Sintered neodymium-iron-boron material and preparation method therefor

A NdFeB, powder material technology, applied in magnetic materials, inductor/transformer/magnet manufacturing, magnetic objects, etc., can solve the problem of low comprehensive performance, and achieve the effects of simple process, high magnetic performance, and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

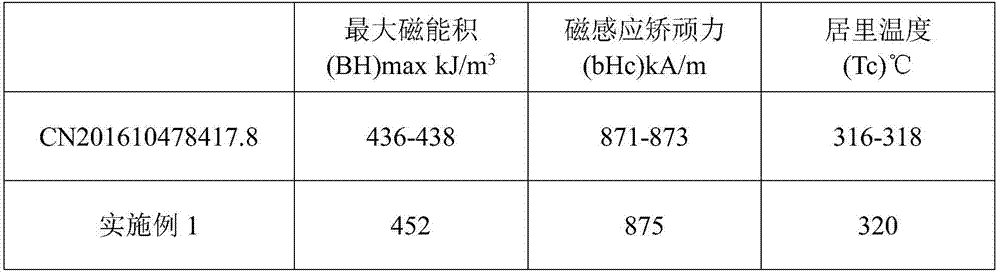

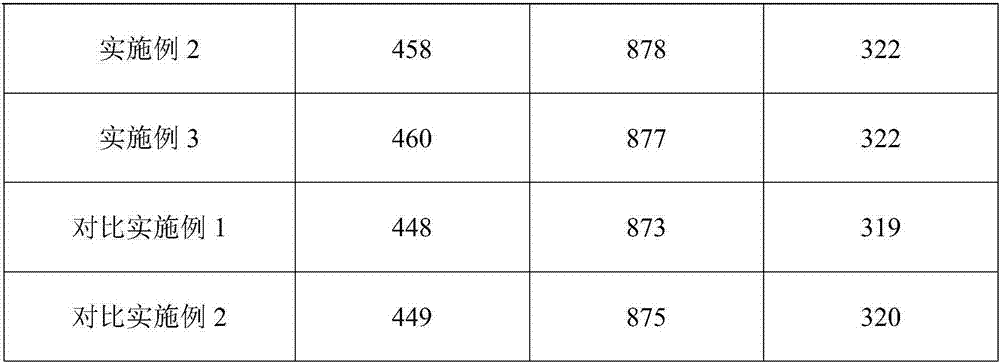

Embodiment 1

[0022] A sintered NdFeB material is composed of iron-based NdFeB powder and composite ferrite powder, nano SnO 2 -Ni composite powder is sintered; the composition and mass percentage of the iron-based NdFeB powder material matrix are: Nd 21%, B 0.3%, Sn0.1%, Co 0.2%, Y 0.3%, Ni 0.3 %, Pb 0.1%, and the balance is Fe. The iron-based NdFeB powder material matrix is also distributed with 0.05% AlN particles by weight, and the average diameter of the particles is 0.3 microns. The weight percent of composite ferrite is: BaO 15%, La 2 o 3 0.6%, CuO 0.1%, CaO 0.02%, Al 2 o 3 0.2%, SiO 2 0.03%, Ce 2 o 3 0.3%, the rest is Fe 2 o 3 . Nano SnO 2 -SnO in Ni composite powder 2 The weight ratio to Ni is 1:0.1. In this embodiment, the iron-based NdFeB powder and composite ferrite, nano SnO sintered NdFeB material 2 - The mass ratio of the Ni composite powder is 100:2:0.2.

[0023] Preparation:

[0024]The preparation method of iron-based NdFeB powder is as follows: raw ma...

Embodiment 2

[0030] A sintered NdFeB material is composed of iron-based NdFeB powder and composite ferrite powder, nano SnO 2 -Ni composite powder is sintered; the composition and mass percentage of the iron-based NdFeB powder material matrix are: Nd 25%, B 0.9%, Sn0.4%, Co 0.9%, Y 0.8%, Ni 0.7 %, Pb 0.4%, and the balance is Fe. The iron-based NdFeB powder material matrix is also distributed with 0.3% AlN particles by weight, and the average diameter of the particles is 0.7 microns. The weight percent of composite ferrite is: BaO 20%, La 2 o 3 0.8%, CuO 0.3%, CaO 0.03%, Al 2 o 3 0.2-0.5%, SiO 2 0.6%, Ce 2 o 3 0.6%, the rest is Fe 2 o 3 . Nano SnO 2 -SnO in Ni composite powder 2 The weight ratio to Ni is 1:0.4. In this embodiment, the iron-based NdFeB powder and composite ferrite, nano SnO sintered NdFeB material 2 - The mass ratio of the Ni composite powder is 100:2:0.6.

[0031] Preparation:

[0032] The preparation method of iron-based NdFeB powder is as follows: raw...

Embodiment 3

[0037] A sintered NdFeB material is composed of iron-based NdFeB powder and composite ferrite powder, nano SnO 2 -Ni composite powder is sintered; the composition and mass percentage of the iron-based NdFeB powder material matrix are: Nd 23%, B 0.5%, Sn0.3%, Co 0.5%, Y 0.5%, Ni 0.4 %, Pb 0.2%, and the balance is Fe. The iron-based NdFeB powder material matrix is also distributed with 0.15% AlN particles by weight, and the average diameter of the particles is 0.5 microns. The weight percent of composite ferrite is: BaO 17%, La 2 o 3 0.7%, CuO 0.2%, CaO 0.025%, Al 2 o 3 0.3%, SiO 2 0.04%, Ce 2 o 3 0.5%, the rest is Fe 2 o 3 . Nano SnO 2 -SnO in Ni composite powder 2 The weight ratio to Ni is 1:0.2. Iron-based NdFeB powder, composite ferrite, and nano SnO of sintered NdFeB material in the present invention 2 - The mass ratio of the Ni composite powder is 100:2:0.4.

[0038] Preparation:

[0039]The preparation method of iron-based NdFeB powder is as follows: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com