Polycarbonate resin composition, production method therefor, masterbatch pellet, and molded body

A technology of polycarbonate resin and composition, which is applied in the field of polycarbonate resin composition and its manufacture, masterbatch pellets and moldings, can solve problems such as poor processability, high melt viscosity, and poor chemical resistance, and achieve Excellent processability, good mechanical properties, and good appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

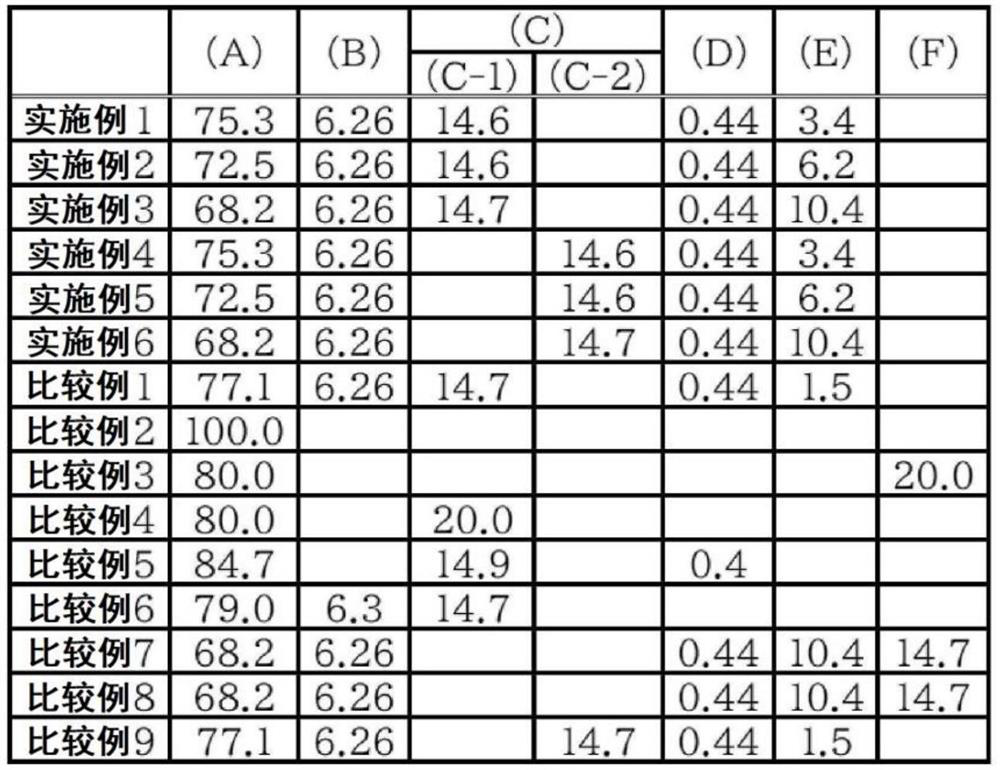

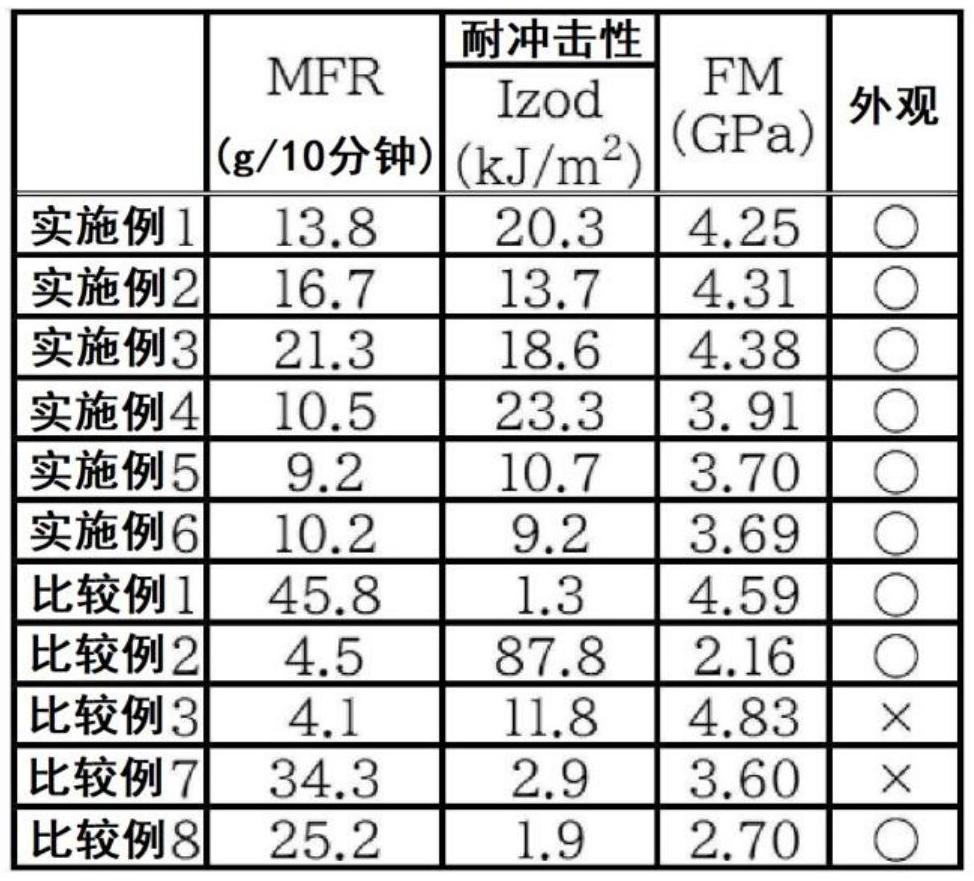

Embodiment 1

[0100] 25.3% by mass of ABS resin (B), 59.1% by mass of fibrous basic magnesium sulfate particles (C-1), 1.8% by mass of fatty acid metal salt (D) and 13.8% by mass of elastomer (E) were mixed, and the resulting mixture Melt-kneading was carried out at 240° C. for 2 minutes. For the melt kneading, a melt kneading extruder Labo Plastomill Roller Mixer (R60 type, capacity 60 cc, manufactured by Toyo Seiki Co., Ltd.) was used, and the rotational speed of the shaft was 120 rpm. The resulting melt-kneaded product was formed into a sheet by hot pressing (at a temperature of 240° C.), and then cut to obtain masterbatch pellets.

[0101] 24.7% by mass of the above-mentioned masterbatch pellets and 75.3% by mass of the polycarbonate resin (A) were mixed. Thereafter, the polycarbonate resin composition of Example 1 was obtained by melt-kneading at 260° C. and 50 rpm using a twin-screw melt-kneading extruder (L / D=25, manufactured by Imoto Seisakusho Co., Ltd.).

Embodiment 2

[0103] Using 22.8% by mass of ABS resin (B), 53.1% by mass of fibrous basic magnesium sulfate particles (C-1), 1.6% by mass of fatty acid metal salt (D) and 22.5% by mass of elastomer (E). In Example 1, masterbatch pellets were obtained in the same manner.

[0104] The polycarbonate resin composition of Example 2 was obtained like Example 1 except having used 27.5 mass % of said masterbatch pellets, and 72.5 mass % of polycarbonate resin (A).

Embodiment 3

[0106] Using 19.7% by mass of ABS resin (B), 46.2% by mass of fibrous basic magnesium sulfate particles (C-1), 1.4% by mass of fatty acid metal salt (D) and 32.7% by mass of elastomer (E), in addition to the same In Example 1, masterbatch pellets were obtained in the same manner.

[0107] The polycarbonate resin composition of Example 3 was obtained like Example 1 except having used 31.8 mass % of said masterbatch pellets, and 68.2 mass % of polycarbonate resin (A).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com