Styrene-butadiene rubber composite material for high-performance tire and preparation method thereof

A technology of styrene-butadiene rubber and composite materials, applied in special tires, tire parts, transportation and packaging, etc., can solve the problem of not meeting the demand, and achieve the effect of reducing toxic gas, increasing adhesion and increasing compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A kind of styrene-butadiene rubber compound material for high-performance tires, its raw material comprises by weight parts:

[0023] 85 parts of powdered styrene-butadiene rubber, 12 parts of nano-loess powder, 15 parts of hydroxyl-terminated liquid styrene-butadiene rubber, 5.5 parts of montmorillonite, 18 parts of aluminum hydroxide, 22 parts of calcium sulfate whiskers, 11 parts of furnace carbon black, sulfur 0.9 parts, accelerator NS 0.75 parts, 1,3-diphenylguanidine 0.33 parts, zinc oxide 1.2 parts, stearic acid 2.1 parts, titanate coupling agent 2.7 parts;

[0024] Among them, the content of bound styrene in powdered styrene-butadiene rubber is 28.2%, and the Mooney viscosity (ML1+4, 100°C) is 55; the content of bound styrene in hydroxyl-terminated liquid styrene-butadiene rubber is 24.4%, and the viscosity is 16Pa.s.

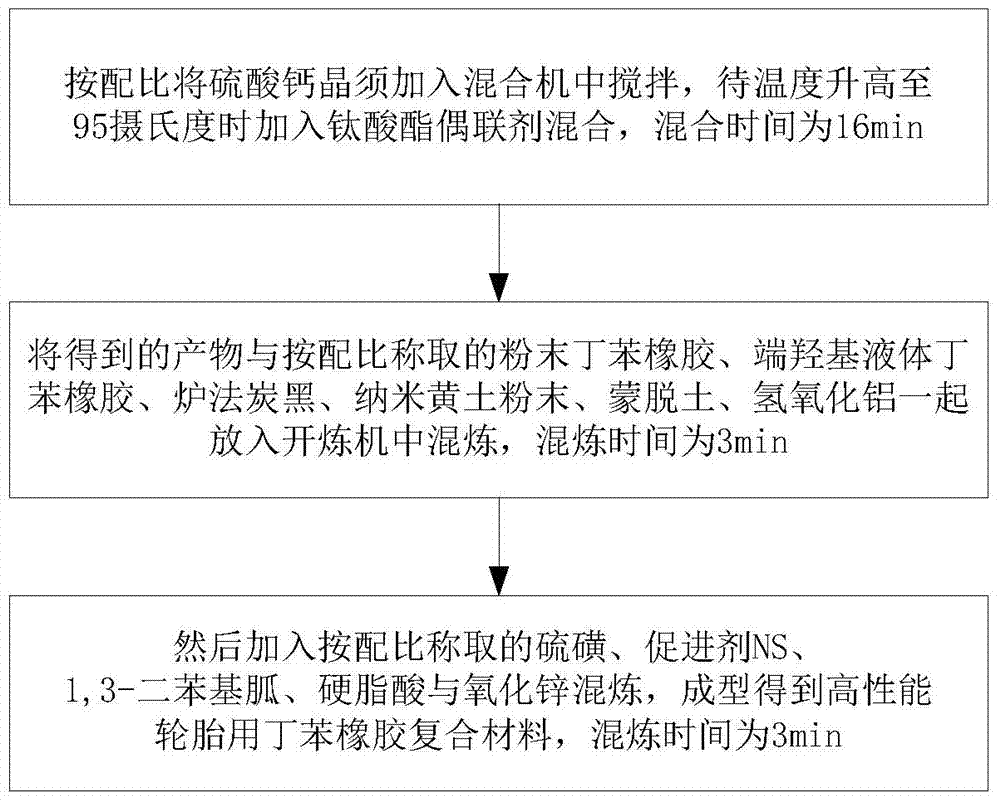

[0025] Such as figure 1 as shown, figure 1 It is a flow chart of the preparation process of a styrene-butadiene rubber composite material for ...

Embodiment 2

[0033] A kind of styrene-butadiene rubber compound material for high-performance tires, its raw material comprises by weight parts:

[0034] 82 parts of powdered styrene-butadiene rubber, 9 parts of nano-loess powder, 19 parts of hydroxyl-terminated liquid styrene-butadiene rubber, 6 parts of montmorillonite, 14 parts of aluminum hydroxide, 21 parts of calcium sulfate whiskers, 9 parts of furnace carbon black, sulfur 0.72 parts, 0.75 parts of accelerator NS, 0.45 parts of 1,3-diphenylguanidine, 1.2 parts of zinc oxide, 1.7 parts of stearic acid, 2.2 parts of titanate coupling agent;

[0035] Among them, the content of bound styrene in powdered styrene-butadiene rubber is 29%, and the Mooney viscosity (ML1+4, 100°C) is 55; the content of bound styrene in hydroxyl-terminated liquid styrene-butadiene rubber is 24.1%, and the viscosity is 15.3Pa.s .

[0036] A kind of preparation method according to above-mentioned styrene-butadiene rubber composite material for high-performance ...

Embodiment 3

[0043] A kind of styrene-butadiene rubber compound material for high-performance tires, its raw material comprises by weight parts:

[0044] 88 parts of powdered styrene-butadiene rubber, 12 parts of nano-loess powder, 19 parts of hydroxyl-terminated liquid styrene-butadiene rubber, 6 parts of montmorillonite, 18 parts of aluminum hydroxide, 21 parts of calcium sulfate whiskers, 9 parts of furnace carbon black, sulfur 0.75 parts, accelerator NS 0.83 parts, 1,3-diphenylguanidine 0.41 parts, zinc oxide 1.6 parts, stearic acid 2.2 parts, titanate coupling agent 2.8 parts;

[0045] Among them, the content of bound styrene in powdered styrene-butadiene rubber is 26%, and the Mooney viscosity (ML1+4, 100°C) is 55; the content of bound styrene in hydroxyl-terminated liquid styrene-butadiene rubber is 25.2%, and the viscosity is 14.5Pa.s .

[0046] A kind of preparation method according to above-mentioned styrene-butadiene rubber composite material for high-performance tires, comprises...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com