Double-sided flexible copper clad laminate and manufacturing method thereof

A technology of flexible copper clad laminate and manufacturing method, which is applied in chemical instruments and methods, other household appliances, synthetic resin layered products, etc. Solderability, the effect of avoiding easy film breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

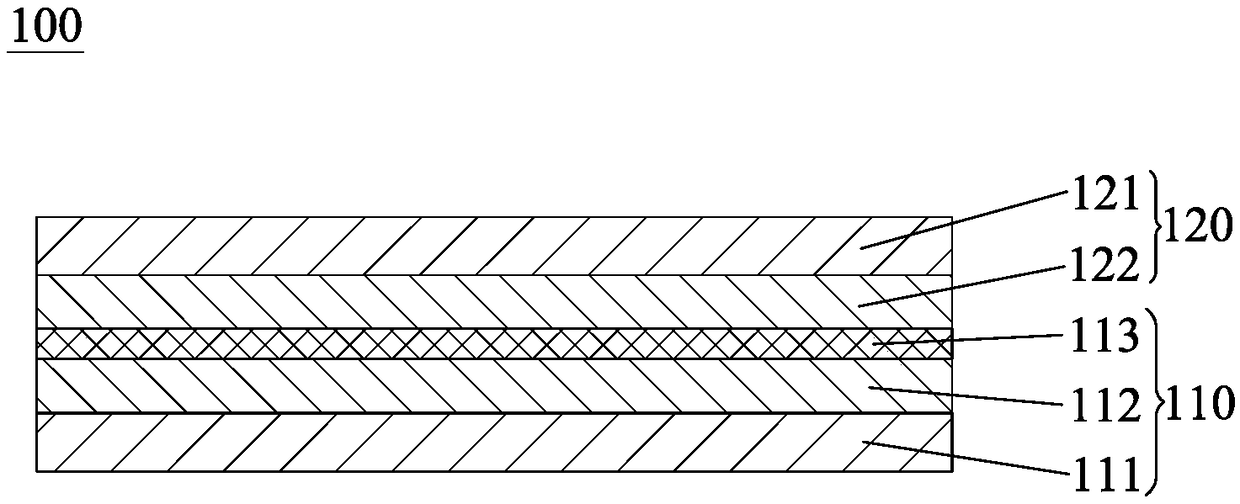

[0024] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

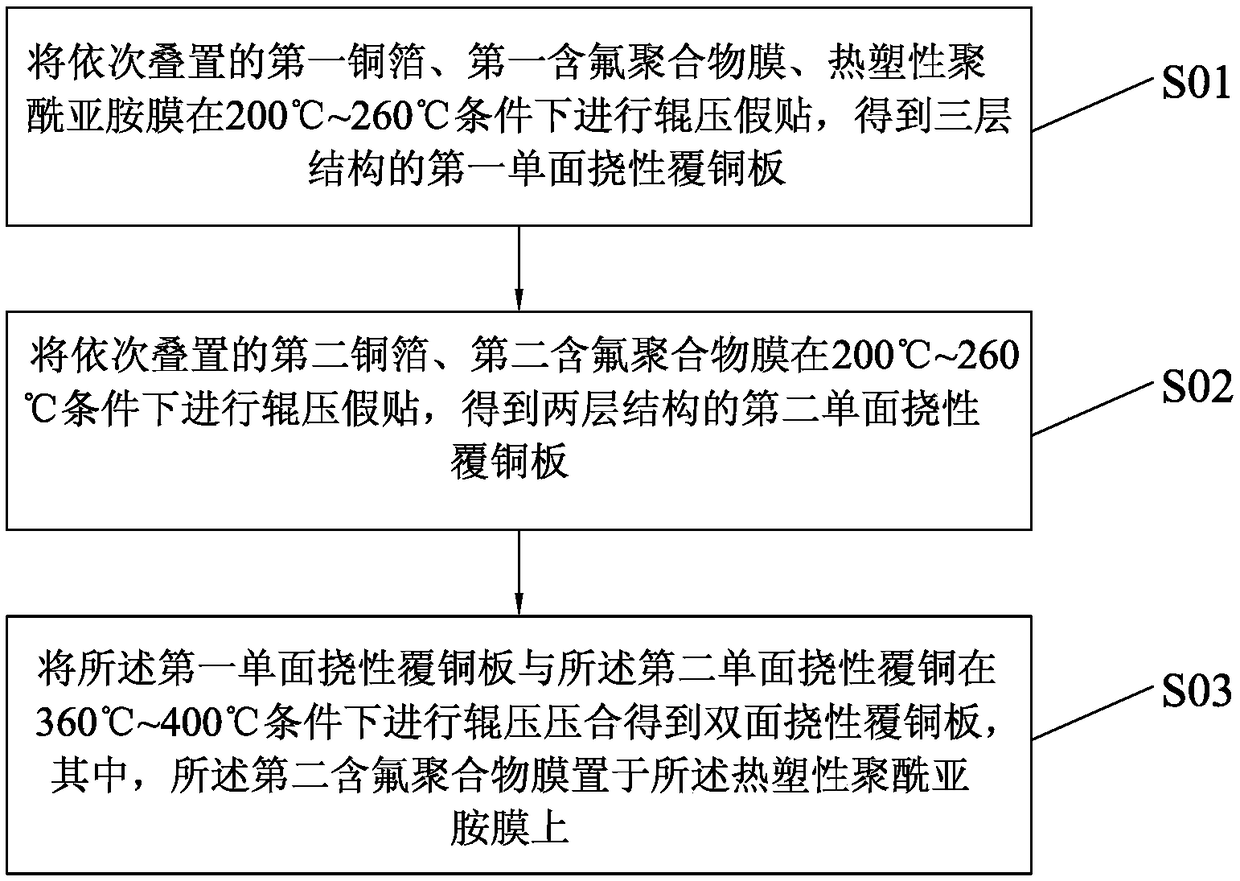

[0025] Such as figure 1 As shown, the double-sided flexible copper-clad laminate manufacturing method provided by the present invention comprises the following steps:

[0026] Step S01: Roll the first copper foil, the first fluoropolymer film, and the thermoplastic polyimide film stacked in sequence at 200 ° C to 260 ° C to obtain the first single side of the three-layer structure Flexible copper-clad laminate; due to the rolling and false bonding at a lower temperature, while ensuring the effect of false bonding, it can reduce the dimensional change of the single-sided copper-clad laminate, so as to avoid the thermoplastic polyimide film being easily damaged under high-temperature rolling. The problem of broken membrane;

[0027] Step S02: Carry out rolling and false bonding of the second copper foil and the second flu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com