Method for manufacturing environment-friendly medium density fiberboard using plant straws instead of partial wood fibers

A plant straw, environmentally friendly technology, applied in fiber raw materials, fiber raw material processing, application and other directions, can solve the problems of difficult gluing, poor product dimensional stability, high water absorption thickness expansion rate, saving wood usage, promoting technological innovation, The effect of improving environmental performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

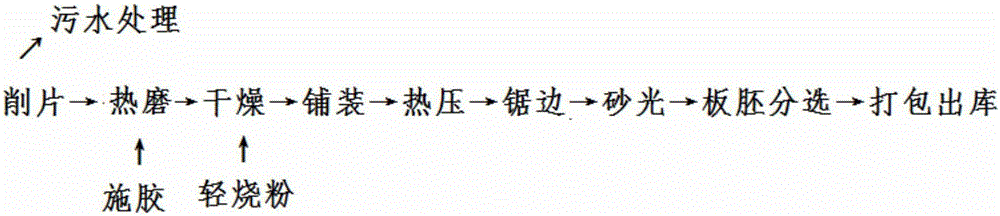

[0036] Process flow of the present invention such as figure 1 Shown, the present invention is specifically described below according to accompanying drawing;

[0037] Straw is the general term for the stems and leaves (ears) of mature crops. It usually refers to the remaining part of wheat, rice, corn, cotton, sugarcane and other crops (usually coarse grains) after harvesting seeds, and is a renewable biological resource with multiple purposes. It is characterized by high crude fiber content (30%-40%), and contains cellulose, lignin, etc., and can be used as a building material at the same time.

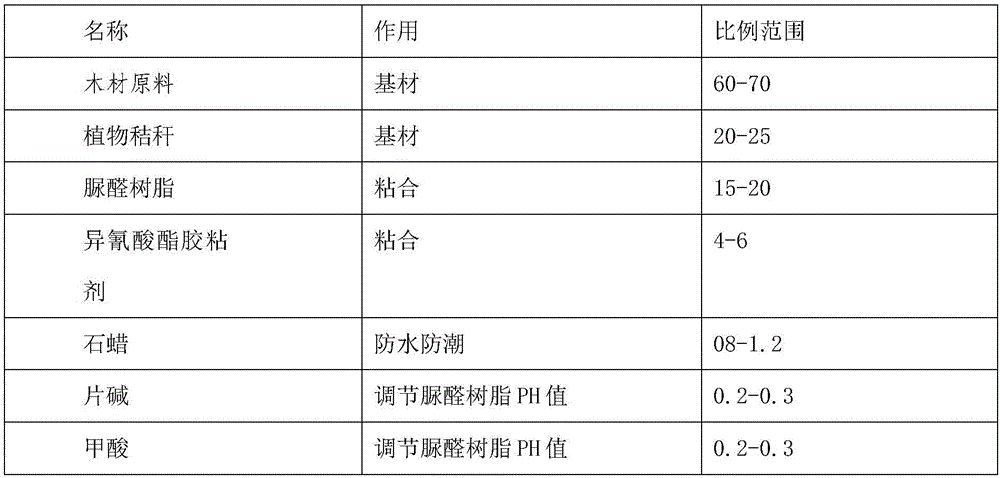

[0038] 1, main component of the present invention (by weight fraction ratio) is as shown in table 1

[0039] Table 1

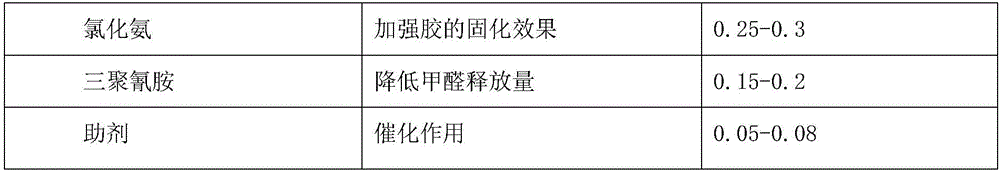

[0040]

[0041]

[0042] 2. Technical methods

[0043] This project is a method of using plant straw instead of some wood fibers to make environmentally friendly medium density boards. By using environmentally friendly adhesives and strictly controlling the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com