Method for preparing WC/W composite powder through in-situ reaction

A composite powder and in-situ reaction technology, which is applied in the field of in-situ reaction to prepare WC/W composite powder, can solve problems such as agglomeration and affect the properties of tungsten-based alloys, and achieve the effect of improving high temperature performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

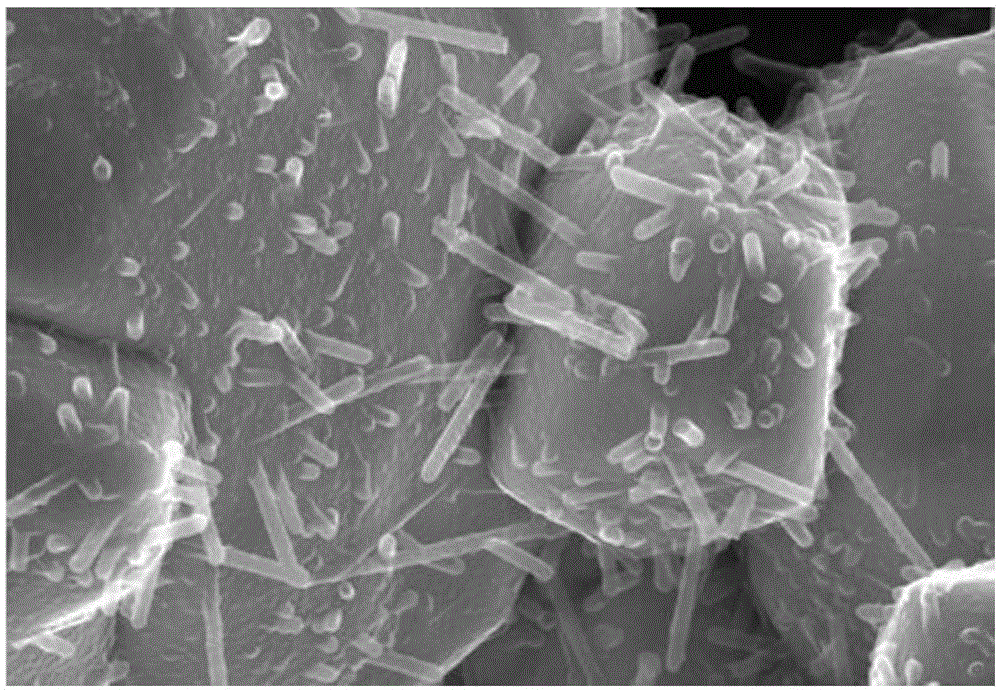

Image

Examples

Embodiment 1

[0025] Step 1, W powder surface pre-plant defect treatment:

[0026] A 40% HF solution and NH 4 Add 40mlHF and 2gNH to F particles according to 1L distilled water 4 Mix the proportion of F to obtain the pickling solution; add 10gW powder to the prepared pickling solution according to the specific gravity of 1L pickling solution, add W powder to the pickling solution, ultrasonically shake for 30min at room temperature, and use deionized water Wash the powder 3 times, and dry it in a vacuum oven at 100°C for 2 hours to obtain W powder with pre-planted defects on the surface;

[0027] Step 2, prepare WC / W composite powder:

[0028] Spread the W powder with pre-planted defects on the surface obtained in step 1 in a corundum crucible, place the crucible horizontally in the middle of the heating body of the tube furnace, and then under the protection of an Ar atmosphere with a flow rate of 1L / min, heat at 10°C / min. The heating rate of min reaches 1000°C, acetone is carried by arg...

Embodiment 2

[0030] Step 1, W powder surface pre-plant defect treatment:

[0031] A 40% HF solution and NH 4 Add 60mlHF and 3gNH to F particles according to 1L distilled water 4 Mix the proportion of F to obtain the pickling solution; add 10gW powder to the prepared pickling solution according to the specific gravity of 1L pickling solution, add W powder to the pickling solution, ultrasonically shake for 45min at room temperature, and use deionized water Wash the powder 5 times, and dry it in a vacuum oven at 80°C for 8 hours to obtain W powder with pre-planted defects on the surface;

[0032] Step 2, prepare WC / W composite powder:

[0033] Spread the W powder with pre-planted defects on the surface obtained in step 1 in a corundum crucible, place the crucible horizontally in the middle of the heating body of the tube furnace, and then under the protection of an Ar atmosphere with a flow rate of 1L / min, heat at 10°C / min. The heating rate of min reaches 800°C, and acetone is carried by a...

Embodiment 3

[0035] Step 1, W powder surface pre-plant defect treatment:

[0036] A 40% HF solution and NH 4 Add 80mlHF and 3gNH to F particles according to 1L distilled water 4 Mix the proportion of F to obtain the pickling solution; add 10gW powder to the prepared pickling solution according to the specific gravity of 1L pickling solution, add W powder to the pickling solution, ultrasonically shake for 60min at room temperature, and use deionized water Wash the powder 4 times and dry it in a vacuum oven at 50°C for 4 hours to obtain W powder with surface pre-planted defects;

[0037] Step 2, prepare WC / W composite powder:

[0038] Spread the W powder with pre-planted defects on the surface obtained in step 1 in a corundum crucible, place the crucible horizontally in the middle of the heating body of the tube furnace, and then under the protection of an Ar atmosphere with a flow rate of 1L / min, heat at 10°C / min. The heating rate of min reaches 600°C, and acetone is carried by argon to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com