Method for preparing modified urea-formaldehyde resin

A urea-formaldehyde resin and modification technology, which is applied in the field of preparation of modified urea-formaldehyde resin, can solve the problems of low free formaldehyde content, high free formaldehyde content, and failure to meet environmental protection requirements, and achieve the goal of reducing formaldehyde emission and free formaldehyde content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

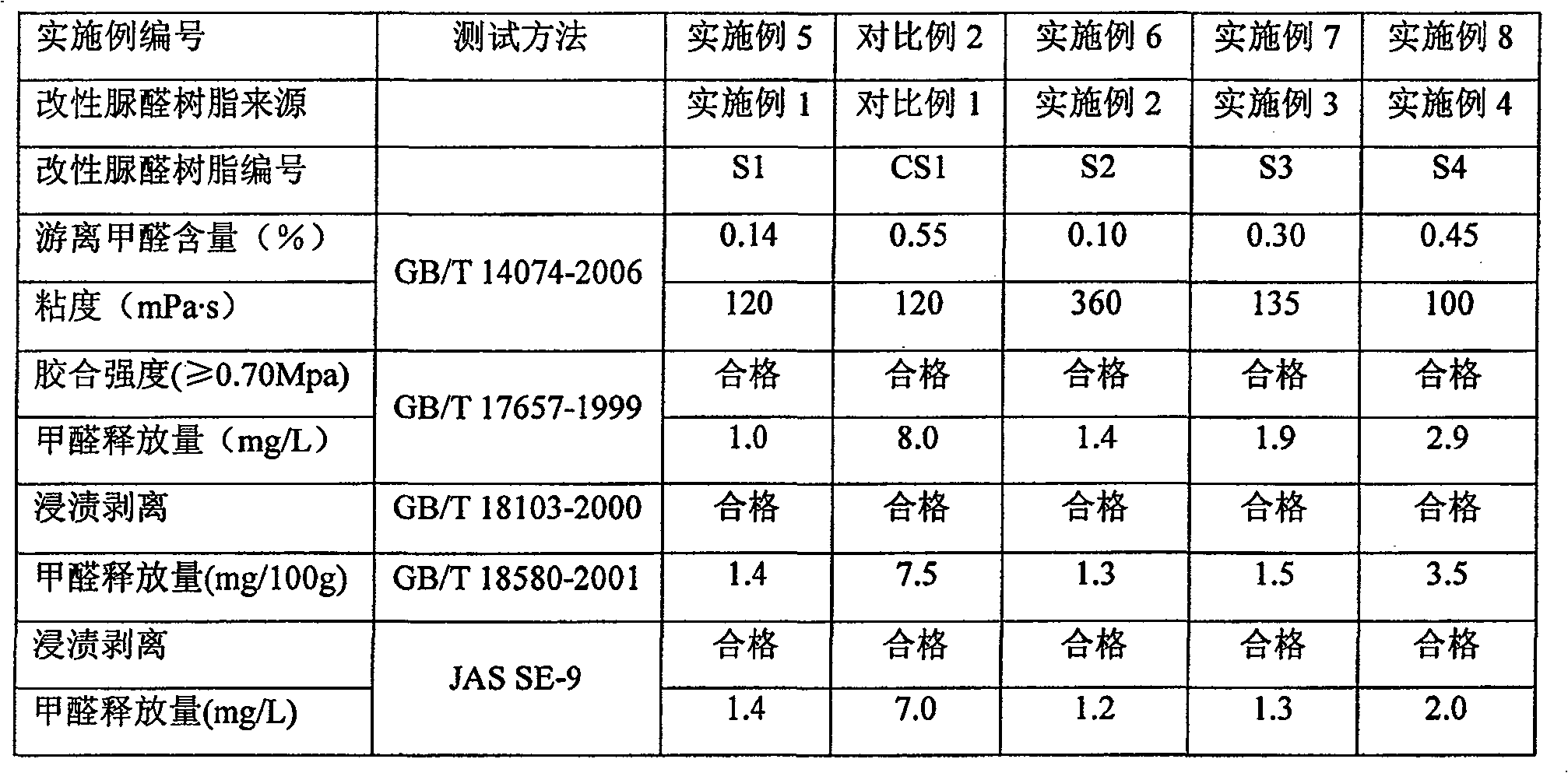

Examples

preparation example Construction

[0014] According to a preferred embodiment of the present invention, the preparation method of the modified urea-formaldehyde resin provided by the present invention includes the following steps: adjust a part of the formaldehyde solution to pH 8-9, and heat it to 40-70°C, then add urea, and the addition is completed Then raise the temperature to 80-95°C, and stir the reaction at this temperature for 10-30 minutes, then adjust the temperature to no more than 85°C, adjust the pH value to 4-6, and continue to stir the reaction until the obtained product is mixed with water The resistance is 1.0-2.5 times; then lower the temperature to 40-60°C, adjust the pH to 8-9, add another part of formaldehyde or its solution, and add the first batch of urea-formaldehyde resin to modify the temperature and pH value. neutralizing agent, adjust the reaction temperature to 75-90°C, pH value to 9.0-9.5, stir the reaction until the water miscibility of the product is 1.0-2.5 times, then lower the ...

Embodiment 1

[0018] This example is used to illustrate the preparation method of the modified urea-formaldehyde resin provided by the present invention.

[0019] 416.67 grams of concentration is 36% formalin (formaldehyde is 5 moles) to join in the 1000 milliliters of four-neck flasks with stirrer, condenser and thermometer, with concentration is the sodium hydroxide aqueous solution of 20% by weight. The formalin was adjusted to pH 8.2 and heated to 50°C, then 151.67 g of urea was added with stirring, the temperature was raised to 90°C and stirred at this temperature for 15 minutes. Then the reaction temperature is reduced to 85°C, and the pH value of the reaction system is adjusted to 5.0 with a concentration of 10% by weight aqueous formic acid, and the stirring reaction is continued until the water miscibility of the product obtained in the flask is 2.5 times, and then cooled to 60°C. The sodium hydroxide solution that is 20% by weight is that the pH value of reaction system is adjuste...

Embodiment 2

[0024] This example is used to illustrate the preparation method of the modified urea-formaldehyde resin provided by the present invention.

[0025] 416.67 grams of concentration is 36% formalin (formaldehyde is 5 moles) to join in the 1000 milliliters of four-neck flasks with stirrer, condenser and thermometer, with concentration is the sodium hydroxide aqueous solution of 20% by weight. The formalin was adjusted to pH 8.2 and heated to 50°C, then 151.67 g of urea was added with stirring, the temperature was raised to 90°C and stirred at this temperature for 15 minutes. Then the reaction temperature is reduced to 85°C, and the pH value of the reaction system is adjusted to 5.0 with a concentration of 10% by weight aqueous formic acid, and the stirring reaction is continued until the water miscibility of the product obtained in the flask is 1.0 times, and then cooled to 60°C. Adding 104.69 grams of formalin with a concentration of 36% after the pH value of the reaction system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com