Preparation method of graphene alloy nanocomposite and SLM (Selective Laser Melting) forming process

A technology of nanocomposite materials and olefin alloys, which is applied in the fields of metal matrix nanocomposites and metal additive manufacturing, can solve the problems of deteriorating material performance and difficult matching of reinforcements, so as to improve strength and toughness, change microstructure, Effect of Reducing Hot Cracking Tendency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A preparation method of graphene alloy nano composite material, comprising the following steps:

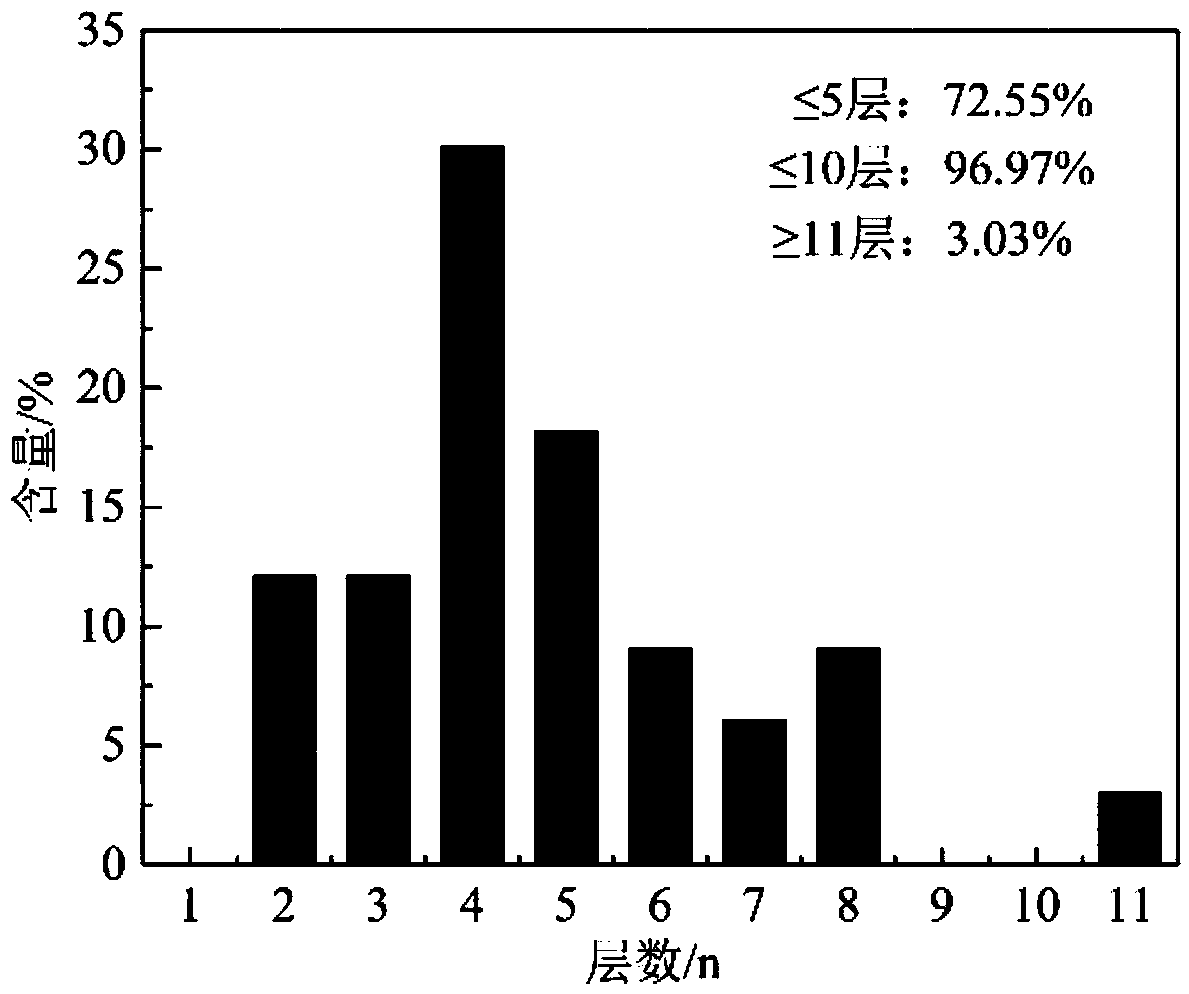

[0037] a. Take graphene powder, graphene powder particle size ≤ 2 μm, graphene is few-layer graphene, and the mass of few-layer graphene with layer number ≤ 5 in the obtained graphene nano-powder is not less than 70% of the total graphene powder mass , the mass of few-layer graphene with the number of layers ≥ 11 is not more than 5% of the mass of the total graphene powder;

[0038] b. Mix the graphene powder and absolute ethanol at a volume ratio of 1: (200-2000) to obtain a graphene-absolute ethanol suspension, place the graphene powder in absolute ethanol, and ultrasonically vibrate for not less than 2 hours. Through sufficient vibration dispersion, it is configured into a graphene-absolute ethanol suspension;

[0039] c, mixing the obtained graphene-dehydrated ethanol suspension with the superalloy powder to obtain a mixture A, so that the graphene content in the graph...

Embodiment 1

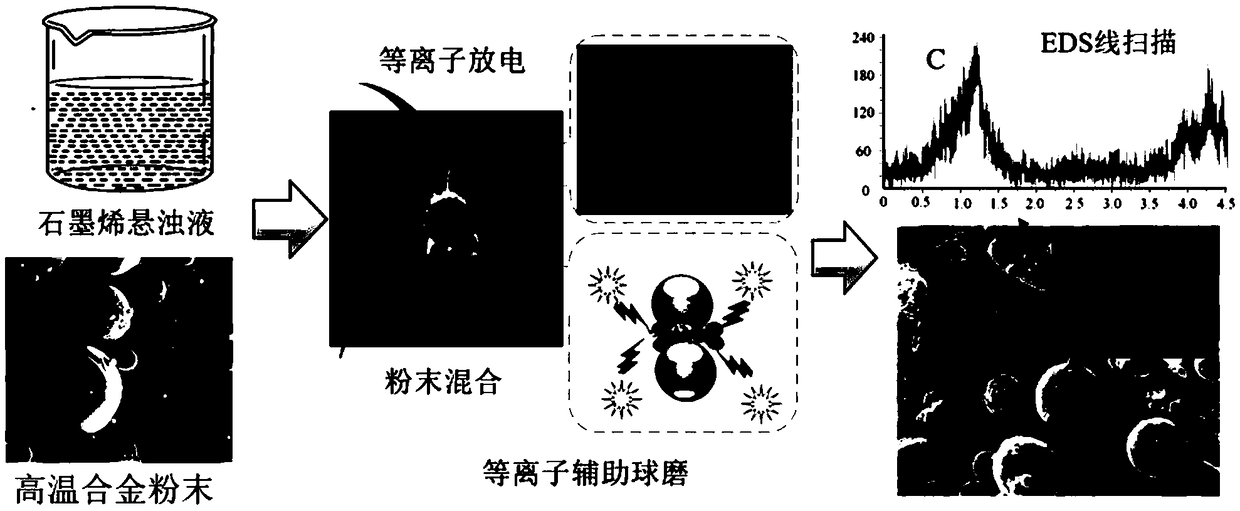

[0047] (1) Use K418 nickel-based superalloy material as the matrix and 0.1g graphene as the nanocomposite reinforcement to prepare graphene-enhanced K418 nanocomposite material (GNPs / K418), and the original K418 powder is normally distributed with a particle size of 15-53μm spherical powder, such as Figure 5 As shown, the graphene powder presents a lamellar shape, the proportion of graphene layers ≤ 5 is 72.55%, the proportion of graphene layers ≥ 11 is 3.03%, and the average particle size is 1 μm, such as figure 2 shown;

[0048] (2) 0.1g graphene powder is added in dehydrated alcohol, is configured into graphene powder mass fraction and is 0.1% suspension liquid, and ultrasonic vibration 2h is mixed in dehydrated alcohol until graphene powder; Will be by 0.1 The suspension mixed with 1 g graphene powder and absolute ethanol is poured into 100 g of K418 alloy powder, and the composite alloy powder is placed in a ball mill for wet milling for 4 hours by mechanical alloying,...

Embodiment 2

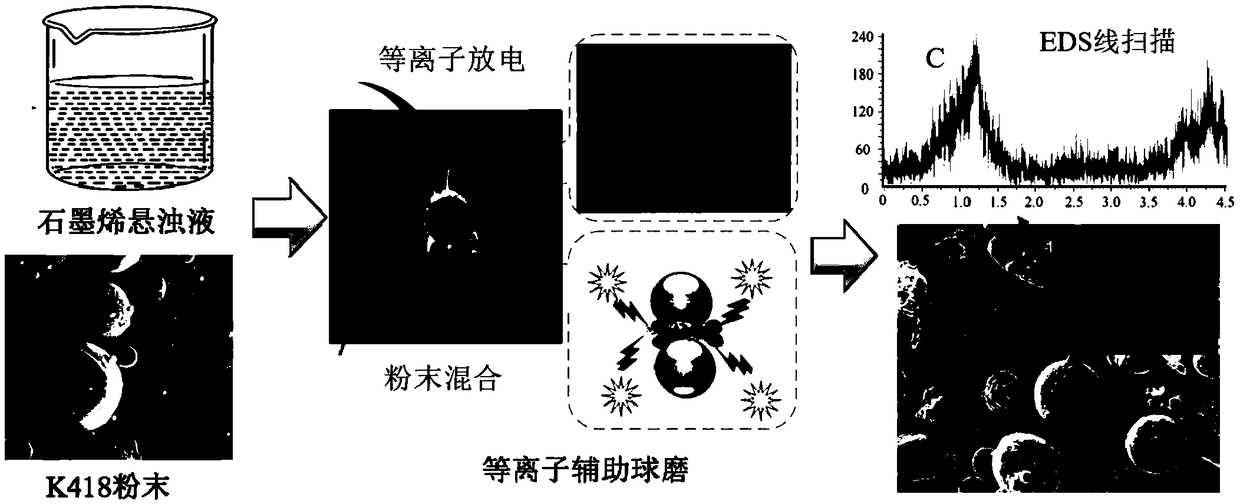

[0053] (1) With 100g K418 nickel-based superalloy material as matrix, 1g graphene as nanocomposite reinforcement, prepare graphene reinforced K418 nanocomposite material (GNPs / K418);

[0054] (2) Add 1g of graphene powder into dehydrated ethanol, configure graphene powder mass fraction as 0.1% suspension, ultrasonically vibrate for 2.5h until graphene powder is mixed evenly into dehydrated ethanol; The suspension mixed with graphene powder and absolute ethanol was poured into 100g of K418 alloy powder, and the composite alloy powder was placed in a ball mill for wet grinding for 6 hours by mechanical alloying method, the ball-to-material ratio was set to 15:1, and the rotational speed was Set as 240rpm, add Ar gas during the whole process to obtain mixed slurry A;

[0055] (3) Take out the protection of absolute ethanol in the mixed slurry A: after standing for 38 hours, dry the mixed powder for 24 hours under vacuum at 105°C, with a vacuum degree of 1×10 -2 Pa; carry out pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com