Preparation method of graphene ceramic material

A technology of ceramic materials and graphene, which is applied in the field of materials, can solve problems such as easy agglomeration and uneven dispersion, and achieve the effects of improved electrical conductivity, obvious growth, and obvious macroscopic mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

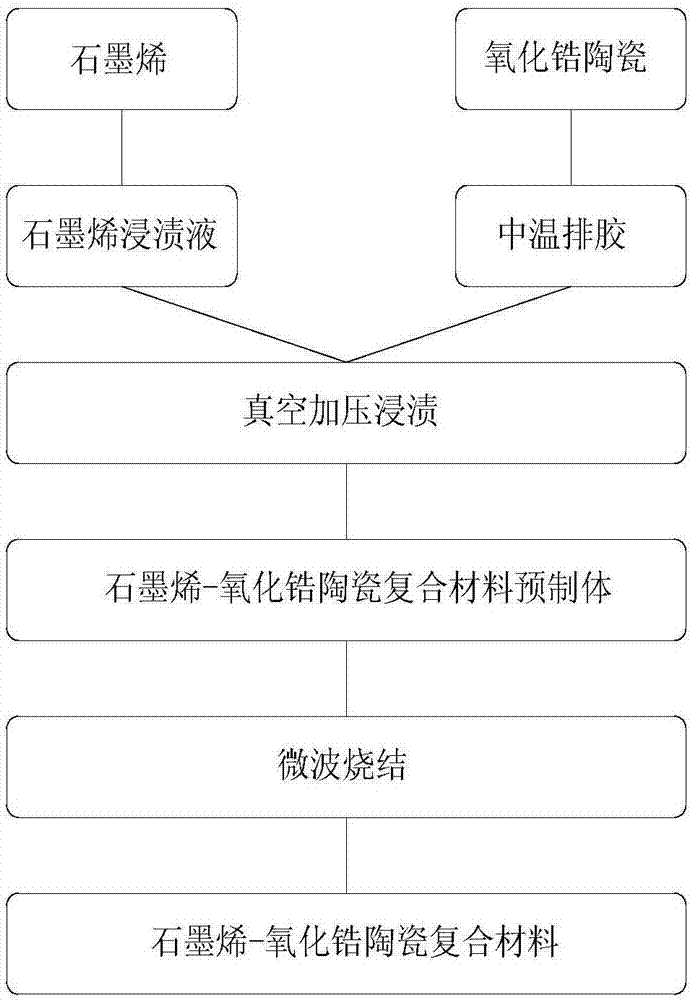

[0021] Such as figure 1 As shown, a method for preparing a graphene ceramic material is characterized in that it includes the following steps: 1) taking graphene to make a graphene impregnation solution; 2) performing debinding treatment on zirconia ceramics; 3) making the Vacuum pressure impregnation of the graphene impregnating solution and the degummed zirconia ceramics obtained in step 2 to obtain a graphene-zirconia ceramic composite preform; 4) microwave sintering of the graphene-zirconia ceramic composite preform, A graphene-zirconia ceramic composite material is obtained.

[0022] The graphene impregnation solution in the step 1 contains 1-10 parts of graphene per 100 parts, 0.5-5 parts of dispersant, and the balance is solvent. The preparation of the impregnation solution includes the following steps: 1) Take graphene, Prepare graphene into powder; 2) Mix graphene powder and dispersant to obtain a mixture; 3) Put the mixed mixture into a ball mill, and use a combinat...

Embodiment 1

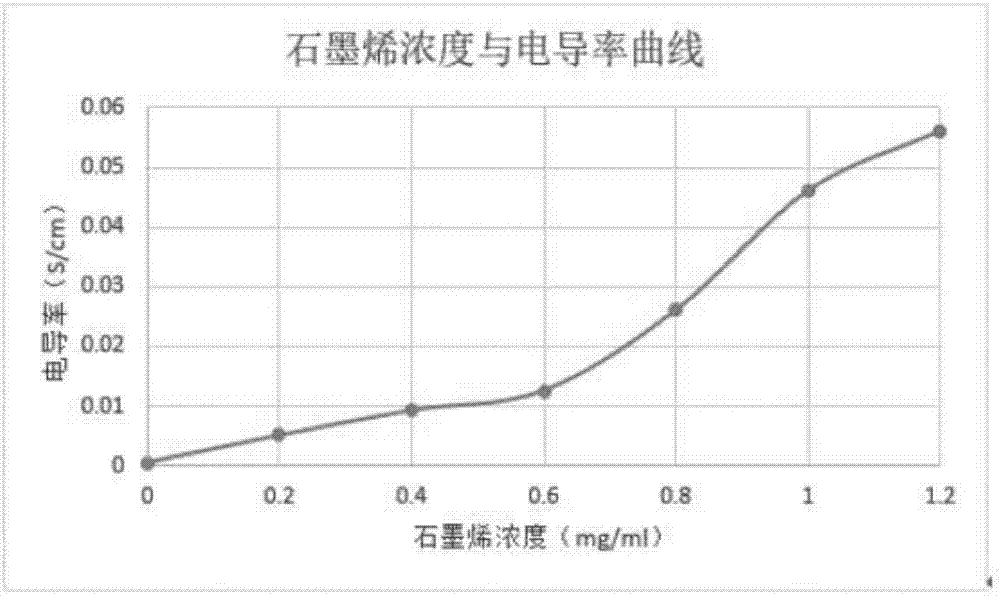

[0030] Such as figure 2 as shown, figure 2 For the electrical conductivity test of graphene zirconia ceramic material of the present invention, from figure 2 It can be seen that the electrical conductivity of the original zirconia is very weak, less than 0.001 S / cm, almost non-conductive, in line with the characteristics of pure ceramic materials, but after adding graphene, its electrical conductivity is exceptionally excellent, and the electrical conductivity continues to increase, because graphite The electron mobility of alkene exceeds 15000cm2 / V s, and graphene is added to the zirconia matrix, which increases the movable electrons in the zirconia matrix, resulting in an increase in the conductivity of the graphene zirconia ceramic material. It shows that graphene is not diffusely distributed in the ceramic matrix, but a network-like dense elemental structure. The graphene ceramic composite material prepared by the invention has changed from the insulator characteristi...

Embodiment 2

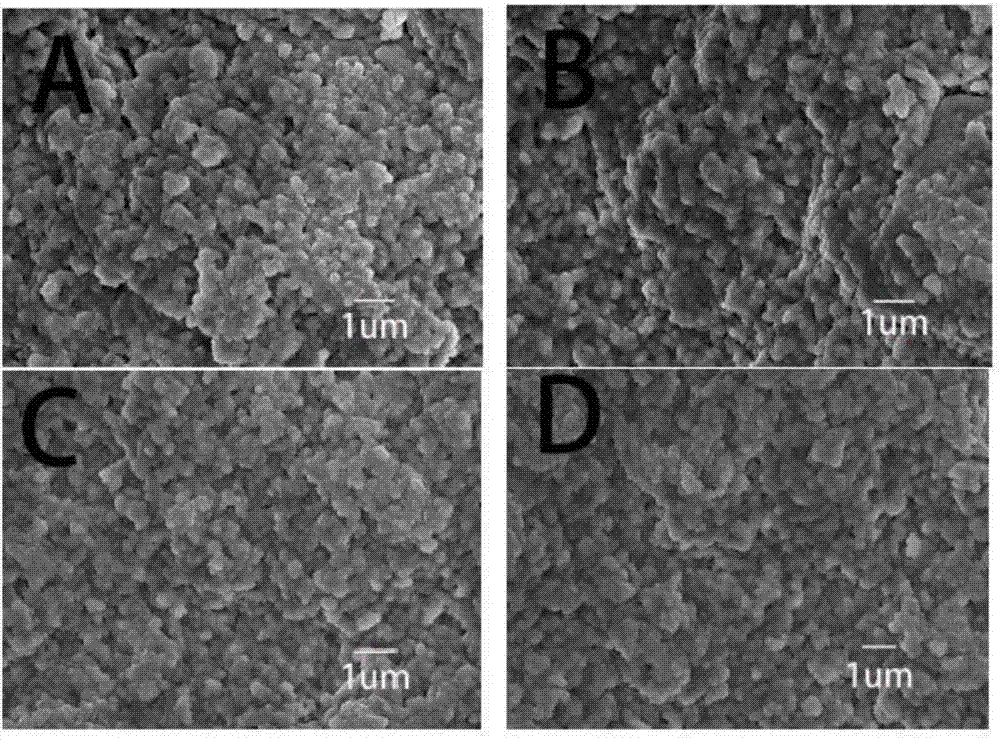

[0032] Such as image 3 as shown, image 3 It is the microscopic electron microscope topography of graphene zirconia ceramic materials prepared by impregnation process of graphene suspension with different concentrations. Part A is a zirconia matrix material, part B is a composite material of zirconia plus 0.4mg / ml graphene, part C is a composite material of zirconia plus 0.6mg / ml graphene, and part D is a composite material of zirconia plus 0.8mg / ml graphene. ml graphene composites. Depend on image 3It can be seen that the effect of different graphene content on its grain size is not obvious. Analyzing the reasons, first, graphene is evenly distributed in the matrix, which has a pinning effect on the grain growth; second, it is reported that graphene has a very high thermal conductivity (5300Wm-1 ▪K-1), and in the matrix The uniform distribution of graphene can not only make the sintering temperature more uniform during sintering, but also make the zirconia grains have a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com