Sn-Ag-Cu-Zn-Ge lead-free solder for inhibiting solid-state interface reaction and preparation method thereof

An interface reaction, lead-free solder technology, used in manufacturing tools, welding equipment, metal processing equipment, etc., can solve problems affecting interface reliability, substrate dissolution, etc., to achieve inhibition of solid-state reaction, reduction of corrosion, and good wetting. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

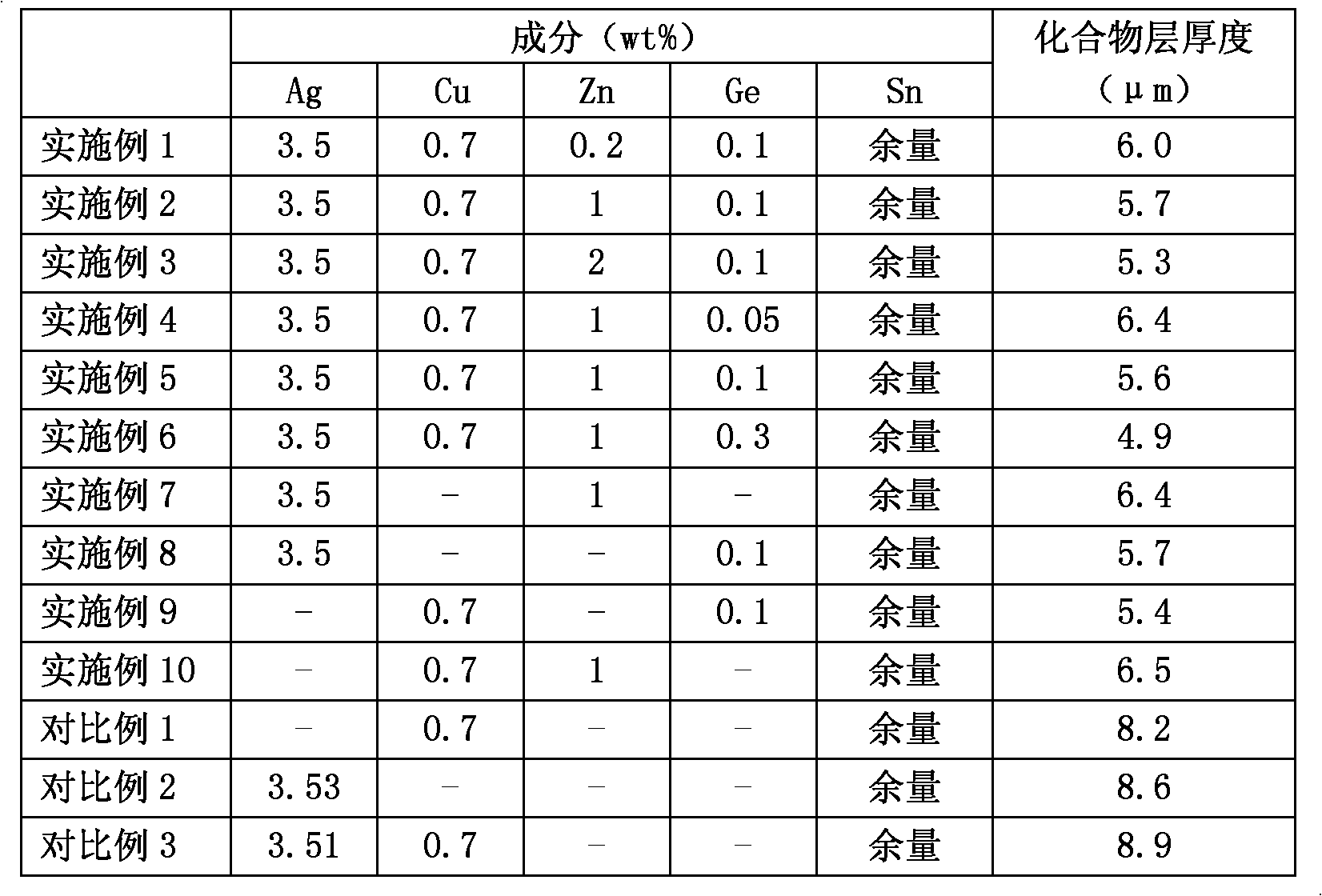

[0023] The components and mass percentages in this embodiment are: Ag 3.5%, Cu 0.7%, Zn 0.2%, Ge 0.1%, Sn balance. First, put the Sn particles into the KCl+LiCl eutectic protective salt melt at 400°C, and raise the temperature to 600°C, add high-purity Ag wire and Cu wire, keep warm for 2-4 hours, and stir well to obtain a uniform Sn- TM solution; then, add a small amount of Zn foil and Ge particles to the alloy solution, keep warm for 2 hours, and stir well. After that, the temperature was lowered to 300°C and poured into stainless steel molds.

[0024] 100 mg of the smelted solder was prepared into a Sn-Ag-Cu-0.2Zn-0.1Ge / Cu brazing joint, and an aging test was carried out. The microstructural evolution of the interface was observed by scanning electron microscopy, and the thickness of the compound layer at the reaction interface was analyzed. The thickness of the compound layer is shown in Table 1.

Embodiment 2

[0026] The components and mass percentages in this embodiment are: Ag 3.5%, Cu 0.7%, Zn 1%, Ge 0.1%, Sn balance. First, put the Sn particles into the KCl+LiCl eutectic protective salt melt at 400°C, and raise the temperature to 600°C, add high-purity Ag wire and Cu wire, keep warm for 2-4 hours, and stir well to obtain a uniform Sn- TM solution; then, add a small amount of Zn foil and Ge particles to the alloy solution, keep warm for 2 hours, and stir well. After that, the temperature was lowered to 300°C and poured into stainless steel molds.

[0027] 100 mg of the smelted brazing filler metal was prepared into a Sn-Ag-Cu-1.0Zn-0.1Ge / Cu brazing joint, and an aging test was carried out. The microstructural evolution of the interface was observed by scanning electron microscopy, and the thickness of the compound layer at the reaction interface was analyzed. The thickness of the compound layer is shown in Table 1.

Embodiment 3

[0029] The components and mass percentages in this embodiment are: Ag 3.5%, Cu 0.7%, Zn 2%, Ge 0.1%, Sn balance. First, put the Sn particles into the KCl+LiCl eutectic protective salt melt at 400°C, and raise the temperature to 600°C, add high-purity Ag wire and Cu wire, keep warm for 2-4 hours, and stir well to obtain a uniform Sn- TM solution; then, add a small amount of Zn foil and Ge particles to the alloy solution, keep warm for 2 hours, and stir well. After that, the temperature was lowered to 300°C and poured into stainless steel molds.

[0030] 100 mg of the smelted brazing filler metal was prepared into a Sn-Ag-Cu-2.0Zn-0.1Ge / Cu brazing joint, and an aging test was carried out. The microstructural evolution of the interface was observed by scanning electron microscopy, and the thickness of the compound layer at the reaction interface was analyzed. The thickness of the compound layer is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com