Silicate framework-containing silicon-based negative electrode material, negative plate and lithium battery

A silicon-based negative electrode material, silicate technology, applied in the direction of negative electrodes, battery electrodes, circuits, etc., can solve the problems of poor cycle performance of silicon-based negative electrodes, achieve the effect of improving cycle performance and reducing deformation stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

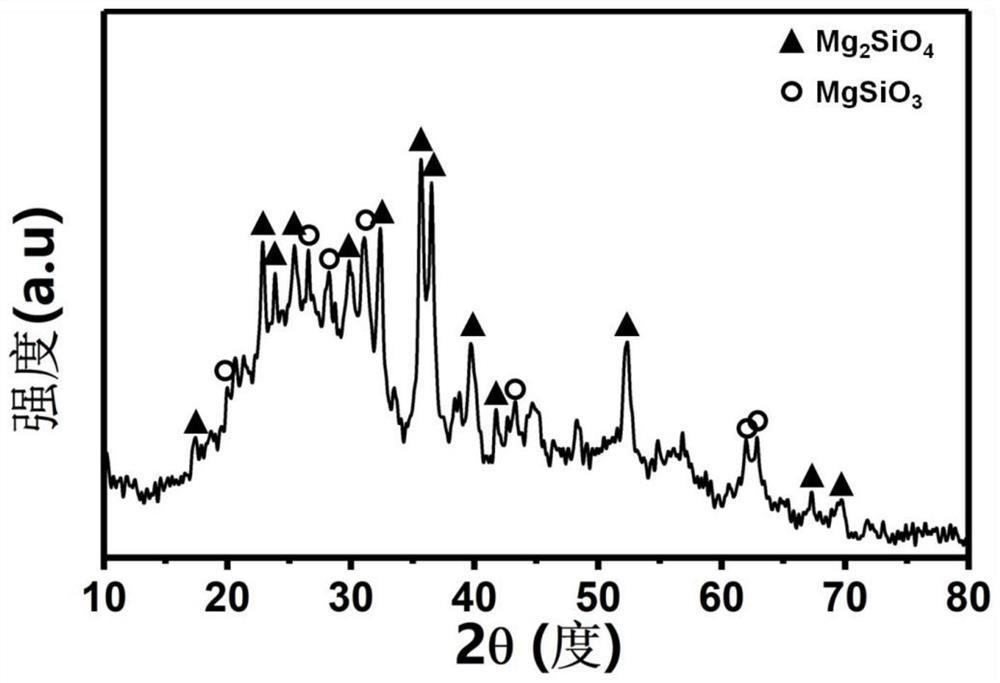

[0059] (1) Mix silicon oxide powder, magnesium metasilicate powder, and magnesium silicate powder evenly according to the mass ratio of 3:0.3:0.7, and place them in a vacuum furnace;

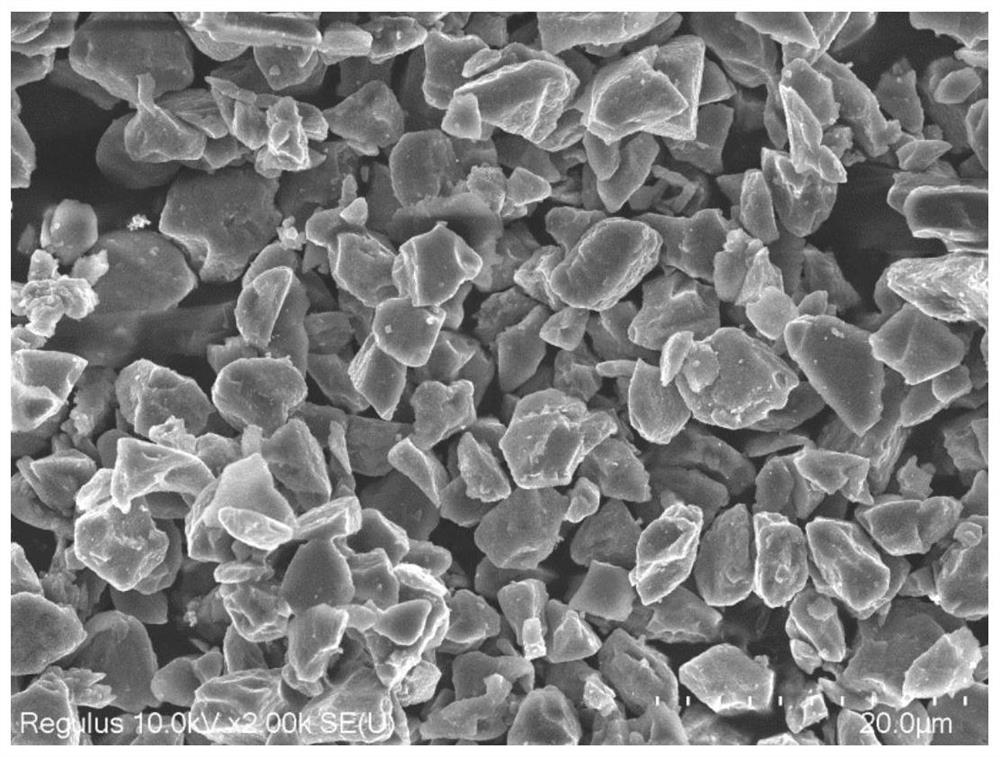

[0060] (2) At 1400°C, the mixture was heat-treated for 2 hours under vacuum, and after cooling, it was crushed and sieved;

[0061] (3) Mix the sieved sample with petroleum asphalt at a mass ratio of 20:1, place it in a high-temperature furnace, and heat-treat it at 900°C for 2 hours in a nitrogen atmosphere to obtain a silicon base containing magnesium metasilicate and a magnesium silicate skeleton. negative electrode.

[0062] In the solid-solid mixture used in the present invention, the silicate first adheres to the surface of the silicon oxide particles, and then undergoes high-temperature treatment. Driven by its own concentration difference, the silicate can quickly diffuse into the interior of the silicon oxide particles to form a skeleton structure.

[0063] (4) Prepare the negative ele...

Embodiment 2

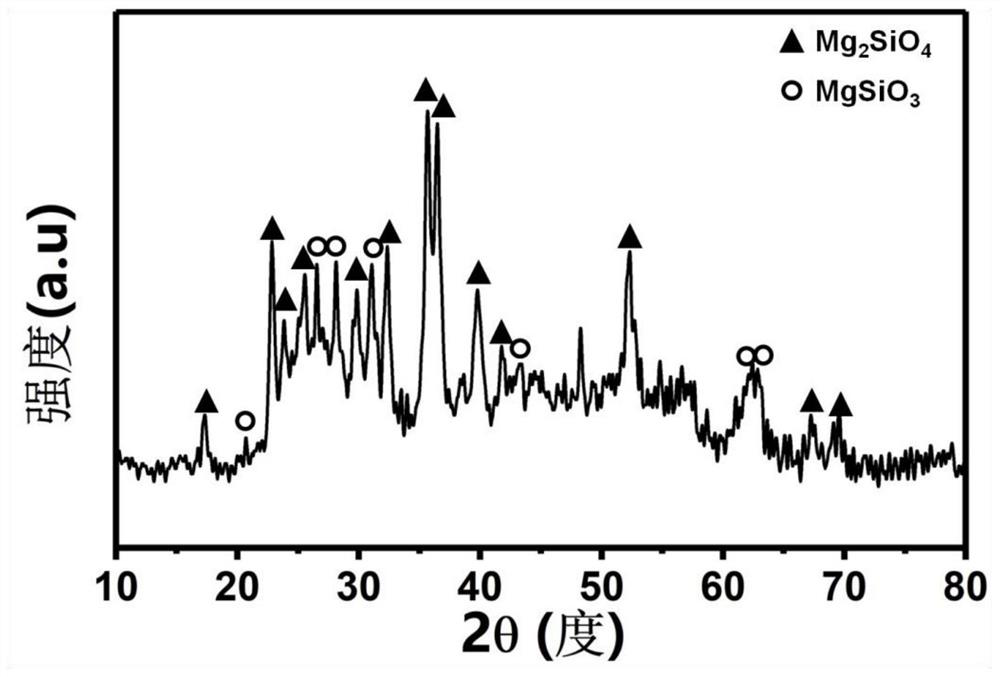

[0067] (1) Mix silicon oxide powder and magnesium metasilicate powder evenly according to a mass ratio of 3:1, and place in a vacuum furnace;

[0068] (2) At 1400°C, the mixture was heat-treated for 2 hours under vacuum, and after cooling, it was crushed and sieved;

[0069] (3) Place the sieved sample in a rotary furnace, pass a mixed gas of argon and methane with a volume ratio of 3:1 at 1000°C, and keep it warm for 2 hours to obtain a silicon base containing a magnesium metasilicate skeleton. negative electrode;

[0070] (4) Prepare the negative electrode slurry with silicon-based negative electrode containing magnesium metasilicate skeleton, carbon black (SP) and sodium carboxymethyl cellulose (CMC) according to the ratio of 7:2:1, after coating and drying The negative pole piece is made, and the positive electrode material lithium cobalt oxide (LCO) is used as the counter electrode, and a button battery is assembled in a glove box, and the charge and discharge test is ca...

Embodiment 3

[0073] (1) Mix silicon oxide powder and nickel silicate powder evenly according to the mass ratio of 3:1, and place them in a vacuum furnace;

[0074] (2) At 1400°C, the mixture was heat-treated for 2 hours under vacuum, and after cooling, it was crushed and sieved;

[0075] (3) Place the sieved sample in a rotary furnace, pass a mixed gas of argon and acetylene with a volume ratio of 2:1 at 950°C, and keep it warm for 2 hours to obtain a silicon-based negative electrode containing a nickel silicate skeleton ;

[0076] (4) Prepare the negative electrode slurry with silicon-based negative electrode containing nickel silicate skeleton, carbon black (SP) and sodium carboxymethyl cellulose (CMC) according to the ratio of 7:2:1, after coating and drying The negative electrode sheet was formed, and the ternary positive electrode material nickel-cobalt lithium manganese oxide NCM 523 was used as the counter electrode, and a button battery was assembled in a glove box, and the charge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com