A kind of road asphalt modifier and preparation method thereof

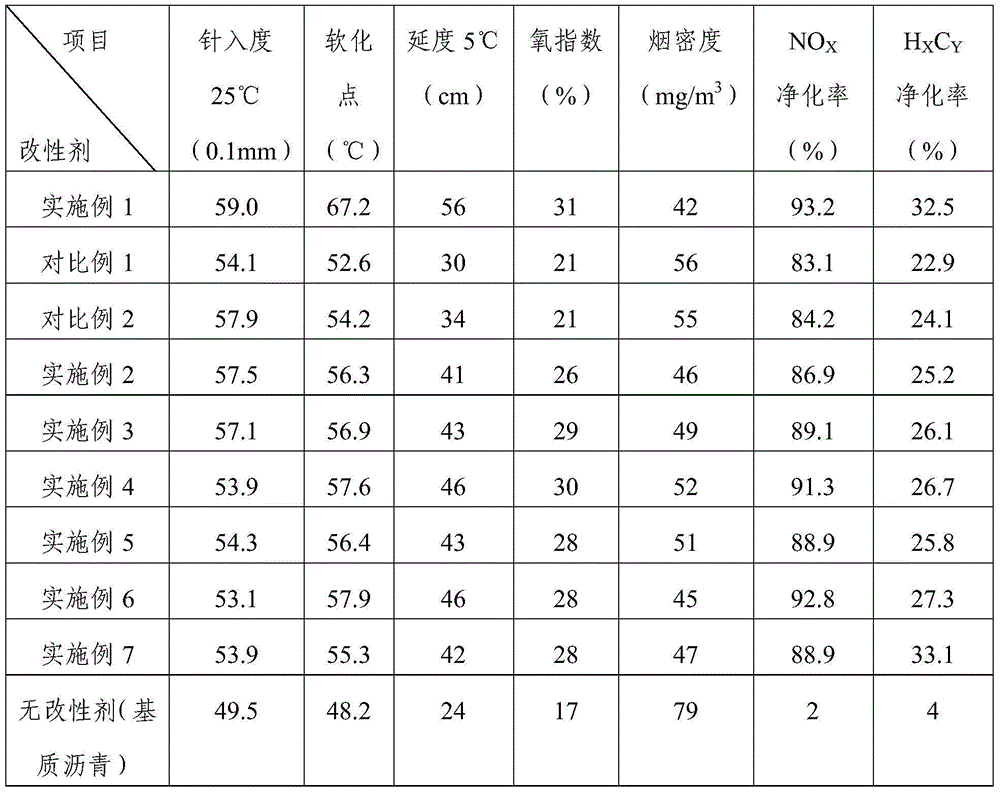

A technology of road asphalt and modifier, applied in the field of asphalt modifier, can solve the problems of poor dispersibility of modifier and single improvement performance, and achieve the effects of good dispersion performance, non-toxic environmental protection cost, and good thermal stability performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The road asphalt modifier of the present embodiment is mainly made of the following raw materials in parts by weight: mullite powder 12g, cordierite powder 10g, fatty alcohol polyoxyethylene ether AEO-32g, polyacrylic acid 3g; The fineness is 3000 mesh, and the fineness of the cordierite powder is 3000 mesh.

[0023] The preparation method of the road asphalt modifier of the present embodiment is:

[0024] Step 1. Mix and stir mullite powder and cordierite powder evenly to obtain a mixture, add the mixture to fatty alcohol polyoxyethylene ether diluted with absolute ethanol, and stir for 3 hours at room temperature to obtain a surface-treated mixture; the anhydrous The mass of ethanol is 20g;

[0025] Step 2: adding polyacrylic acid to the surface-treated mixture in Step 1, and stirring evenly to obtain a road asphalt modifier.

Embodiment 2

[0031] The road asphalt modifier of the present embodiment is mainly made of the following raw materials in parts by weight: mullite powder 4g, cordierite powder 14g, fatty alcohol polyoxyethylene ether AEO-31g, polyacrylic acid 1g; The fineness is 1000 mesh, and the fineness of the cordierite powder is 2000 mesh.

[0032] The preparation method of the road asphalt modifier of the present embodiment is:

[0033] Step 1. Mix and stir mullite powder and cordierite powder evenly to obtain a mixture, add the mixture to fatty alcohol polyoxyethylene ether diluted with absolute ethanol, and stir for 4 hours at room temperature to obtain a surface-treated mixture; the anhydrous The mass of ethanol is 9g;

[0034] Step 2: adding polyacrylic acid to the surface-treated mixture in Step 1, and stirring evenly to obtain a road asphalt modifier.

Embodiment 3

[0036] The road asphalt modifier of the present embodiment is mainly made of the following raw materials in parts by weight: 8 jin of mullite powder, 10 jin of cordierite powder, 2 jin of fatty alcohol polyoxyethylene ether AEO-52 jin, and 4 jin of polyacrylic acid; The fineness of the mullite powder is 2000 mesh, and the fineness of the cordierite powder is 1000 mesh.

[0037] The preparation method of the road asphalt modifier of the present embodiment is:

[0038] Step 1. Mix and stir mullite powder and cordierite powder evenly to obtain a mixture, add the mixture to fatty alcohol polyoxyethylene ether diluted with absolute ethanol, and stir for 3.5 hours at room temperature to obtain a surface-treated mixture; The mass of water ethanol is 28 jin;

[0039] Step 2: adding polyacrylic acid to the surface-treated mixture in Step 1, and stirring evenly to obtain a road asphalt modifier.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com