Multifunctional physical simulation test system for coal engineering and coal model test method

A simulation test system, multi-functional physics technology, applied in the analysis of suspensions and porous materials, the use of stable tension/pressure to test the strength of materials, instruments, etc. Complex engineering problems, etc., to achieve the effect of large model size, comprehensive functions, and high loading tonnage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

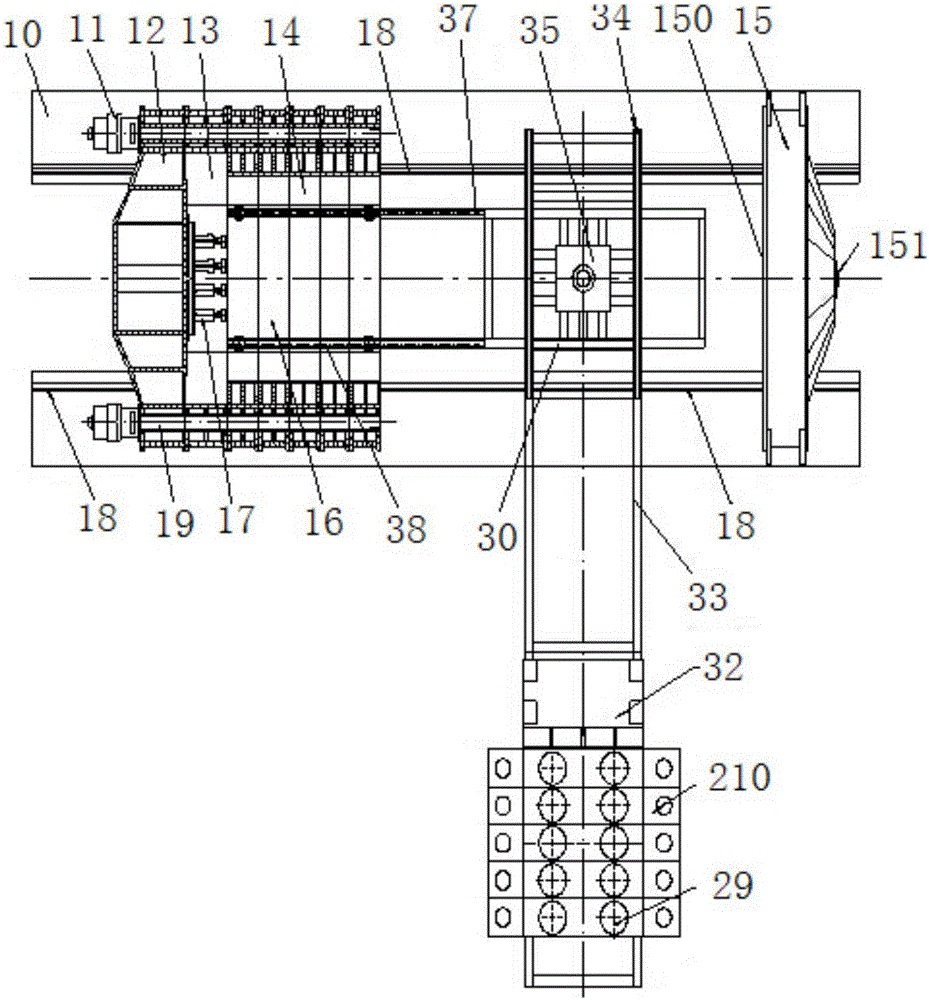

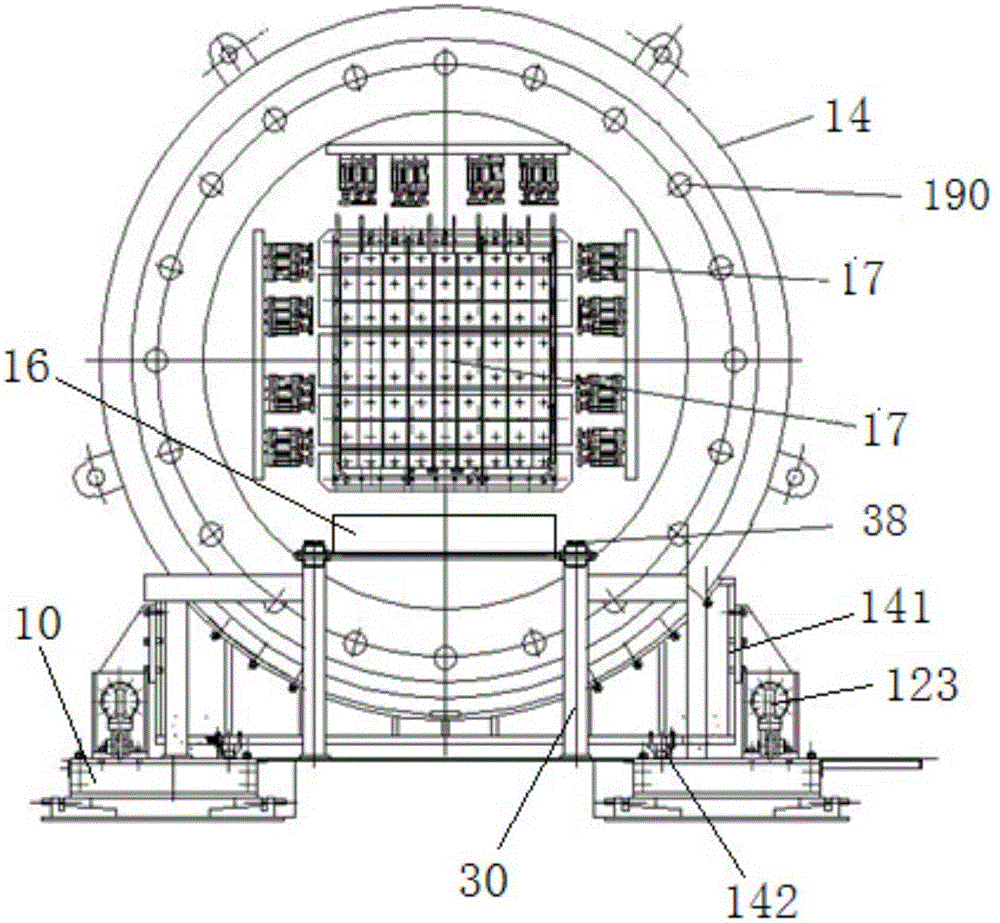

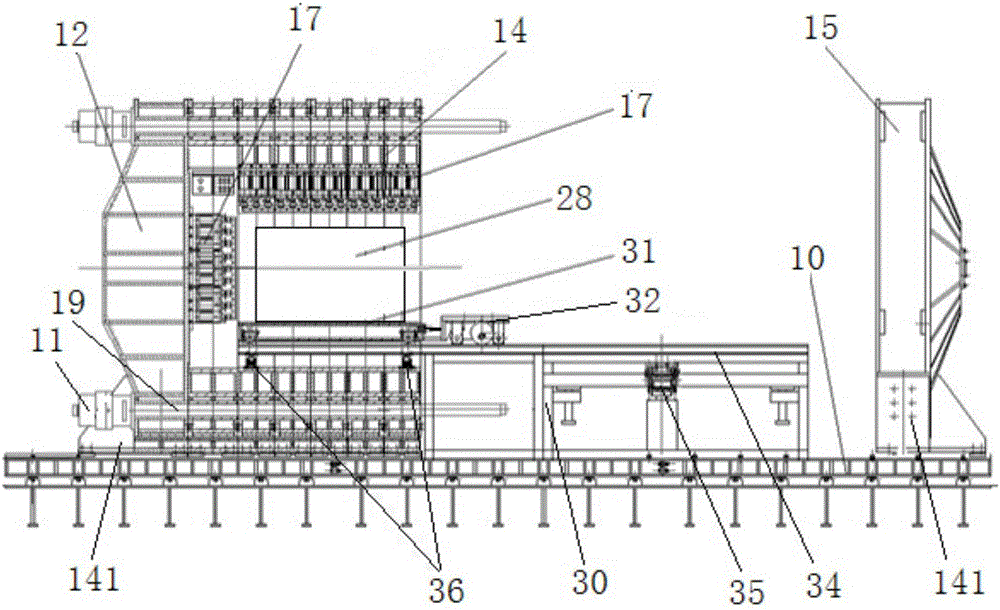

[0041] A multi-functional physical simulation test system for coal and rock engineering. After the model forming subsystem completes the model, it is transported to the test chamber by the rail conveying subsystem. The hydraulic multi-dimensional stress loading component is installed in the test cavity, and the multi-dimensional stress loading component is connected. Servo oil source, the servo oil source is controlled by the hydraulic loading control subsystem, and then controls the stress exerted on the model by the multi-dimensional stress loading component. Connected with the test chamber is also a gas pumping and injection subsystem, which is used to regulate the air pressure in the chamber to truly simulate the working conditions of coal and rock engineering under gas such as gas. The stress change of the model in the test chamber, the air pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com