Leadless piezoelectric ceramics with bismuth ion replacing modified potassium sodium niobate base and method for preparing same

A potassium-sodium niobate-based, lead-free piezoelectric technology, applied in chemical instruments and methods, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc., can solve the problems of reducing material performance and achieve densification Improvement, the upper limit of sintering temperature is increased, and the effect of avoiding residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

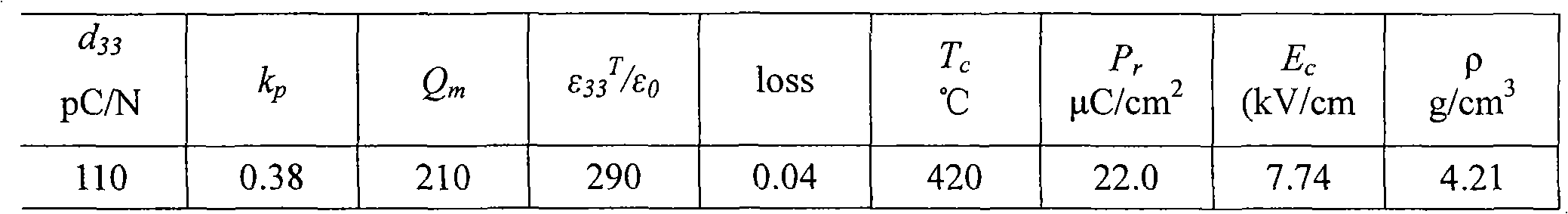

Embodiment 1

[0018] The raw material of present embodiment comprises anhydrous potassium carbonate, anhydrous sodium carbonate, niobium pentoxide and bismuth trioxide, and its stoichiometric ratio is (K 0.5 Na 0.5 )NbO 3 .

[0019] The preparation process of this embodiment is:

[0020] (1) Analytical pure anhydrous potassium carbonate, anhydrous sodium carbonate, and niobium pentoxide were dried at 150°C for 5 hours, and the stoichiometric ratio was (Na 0.5 K 0.5 )NbO 3 ingredients.

[0021] (2) The raw material is ZrO in ethanol 2 The ball is a medium planetary ball mill for 24 hours, dried and ground to obtain a dry powder. Keep the obtained powder in the air at 900°C for 5 hours. The calcined powder is manually ground and calcined again in the air at 900°C for 5 hours. After grinding and sieving, the potassium sodium niobate powder with perovskite phase is obtained.

[0022] (3) Put the pre-burned potassium sodium niobate powder in ethanol for another 12 hours and mix it by pla...

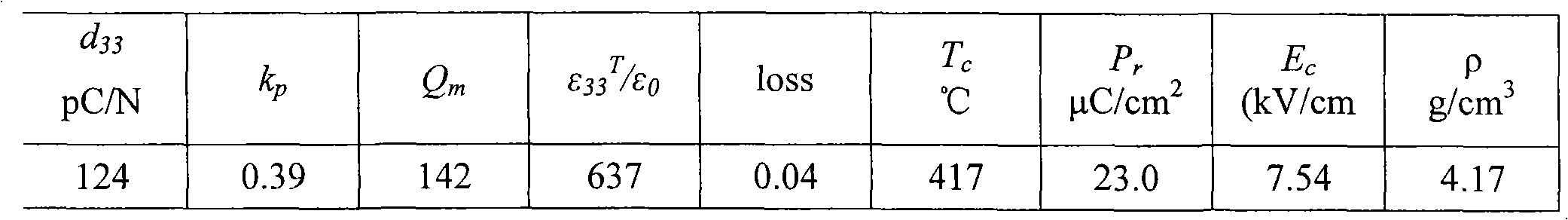

Embodiment 2

[0029] (1) Place analytically pure anhydrous potassium carbonate, anhydrous sodium carbonate, niobium pentoxide and bismuth trioxide at 150°C for 5 hours, and the stoichiometric ratio is (K 0.5 Na 0.5 ) 0.997 Bi 0.001 NbO 3 ingredients.

[0030] (2) The raw material is ZrO in ethanol 2 The ball is a medium planetary ball mill for 24 hours, dried and ground to obtain a dry powder. The obtained powder was kept at 900°C in air for 5 hours, the calcined powder was manually ground and calcined again in 900°C in air for 5 hours, and the powder with perovskite phase was obtained after grinding and sieving.

[0031] (3) The pre-burned powder was mixed again by planetary ball milling in ethanol for 12 hours. After drying the mixed material, polyvinyl alcohol was added to manually grind and granulate (60 mesh sieve), and dry-pressed under 300MPa pressure to form a diameter of 12mm. A wafer blank with a thickness of 1.5mm.

[0032] (4) Slowly raise the temperature of the green bod...

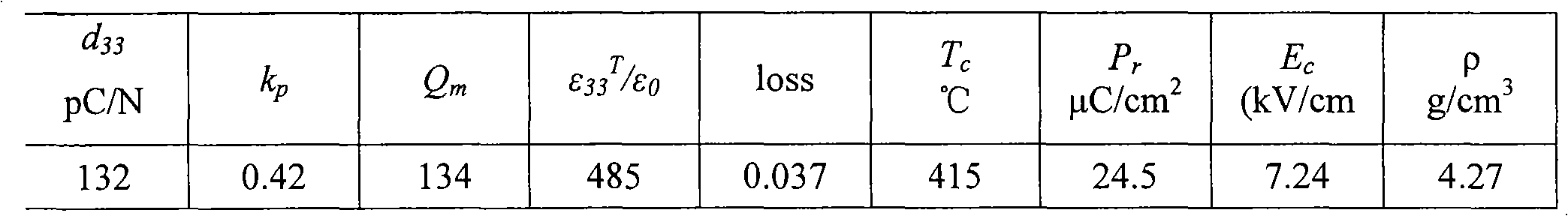

Embodiment 3

[0038] (1) Place analytically pure anhydrous potassium carbonate, anhydrous sodium carbonate, niobium pentoxide and bismuth trioxide at 150°C for 5 hours, and the stoichiometric ratio is (K 0.5 Na 0.5 ) 0.99 1Bi 0.003 NbO 3 ingredients.

[0039] (2) The raw material is ZrO in ethanol 2 The ball is a medium planetary ball mill for 24 hours, dried and ground to obtain a dry powder. The obtained powder was kept at 950°C in air for 5 hours, the calcined powder was manually ground and calcined again in 950°C in air for 5 hours, and the powder with perovskite phase was obtained after grinding and sieving.

[0040] (3) Mix the pre-burned powder in ethanol by planetary ball mill again for 24 hours, add polyvinyl alcohol to manually grind and granulate (60 mesh sieve) after drying the mixed material, and dry press to form a diameter of 12mm under a pressure of 300MPa. A wafer blank with a thickness of 1.5mm.

[0041] (4) Slowly raise the temperature of the green body to 500°C in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com