UV light-cured varnish spraying waste gas recycling equipment and technology

A waste gas recovery and treatment equipment technology, which is applied to chemical instruments and methods, combined devices, and dispersed particle separation, can solve problems such as high adsorption costs, large water pollution, and poor adsorption effects, and achieve improved utilization, convenient processing, and cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

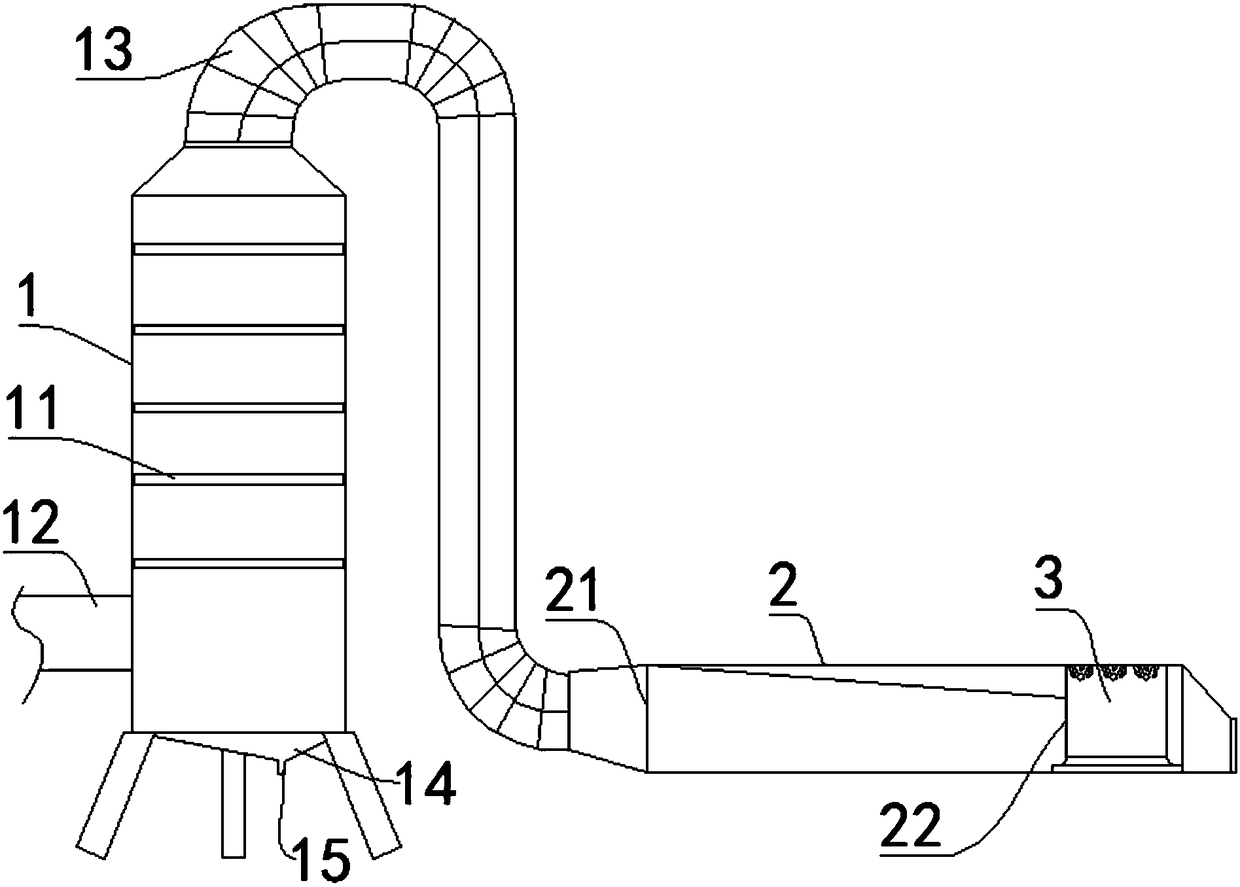

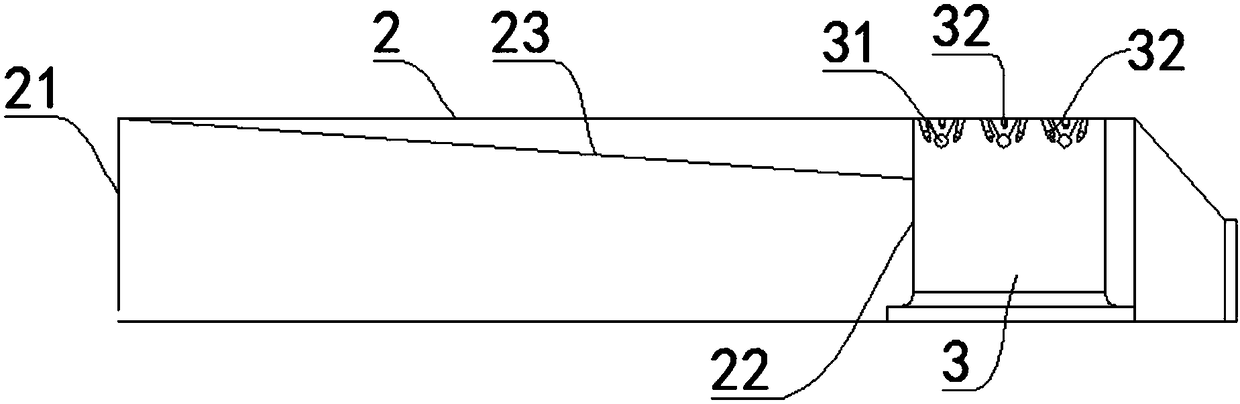

[0028] Embodiment one: if Figure 1 to Figure 3 As shown, the present invention provides a kind of UV photocuring varnish spraying waste gas recovery treatment equipment, comprises the collection tower 1 that is connected in sequence, the changing direction deceleration air duct 2 and drying and curing box 3, and the described collection tower 1 is fixedly installed with multiple A layer separation plate 11, and an ultraviolet lamp 31 is installed in the upper part of the drying and curing box 3.

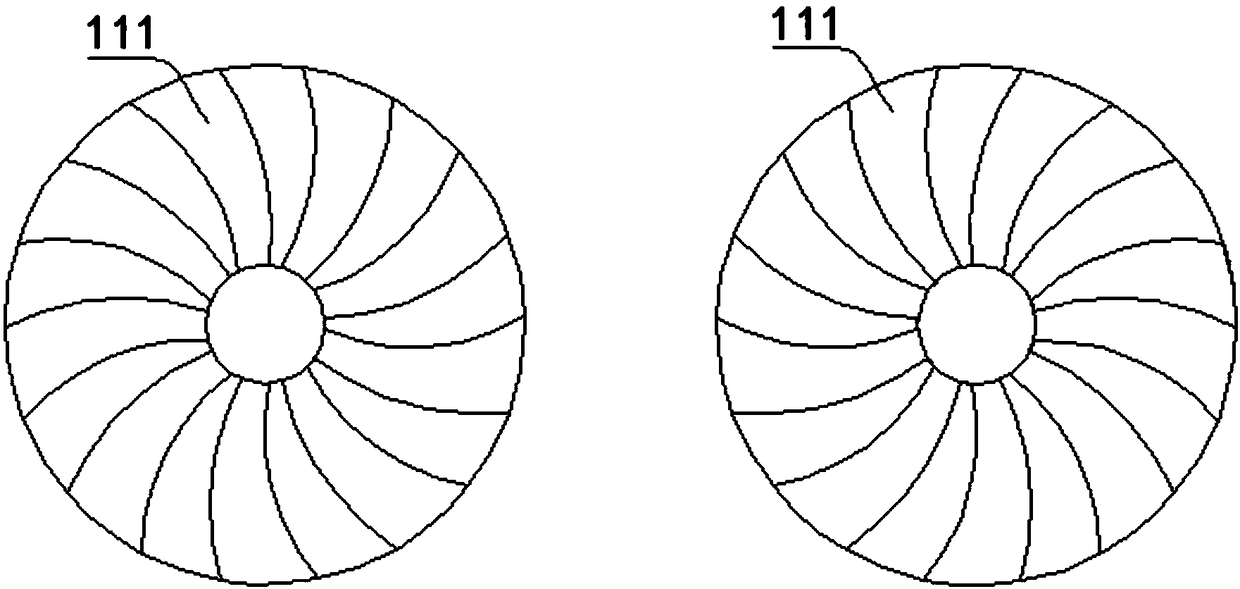

[0029] The separation plate 11 includes a plurality of helical blades 111 stacked end to end fixedly installed, and air passages are arranged between the adjacent helical blades 111 .

[0030] The lower part of the collection tower 1 is provided with a waste gas inlet pipe 12. The separation plate 11 in the collection tower 1 has five layers. The gas outlet pipe 13, the bottom of the collection tower 1 is provided with an oil storage device 14, and the bottom of the oil storage dev...

Embodiment 2

[0035] Embodiment two: if Figure 5 As shown, the present invention provides a kind of UV photocuring varnish spraying waste gas recovery treatment equipment, comprises the collection tower 1 that is connected in sequence, the changing direction deceleration air duct 2 and drying and curing box 3, and the described collection tower 1 is fixedly installed with multiple A layer separation plate 11, and an ultraviolet lamp 31 is installed in the upper part of the drying and curing box 3. The rear part of the drying and curing box 31 is also connected with a dust removal tower 4, a filter 5, a UV photocatalytic oxidation device 6, a centrifugal fan 7 and a discharge chimney 8 in sequence. A circulating water tank 41 is provided at the bottom of the dedusting tower 4 .

[0036] The dedusting tower 4, filter 5, UV photocatalytic oxidation device 6, centrifugal fan 7 and discharge chimney 8 are all existing conventional equipment. The exhaust gas of paint mist after drying and soli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com