Method for determining content of tantalum element in nickel-based alloy

A nickel-based alloy, element content technology, applied in the preparation of test samples, thermal excitation analysis, material excitation analysis, etc., can solve the problems of content interference, low sensitivity, etc., to achieve simple operation, improve detection efficiency, and good test accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

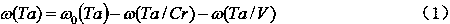

Method used

Image

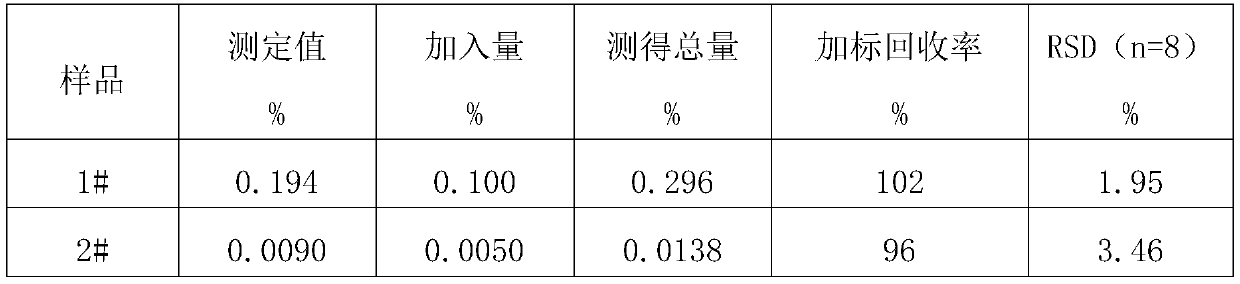

Examples

Embodiment 1

[0022] Embodiment 1: Tantalum element in nickel-based alloys Taking a nickel-based alloy sample as an example, details are as follows.

[0023] (1) Prepare standard solution: Accurately weigh 6 parts of 0.2500g high-purity nickel, add mixed acid prepared from 6ml high-purity hydrochloric acid, 3ml high-purity nitric acid, and 0.5ml hydrofluoric acid for digestion. After the digestion is completed, transfer to 6 100ml volumetric flask; accurately pipette different volumes of tantalum element standard diluent with a concentration of 10μg / L into the above six 100mL volumetric flasks, shake up with ultrapure water with a resistivity of 18.2MΩ·cm, and prepare a A series of Ta element standard solutions with different concentrations, the mass percentage of Ta element in the high-purity nickel in the standard solution, that is, the content of tantalum element is shown in Table 1.

[0024] Table 1: Content of tantalum element in standard solution

[0025] standard solution ...

Embodiment 2

[0041] Embodiment 2: Tantalum element in nickel-based alloy Taking a nickel-based alloy sample as an example, the details are as follows.

[0042] (1) Prepare standard solution: Accurately weigh 6 parts of 0.2500g high-purity nickel, add mixed acid prepared from 5ml high-purity hydrochloric acid, 5ml high-purity nitric acid, and 0.5ml hydrofluoric acid for digestion. After the digestion is completed, transfer to 6 100ml volumetric flask; accurately pipette different volumes of tantalum element standard diluent with a concentration of 10μg / L into the above six 100mL volumetric flasks, shake up with ultrapure water with a resistivity of 18.2MΩ·cm, and prepare a A series of Ta element standard solutions with different concentrations, the mass percentage of Ta element in the high-purity nickel in the standard solution, that is, the content of tantalum element is shown in Table 1.

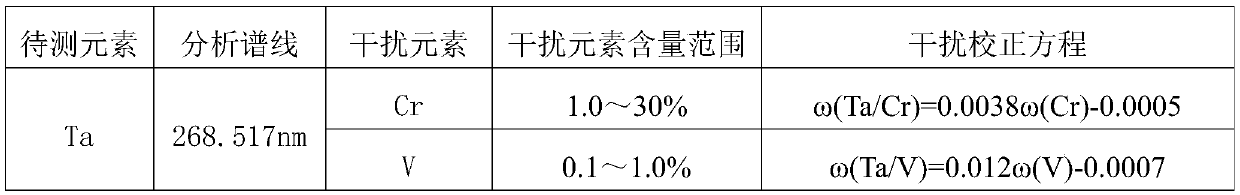

[0043] (2) Establish the interference correction model: according to the actual content range of Cr,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com