Equipment for small scale booster test

A test device and small-scale test technology, used in measuring devices, machine/structural parts testing, instruments, etc., can solve the problems of small volume of gas detection chamber, energy transfer to the external environment, and explosion, etc., and reach perfect national standards Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

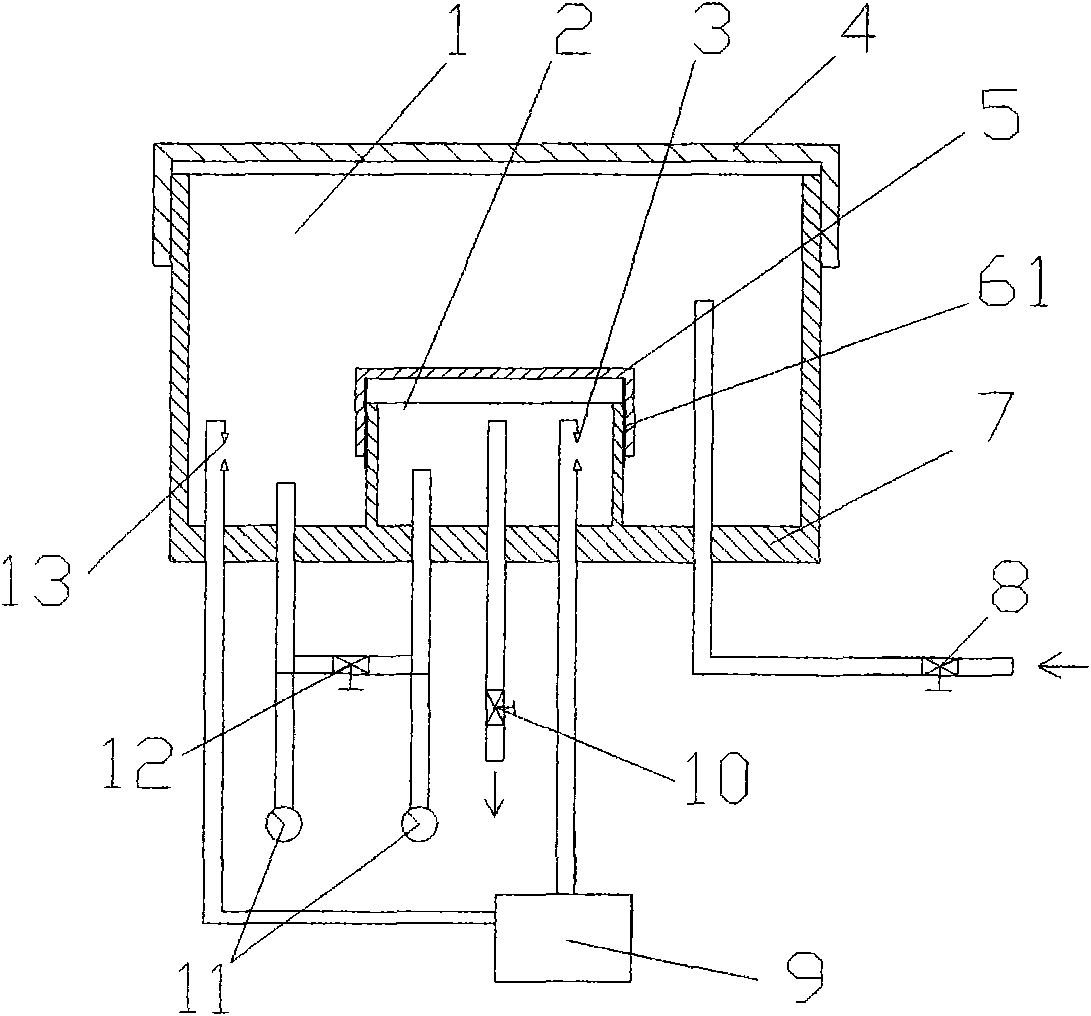

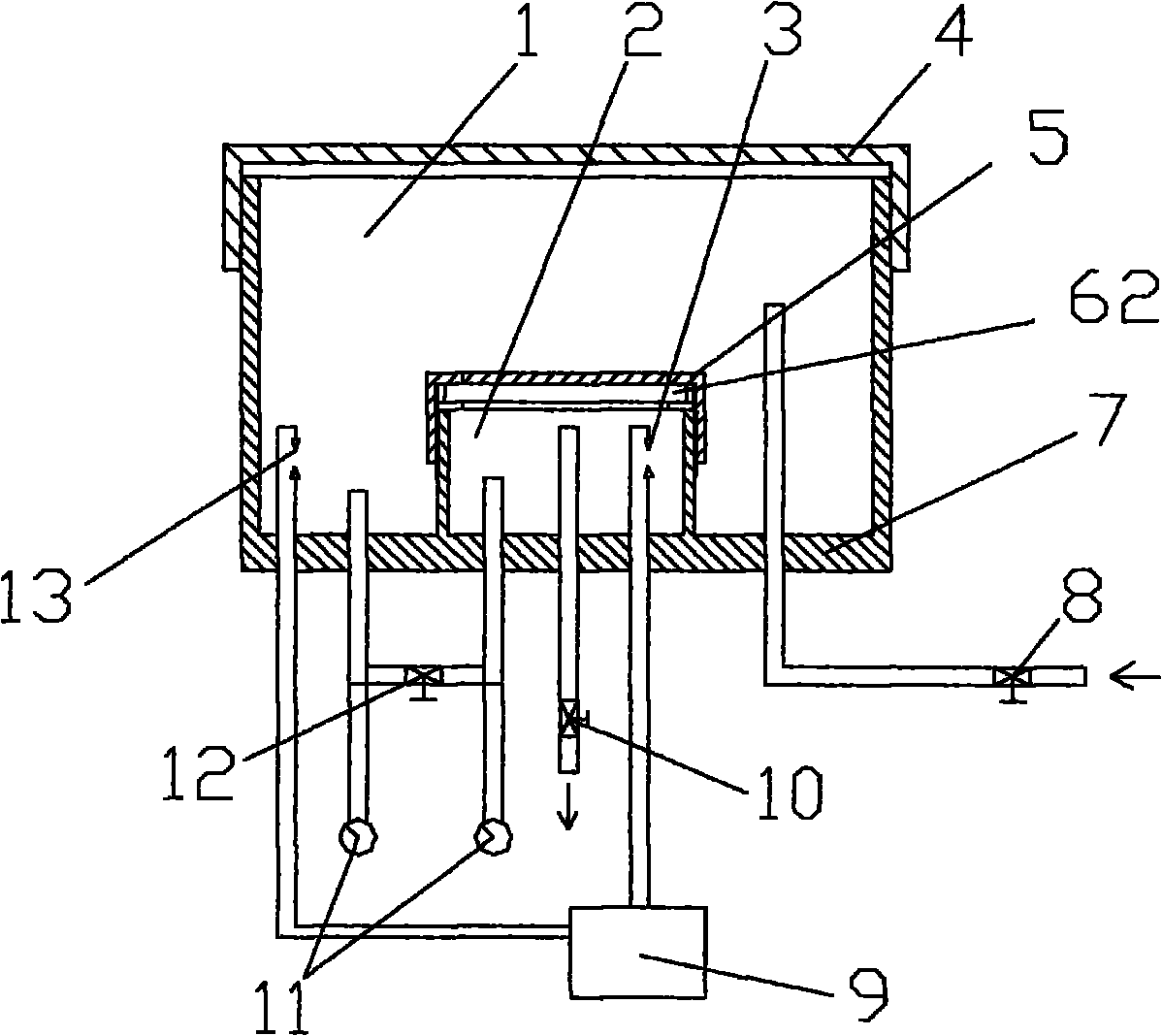

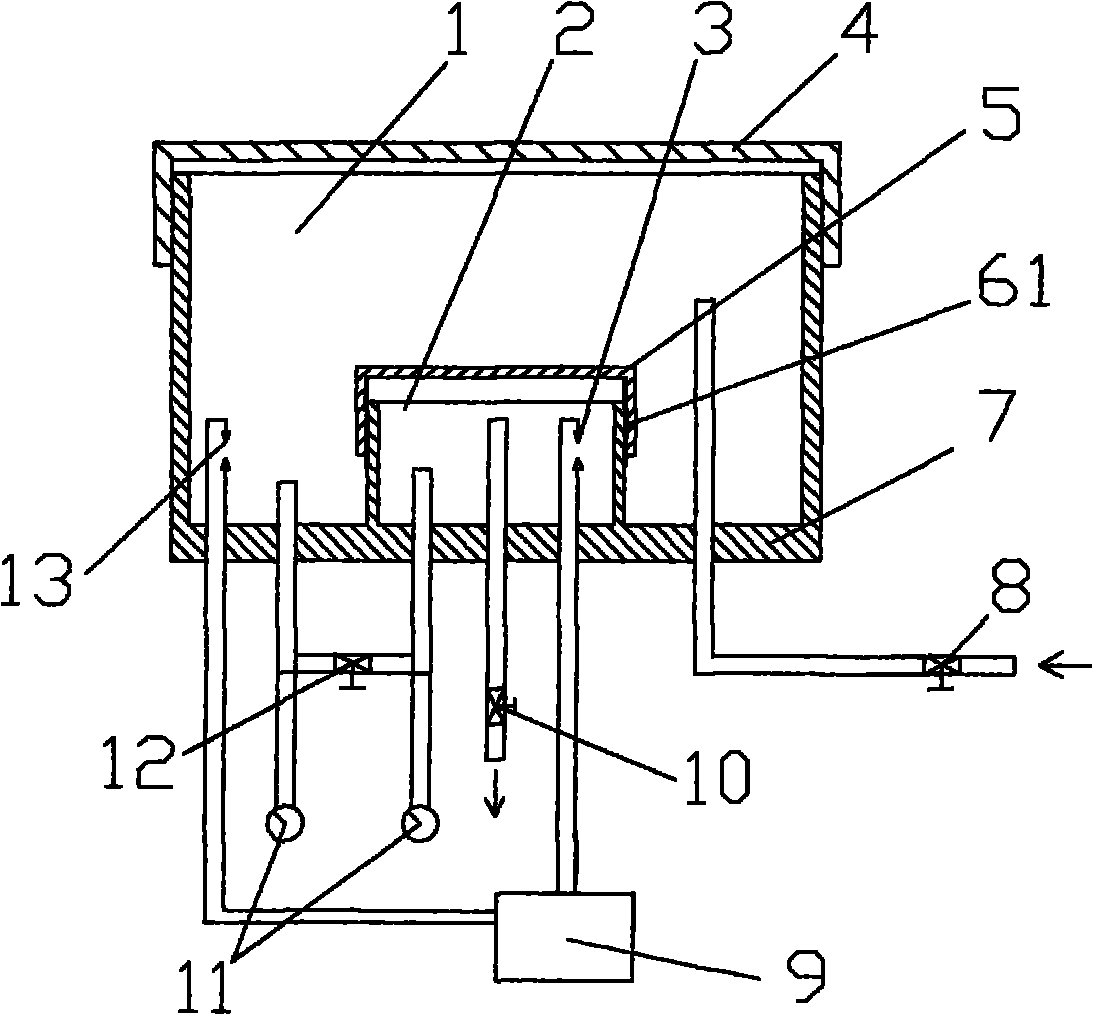

[0013] Please refer below figure 1 and figure 2 As shown, the small-scale explosion transmission test device of the present invention is used for testing explosion-proof parameters, and the small-scale test explosion transmission device includes an independent inner test chamber 2 set in a metal outer test chamber 1, and the metal outer test chamber 1 It shares a base 7 with the independent inner test chamber 2 and communicates with the outside through a shut-off valve 12. The upper cover of the inner test chamber 2 is threaded and placed in the outer test chamber 1. Between the inner and outer test chambers 1 Use metal sintered breathing apparatus connection, in this example, the metal shell is stainless steel, in order to prevent the metal shell from rusting and affect the test results.

[0014] The metal outer test chamber 1 and the independent inner test chamber 2 are fed with an explosive gas mixture at the same time and when the inner test chamber 2 is ignited, the exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com