Tape for electric wire

A technology of wires and wires, applied in circuits, electrical components, insulated cables, etc., can solve the problems of flame retardancy, low wear resistance, unsuitable use, etc., and achieve the effect of excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] A first embodiment of the tape for electric wires of the present invention will be described below.

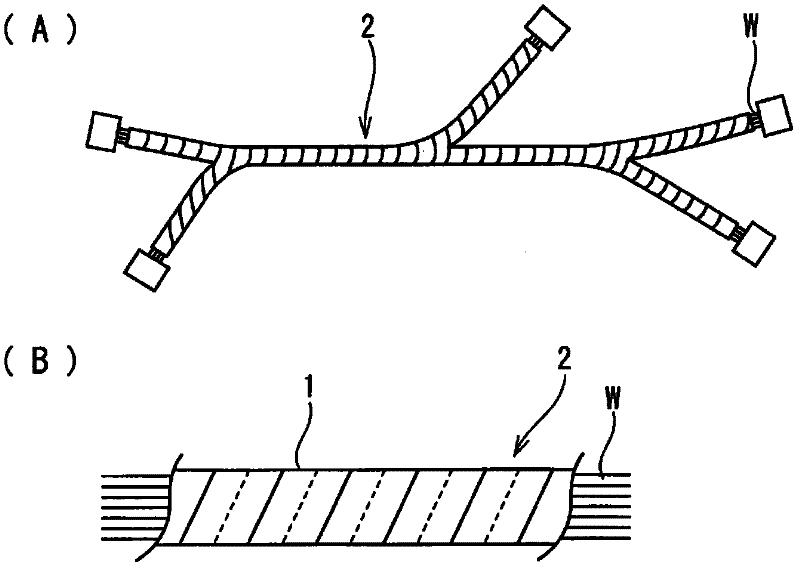

[0041] like figure 1 As shown in (A), the tape 1 for electric wires of the present invention is used for bundling the outer peripheral surface of a wire harness 2 composed of a group of electric wires W wired on an automobile by half-overlapping winding, sparse winding, etc. , the above semi-overlapping winding is as figure 1 (B) Winding with half the width of the tape overlapped as shown. In addition, it can also be used for partial winding in which the electric wire group is partially wound in the longitudinal direction, and it can be used in the same usage place as a conventional general-purpose electric wire tape.

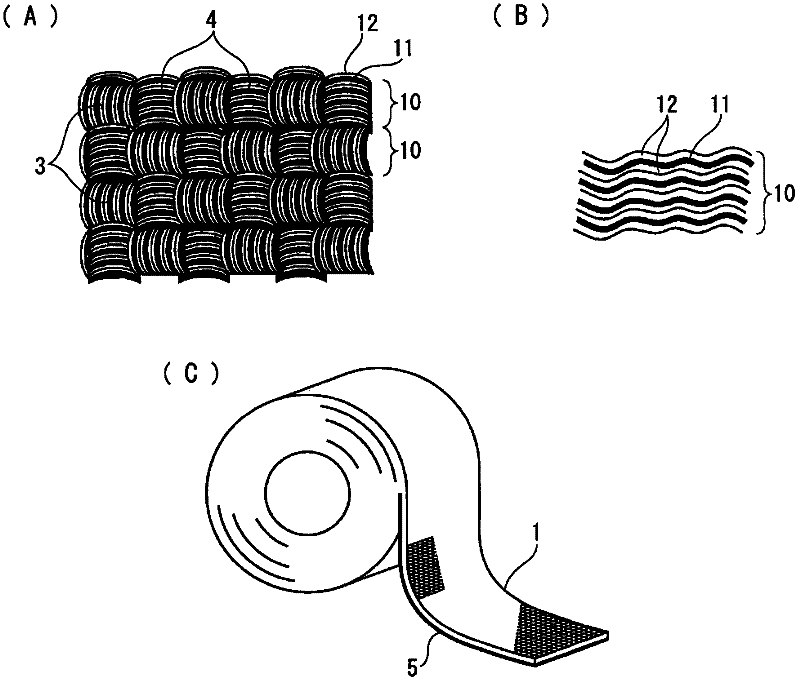

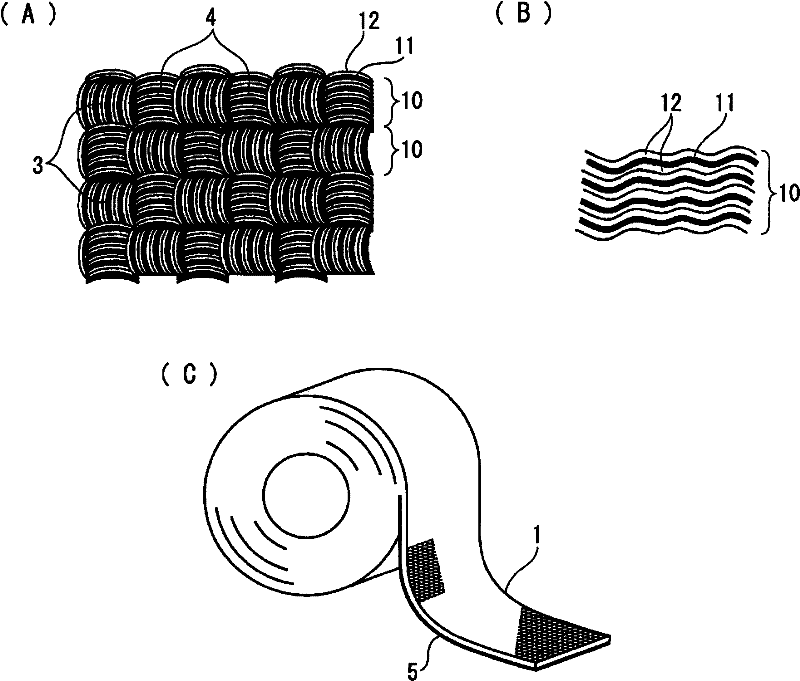

[0042] as in figure 2 As shown enlarged in (A), the above-mentioned belt 1 is composed of a cloth belt formed by weaving longitudinal yarns 3 and weft yarns 4, as figure 2 As shown in the schematic perspective view of (C), the adhesive 5 is applied...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com