Infrared window anti-reflection protection structure and preparation method thereof

An anti-reflection protection, infrared window technology, applied in the direction of ion implantation plating, gaseous chemical plating, superimposed layer plating, etc., can solve the problems of reducing film stress, depositing diamond-like film, etc. , The structure is simple, the effect of improving the optical transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

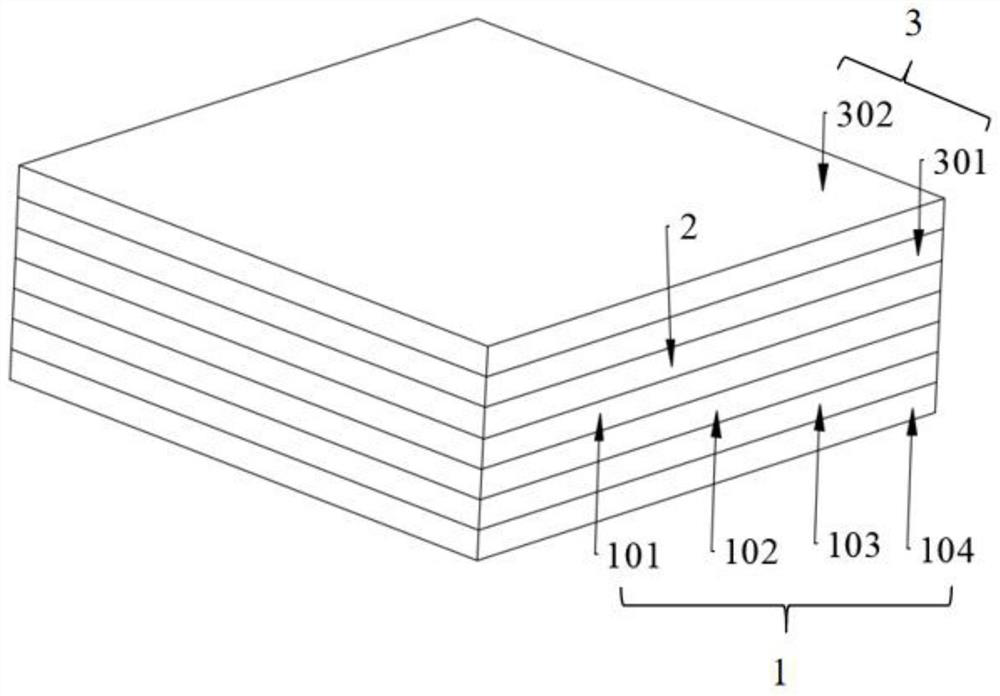

[0027] An infrared window anti-reflection protection structure, the structure includes an anti-reflection layer 1, a base 2 and a protective layer 3, the anti-reflection layer 1 is attached to one side of the base 2, and the protective layer 3 is attached to the other side;

[0028] The anti-reflection layer 1 sequentially includes a first germanium layer 101, a first zinc sulfide layer 102, a second germanium layer 103 and a second zinc sulfide layer 104 starting from the substrate 2;

[0029] The protection layer 3 includes a GeAsSe layer 301 and a diamond-like carbon layer 302 sequentially from the substrate 2 .

[0030] Specifically, the substrate 2 is chalcogenide glass IRG206.

[0031] Specifically, the thickness of the first germanium layer 101 is 100 nm; the thickness of the first zinc sulfide layer 102 is 2200 nm; the thickness of the second germanium layer 103 is 50 nm; the thickness of the second zinc sulfide layer 104 is 1100 nm.

[0032] Specifically, the thickne...

Embodiment 2

[0039] The difference with Embodiment 1 is:

[0040] Specifically, the substrate 2 is germanium glass.

[0041] Specifically, the thickness of the first germanium layer 101 is 500 nm; the thickness of the first zinc sulfide layer 102 is 500 nm; the thickness of the second germanium layer 103 is 100 nm; the thickness of the second zinc sulfide layer 104 is 500 nm.

[0042] Specifically, the thickness of the GeAsSe layer 301 is 500 nm; the thickness of the DLC layer 302 is 500 nm.

Embodiment 3

[0044] The difference with Embodiment 1 is:

[0045] Specifically, the substrate 2 is silicon glass.

[0046] Specifically, the thickness of the first germanium layer 101 is 800nm; the thickness of the first zinc sulfide layer 102 is 1800nm; the thickness of the second germanium layer 103 is 200nm; the thickness of the second zinc sulfide layer 104 is 800nm.

[0047] Specifically, the thickness of the GeAsSe layer 301 is 800 nm; the thickness of the DLC layer 302 is 1000 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com