A kind of unsaturated organosilicon and preparation method, a kind of silicon-acrylic emulsion and preparation method and use thereof

A silicone-acrylic emulsion and organosilicon technology, which is applied in the fields of building interior wall latex paint, silicone-acrylic emulsion and preparation, unsaturated silicone and preparation field, can solve the problem of reducing the usage of titanium dioxide, incapable of adding a large amount, affecting the performance of paint film, etc. problem, to achieve the effect of excellent scrub resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

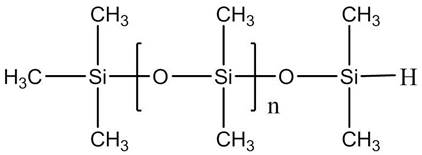

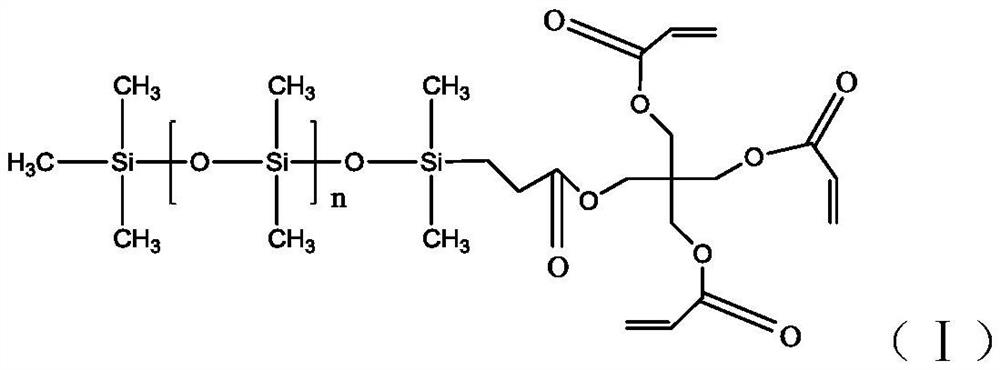

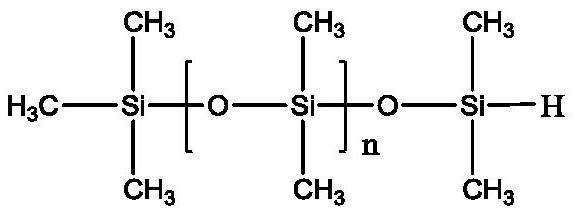

[0069] Preparation of unsaturated organosilicon M20 (n=20) represented by formula (I):

[0070] 1) 1600g (1mol) of single-ended hydrogen-containing silicone oil with a degree of polymerization of 20 is added to the reactor, stirring and heating are turned on; after the temperature rises to 70°C, 352g (1mol) pentaerythritol tetraacrylate and 0.016g are added dropwise. Casterplatin catalyst was added dropwise for 2 hours, while the drop rate was controlled to keep the reaction temperature below 90°C.

[0071] 2) After the dropwise addition, keep the temperature at 80°C for 1h, check that the residual of silicon hydrogen is less than 10ppm and the reaction ends, cool down to below 40°C, filter and discharge the material to obtain unsaturated silicone M20.

[0072] In the infrared test spectrum, the Si-H characteristic peak basically disappears after the reaction, which proves that the single-ended hydrogen-containing silicone oil and pentaerythritol tetraacrylate undergo a hydros...

Embodiment 2

[0074] Preparation of unsaturated silicone 10 (n=10) represented by formula (I):

[0075] 1) 860g (1mol) of single-ended hydrogen-containing silicone oil with a degree of polymerization of 10 is added to the reactor, and stirring and heating are turned on; after the temperature rises to 75°C, 373.12g (1.06mol) of pentaerythritol tetraacrylate and 0.0017g of Custer catalyst was added dropwise for 1h, while the drop rate was controlled to keep the reaction temperature not exceeding 90°C.

[0076] 2) After the dropwise addition, keep the temperature at 70°C for 1 hour, check that the residual of silicon hydrogen is less than 10 ppm and the reaction is completed, cool down to below 40°C, and filter out the material to obtain unsaturated silicone M10.

Embodiment 3

[0078] Preparation of unsaturated organosilicon 15 (n=15) represented by formula (I):

[0079] 1) 1230g (1mol) of single-ended hydrogen-containing silicone oil with a degree of polymerization of 15 is added to the reactor, and stirring and heating are turned on; after the temperature rises to 80°C, 380.16g (1.08mol) of pentaerythritol tetraacrylate and 0.0246g of Castel catalyst was added dropwise for 3 hours, while the drop rate was controlled to keep the reaction temperature not exceeding 90°C.

[0080] 2) After the dropwise addition is completed, keep the temperature at 75°C for 0.5h, detect that the residual silicon hydrogen is less than 10ppm and the reaction is completed, cool down to below 40°C, and filter out the material to obtain unsaturated silicone M15.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com