxygen barrier propertiesSynthetic resin layered productsPretreated surfacesVolumetric Mass DensityMoisture

The present invention makes it possible to provide a film exhibiting an excellent oxygen-gas barrier properties and an excellent moisture proofness, the film containing at least a multivalent metal salt of a polycarboxylate-based polymer (A), the film having the density which is not lower than 1.80 g / cm3; the surface ratio α [the peak surface S1 (3700 to 2500 cm−1) / the peak surface S2 (1800 to 1500 cm−1)] of an infrared absorption spectrum which is not larger than 2.5; and the peak ratio β [the peak A1 (1560 cm−1) / the peak A2 (1700 cm−1)] of the infrared absorption spectrum which is not smaller than 1.2, by means of applying a solution containing the polycarboxylate-based polymer (A) and the multivalent metal compound (B) to a substrate, thus obtaining a dried film, and thereafter treating the dried film with heat under predetermined conditions. Accordingly, the present invention makes it possible to provide packaging materials and packaging containers for not only foods which are required not to contact an oxygen gas, but also foods, beverages, chemicals, pharmaceuticals, and precision metal parts such as electronic parts, as well as members of electronic equipment, all of which are required to be protected from moisture.

Owner:TOPPAN PRINTING CO LTD

Crystalline composition, wafer, device, and associated method

A crystalline composition is provided that includes gallium and nitrogen. The crystalline composition may have an amount of oxygen present in a concentration of less than about 3×1018 per cubic centimeter, and may be free of two-dimensional planar boundary defects in a determined volume of the crystalline composition. The volume may have at least one dimension that is about 2.75 millimeters or greater, and the volume may have a one-dimensional linear defect dislocation density of less than about 10,000 per square centimeter.

Owner:SLT TECH

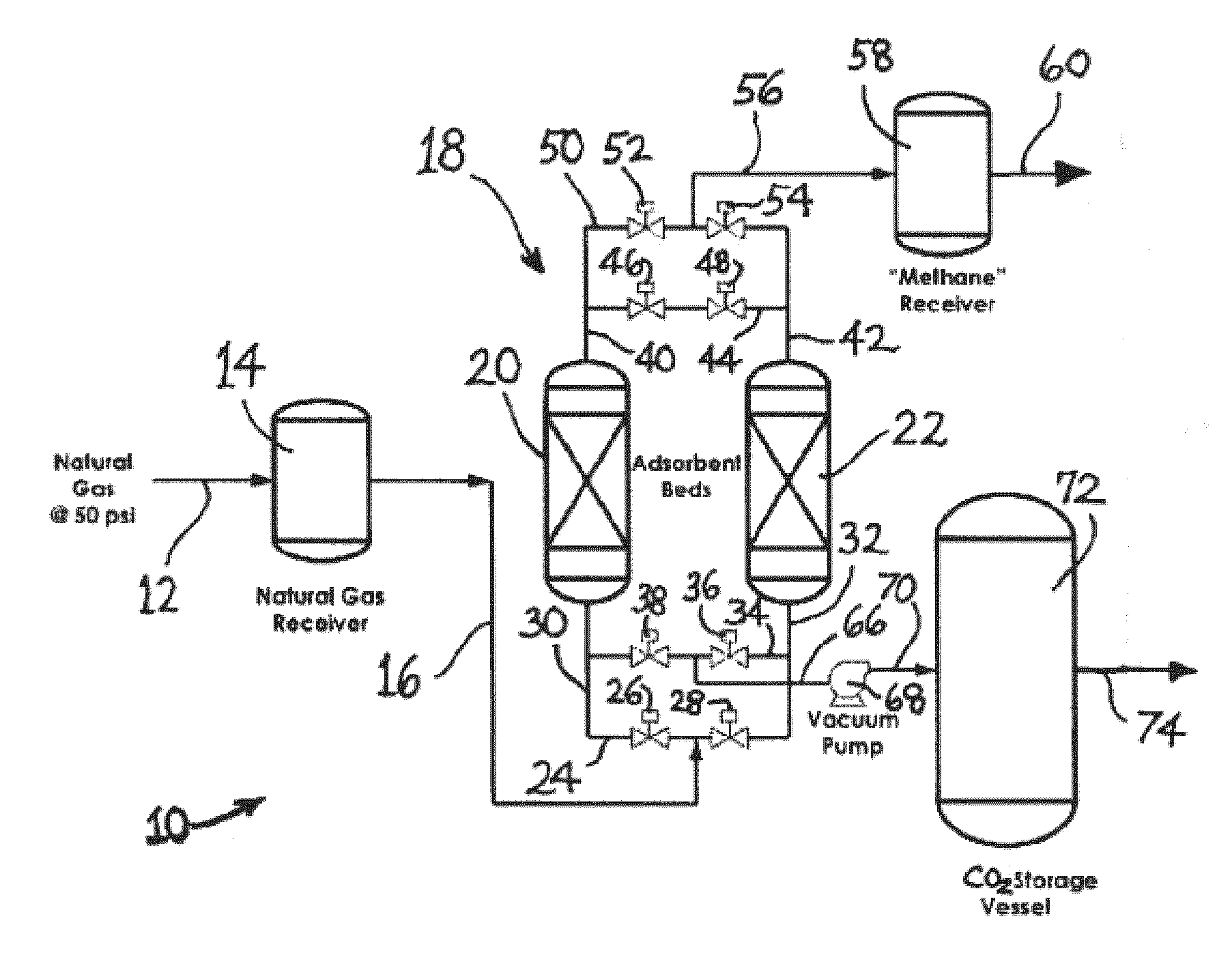

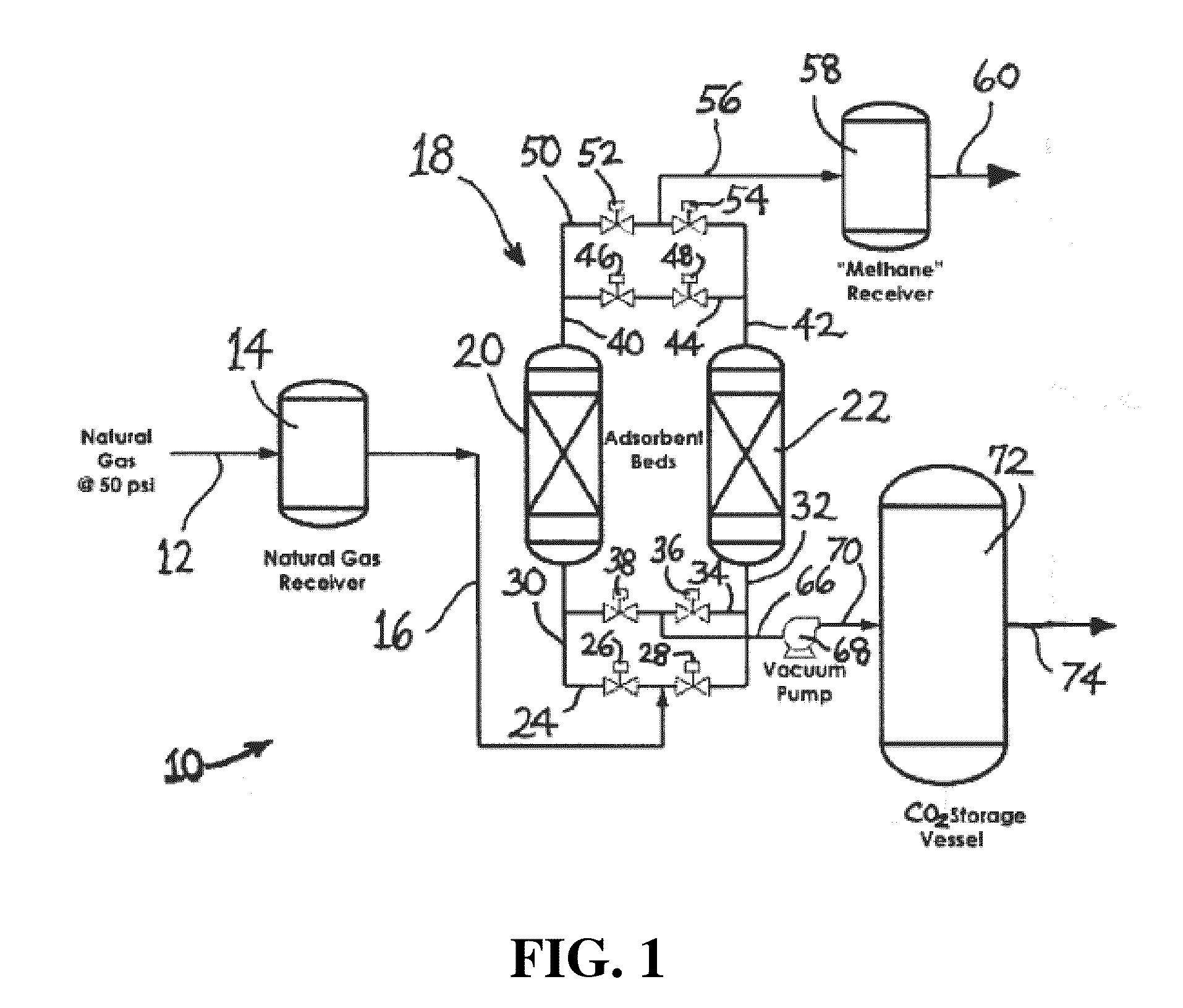

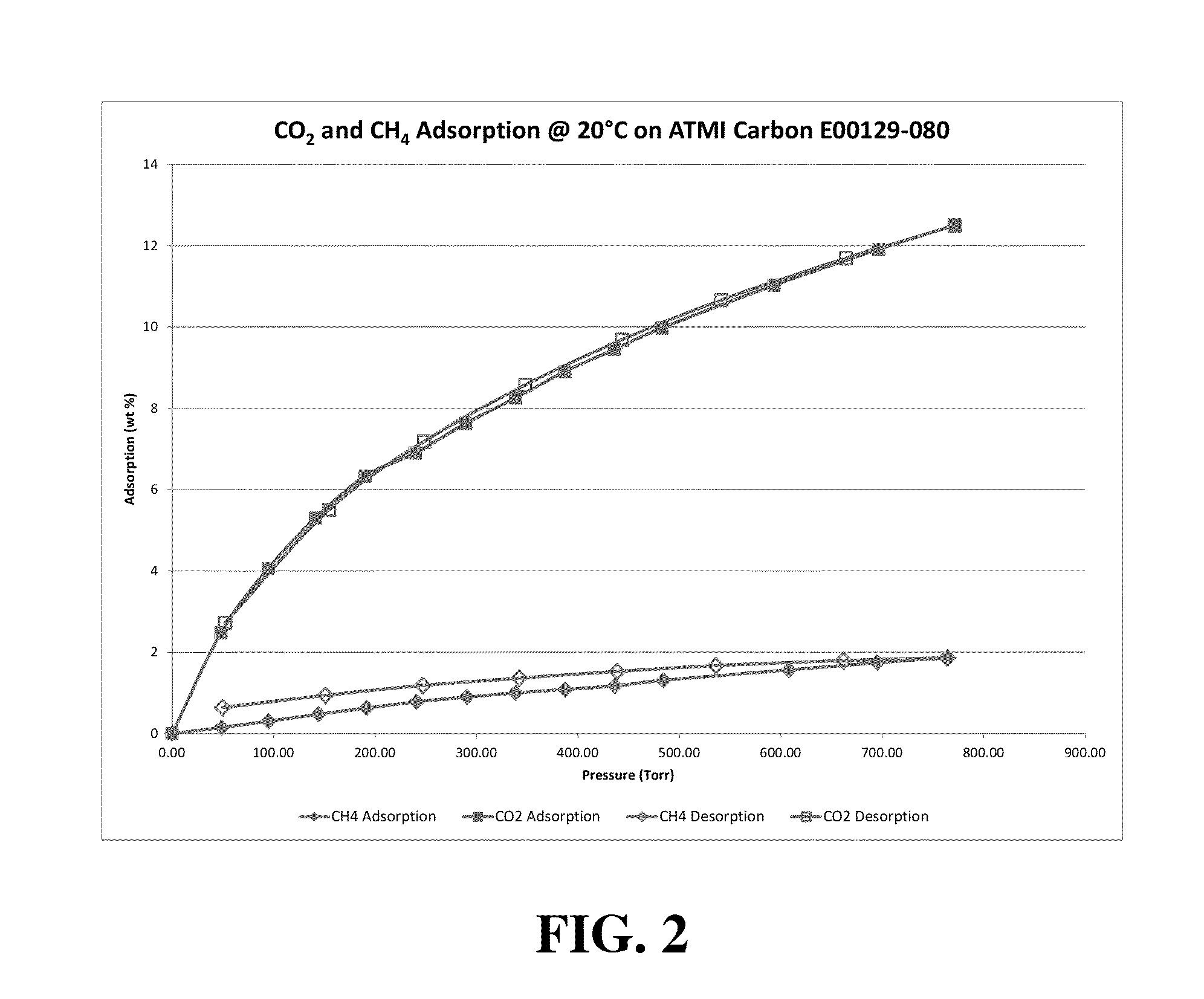

Adsorbent having utility for co2 capture from gas mixtures

A carbon pyrolyzate adsorbent is described that is selective for carbon dioxide in contact with gas mixtures including carbon dioxide and methane. The adsorbent has a carbon dioxide adsorbent capacity at 1 bar pressure of greater than 50 cm3 carbon dioxide per gram of adsorbent at 273K, a methane adsorption capacity at 1 bar pressure of less than 35 cm3 methane per gram of adsorbent at 21° C., and a bulk density of greater than 0.55 gram per cubic centimeter of volume. Such adsorbent can be utilized, for example, for biogas upgrading, natural gas purification, coal bed methane purification, and refining operations.

Owner:ENTEGRIS INC

Manufacturing method for balance weight of compressor and balance weight manufactured by using manufacturing method

The invention relates to a manufacturing method for a balance weight of a compressor and a balance weight manufactured by using the manufacturing method. The balance weight of the compressor is manufactured by using alloy powder by a powder metallurgy method. The manufacturing method for the balance weight of the compressor is characterized by comprising the following steps of (a) placing raw materials comprising the alloy powder and adhesives in a blender mixer and uniformly mixing the raw materials; (b) feeding the mixed materials into a powder pressing machine, and performing compression moulding on the mixed materials to obtain a pressed blank of the balance weight; (c) covering copper plates on the outer surface of the pressed blank of the balance weight, placing the pressed blank of the balance weight in a sintering furnace, and sintering and solidifying the pressed blank of the balance weight to obtain a sintered blank of the balance weight; and (d) polishing the sintered blank of the balance weight and removing burs of the sintered blank of the balance weight. Compared with the prior art, the manufacturing method for the balance weight of the compressor and the balance weight manufactured by using the manufacturing method have the advantages that the density of the balance weight, which is manufactured by using the method, of the compressor is 7.5-8.0 grams per cubic centimeter, and the using range of the existing alloy for balance weights is greatly extended; and the balance weight has characteristics of zero magnetism, rust protection and the like, and can serve as a substitute product of various copper alloy balance weights and various stainless steel balance weight.

Owner:舒思雄

Thermoplastic wear resistant compositions, methods of manufacture thereof and articles containing the same

Disclosed herein is a composition comprising a polycarbonate resin; a polycarbonatepolysiloxane copolymer; and an anhydride modified polyolefin. Disclosed herein too is a composition comprising a blend of a polycarbonate resin with a polycarbonatepolysiloxane copolymer; and an anhydride modified polyethylene, wherein the composition has a wear factor of less than or equal to about 350 in<5>min / ftlb-hr and an impact strength of greater than or equal to about 500 joules per meter, and wherein the wear factor is measured according to the formula: Wear Factor= [(6.1 x10 <8 >)(W)] / [(PxV)x (D) x (T)] where P is the applied pressure in pounds per square inch and V is the velocity in feet per minute, W is the weight loss in grams, D is the density in grams per cubic centimeter and T represents 100 hours.

Owner:SABIC INNOVATIVE PLASTICS IP BV

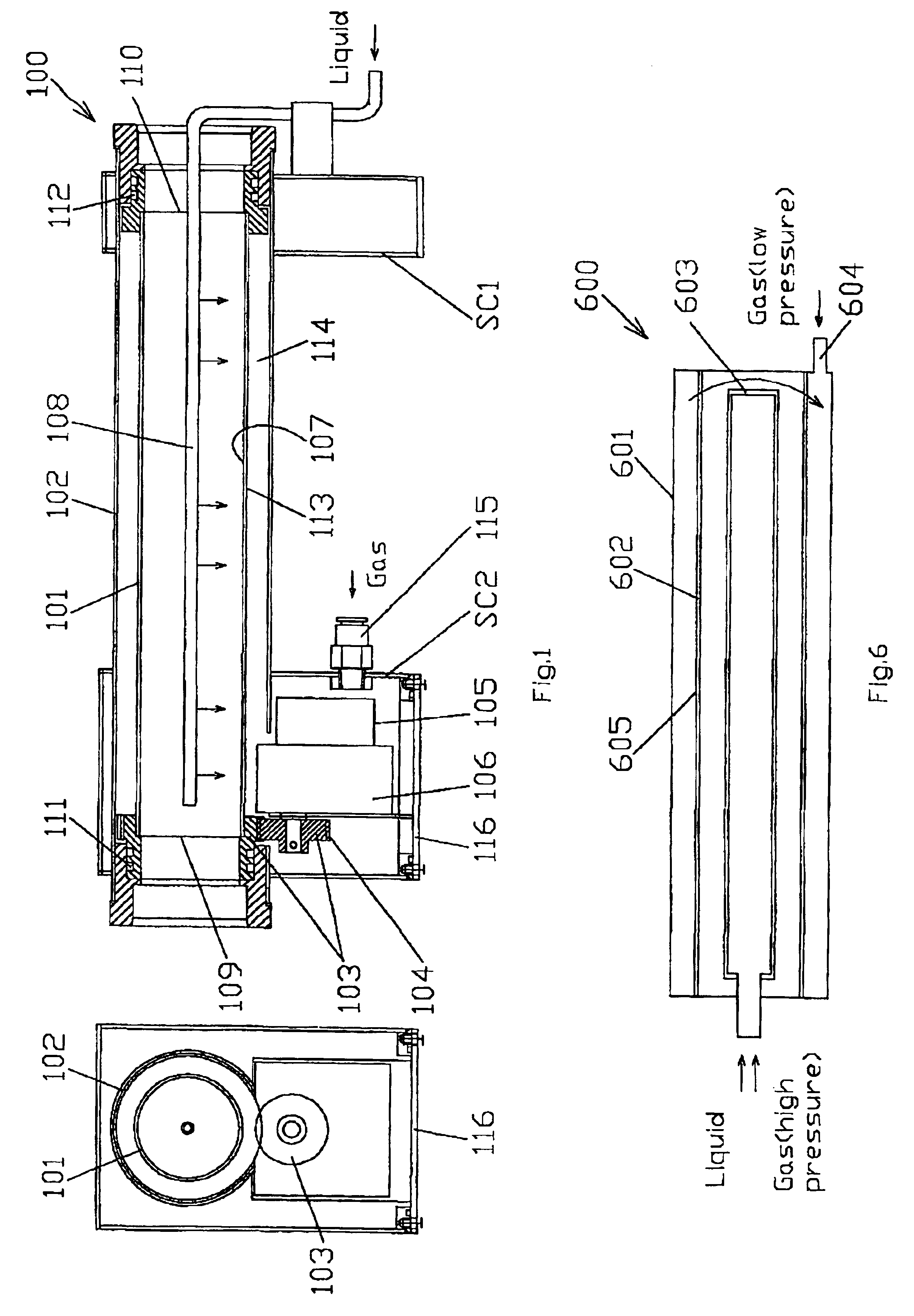

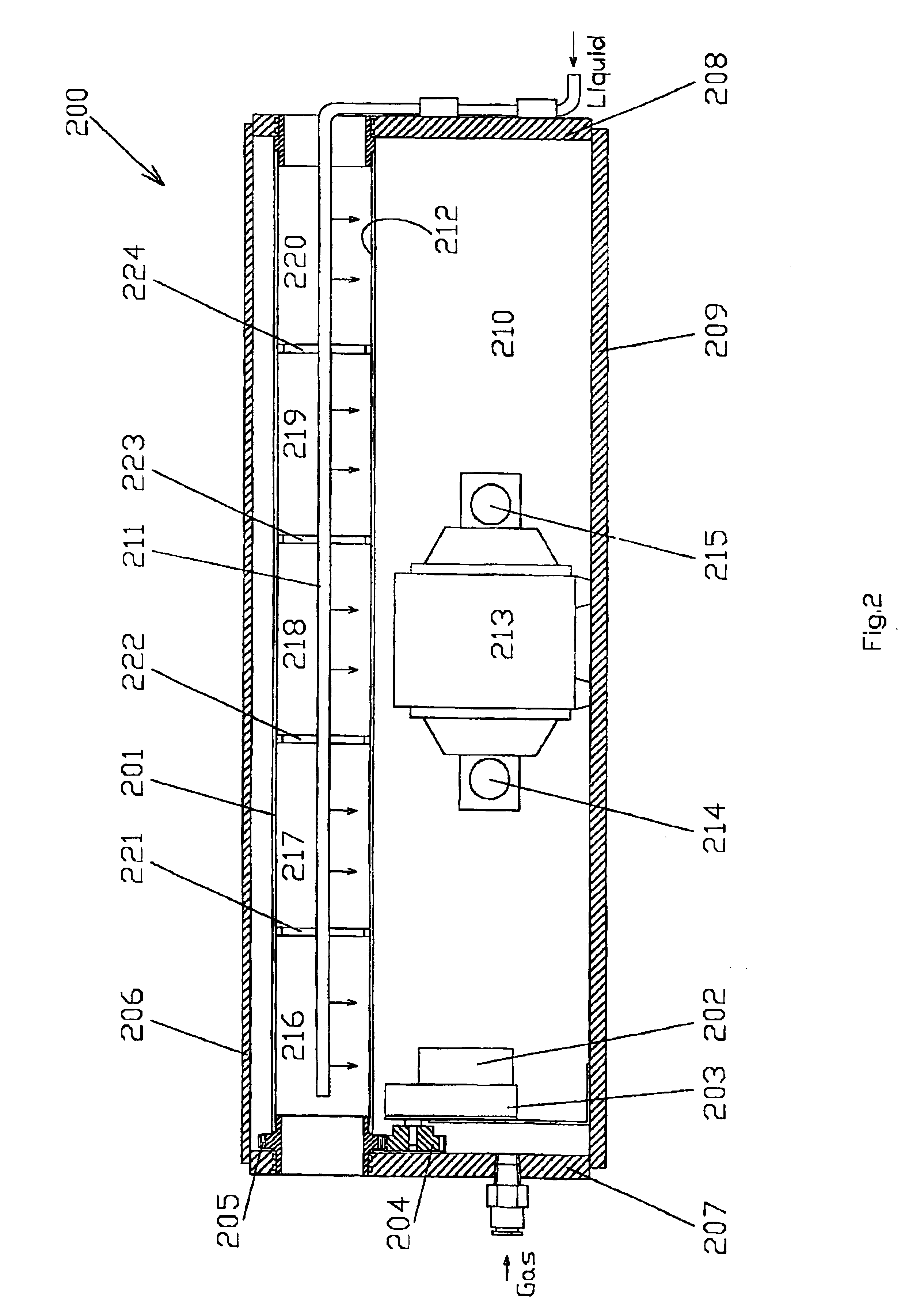

Method and apparatus for production of droplets

InactiveUS6899322B2Reduce the average velocityControl performanceUsing liquid separation agentMixing methodsEngineeringLiquid phase

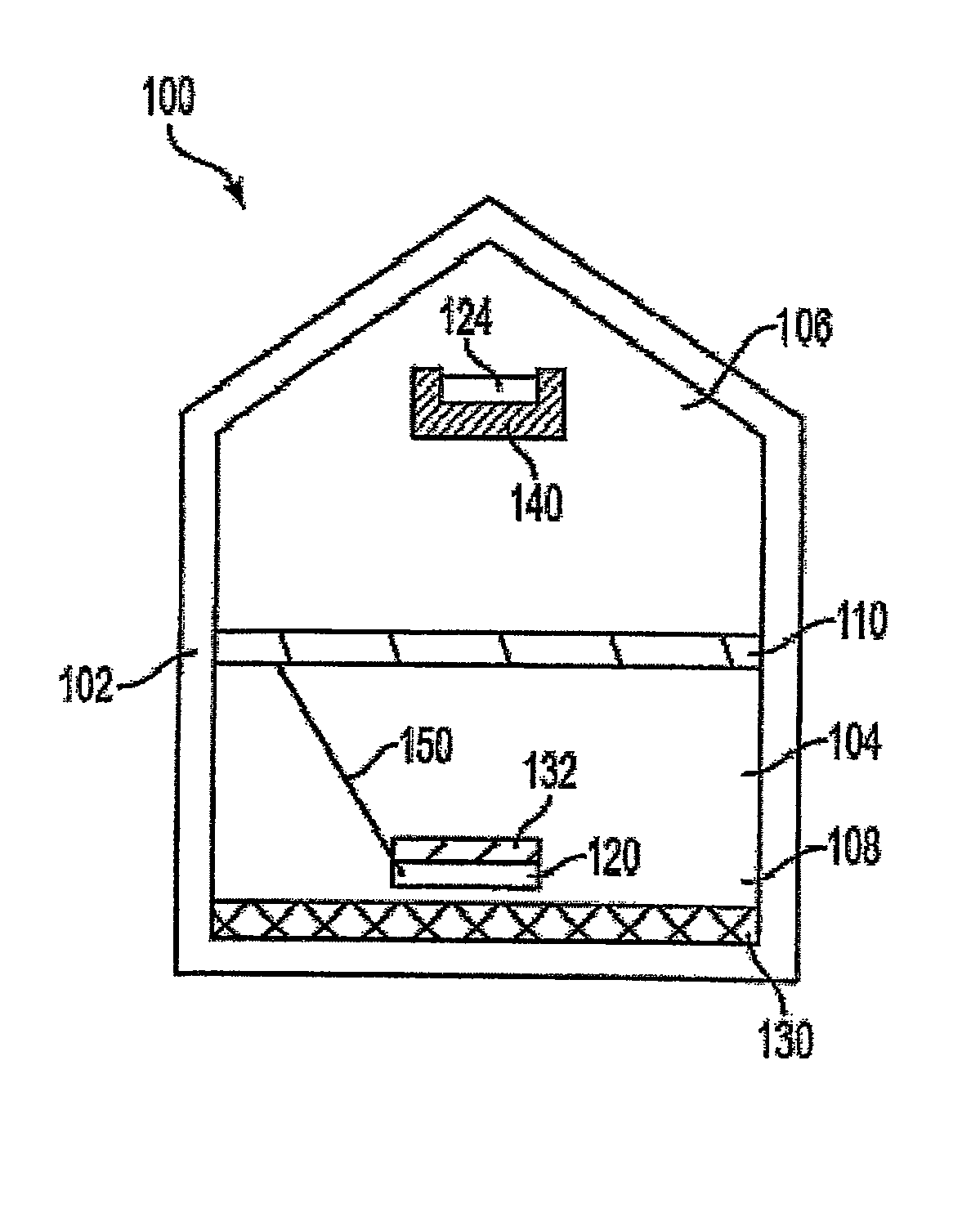

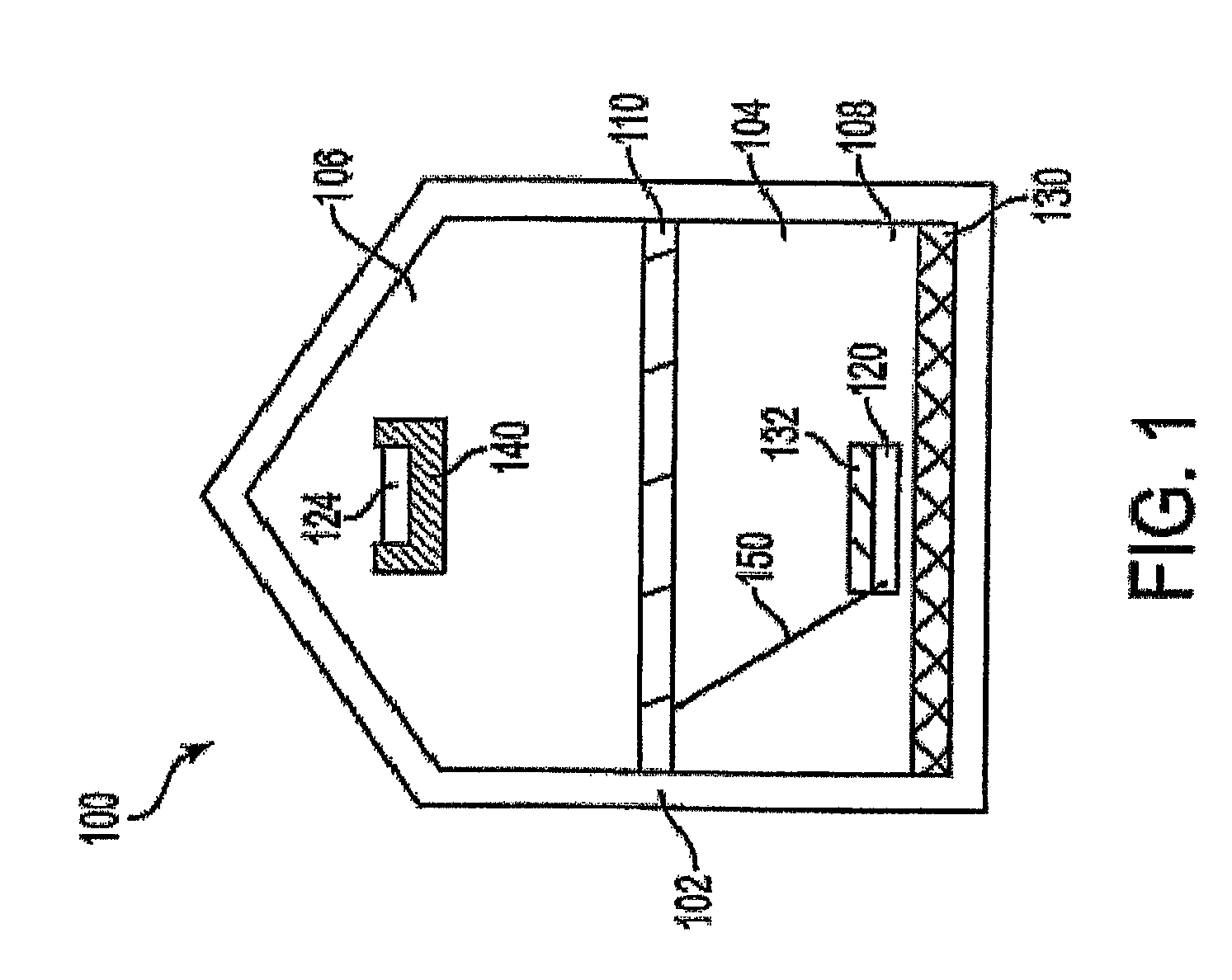

The invention concerns a method and apparatus (100) for producing mist of a liquid phase having very fine and mono-dispersed droplets. The method is realized by an apparatus (100) including a partition (101), defined by a first side surface (107) and a second side surface (113). The first side surface (107) is wetted by a liquid phase to form a film thereon, while the second side surface (113) is substantially dry. A gas stream is directed through the partition (101) from the dry side (113) to the wetted side (107) thereby forming a mist having droplets of less than 1 micron in size and a concentration of at least 1,000,000,000,000 per cubic cm.

Owner:ULTRASONIC DRYER +1

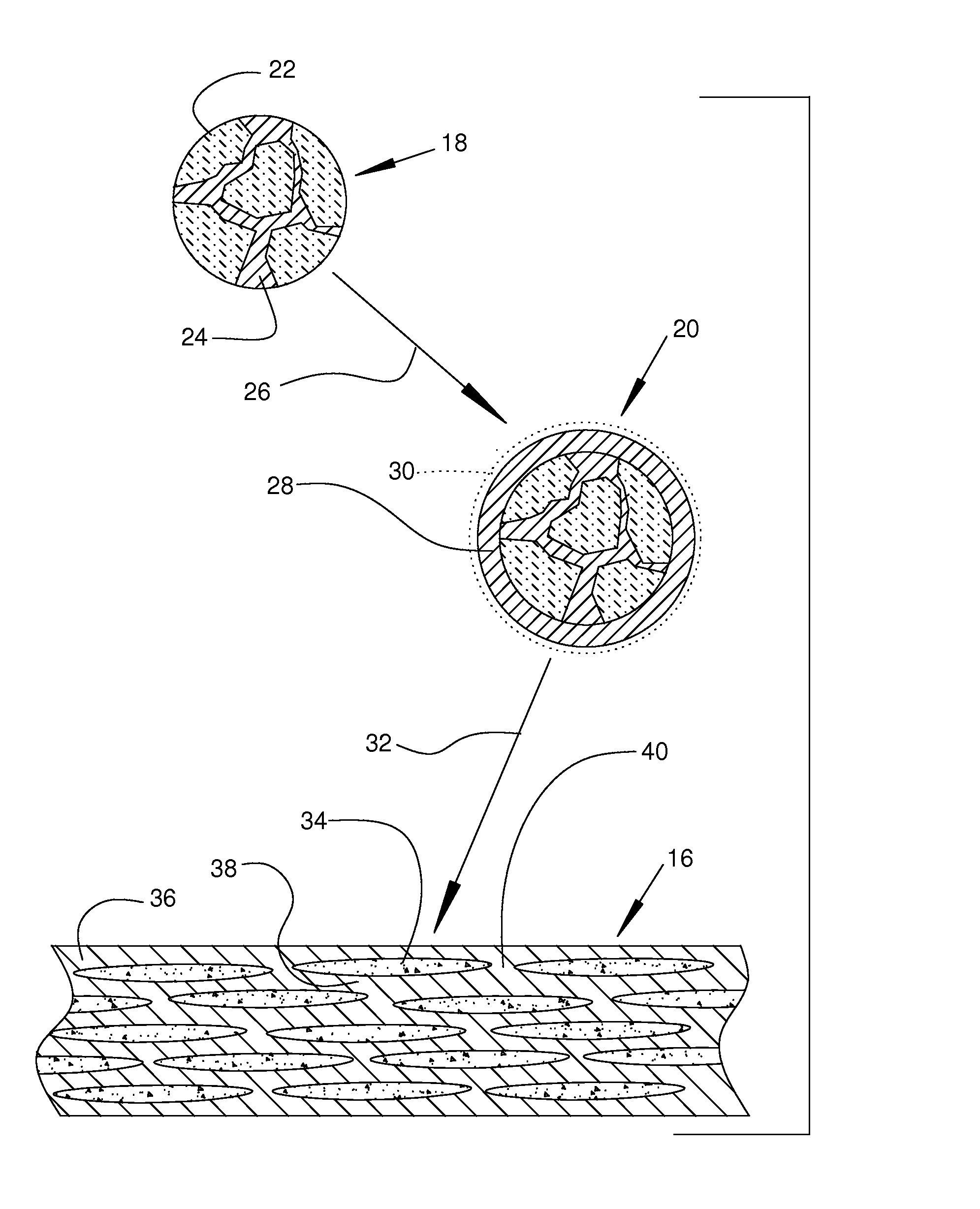

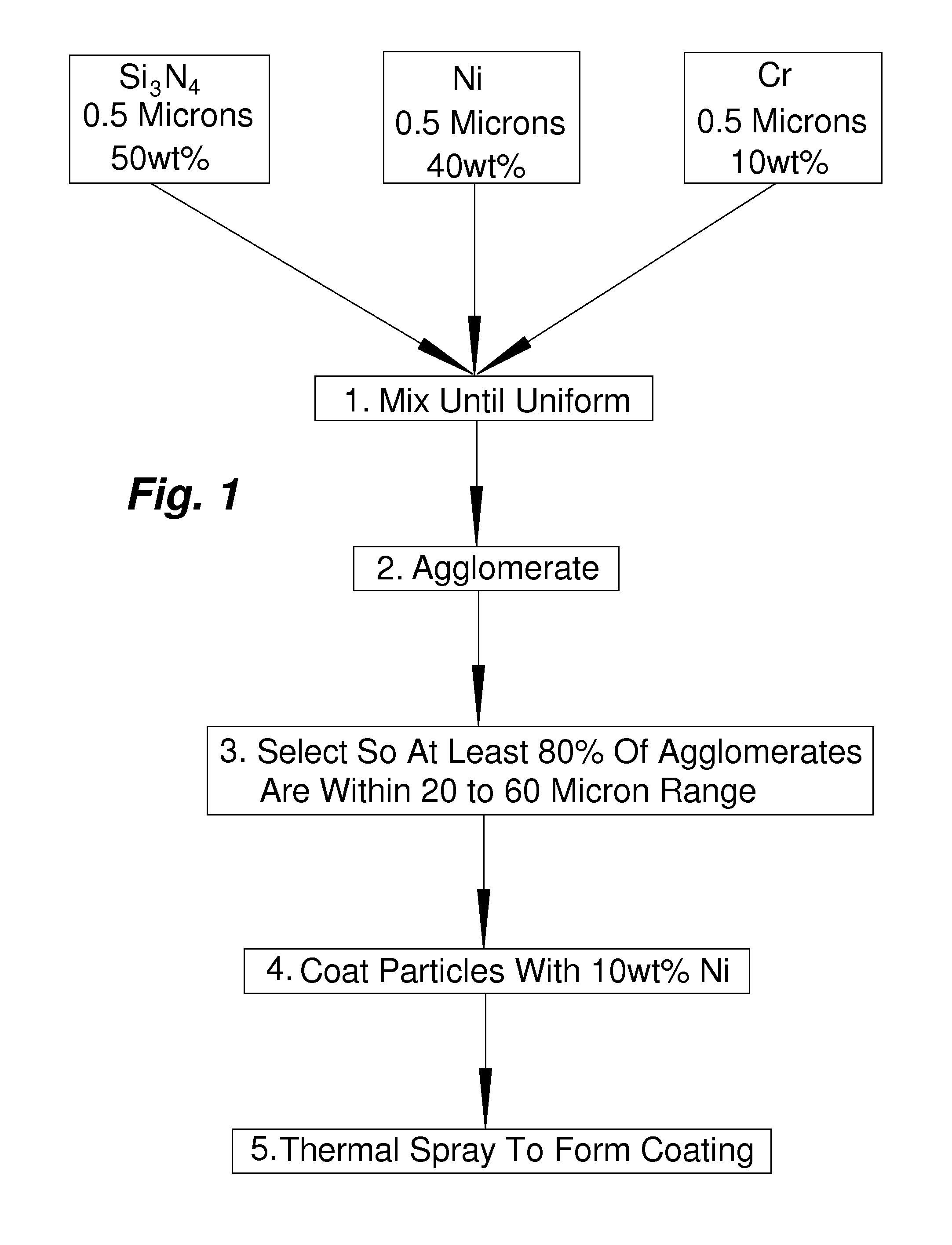

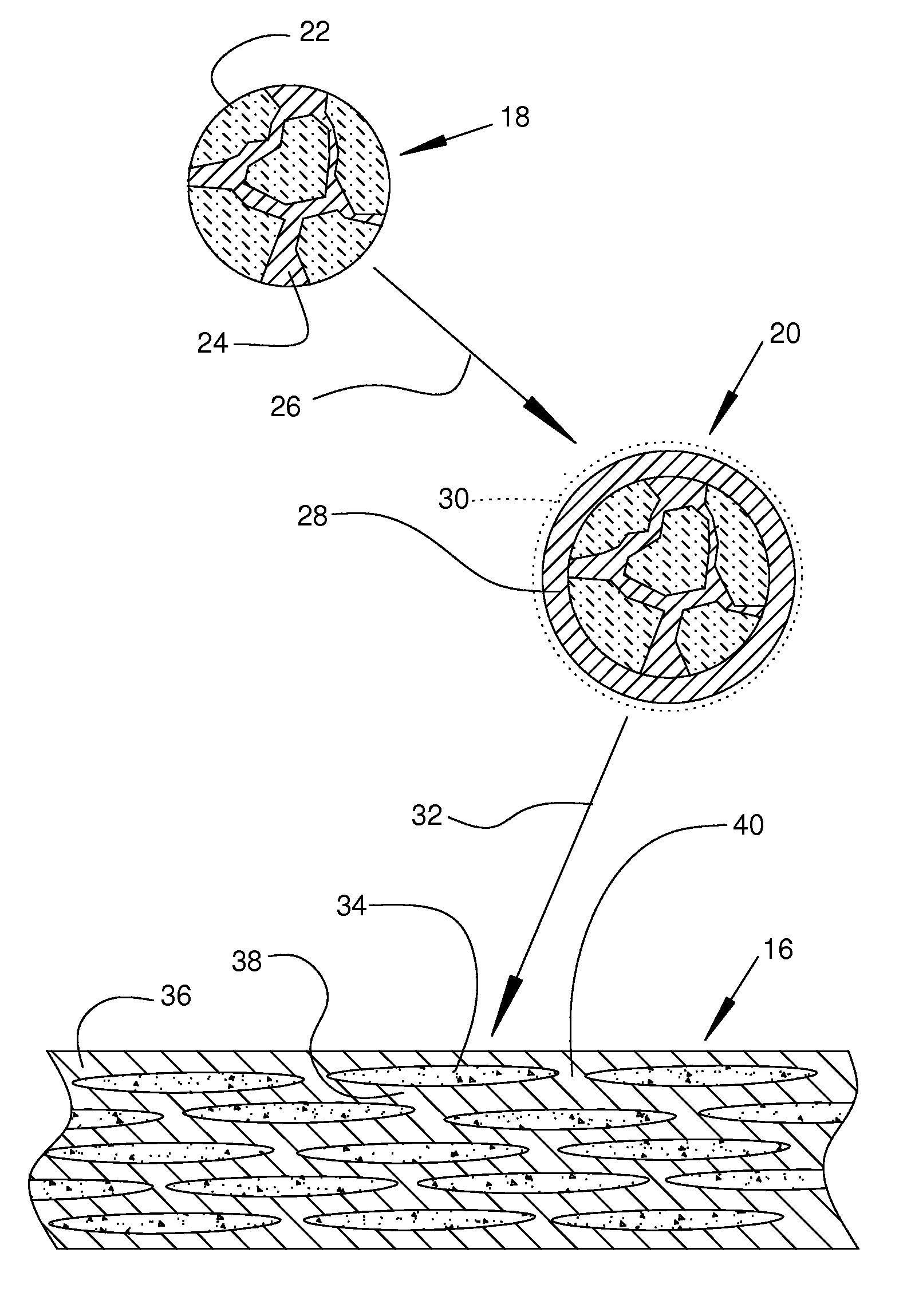

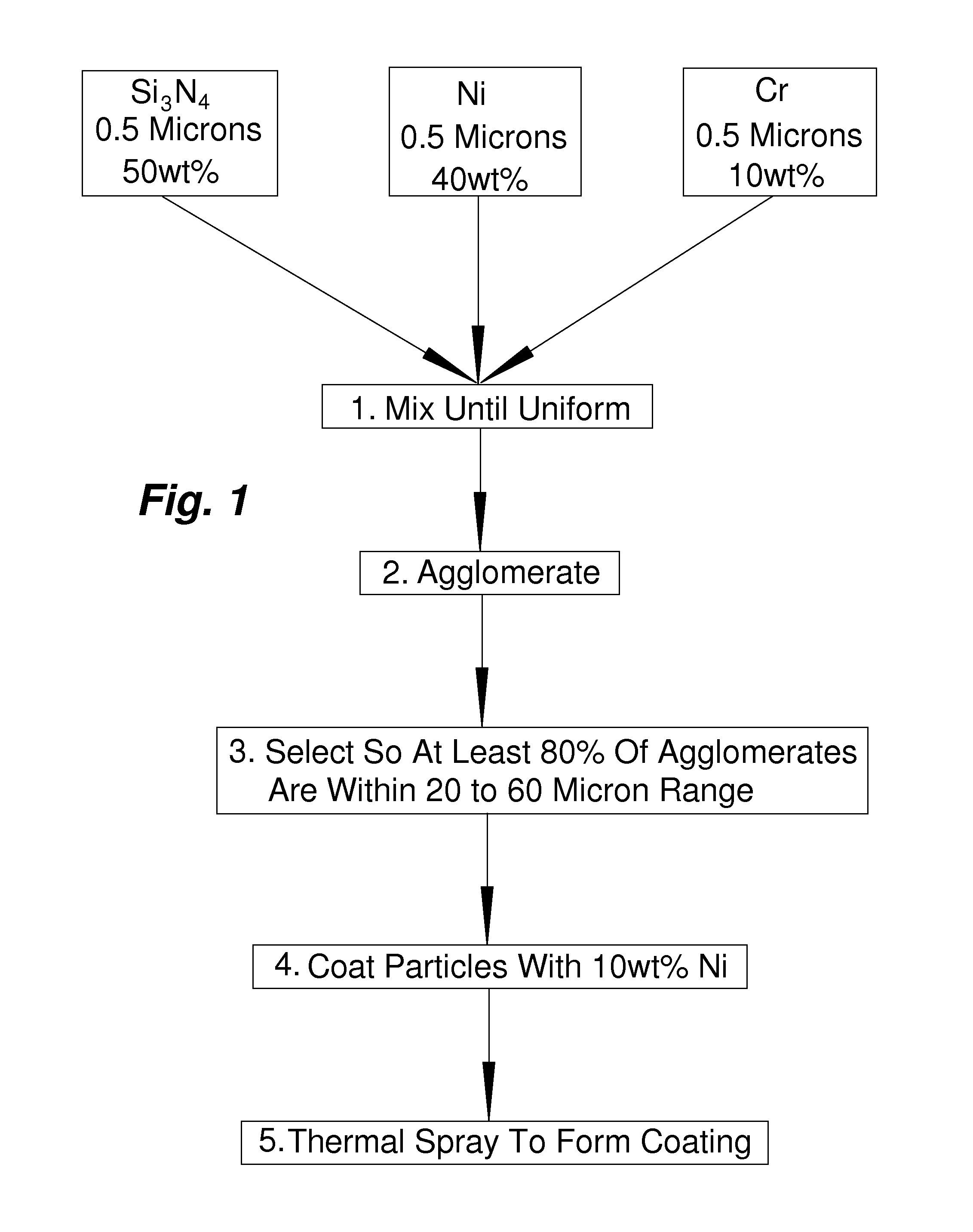

Coatings, composition, and method related to non-spalling low density hardface coatings

ActiveUS8460796B2Efficient solutionSuitable for useLiquid surface applicatorsMolten spray coatingCubic centimetreToughening

A composite body that is spall resistant and comprises a substantially discontinuous cermet phase in a substantially continuous metal rich matrix phase. The composite body is typically bonded to a substrate to form a hardfacing on the substrate. The composite body exhibits ductile phase toughening with a strain to failure of at least about 2 percent, a modulus of elasticity of less than about 46 million pounds per square inch, and a density of less than about 7 grams per cubic centimeter. The metal rich matrix phase between the ceramic rich regions in the composite body has an average minimum span of about 0.5 to 8 microns to allow ductility in the composite body. The composite body has a Vicker's hardness number of greater than approximately 650. The discontinuous cermet phase is in the form of ceramic rich regions embedded within the composite body, and it includes ceramic particles and a cermet binder. The ceramic particles having a Moh's hardness of at least approximately 7.5, a modulus of elasticity of less than approximately 46 million pounds per square inch, and an average particle size of from about 0.1 to 10 microns. The ceramic rich regions exhibit high hardness as compared with the matrix phase.

Owner:HYBRID MATERIALS LLC

High-molecular material with health care effect

The invention relates to a high-molecular material with a health care effect. The high-molecular material comprises the following raw materials, by weight, 47-84% of a high-molecular compound, 13-28% of tourmaline powder and 3-25% of nanometer negative ion powder. The high-molecular compound is propionate fiber or cellulose acetate fiber or plastic titanium. According to the invention, color fiber powder for changing color of the high-molecular compound also can be added. The high-molecular material generates 2-18 microns of far infrared emission, and release amount of negative ions reaches 500-50000 per cubic centimetre. Legs of glasses, spectacle frames or nose pads prepared from the high-molecular material have functions of releasing negative ions, emitting far infrared rays and changing colors of macromolecules, have a good health care effect and can be used to effectively relieve fatigue and acerbity of wearers' eyes.

Owner:葛家波

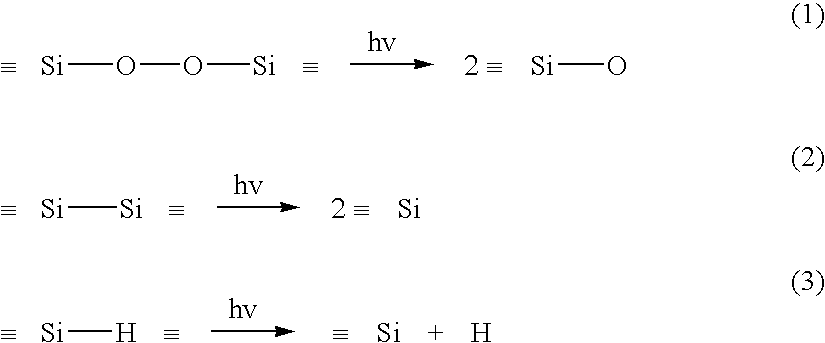

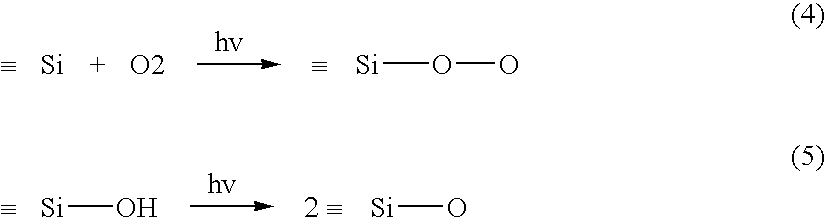

Synthetic quartz glass for optical member and its production method

ActiveUS7514382B2Improve uniformityStably smallGlass shaping apparatusGlass deposition burnersOxygen deficientLength wave

A synthetic quartz glass for an optical member which is free from compaction and rarefaction is obtained. A synthetic quartz glass for an optical member to be used for an optical device employing a light having a wavelength of at most 400 nm and at least 170 nm as a light source, which contains substantially no oxygen excess defects, dissolved oxygen molecules nor reduction type defects, which has a chlorine concentration of at most 50 ppm and a OH group concentration of at most 100 ppm, and which contains oxygen deficient defects within a concentration range of at most 5×1014 defects / cm3 and at least 1×1013 defects / cm3. The fluorine concentration is preferably at most 100 ppm.

Owner:ASAHI GLASS CO LTD

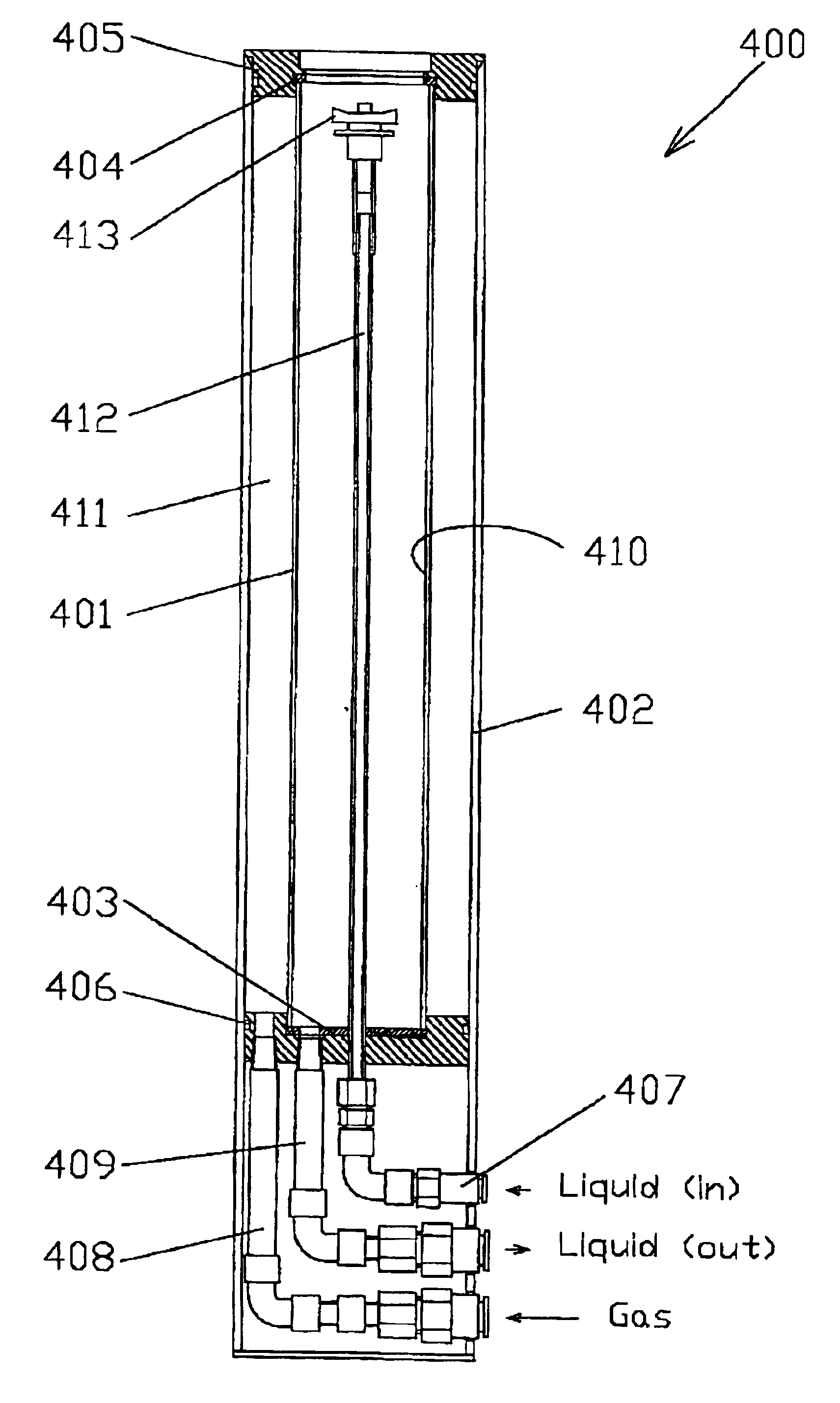

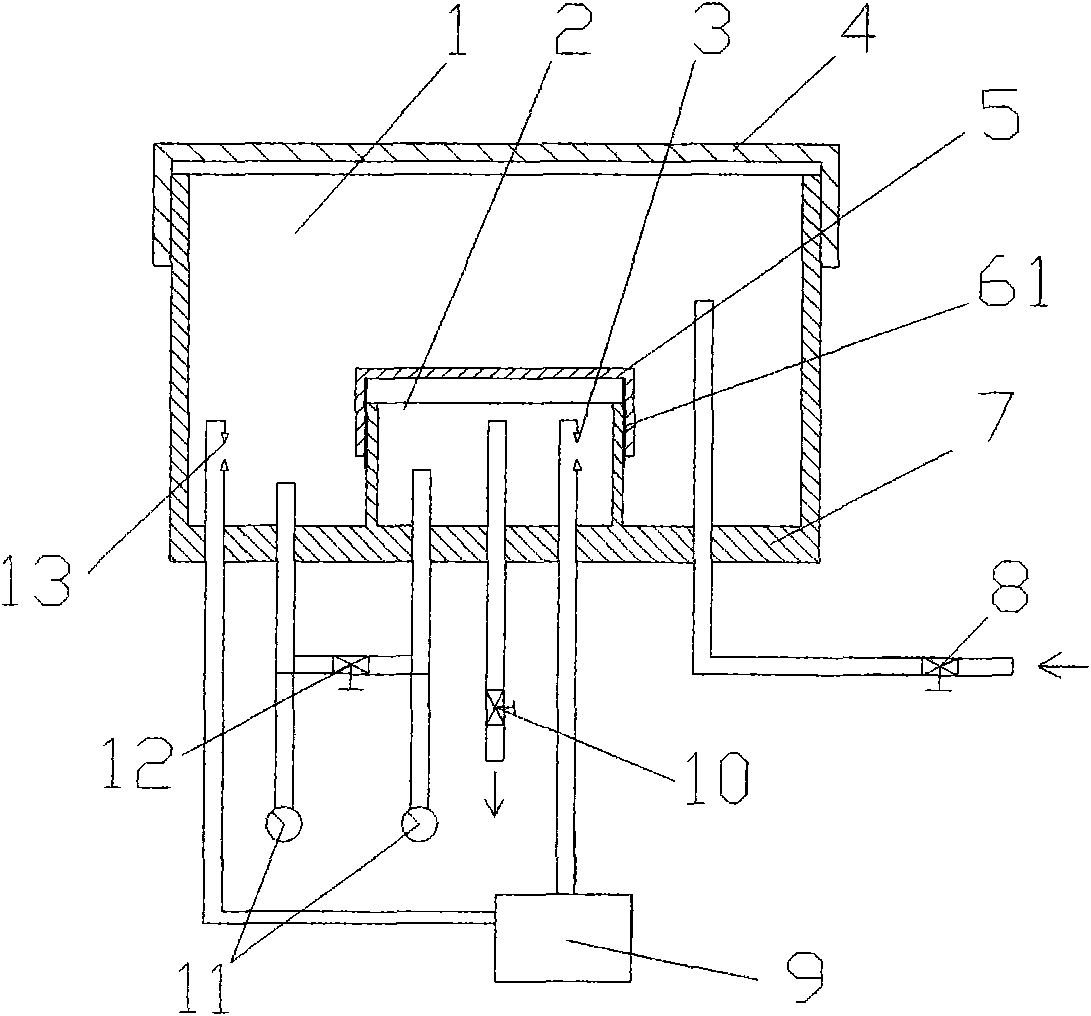

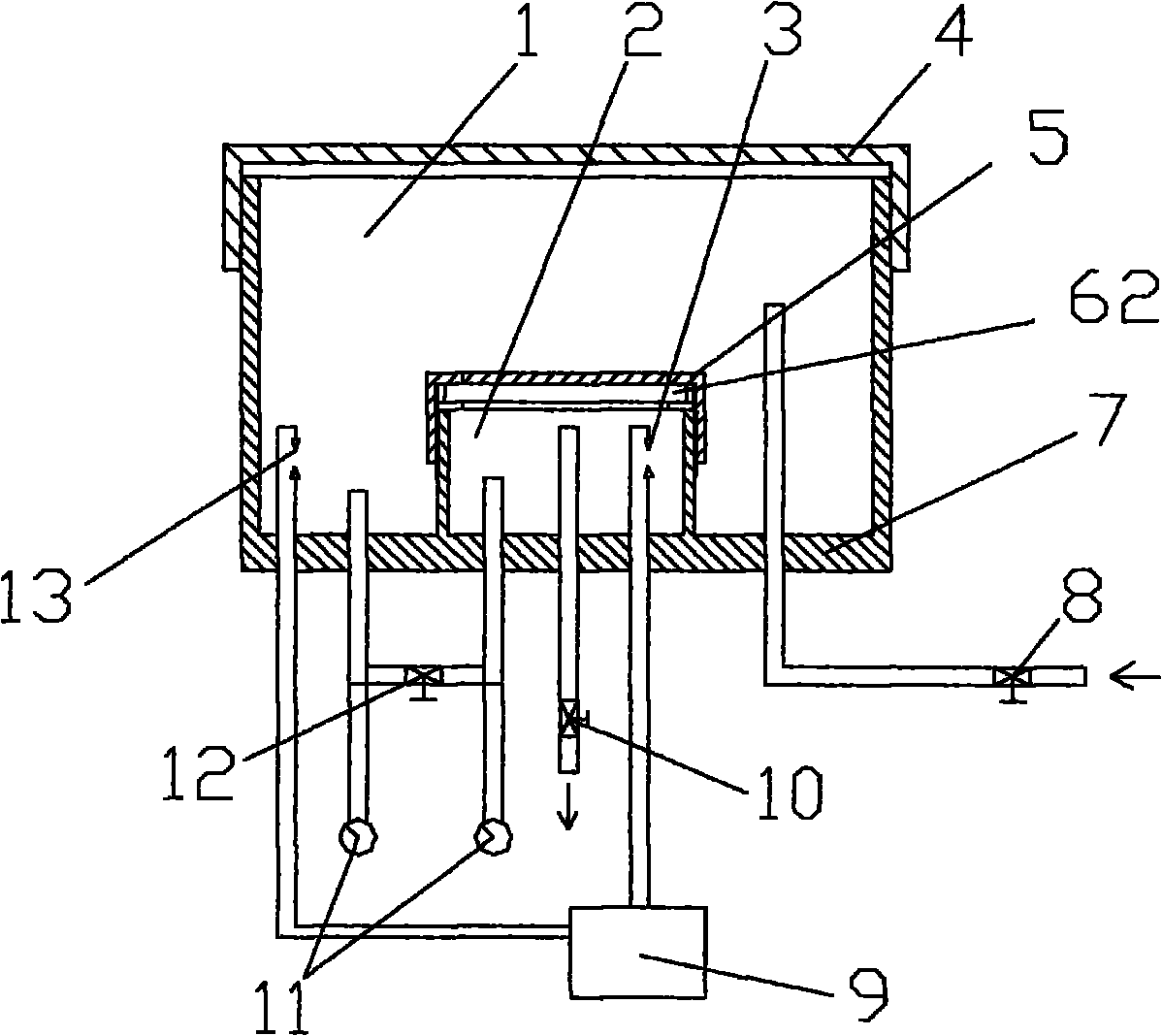

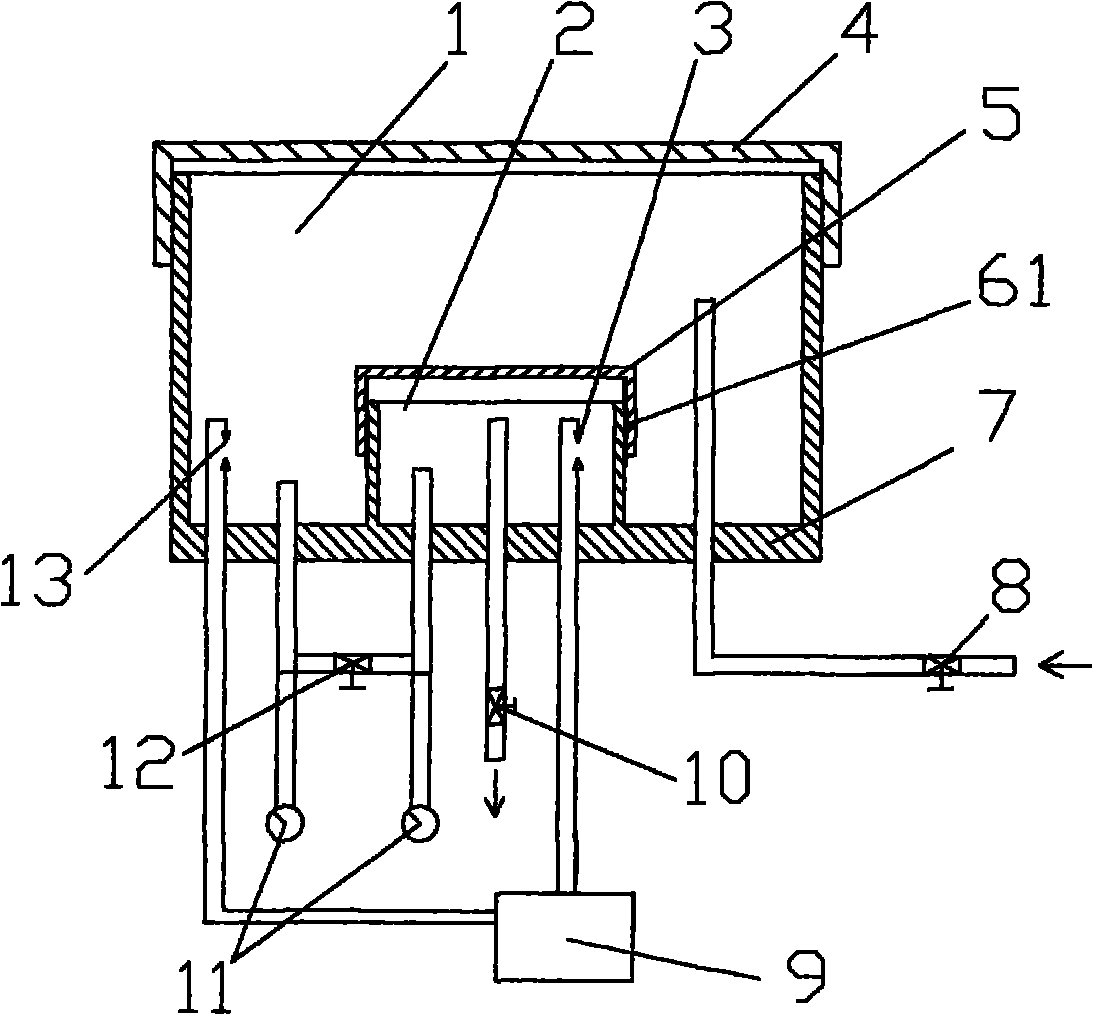

Equipment for small scale booster test

The invention relates to a device for small scale booster test. The device is used to test the explosion-proof parameters of the explosion-proof equipments, in particular booster tests with a volume of less than 20 cubic centimetres. The device comprises a metallic external test chamber, in which an independent internal test chamber is set. The metallic external chamber and the internal chamber share a chassis and are externally interconnected with a stop valve. The internal test chamber cover is arranged in the external test chamber, connected by a screw thread. The internal and external test chambers are interconnected with metallic sintered breathing apparatus. By repetitive booster experiments with all kinds of gas mixture, the device for small scale booster test can further calculate the explosion-proof parameters at smaller volume so as to complete the national standards.

Owner:SHENZHEN JINMING TECH

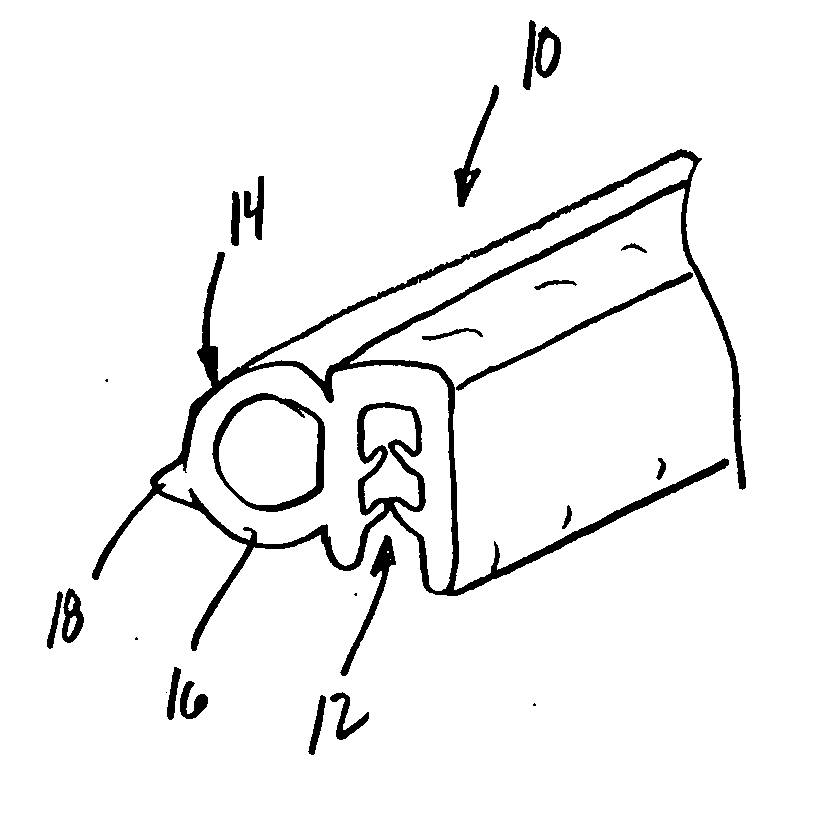

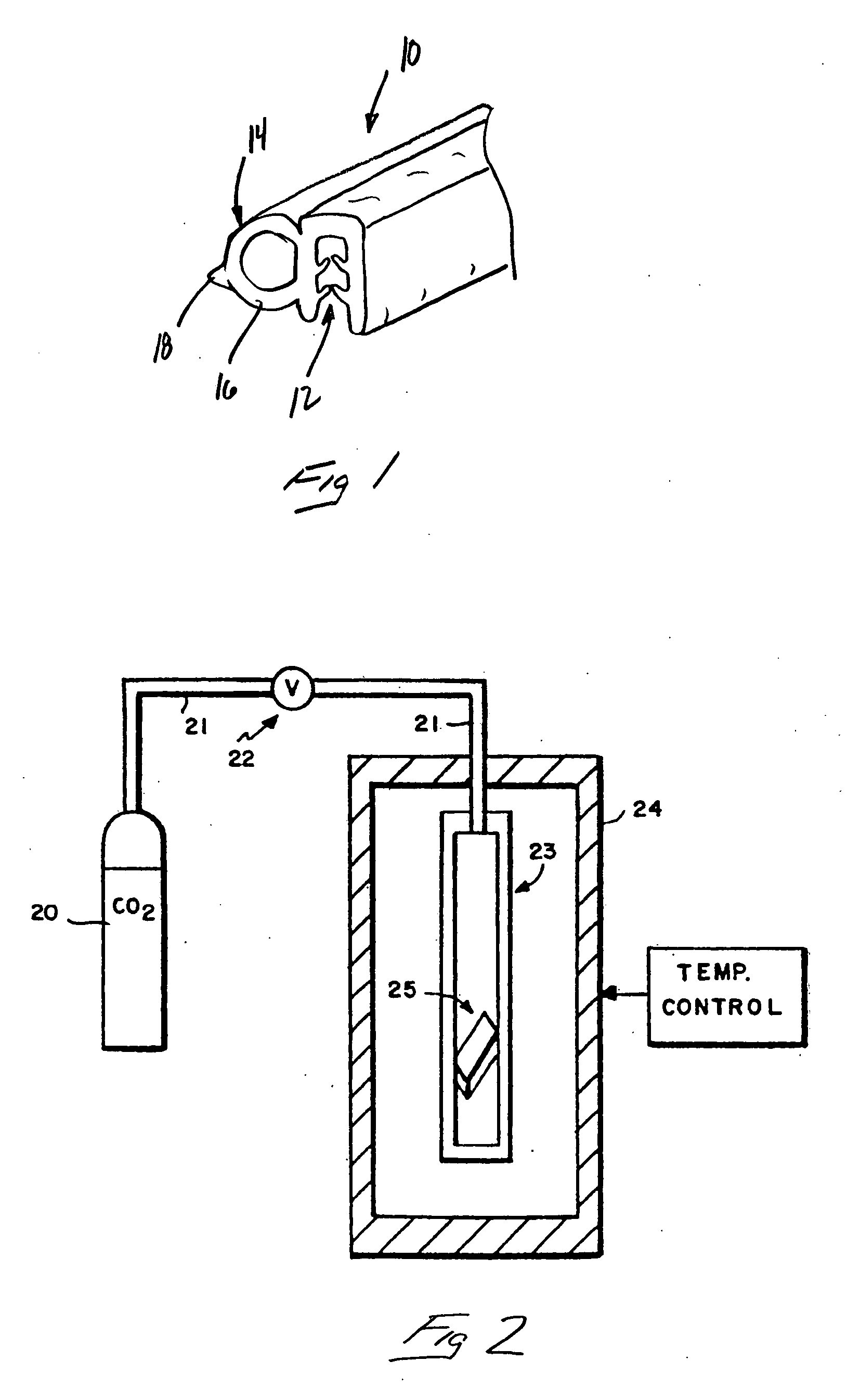

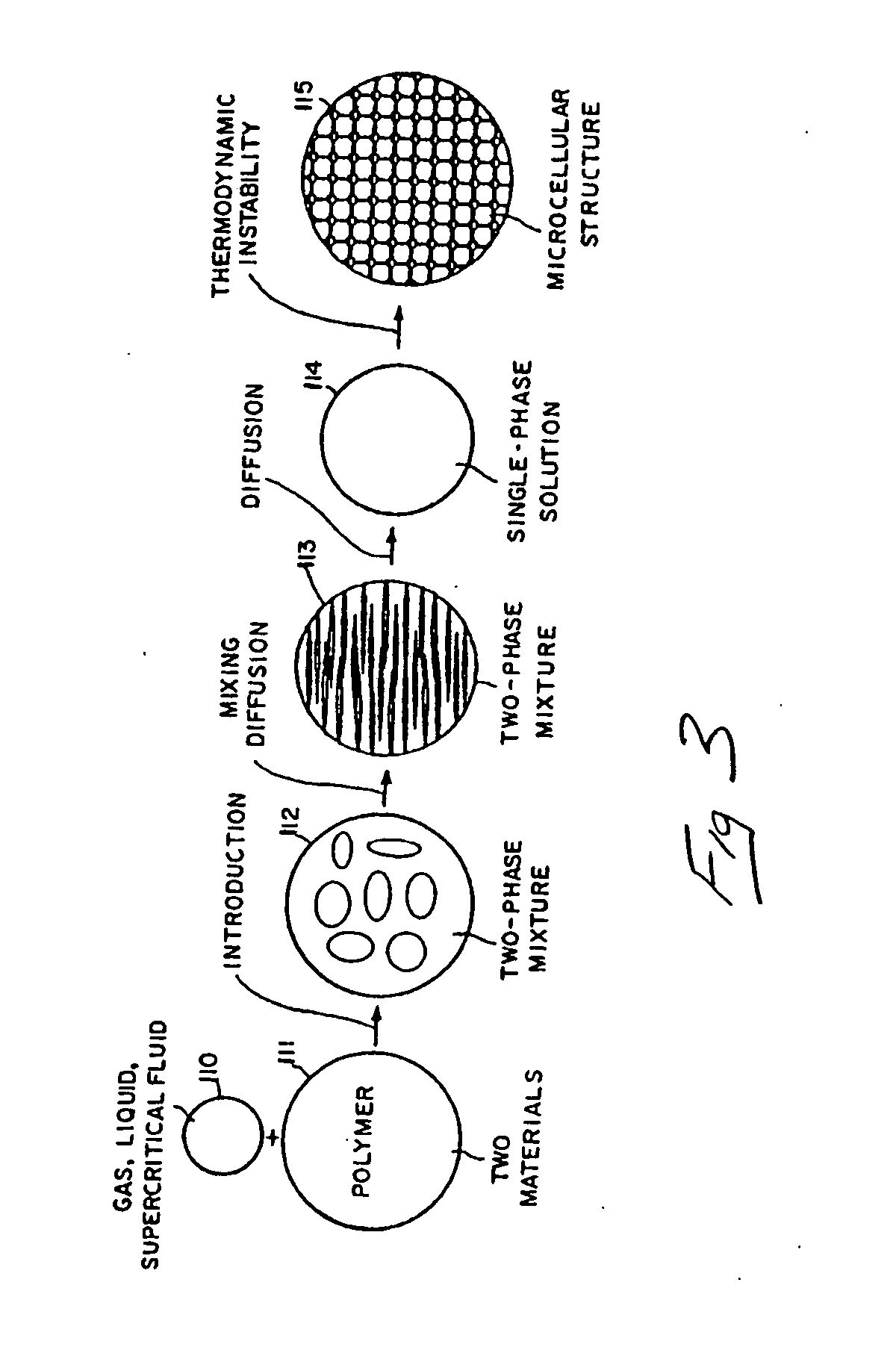

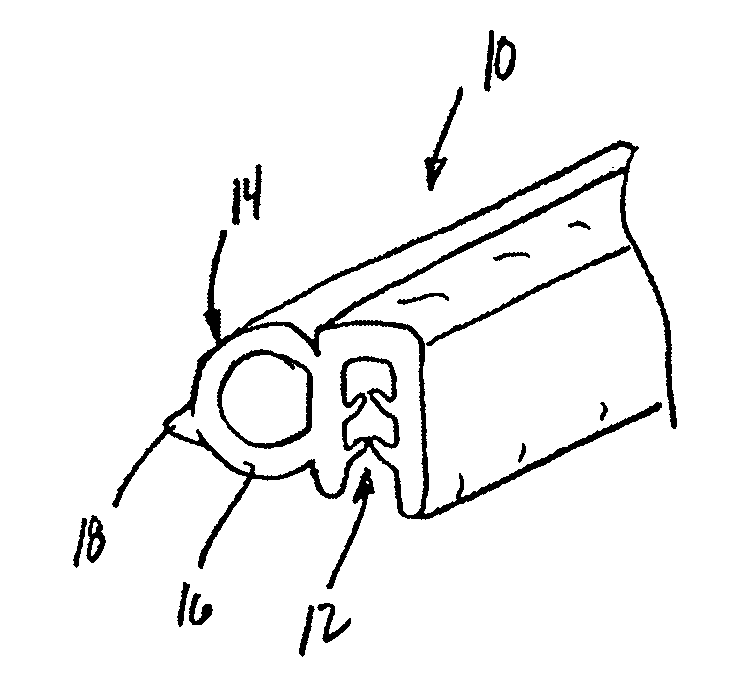

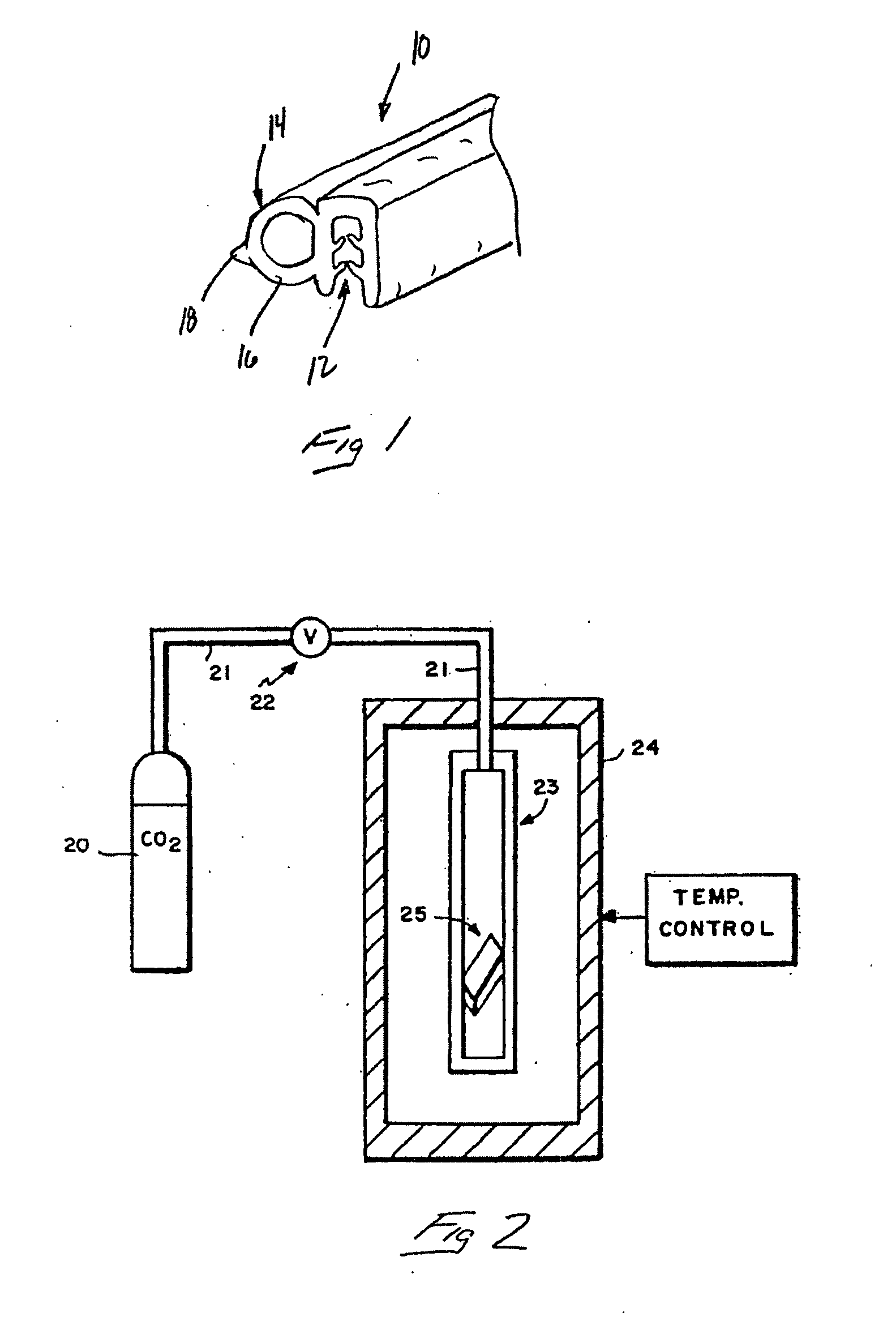

Thermoplastic vehicle weather stripping

InactiveUS20050193636A1Light weightLess expensiveEngine sealsSills/thresholdEngineeringVolumetric Mass Density

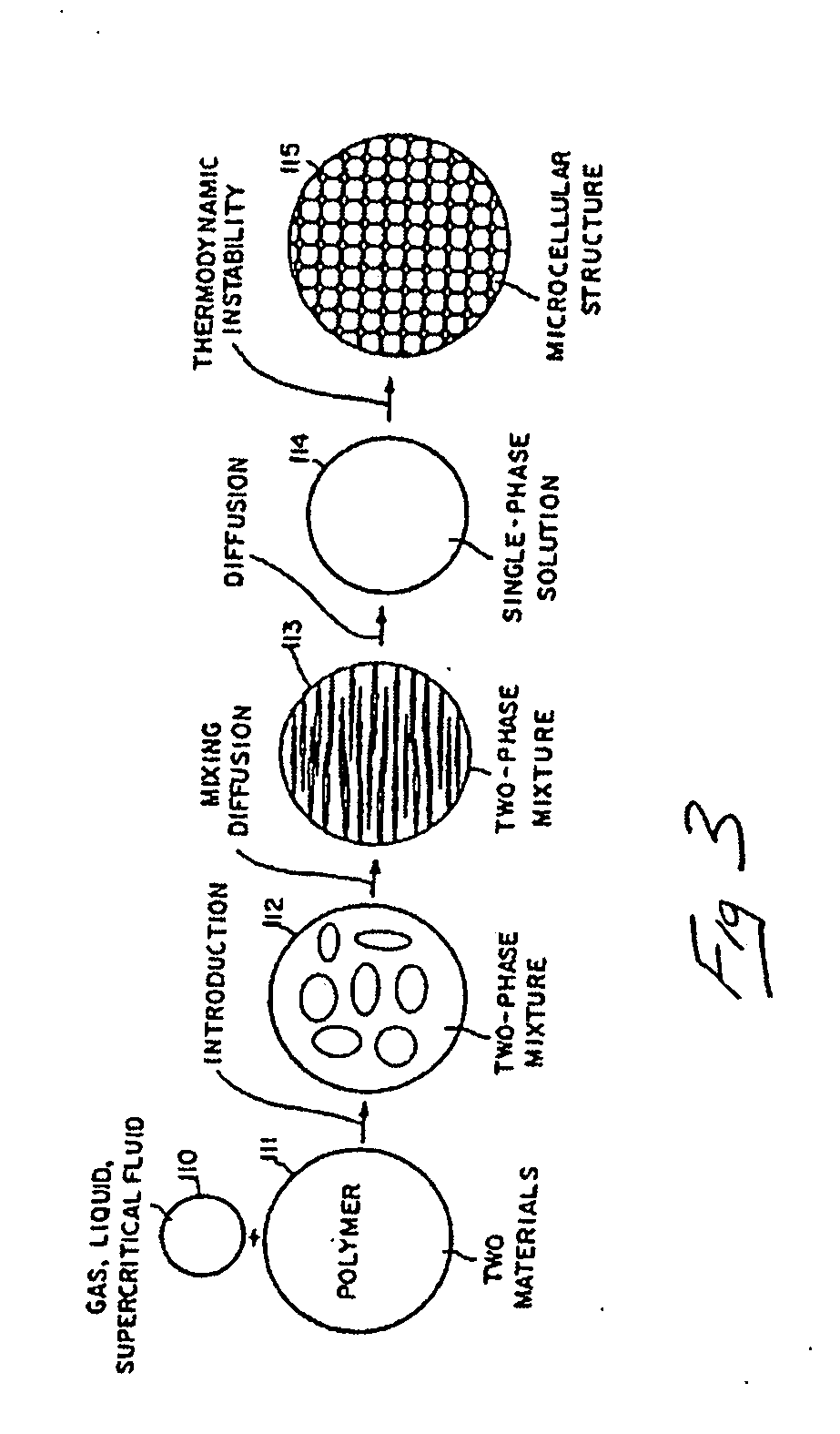

Weather stripping for use in sealing an interface between selected vehicle portions is made using a thermoplastic material such as TPV with a supercritical fluid introduced during the manufacturing process to provide a microcellular structure. The microcellular structure of one example implementation of this invention includes a cell density in a range from about 109 to about 1015 per cubic centimeter. Average cell sizes preferably are less than 2 microns. A preferred range in one example is between about 0.1 micron and about 1.0 micron. The inventive design provides superior performance with cost savings compared to rubber weather stripping.

Owner:JYAWOOK SAM M +1

Filtering devices

The invention provides a low-resistance gas adsorption filter provided with an activated carbon bed of bulk density less than 0.6 gram / cubic centimeter, the activated carbon bed being free of chromium 6+ salt, the filter being characterized by a gas holding capacity exceeding 300,000 milligram Dimethyl-methyl Phosphonate (DMMP)×minute / cubic meter and an airflow resistance such that the numerical value of air flow resistance in Pascal per millimeter of bed thickness does not exceed by more than 50% the numerical value of air velocity in centimeters per second.

Owner:BETH EL ZIKHRON YAAQOV

Thermoplastic vehicle weather stripping

InactiveUS20080034666A1Light weightReduce wind noiseLaminationLamination apparatusVolumetric Mass DensityEngineering

Weather stripping for use in sealing an interface between selected vehicle portions is made using a thermoplastic material such as TPV with a supercritical fluid introduced during the manufacturing process to provide a microcellular structure. The microcellular structure of one example implementation of this invention includes a cell density in a range from about 109 to about 1015 per cubic centimeter. Average cell sizes preferably are less than 2 microns. A preferred range in one example is between about 0.1 micron and about 1.0 micron. The inventive design provides superior performance with cost savings compared to rubber weather stripping.

Owner:JYAWOOK SAM M +1

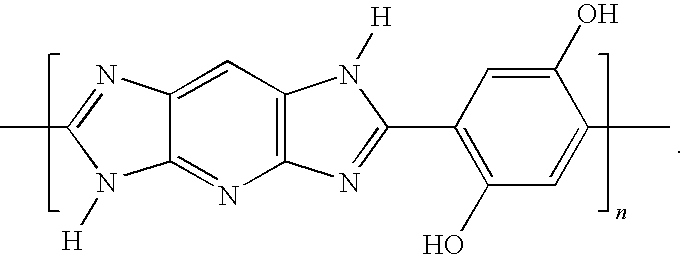

Matrix Free Non-Woven Layer of Polypyridazle Short Fiber

Provided are non-woven constructions and fabrics comprising polypyridazole short fiber; said short fiber characterized by an average filament tenacity of at least 15 grams per denier (gpd); an average filament modulus of at least 500 gpd; an average filament density of at least 1.6 g / cc; an average filament length of 30 to 100 mm; and an average filament denier per filament (dpf) of 0.1 to 10; wherein the construction is substantially free of matrix.

Owner:EI DU PONT DE NEMOURS & CO

Application of high-purity polysilicon rod as feed rod to monocrystalline silicon zone melting method and preparation method thereof

InactiveCN101717990AReduce consumptionExpand sourcePolycrystalline material growthBy zone-melting liquidsZone meltingDensity difference

The invention relates to application of a high-purity polysilicon rod as a feed rod in a monocrystalline silicon zone melting method and a preparation method thereof. The high-purity silicon rod is pressed into a silicon rod with the diameter of 20-300mm by silicon powder with the purity of 99.9999-99.9999999999 percent through an isostatic pressing method, and the particle diameter of a silicon powder raw material adopted by the raw material silicon rod is between 0.1 microns and 100 microns; the density of the raw material silicon rod is 1.60-2.29g / cubic centimeter, the compression resistant parameter of the raw material silicon rod is between 0.1MPa and 50MPa, and the purity of the raw material silicon rod is between 99.999 percent and 99.9999999999 percent; the raw material silicon rod has even density which is expressed in 0-18 percent of density difference amplitude of any two points on any section of the silicon block; and the high-purity polysilicon rod has favorable compression resistance and can be directly used as the feed rod of the monocrystalline silicon of the zone melting method.

Owner:JIANGXI SAI WEI LDK SOLAR HI TECH CO LTD

Coatings, composition and method related to non-spalling low density hardface coatings

ActiveUS20140134452A1Efficient solutionSuitable for useMolten spray coatingVacuum evaporation coatingHardnessLow density

A heterogeneous composite body that is spall resistant and comprises a substantially discontinuous cermet phase in a substantially continuous metal rich matrix phase. The heterogeneous composite body is typically bonded to a substrate to form a hardfacing on the substrate. The heterogeneous composite body exhibits ductile phase toughening with a strain to failure of at least about 2 percent, a modulus of elasticity of less than about 35 million pounds per square inch, and a density of less than about 7 grams per cubic centimeter. The metal rich matrix phase between the ceramic rich regions in the heterogeneous composite body has an average minimum span of about 0.5 to 8 microns to allow ductility in the heterogeneous composite body. The heterogeneous composite body has a Vicker's hardness number of greater than approximately 500. The ceramic rich regions exhibit high hardness as compared with the matrix phase.

Owner:HYBRID MATERIALS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com