Gold-plating method of high silicon-aluminum composite material

A composite material, high-silicon-aluminum technology, applied in the direction of superimposed layer plating, metal material coating process, liquid chemical plating, etc., can solve the problem of affecting the welding performance and air tightness of the shell, the difficulty of surface plating, and the combination of plating Insufficient strength and other problems, to achieve the effect of releasing internal stress, clear transition interface, and improving the bonding force of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

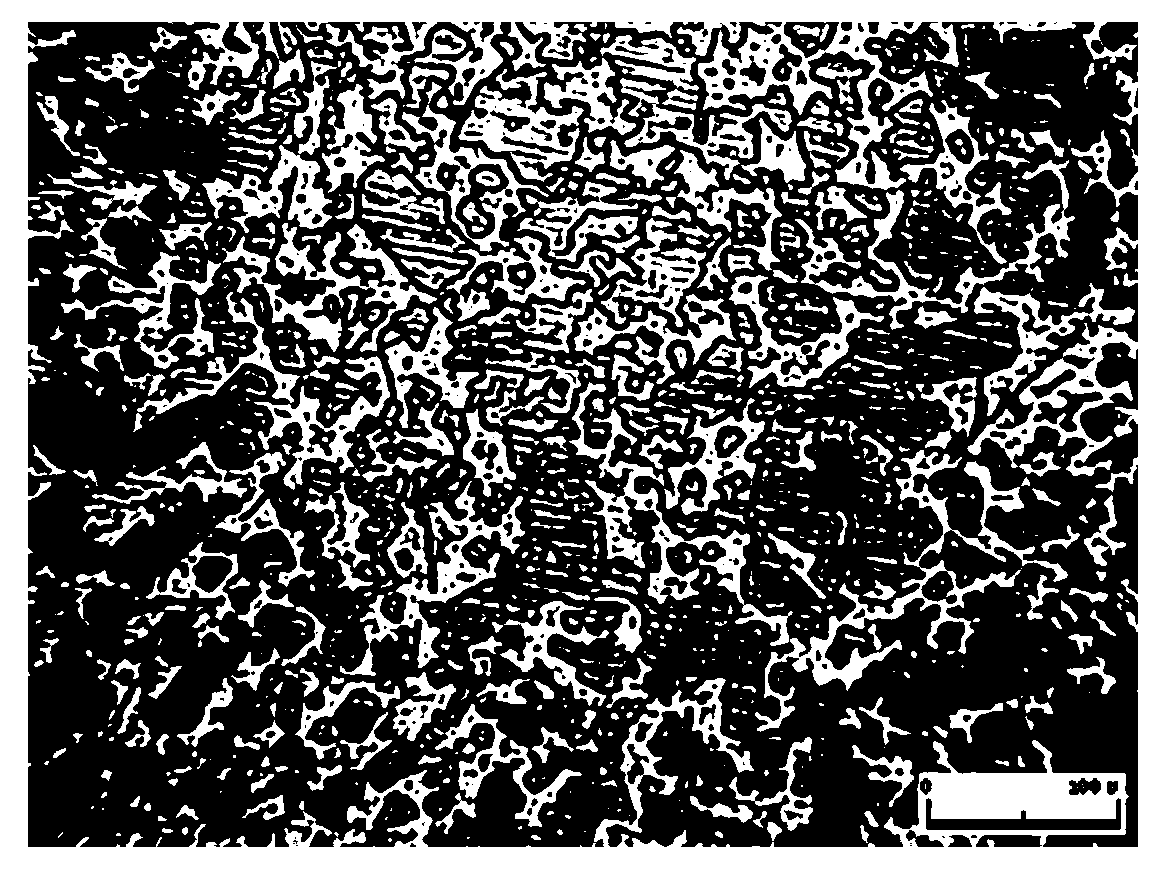

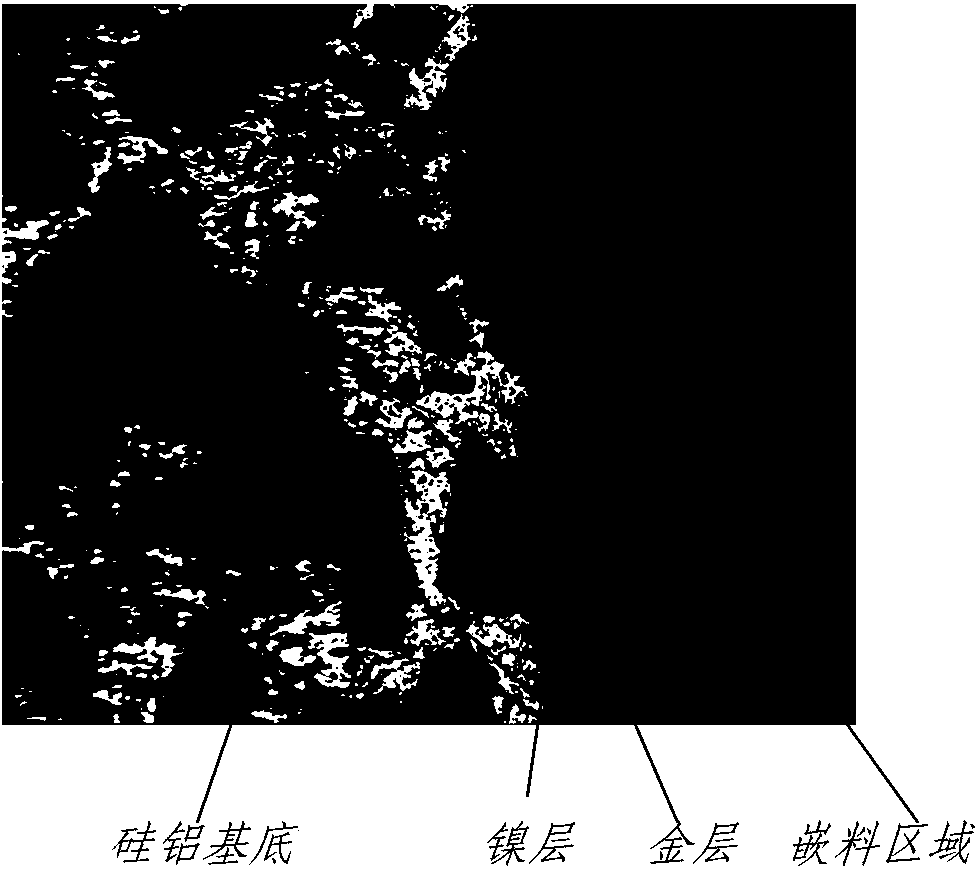

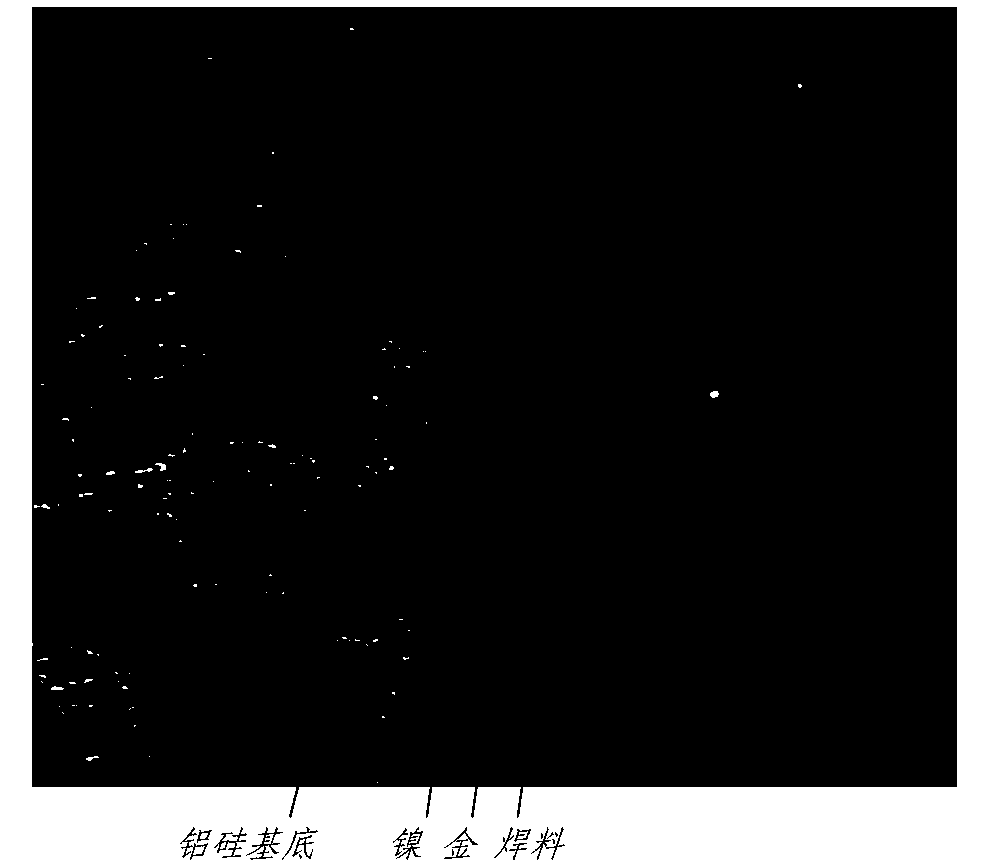

Image

Examples

Embodiment 1

[0025] The specific operation steps of Si-50Al composite gold plating are as follows:

[0026] Preparation of gold plating solution: weigh potassium gold cyanide, citric acid, and potassium citrate according to the formula, inject one-third of deionized water into the plating solution, add the weighed potassium gold cyanide and make it fully dissolved; Dissolve the weighed citric acid and potassium citrate in deionized water separately and pour them into the plating tank, and replenish the deionized water to the working level. The composition and content of the prepared gold plating solution are: potassium gold cyanide 20 g / L, citric acid 12 g / L, and potassium citrate 30 g / L.

[0027] Prepare alkaline etching solution: weigh sodium hydroxide, sodium carbonate, and sodium phosphate according to the formula, and prepare a solution. The composition and content of the prepared alkaline etching solution are NaOH 5g / L, NaOH 5g / L, NaOH 2 CO 3 30g / L, Na 3 PO 4 40g / L and 1L of wa...

Embodiment 2

[0045] The specific operation steps of Si-50Al composite gold plating are as follows:

[0046] Preparation of gold plating solution: weigh potassium gold cyanide, citric acid, and potassium citrate according to the formula, inject one-third of deionized water into the plating solution, add the weighed potassium gold cyanide and make it fully dissolved; Dissolve the weighed citric acid and potassium citrate in deionized water separately and pour them into the plating tank, and replenish the deionized water to the working level. The composition and content of the prepared gold plating solution are: potassium gold cyanide 22 g / L, citric acid 11 g / L, and potassium citrate 32 g / L.

[0047] Preparation of alkali etching solution: weigh sodium hydroxide, sodium carbonate, and sodium phosphate according to the formula, and prepare a solution. The composition and content of the prepared alkali etching solution are NaOH 8g / L, NaOH 8g / L, NaOH 2 CO 3 35g / L, Na 3 PO 4 50g / L and 1L of...

Embodiment 3

[0063] The specific operation steps of Si50% silicon-aluminum composite material gold plating are as follows:

[0064] Preparation of gold plating solution: weigh potassium gold cyanide, citric acid, and potassium citrate according to the formula, inject one-third of deionized water into the plating solution, add the weighed potassium gold cyanide and make it fully dissolved; Dissolve the weighed citric acid and potassium citrate in deionized water separately and pour them into the plating tank, and replenish the deionized water to the working level. The composition and content of the prepared gold plating solution are: potassium gold cyanide 25 g / L, citric acid 10 g / L, and potassium citrate 35 g / L.

[0065] Prepare alkaline etching solution: weigh sodium hydroxide, sodium carbonate, and sodium phosphate according to the formula, and prepare a solution. The composition and content of the prepared alkaline etching solution are NaOH 6g / L, NaOH 6g / L, NaOH 2 CO 3 40g / L, Na 3 P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com