Preparation method of Sn-Cu-Al series lead-free solder

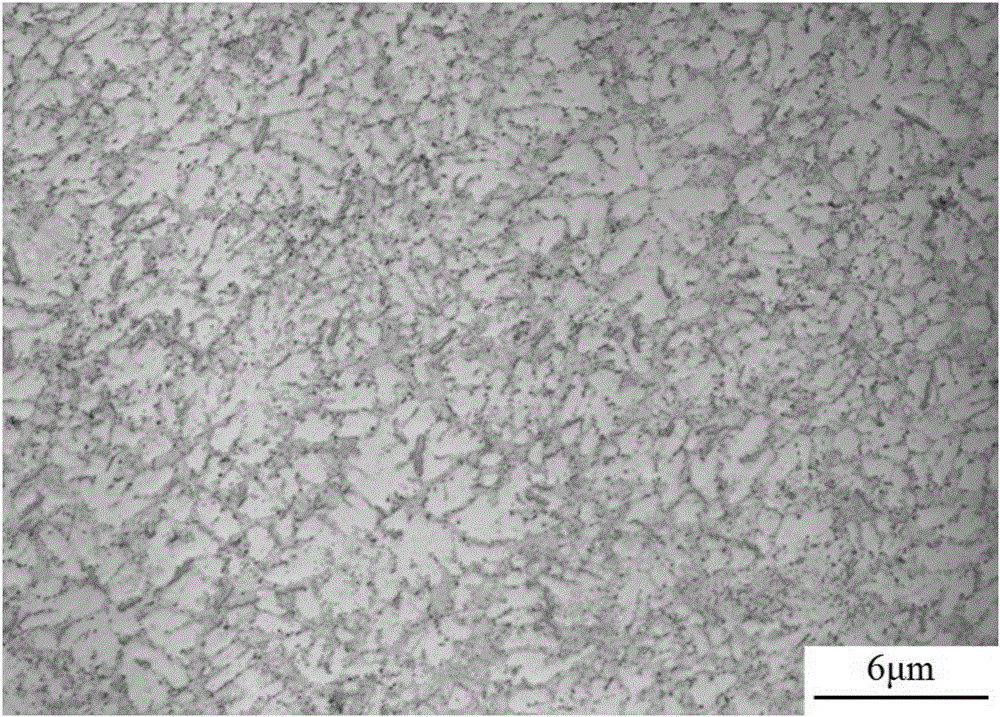

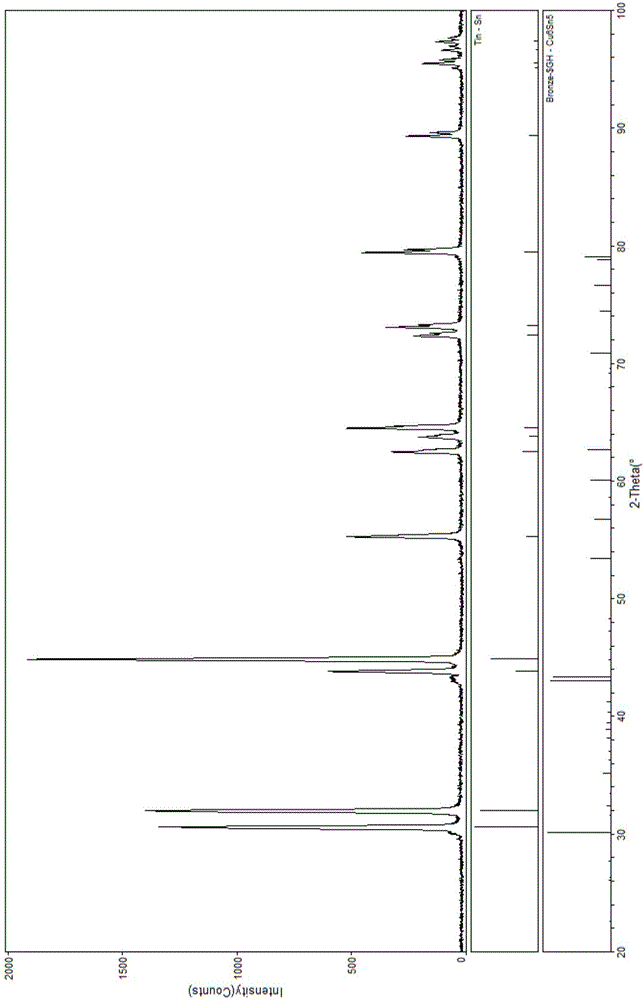

A lead-free solder, sn-cu-al technology, applied in the direction of welding equipment, welding/cutting medium/material, welding medium, etc., can solve the problem of insufficient uniformity of the alloy structure, and achieve the effect of promoting the refinement and solid solution of the structure Ideal for homogenization and improvement of microhardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. Raw material formula

[0029] The raw material components and weight percentages are: copper 0.70%, aluminum 0.075%, and the balance is tin. Tin, copper and aluminum raw materials are all 200-mesh metal powder with a purity higher than 99.9%.

[0030] 2. Preparation method

[0031] (1) Raw materials are weighed. According to the weight percentage of each raw material component, tin powder, copper powder, and aluminum powder are respectively weighed and put into a ball mill jar. The weight accuracy of each powder is controlled within ±0.00005g.

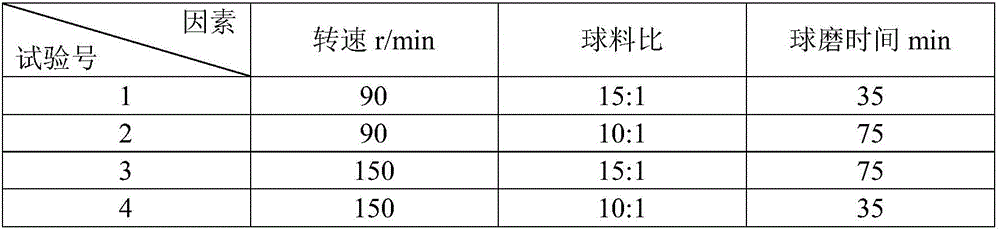

[0032] (2) Ball milling mixture, according to the ratio of balls and materials listed in Table 1-1, put stainless steel balls with diameters of 4mm and 6mm into the ball milling tank with the raw materials at a mass ratio of 1:1.3; then pump the ball milling tank Vacuum, the vacuum degree is controlled at 5-10 Pa; then fill with argon, put the ball mill jar into the planetary ball mill, the ball mill operating parameters ar...

Embodiment 2

[0045] 1. Raw material formula: raw material components and weight percentages are: copper 0.70%, aluminum 0.075%, and the balance is tin. Tin, copper and aluminum raw materials are all 200-mesh metal powder with a purity higher than 99.9%.

[0046] 2. Preparation method

[0047] (1) Raw materials are weighed. According to the weight percentage of each raw material component, tin powder, copper powder, and aluminum powder are respectively weighed and put into a ball mill jar. The weight accuracy of each powder is controlled within ±0.00005g.

[0048] (2) Ball mill mixing, according to the ball-to-material ratio of 10:1, put stainless steel balls of two specifications with a diameter of 4mm and 6mm into the ball mill tank with the raw materials at a mass ratio of 1:1.3; then vacuumize the ball mill tank, vacuum The temperature is controlled at 5-10 Pa; then filled with argon, and put into a planetary ball mill. The operating parameters of the ball mill are 5 minutes of alterna...

Embodiment 3

[0056] 1. Raw material formula: raw material components and weight percentages are: copper 0.62%, aluminum 0.055%, and the balance is tin. Tin, copper and aluminum raw materials are all 200-mesh metal powder with a purity higher than 99.9%.

[0057] 2. Preparation method

[0058] (1) Raw materials are weighed. According to the weight percentage of each raw material component, tin powder, copper powder, and aluminum powder are respectively weighed and put into a ball mill jar. The weight accuracy of each powder is controlled within ±0.00005g.

[0059] (2) Ball mill mixing, according to the ball-to-material ratio of 12:1, put stainless steel balls with a diameter of 4mm and 6mm in a mass ratio of 1:1 into the ball mill tank filled with raw materials; then vacuumize the ball mill tank, vacuum The temperature is controlled at 5-10 Pa; then filled with argon, and put into the planetary ball mill. The operating parameters of the ball mill are 8 minutes of alternate operation time, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com