Tin oxide target material doped with silver as well as preparation method and application thereof

A tin oxide and target technology, which is used in transportation and packaging, metal processing equipment, metal material coating technology, etc., can solve the problems of high surface resistance and reduced electrode ceramic conductivity, target purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

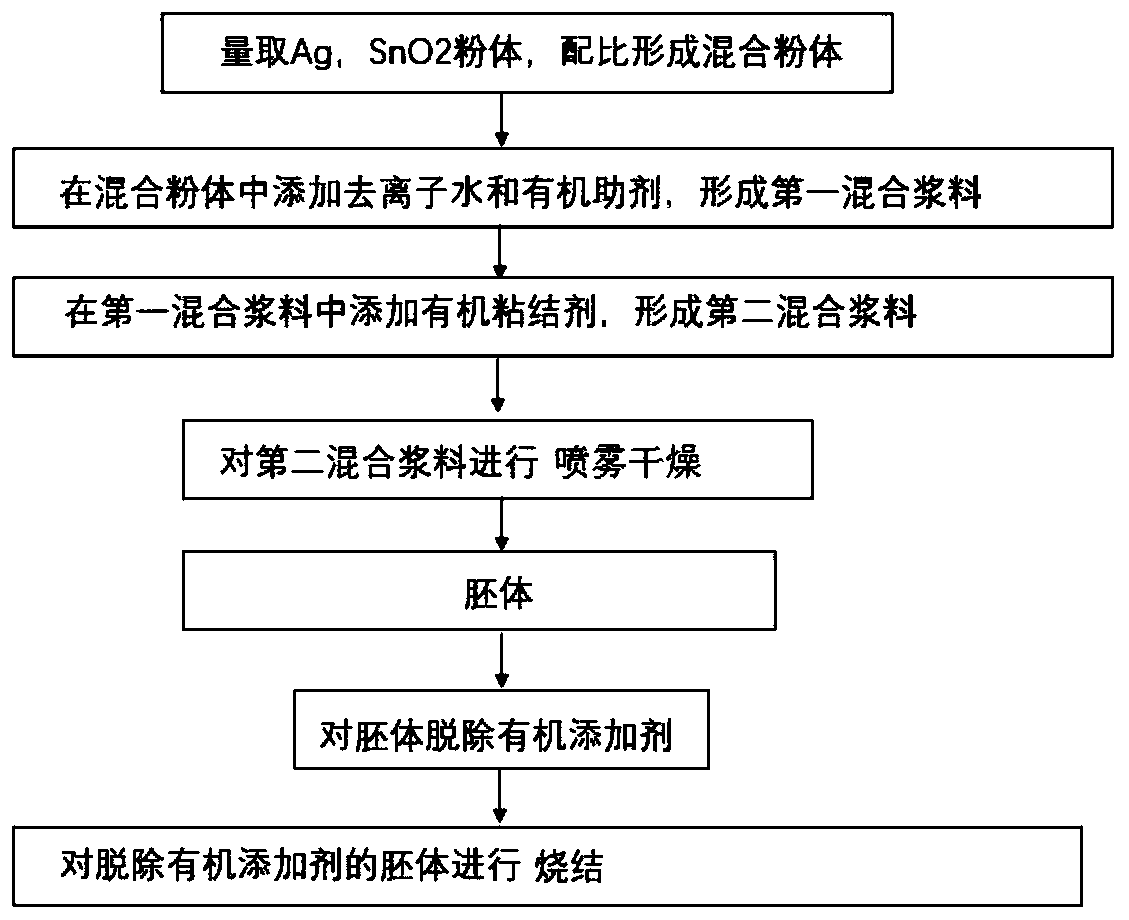

[0028] The present invention also provides a method for preparing a silver-doped tin oxide target described in the above technical solution, comprising the following steps:

[0029] Ag powder and SnO 2 The powders are mixed to obtain a mixed powder;

[0030] Mixing the mixed powder, water and triethanolamine to obtain the first mixed slurry;

[0031] mixing the first mixed slurry with polyvinyl alcohol to obtain a second mixed slurry;

[0032] Spray drying the second mixed slurry to obtain dry powder;

[0033] performing cold isostatic pressing on the dry powder in a target mold to obtain an embryo body;

[0034] The green body is kept warm and sintered in sequence to obtain the silver-doped tin oxide target.

[0035] The present invention combines Ag powder and SnO 2 The powders are mixed to obtain a mixed powder. In the present invention, there is no special limitation on the specific mixing method, and a mixing method well known to those skilled in the art can be used...

Embodiment 1

[0054] Step 1: Measure 50g of Ag powder (particle size: 20nm) with a purity of 99.99% and SnO with a purity of 99.99% 2 powder (particle size is 10nm), and Ag powder and SnO 2 The mass ratio of the powder is 1:50 for mixing to form a mixed powder;

[0055] Step 2: Add 400 mL of deionized water to the mixed powder, and use 0.3wt% (based on the mass of the mixed powder) triethanolamine as an organic additive, and ball mill for 15 hours to form the first mixed slurry;

[0056] Step 3: Add 1wt% (based on the mass of mixed powder) polyvinyl alcohol as an organic binder to the first mixed slurry, and grind for 2 hours to form a second mixed slurry;

[0057] Step 4: Spray drying and granulating the second mixed slurry, so that the particle size of the powder after drying is 40 μm;

[0058] Step 5: Filling the dried powder into the target mold, and subjecting it to cold isostatic pressing (CIP) at 200 MPa for 3 minutes to obtain an embryo body with a relative density greater than 50...

Embodiment 2

[0064] Step 1: Measure 50g of Ag powder (particle size: 30nm) with a purity of 99.99% and SnO with a purity of 99.99% 2 powder (particle size is 15nm), and with Ag powder and SnO 2 The mass ratio of the powder is 1:100 for mixing to form a mixed powder;

[0065] Step 2: Add 600 mL of deionized water to the mixed powder, and use 0.6 wt % (based on the mass of the mixed powder) of triethanolamine as an organic additive, and ball mill for 24 hours to form the first mixed slurry;

[0066] Step 3: Add 2wt% (based on the mass of mixed powder) polyvinyl alcohol as an organic binder to the first mixed slurry, and grind for 3 hours to form a second mixed slurry;

[0067] Step 4: Spray drying and granulating the second mixed slurry, so that the particle size of the powder after drying is 100 μm;

[0068] Step 5: Filling the dried powder into the target mold, and subjecting it to cold isostatic pressing (CIP) at 300 MPa for 4 minutes to obtain an embryo body with a relative density gre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Carrier concentration | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com