Low-temperature-resistant acrylic acid coating adhesive and preparation method and application thereof

A technology of acrylic acid and low temperature resistance, applied to a low temperature resistant acrylic coating adhesive for building sealing and its preparation field, can solve the problems of low bonding performance, low temperature resistance, poor acid and alkali resistance, etc., and achieves improved peel strength, The effect of reducing surface energy and good low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

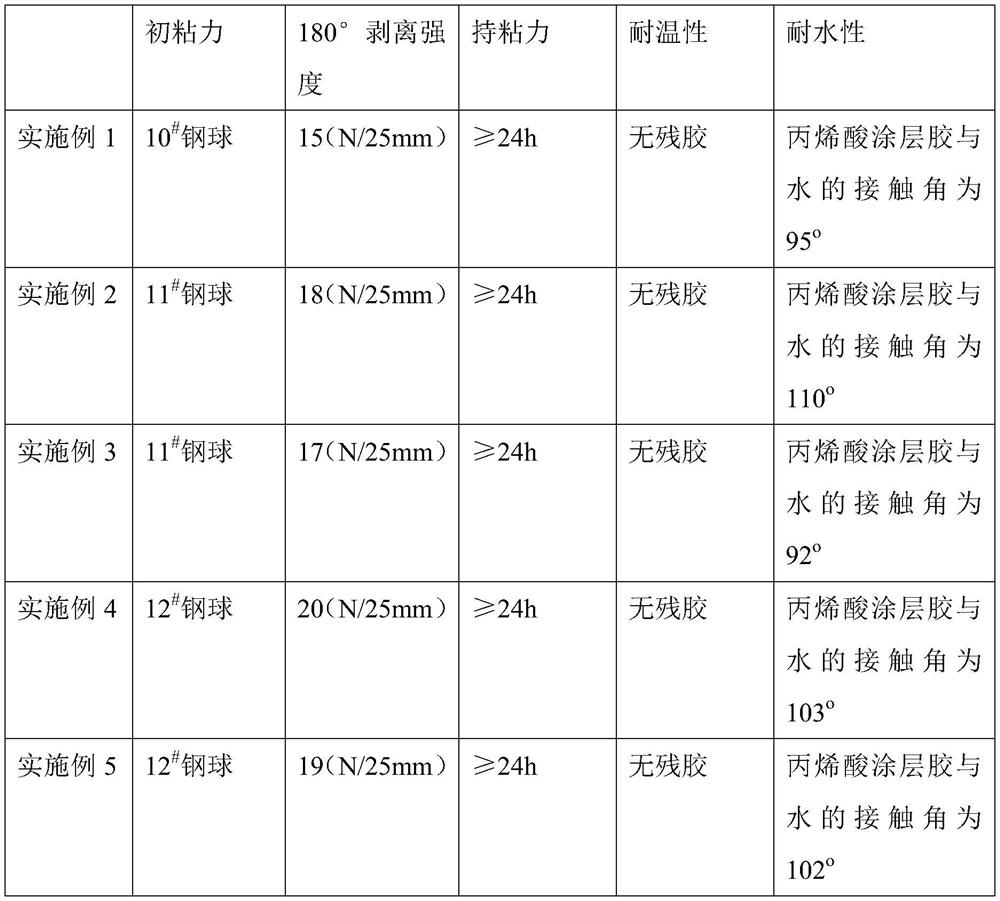

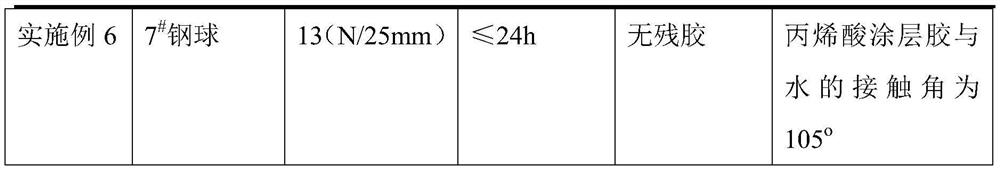

Examples

Embodiment 1

[0043] (1) Pre-emulsion preparation: with 80g butyl acrylate, 10g ethyl acrylate, 5g methyl acrylate, 5g methyl methacrylate, 1.5g 2-perfluoropropoxy perfluoropropyl trifluorovinyl ether, 2g Perfluoromethyl vinyl ether, 1.5 g perfluoroethyl vinyl ether, 2 g 2-acrylamide-2-methylpropanesulfonic acid and 50 g deionized were added to a 500 mL round bottom flask and mixed vigorously at 12000 rpm to Form a pre-emulsion and set aside;

[0044] (2) Seed emulsion preparation: join the pre-emulsion of 10wt% to a 500mL and have reflux condenser, constant pressure dripping device, in the four-neck round-bottomed flask of nitrogen feed tube and mechanical stirrer, add 0.15g carbonic acid in flask Sodium hydrogen, set the reaction temperature to 70-85°C, set the stirring speed to 250rpm, and dropwise add potassium persulfate aqueous solution prepared by 0.15g potassium persulfate and 50g deionized water, and reflux reaction under nitrogen protection until the system appears Blu-ray;

[0...

Embodiment 2

[0047] (1) Pre-emulsion preparation: 70g n-octyl acrylate, 10g isooctyl acrylate, 10g isooctyl methacrylate, 10g ethyl methacrylate, 3g 2-perfluoropropyl vinyl ether, 3g 1,1 ,2,4,4,5,7,7,8,10,10,11,11,12,12,12-hexadecafluoro-5,8-bis(trifluoromethyl)-3,6,9 - Trioxadodecyl-1-ene, 4 g 3-(1-(difluoro((trifluorovinyl)oxy)methyl)-1,2,2,2-tetrafluoroethoxy) - 2,2,3,3-Tetrafluoropropanol, 2g sodium alkylvinylsulfonate and 50g deionized were added to a 500mL round bottom flask and mixed vigorously at 12000rpm to form a pre-emulsion, ready for use;

[0048] (2) Seed emulsion preparation: join the pre-emulsion of 10wt% to a 500mL and have reflux condenser, constant pressure dripping device, in the four-neck round-bottom flask of nitrogen feed pipe and mechanical stirrer, add 1.5g carbonic acid in flask Sodium hydrogen, set the reaction temperature at 70-85°C, set the stirring speed at 250rpm, add dropwise an aqueous sodium persulfate solution prepared by 0.15g sodium persulfate and 50g ...

Embodiment 3

[0051] (1) Pre-emulsion preparation: first mix 80g lauryl acrylate, 15g 1,6-hexanediol diacrylate, 2g butyl methacrylate, 3g vinyl acetate, 1.5g 1,1,2,2,3, 3,4,4,5,5-Decafluoro-1-((trifluorovinyl)oxy)pentane, 2g 1-chloro-1,1,2,2,3,3-hexafluoro-3-( (trifluorovinyl)oxy)propane, 1.5g 2-chloro-1,1,1,2,3,3-hexafluoro-3-((trifluorovinyl)oxy)propane, 2g 2-propene Add amide-2-methylpropanesulfonic acid and 50g deionized into a 500mL round bottom flask and mix vigorously at 12000rpm to form a pre-emulsion, ready for use;

[0052] (2) Seed emulsion preparation: join the pre-emulsion of 10wt% to a 500mL and have reflux condenser, constant pressure dripping device, in the four-neck round-bottomed flask of nitrogen feed tube and mechanical stirrer, add 0.15g carbonic acid in flask Sodium hydrogen, set the reaction temperature to 70-85°C, set the stirring speed to 250rpm, and add dropwise an ammonium persulfate aqueous solution prepared by 0.15g ammonium persulfate and 50g deionized water,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com