Methanesulfonic acid-based matte pure tin electroplating solution and additive thereof

A technology of methanesulfonic acid and additives, which is applied in the field of methanesulfonic acid-based matte pure tin electroplating solution additives and electroplating solutions, can solve the problem that the performance of the electroplating solution and the coating layer is not easy to maintain stable, the wettability is poor, and it is easy to grow. Solder problems such as tin whiskers, and achieve the effect of excellent solderability, good positioning performance, good flexibility and ductility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

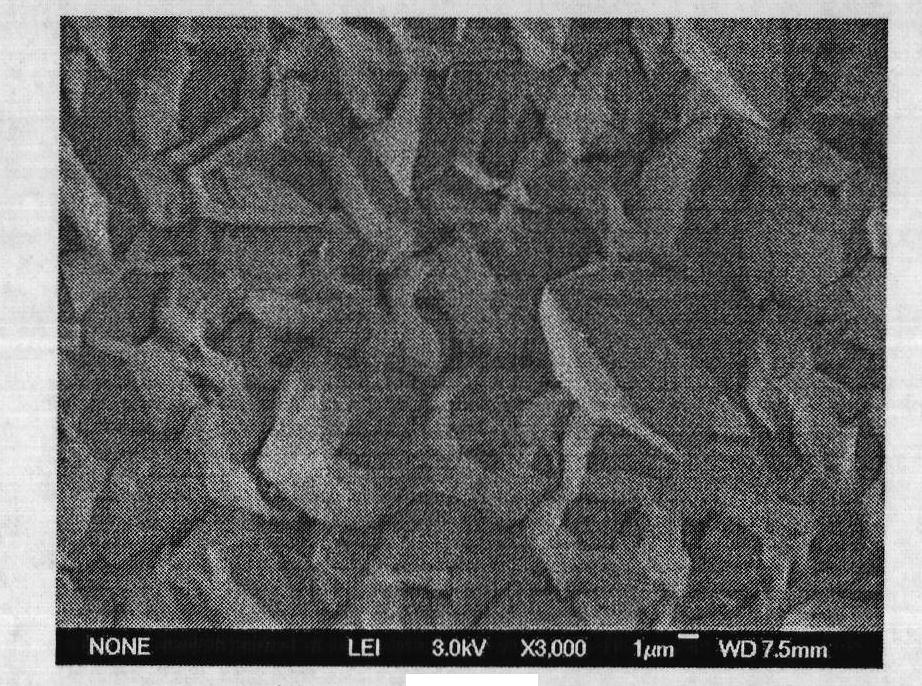

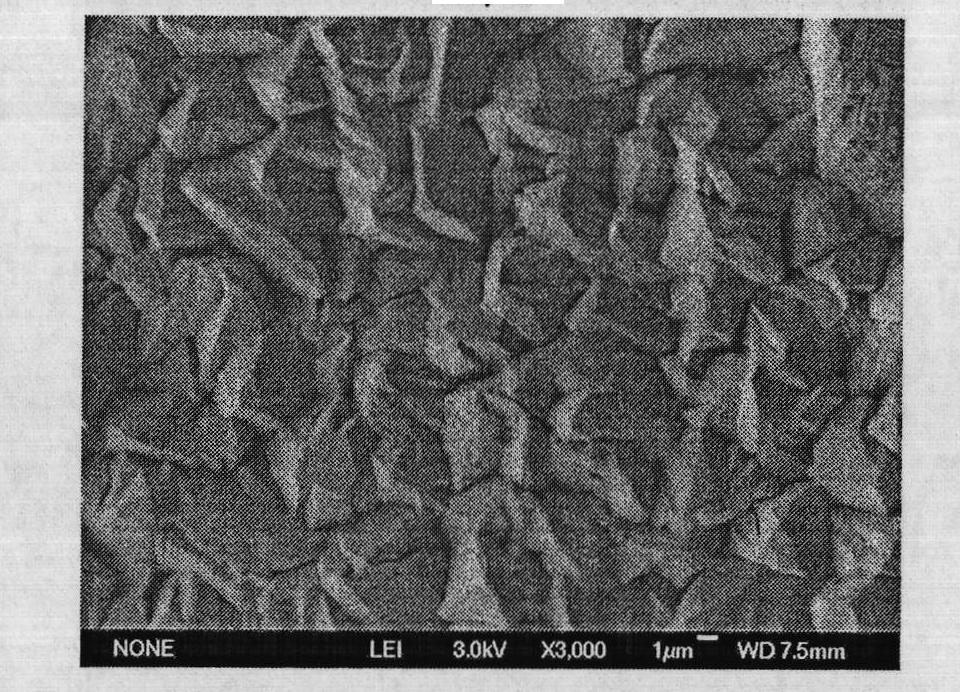

Image

Examples

Embodiment 1

[0030] Additive water formulation 1

[0031] Hydroquinone 12.5g / L

[0032] Lactic acid 5g / L

[0033] N-Dimethylformamide 1.25g / L

[0034] 2-Mercaptobenzothiazole 0.75g / L

[0035] Nonylphenol polyoxyethylene ether (8EO) 50g / L

[0036] EO-PO (EO=8, PO=6) copolymer 100g / L

[0037] Isopropanol 125g / L

[0038]Water 700g / L

[0039] The preparation method is: mix hydroquinone, lactic acid, N-dimethylformamide and 2-mercaptobenzothiazole with nonylphenol polyoxyethylene ether (8EO), EO-PO (EO=8, PO=6) Dissolve the copolymer and isopropanol, stir to dissolve completely, add water to make up to volume.

Embodiment 2

[0041] Additive water formulation 2

[0042] Catechol 15g / L

[0043] Ascorbic acid 12g / L

[0044] Coconut Oil Diethanolamide 1.0g / L

[0045] 4-Methylquinoline 1.0g / L

[0046] Fatty alcohol polyoxyethylene ether (12C, 8EO) 64g / L

[0047] EO-PO (EO=8, PO=6) copolymer 90g / L

[0048] Methanol 100g / L

[0049] Water 725g / L

[0050] Preparation method: dissolve antioxidant and grain refiner with organic solvent and non-ionic surfactant, stir to dissolve completely, add water to make up volume.

Embodiment 3

[0052] Additive water formulation 3

[0053] Catechol 13g / L

[0054] Ascorbic acid 10g / L

[0055] Acetyl ethanolamine 2g / L

[0056] 4-Methylquinoline 0.5g / L

[0057] p-cumylphenol polyoxyethylene ether (11EO) 80g / L

[0058] Polyethylene glycol 50g / L

[0059] Methanol 50g / L

[0060] Isopropanol 60g / L

[0061] Water 730g / L

[0062] Preparation method is the same as embodiment 2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com