Marble composite board processing technique

A production process, marble slab technology, applied in the field of building decoration materials, can solve the problems of expensive marble materials, easy aging, easy deformation, etc., and achieve the effect of protecting decorative performance, low cost, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

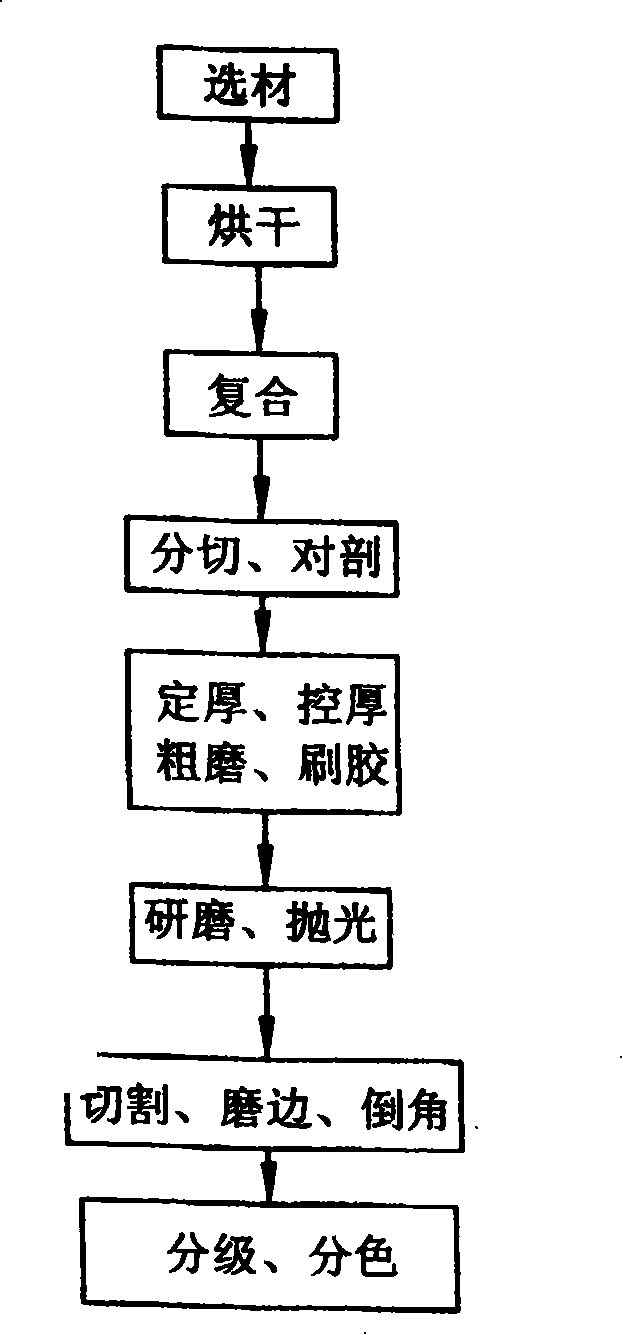

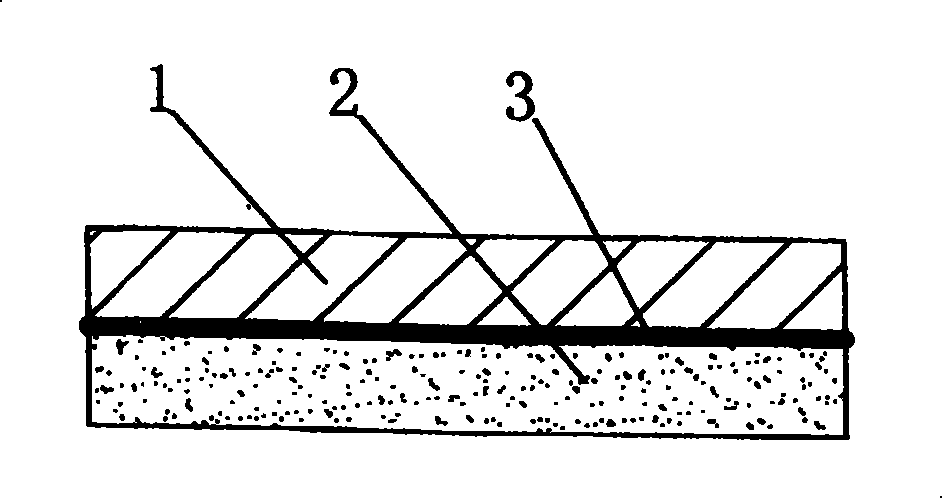

[0012] Such as figure 1 , figure 2 As shown, the production process of marble composite board: (1) Material selection: first select high-grade marble 1 variety, and process it into a board with a thickness of 15-30mm and a size 5-10mm larger than the finished product specification through professional equipment. Secondly, choose the composite carrier blank 2 tiles, glass, aluminum honeycomb panel, aluminum-plastic panel, and process it into a specification panel that is 5-10mm larger than the finished product specification through professional equipment. (2) Drying: the marble 1 is subjected to thickness determination, delustering, and then de-netting treatment. It is discharged on the automatic conveying line according to a suitable ratio, and after being cleaned by brushes, rinsed with clean water, and blown by a fan, it enters the automatic rolling kiln for drying. The temperature of the rolling kiln is 40°C to 90°C. The platform should check the smoothness of the compos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com