Decorating process for inlaying metal to ceramic

A technology of inlaying metal and craftsmanship, which is applied in the direction of decorative arts and crafts for producing decorative surface effects, etc. It can solve the problems of metal ornaments falling off, achieve the effect of ensuring the overall decorative effect, enhancing the ornamental value and collection value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The process of inlaying metal ornaments on ceramic products prepared by manual casting process is as follows:

[0036]a. Prepare semi-finished ceramic products by manual drawing;

[0037] b. draw a sketch on the surface of the semi-finished ceramic product;

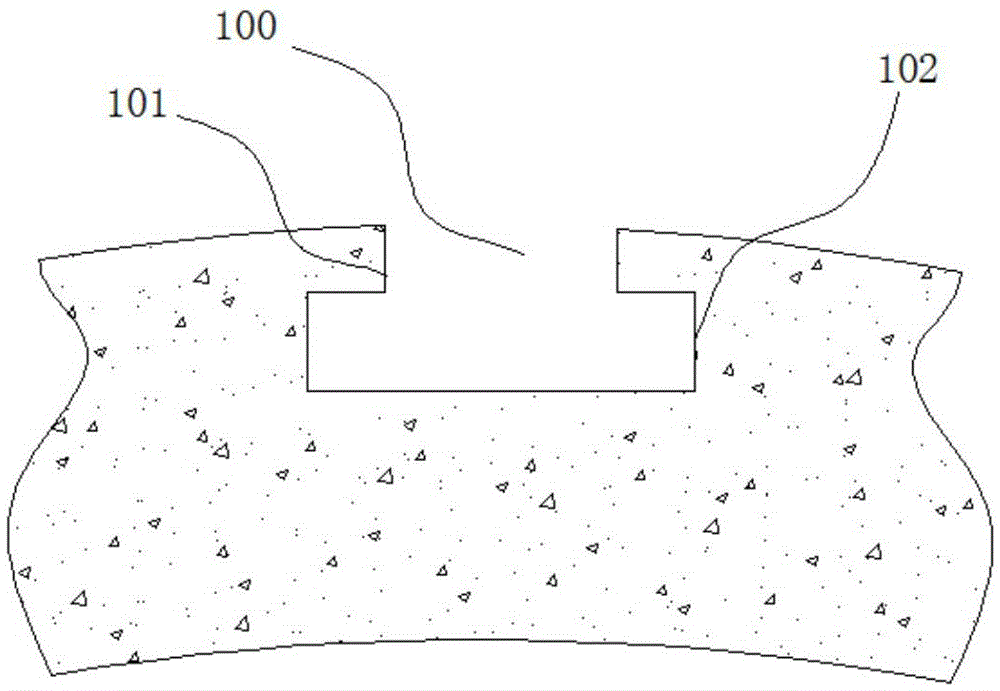

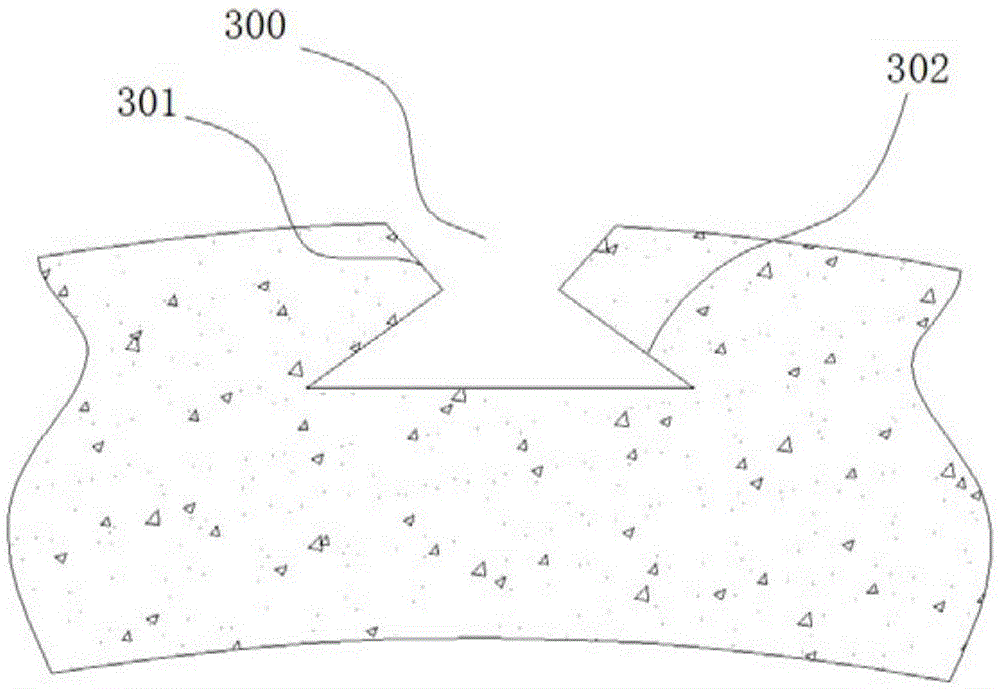

[0038] c. On the surface of the semi-finished ceramic product, a groove is carved with a knife according to the drawing, and the groove includes a first groove part, and a second groove part is opened at the bottom of the first groove part, and the second groove part is opened at the bottom of the first groove part. The groove width of the groove bottom of the second groove part is greater than the groove width of the groove bottom of the first groove part;

[0039] d. putting the semi-finished ceramic product prepared in step c into a kiln to continue firing to form a ceramic product;

[0040] e. Processing the metal ornaments into metal wires or metal sheets;

[0041] f. Taking the ceramic product out of the k...

Embodiment 2

[0055] Embodiment 2 is described with reference to Embodiment 1. The same steps use the same process. The difference between this embodiment and Embodiment 1 is that the ceramic product described in Embodiment 1 is formed by manual drawing, and this embodiment adopts mechanical molding, resulting in the manufacturing method of the groove. Also different.

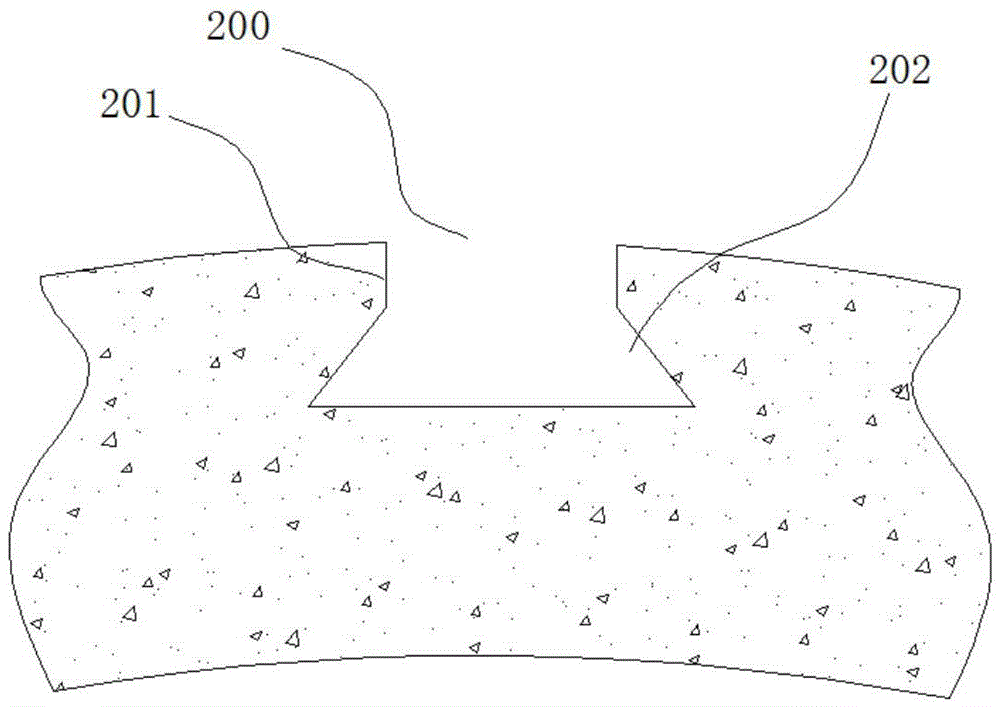

[0056] The process of making grooves on ceramic products prepared by machine-molding process is as follows:

[0057] a. Ceramic products are prepared by mechanical molding process;

[0058] b. draw a sketch on the surface of the ceramic product;

[0059] c. On the surface of the ceramic product, a groove is etched with a laser according to the drawing, and the groove includes a first groove portion, and a second groove portion is opened at the bottom of the first groove portion, and the second groove portion The groove width of the groove bottom is larger than the groove width of the groove bottom of the first groove part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com