Double-sided flexible CCL (copper-clad plate) and production method thereof

A technology of flexible copper clad laminate and manufacturing method, which is applied in chemical instruments and methods, other household appliances, electronic equipment, etc. The effect of size change improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

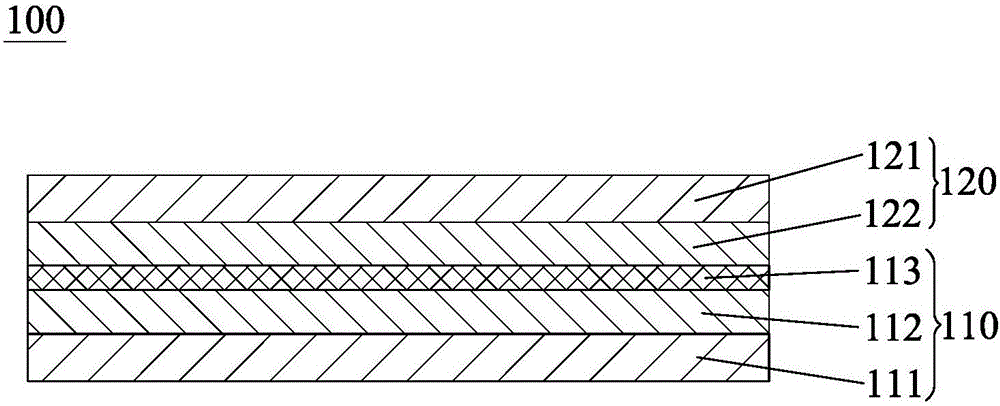

[0024] Embodiments of the present invention will now be described with reference to the accompanying drawings, in which like reference numerals represent like elements.

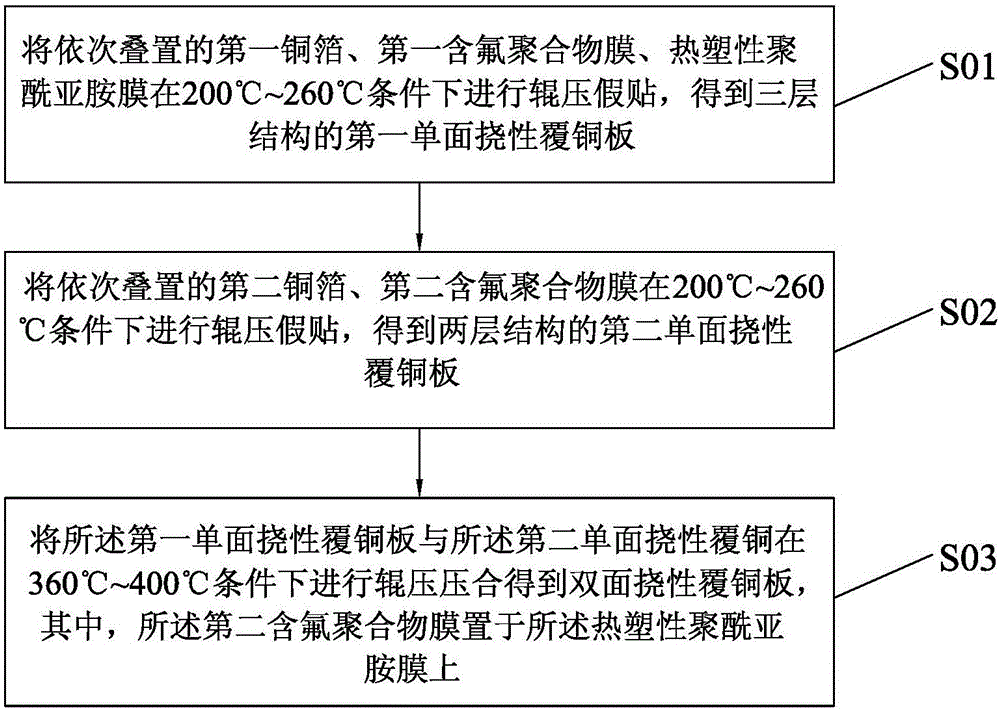

[0025] like figure 1 As shown, the method for manufacturing a double-sided flexible copper clad laminate provided by the present invention includes the following steps:

[0026] Step S01 : rolling the first copper foil, the first fluoropolymer film, and the thermoplastic polyimide film stacked in sequence at 200° C. to 260° C. to obtain the first single side of the three-layer structure Flexible copper clad laminate; due to the low temperature condition of rolling fake paste, while ensuring the fake paste effect, it can reduce the dimensional change of single-sided copper clad laminate, to avoid the thermoplastic polyimide film easy to be rolled under high temperature film breakage problem;

[0027] Step S02 : rolling the second copper foil and the second fluoropolymer film stacked in sequence at 200° C. to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com