Unit curtain wall of composite bearing structure

A unit curtain wall and bearing structure technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of high engineering cost and large building energy consumption, and achieve the effect of reducing mechanical performance requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

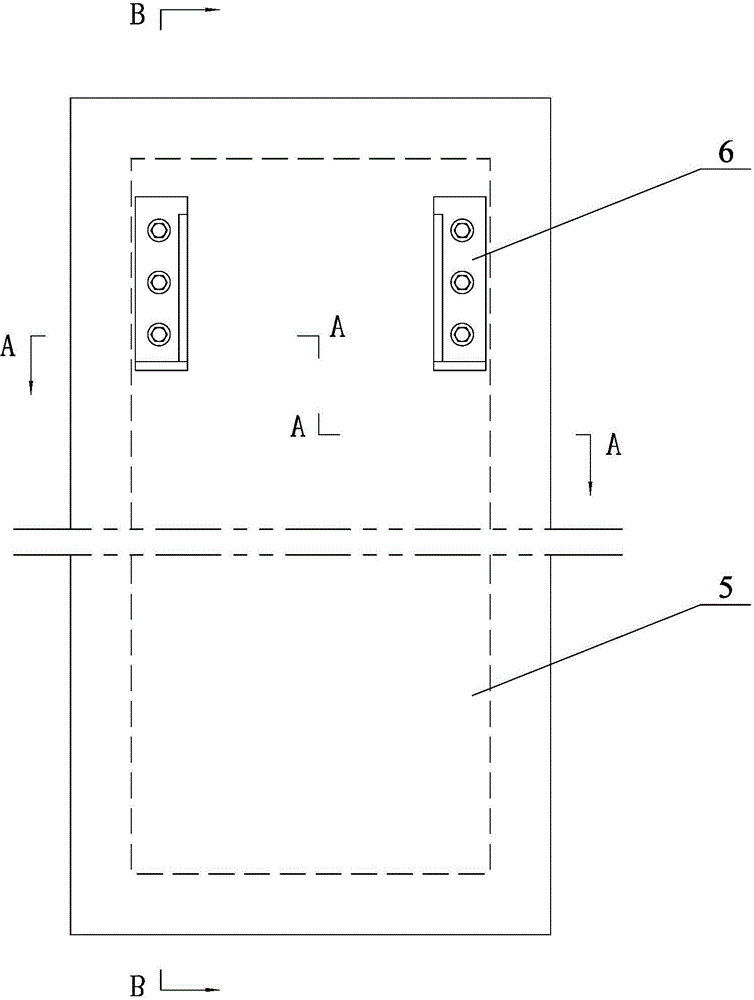

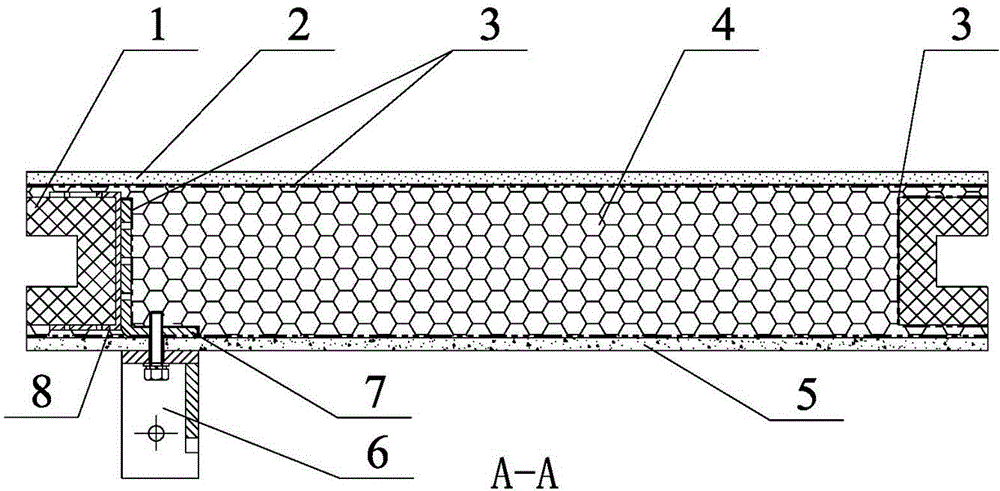

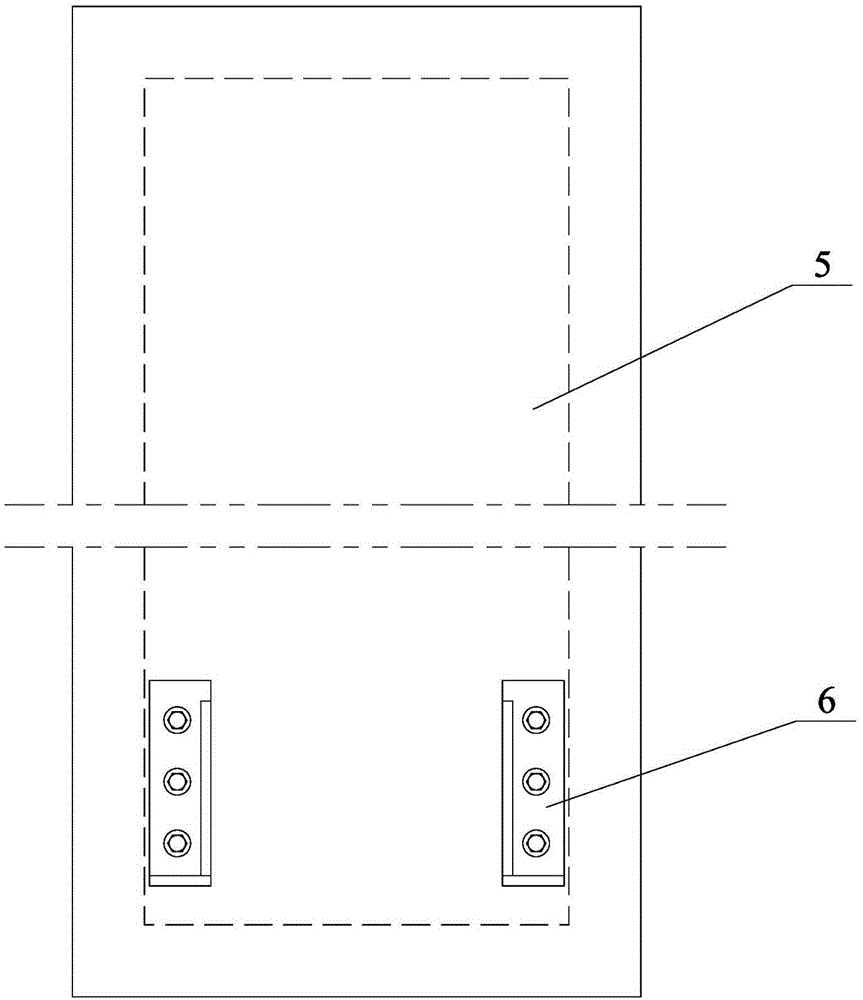

[0029] according to Figure 1-11 The specific structure of the present invention will be described in detail. The combined bearing structure unit curtain wall includes a unit plate, a connecting component for assembling the unit plate and the main body of the building, and the like. Among them, the unit plate uses the core material 4 and the adhesive layer 3 to combine the inner panel 5, the outer panel 2 and the frame body 1 with the interface to form an overall structure with a skin effect. The connection assembly includes the embedded parts of the panel, the panel connector 6, the main structure connector 9, the sealing rubber strip 10, the panel insertion positioning block 11 or the panel insertion positioning frame 12 and the like. And according to the sealing requirements, the edge banding profile 13 of special section can be added to realize the sealing of the plate joints (such as Image 6 shown). The sealing rubber strips 10 of various shapes are mainly used for th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com