Production method for damp-proof full-eucalyptus laminated wood veneer

A production method and veneer technology, which are used in the joining of wooden veneers, veneer presses, plywood presses, etc., can solve the problem of increased sizing, difficulty in releasing formaldehyde, and unacceptable costs. and other problems, to achieve the effect of less residue, improved moisture resistance and less formaldehyde emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

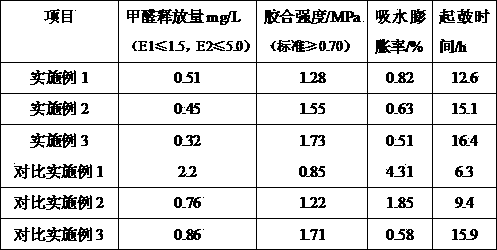

Examples

Embodiment 1

[0012] First prepare the adhesive, add formaldehyde to the reaction kettle, adjust the pH value to 2-2.5 with formic acid, add polyvinyl alcohol with 0.5-0.6% formaldehyde weight, add urea with 10% formaldehyde weight, heat up to 50°C, and keep warm for reaction 30min, adjust the pH value of the reaction solution to 8-8.5, add urea with 25% formaldehyde weight, add melamine with 1% formaldehyde weight, heat up to 90-95°C, keep warm for 90min, check after the reaction, if formaldehyde is still contained, Add appropriate amount of urea or melamine to continue the reaction until the detected formaldehyde content is less than 5 mg / L, and add alkali to adjust the pH value of the reaction end solution to 7.2-7.5.

[0013] Manually select eucalyptus veneers of the same size, apply the above-mentioned adhesive, the amount of glue applied is 250g / ㎡, and the billets are assembled in 3 layers. Hot pressing, the temperature is 120°C, and the pressure is 1.5MPa; 4-6 hours of standing in a ...

Embodiment 2

[0015] Manually select eucalyptus veneers of the same size, apply the adhesive of Example 1, the glue amount is 280g / ㎡, form a blank (7 layers), cold press for the first time, the temperature is normal temperature, and the pressure is 0.9MPa , the first hot pressing, the temperature is 120-125°C, and the pressure is 1.8MPa; 80-90°C constant temperature room for 4-6 hours, the constant temperature room is ventilated and naturally cooled, heat dissipation and health care for 3-4 hours; the second cold pressing , the temperature is normal temperature, the pressure is 1.0MPa, the second hot pressing, the temperature is 115-120°C, and the pressure is 1.8MPa; the second time is to keep in a constant temperature room, the temperature is 80-90°C, and the time is 90-120min , the constant temperature room is ventilated to cool down naturally, heat dissipation and health preservation for 3-4 hours; the third cold pressing is at room temperature and the pressure is 1.0MPa, the third hot pr...

Embodiment 3

[0017] Manually select eucalyptus veneers of the same size, apply the adhesive of Example 1, the glue amount is 300g / ㎡, form a blank (11 layers), the first cold pressing, the temperature is normal temperature, and the pressure is 1.0MPa , the first hot pressing, the temperature is 120-125°C, and the pressure is 1.6MPa; 80-90°C constant temperature room for 4-6 hours, the constant temperature room is ventilated to cool down naturally, heat dissipation and health care for 3-4 hours; the second cold pressing , the temperature is normal temperature, the pressure is 1.0MPa, the second hot pressing, the temperature is 115-120°C, and the pressure is 2.0MPa; the second time is to keep in a constant temperature room, the temperature is 80-90°C, and the time is 90-120min , the constant temperature room is ventilated to cool down naturally, heat dissipation and health preservation for 3-4 hours; the third cold pressing is at room temperature and the pressure is 1.0MPa, the third hot press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com