Patents

Literature

82results about How to "With decorative function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

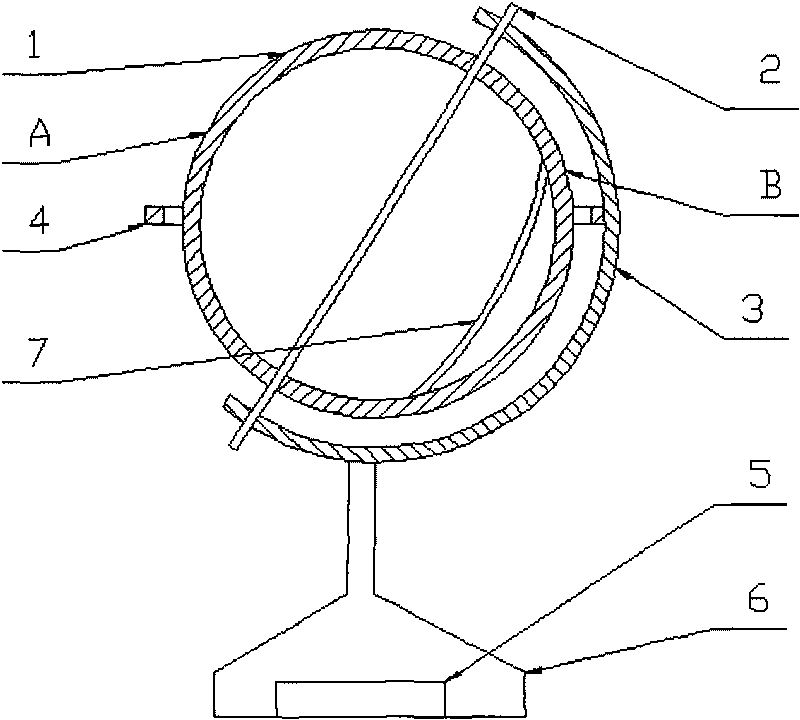

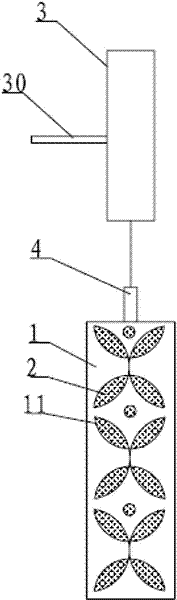

Globe type wireless signal receiving antenna

InactiveCN101719589AWith signal receptionWith processing functionRadiating elements structural formsMetallic materialsTreatment system

The invention relates to a globe type wireless signal receiving antenna. In theory, the traditional wireless signal receiving and processing technology is adopted, and the appearance of the wireless signal receiving antenna is similar to a globe. A wireless signal receiving and processing system is arranged in a base of the globe, and the globe comprises a polar shaft, a bracket and an equator, or the sphere of the globe is designed into a hidden antenna. When the wireless signal receiving antenna is used as a satellite signal receiving antenna, a satellite signal gathering pan can be arranged in the sphere of the globe, wherein the sphere of the globe is made of a nonmetallic material. In addition, when the wireless signal receiving antenna is used as the satellite signal receiving antenna as required, the sphere of the globe can also be divided into two parts which are respectively made of a metallic material and the nonmetallic material, wherein the part made of the metallic material is used as the satellite signal gathering pan. The wireless signal receiving device has beautification and decoration effects.

Owner:张鹏飞

Anion coating material and preparation method thereof

ActiveCN102504662AQuality improvementPollution is quickly eliminatedCoatingsPigment physical treatmentIndoor air qualityAcrylic resin

The invention relates to a coating material and a preparation method thereof, in particular to an anion coating material and a preparation method thereof, and mainly solves the technical problem that the anion material in the conventional anion coating material is not pretreated. The invention adopts the technical scheme that the anion coating material comprises the following raw materials by weight percentage: acrylic resin 20 to 30 percent, titanium dioxide 10 to 15 percent, calcium carbonate 15 to 20 percent, composite anion material 1 to 4 percent, zinc oxide1 to 3 percent, talcum powder 7 to 11 percent, ethylene glycol 1 to 2 percent, sodium tripolyphosphate 6 to 10 percent, water 21 to 25 percent, and assistant 0.3 to 0.7 percent. The anion coating material not only can be used for decoration, but also can release anions continuously per minute, and can effectively improve the quality of indoor air and remove harmful pollutants in the indoor air, such as formaldehyde and the like.

Owner:杨震源 +1

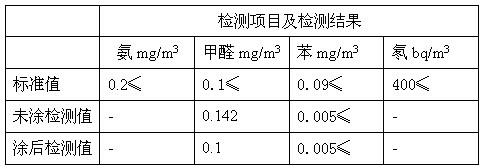

Glazed ceramic decorative wall tile and manufacturing method thereof

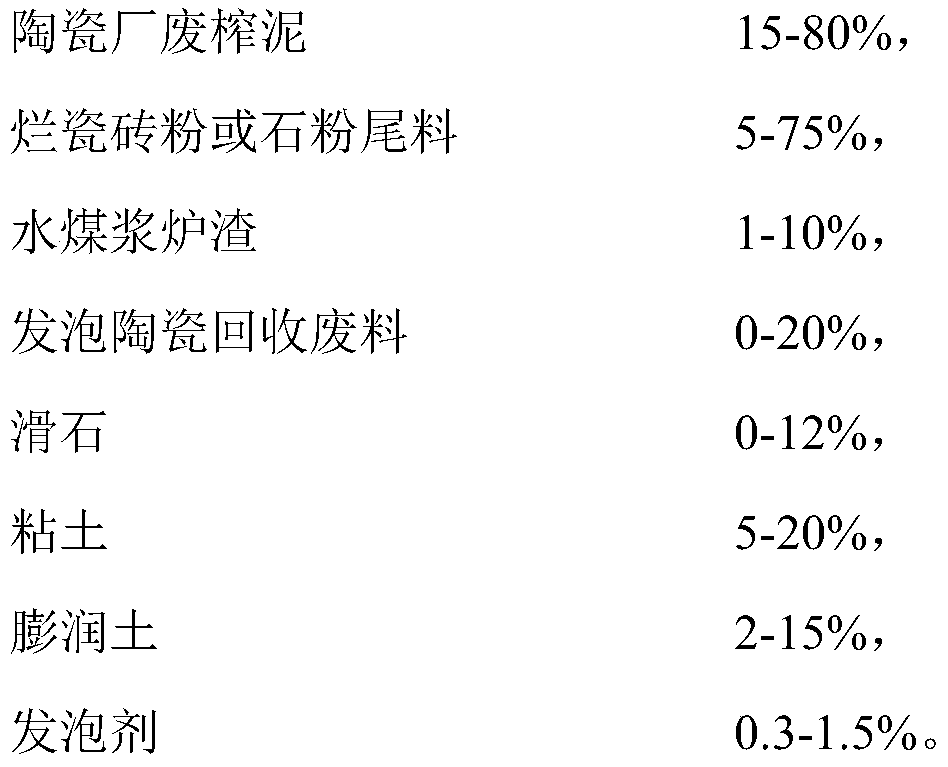

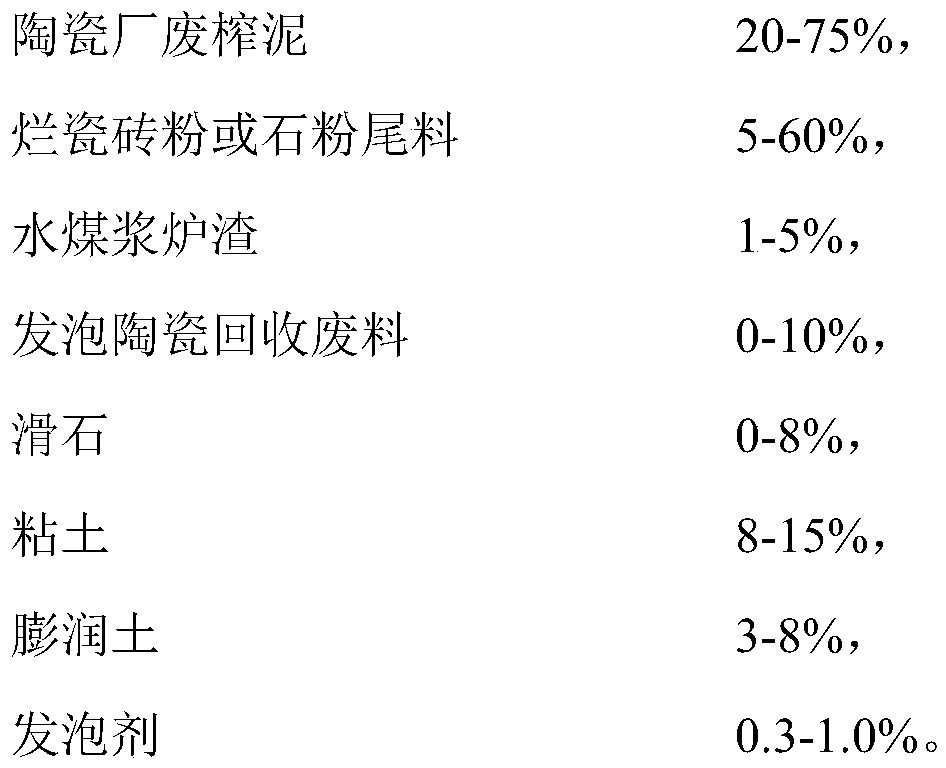

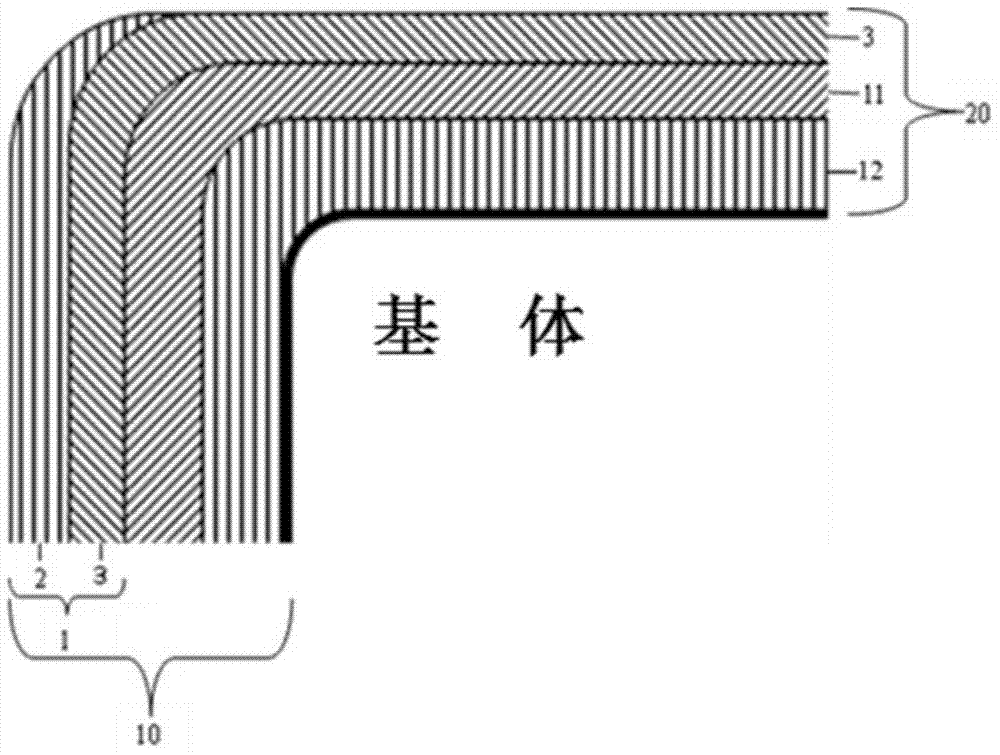

InactiveCN110606764AEasy to prepareIncrease productivityCeramic materials productionCeramicwareBrickSodium Bentonite

The invention discloses a glazed ceramic decorative wall tile. The wall tile comprises a ceramic tile body and a glaze surface, wherein the ceramic tile body comprises 15-80% of ceramic factory wastepressed mud, 5-75% of rotten ceramic tile powder or stone powder tailings, 1-10% of coal water slurry slag, 0-20% of foamed ceramic recycled waste, 0-12% of talc, 5-20% of clay, 2-15% of bentonite and0.3-1.5% of a foaming agent; and the glaze surface comprises an isolation glaze located on the surface of the ceramic tile body, a surface glaze located on the isolation glaze and a protective glazelocated on the surface glaze. Solid waste in the ceramic industry is used as main raw materials, and the wall tile and the method conform to the trend of environmental protection, greenness and sustainable development. The foamed ceramic wall tile has a water absorption rate of less than 0.4%, a density of 0.9-1.4 g / cm<3>, compressive strength of more than 8 MPa, breaking strength of more than 5 MPa, tensile strength of more than 2 MPa, a heat conductivity coefficient of 0.25-0.46 w / m.k, and a combustion performance of AI grade.

Owner:恩平市华昌陶瓷有限公司

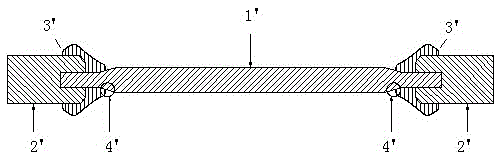

Method for preparing coating on cutting blade

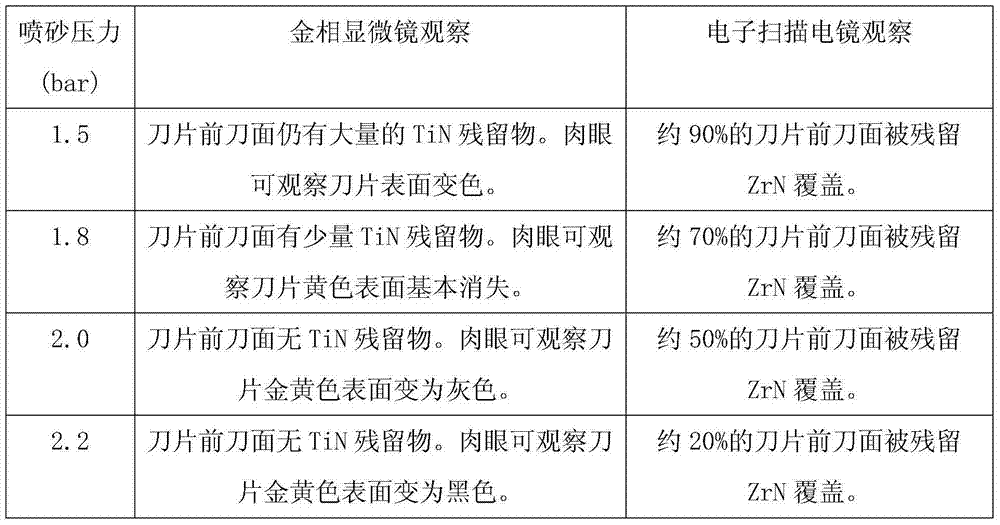

ActiveCN103668105AWith decorative functionWith indication functionChemical vapor deposition coatingHafniumTitanium

The invention discloses a method for preparing a coating on a cutting blade, and relates to a cutting blade. The method comprises the following steps: (1) selecting a cutting blade substrate; (2) coating a TiN layer on the cutting blade substrate; (3) coating a TiCxNy layer, wherein x is more than or equal to 0, y is more than or equal to 0, and (x+y)=1; (4) depositing an M1M2CxNyOz transition layer, wherein x is more than or equal 0, y is more than or equal to 0, z is more than or equal to 0, (x+y+z)=1, M1 is one of titanium, aluminum, zirconium, hafnium, boron, silicon and the like, and M2 is one of titanium, aluminum, zirconium, hafnium, boron, silicon and the like; (5) depositing an alpha-Al2O3 layer; (6) depositing a ZrN layer; (7) depositing a TiN layer on the top; (8) removing a covering layer outside the front blade surface of the blade. The prepared coating is a coating having decorating and indicating functions for the cutting blade, and can be produced relatively easily at lower cost by adopting a CVD (Chemical Vapor Deposition) method.

Owner:XIAMEN GOLDEN EGRET SPECIAL ALLOY

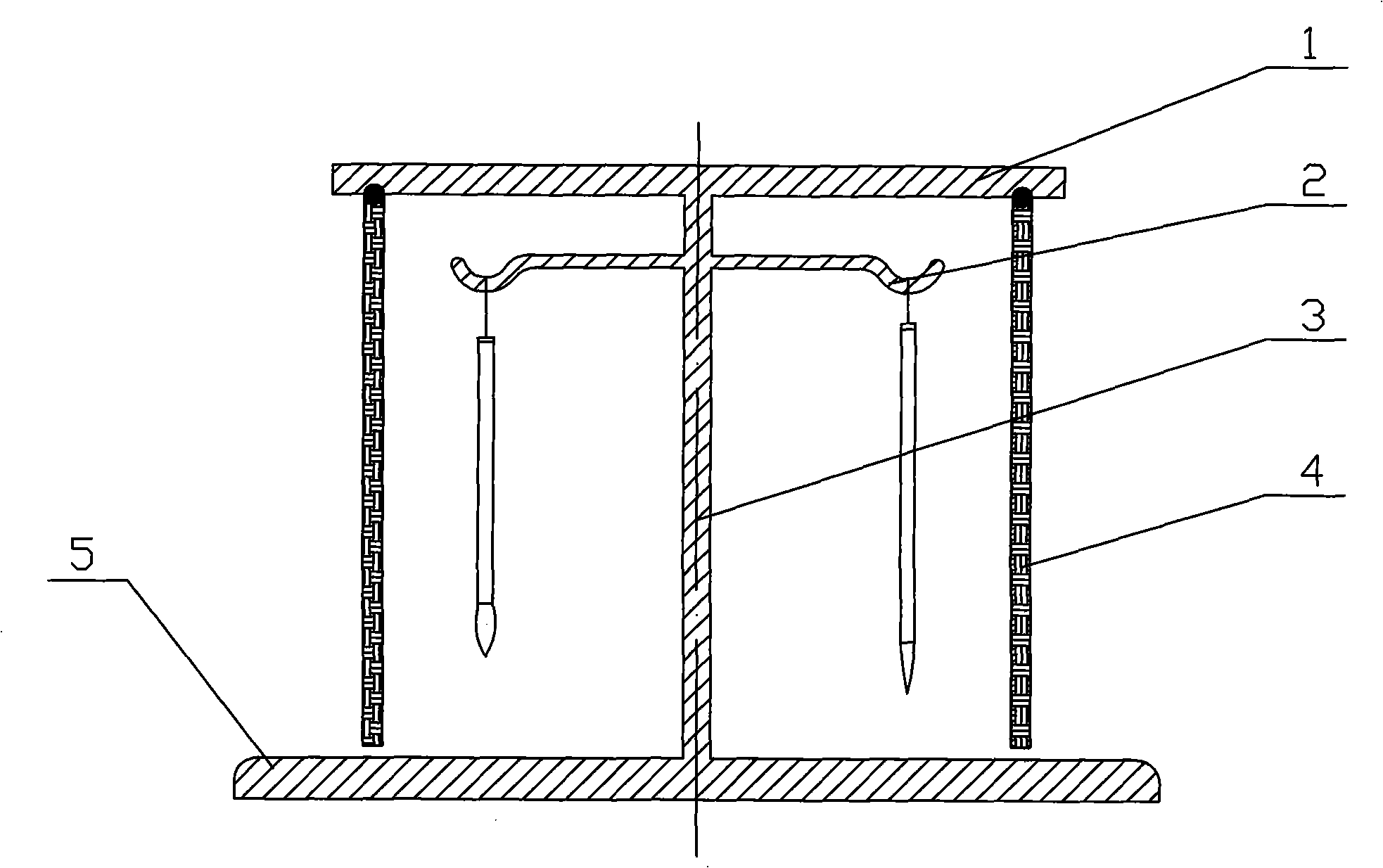

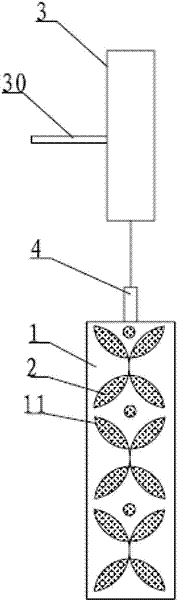

Chinese writing brush frame

InactiveCN101402294AMeet maintenance requirementsWith decorative functionWriting accessoriesEngineering

The invention provides a brush pen holder, and relates to an office supply, in particular to a pen holder with a function of naturally drying a brush pen in the shade. The pen holder comprises a base, a supporting rod and a hook, wherein the lower end of the supporting rod is fixed on the base, and the hook is fixed on the upper part of the supporting rod in a radial mode. The pen holder is characterized in that the pen holder also comprises a top tray and a falling curtain, wherein the top tray is fixed at the top end of the supporting rod, the radius of the top tray is larger than the length of the hook, and the falling curtain is movably connected to the edge of the top tray through a sliding track. The pen holder can keep the brush pen in a shady ventilating environment all along, and accords with the requirement of maintaining the brush pen.

Owner:缪明昊

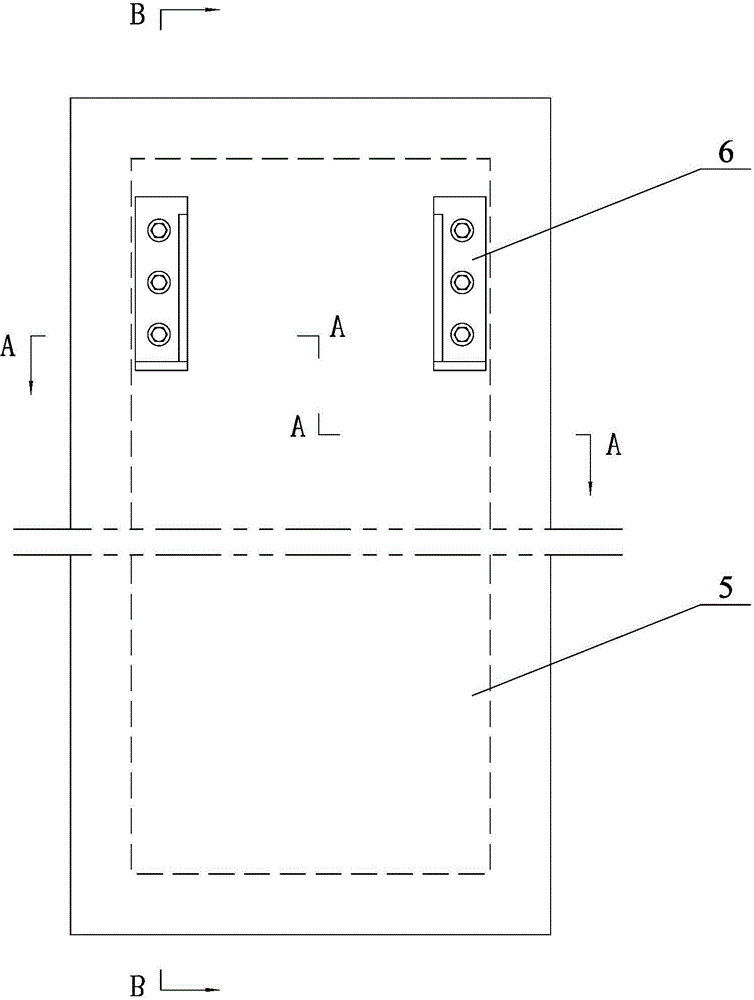

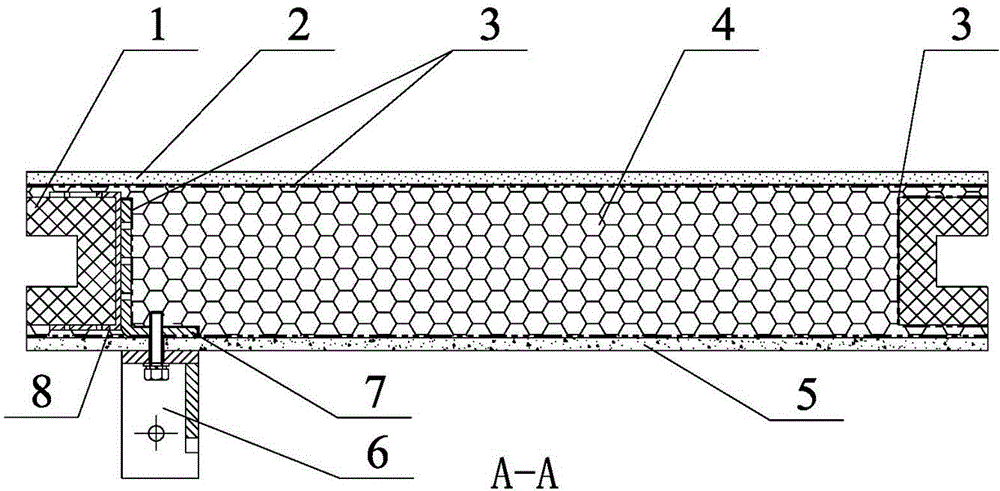

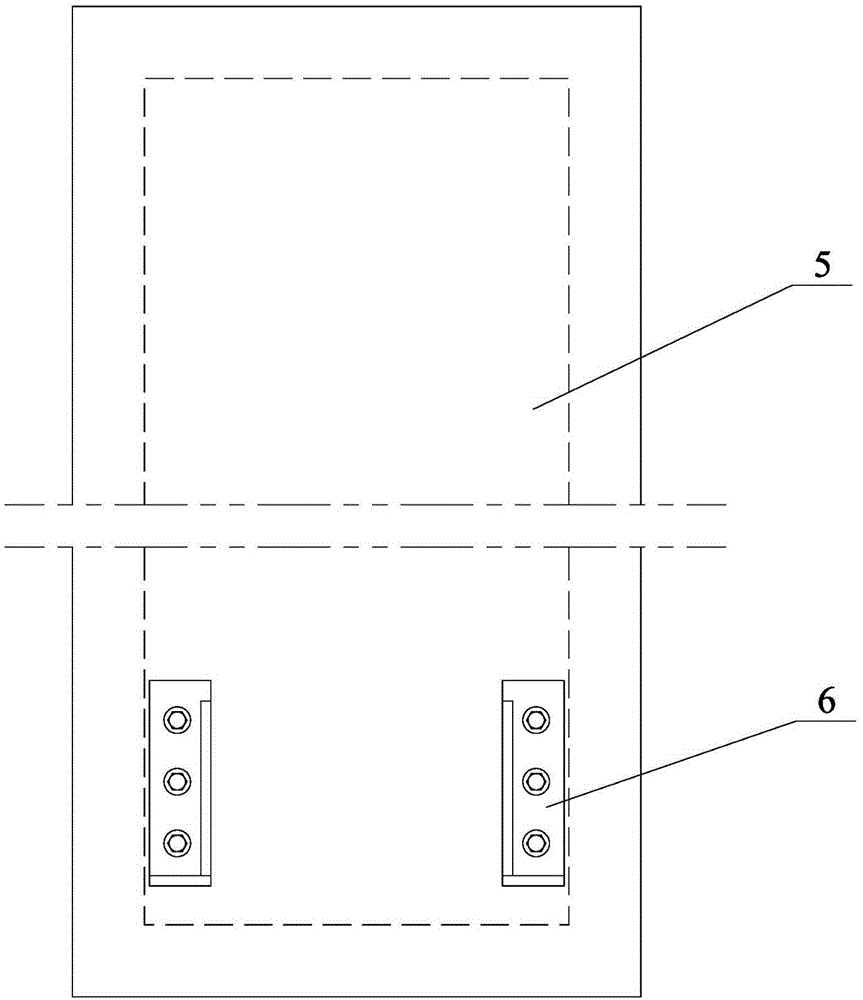

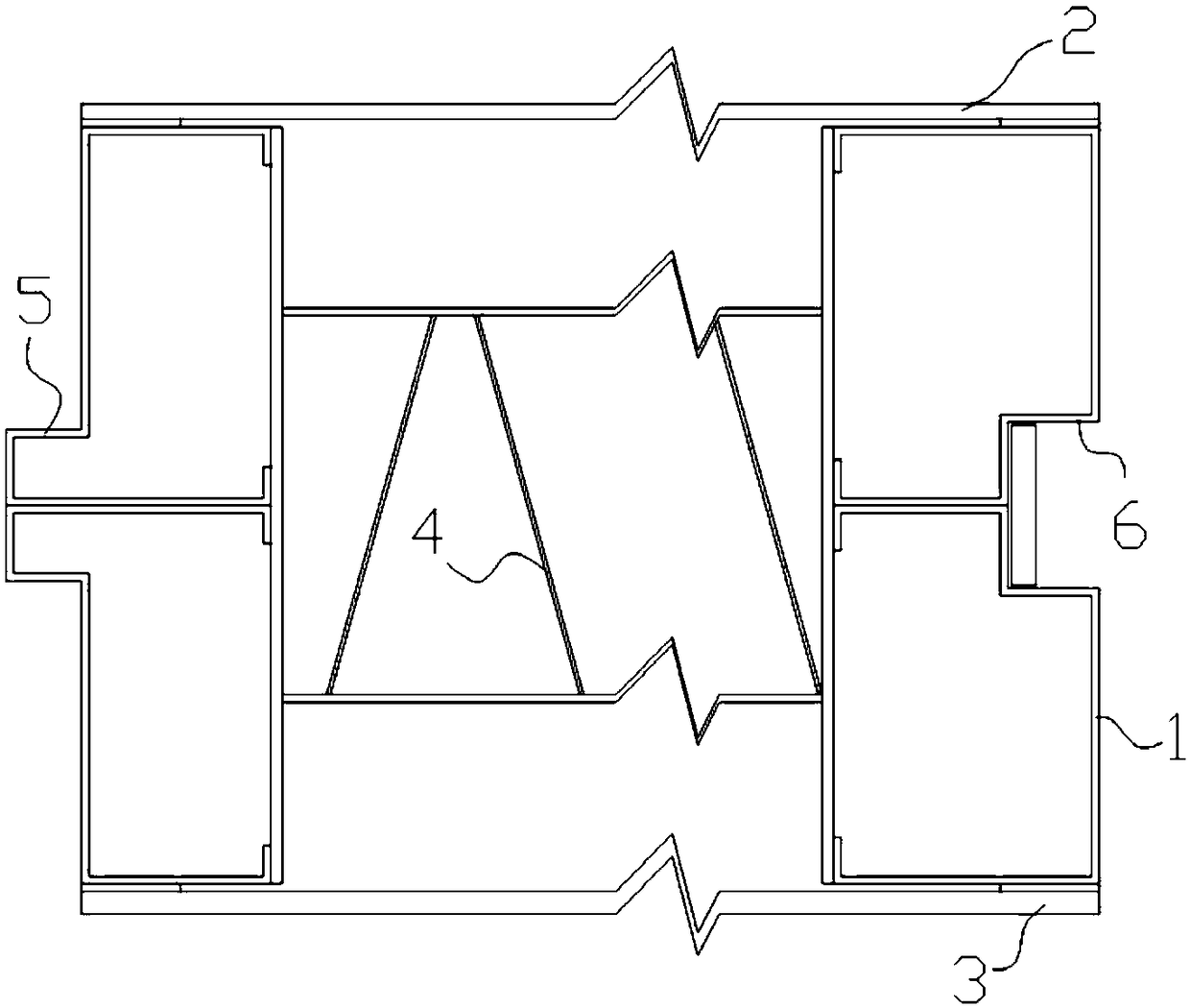

Unit curtain wall of composite bearing structure

InactiveCN104594535AReduce mechanical performance requirementsReasonable forceWallsSkin effectEngineering

A unit curtain wall of a composite bearing structure solves the problems that high-rigidity panels of an existing curtain wall of a frame supporting system do not share wind loads and consequently construction cost is high and construction energy consumption is large. The unit curtain wall comprises unit plates and connecting assemblies for assembling the unit plates and a building main body, and is technically characterized in that according to each unit plate, an inner panel, an outer panel and a frame with a port are combined through core materials and bonding layers to form an integrated structure with a skin effect; each connecting assembly comprises a plate inner embedded part, a plate connecting part, a main body structure connecting part, a sealing rubber strip and a plate insertion positioning block or a plate insertion positioning frame, and the two ends of each main body structure connecting part are fixedly connected with the corresponding plate connecting part and a building main body structure. The composite bearing structure design is adopted, the plates of the curtain wall bear force more reasonably, and the materials are utilized more sufficiently; on the basis of guaranteeing construction safety and decoration effects, the materials are further saved, the construction cost and energy consumption of the curtain wall are reduced, and diversified demands of construction effects are met.

Owner:上海易旋建筑设计咨询有限公司

Low-cost energy storage luminescent paint and preparation method thereof

InactiveCN110066564AReduce collisional quenching effectIncrease light energy storageLuminescent paintsAnti-corrosive paintsPolyvinyl alcoholMicrosphere

The invention discloses a low-cost energy storage luminescent paint and a preparation method thereof. The low-cost energy storage luminescent paint is prepared from, by weight, 30-50 parts of silicondioxide microspheres, 2-3 parts of a coupling agent, 20-30 parts of luminous powder, 10-25 parts of polyvinyl alcohol, 15-25 parts of an acrylic acid emulsion, 10-20 parts of a styrene-acrylic emulsion, 0.5-1 part of a wetting agent, 1-5 parts of dihydroxypropane, 0.1-0.2 part of an antifoaming agent, 0.05-2 parts of a dispersing agent, 0.2-0.5 part of talcum powder, 0.1-0.5 part of a water repellent, 0.1-0.5 part of a coalescing agent, 0.1-0.5 part of a thickening agent, 0.1-0.5 part of a pH adjuster and 10-15 parts of water. The low-cost energy storage luminescent paint and the preparation method thereof have the advantages that fluorescent powder is embedded in the silicon dioxide microspheres, and the surfaces of the silicon dioxide microspheres are modified with the polyvinyl alcohol,so that not only is the luminous efficiency of the fluorescent powder improved, but also the stability of the fluorescent powder is improved, the service life and lighting time of the paint are prolonged, the environmental friendliness is achieved, the brightness of the coating is high, the persistence time is long, the adhesion and corrosion resistance are good, and the application prospects aregood.

Owner:CHONGQING JINHONG CONSTR ENG

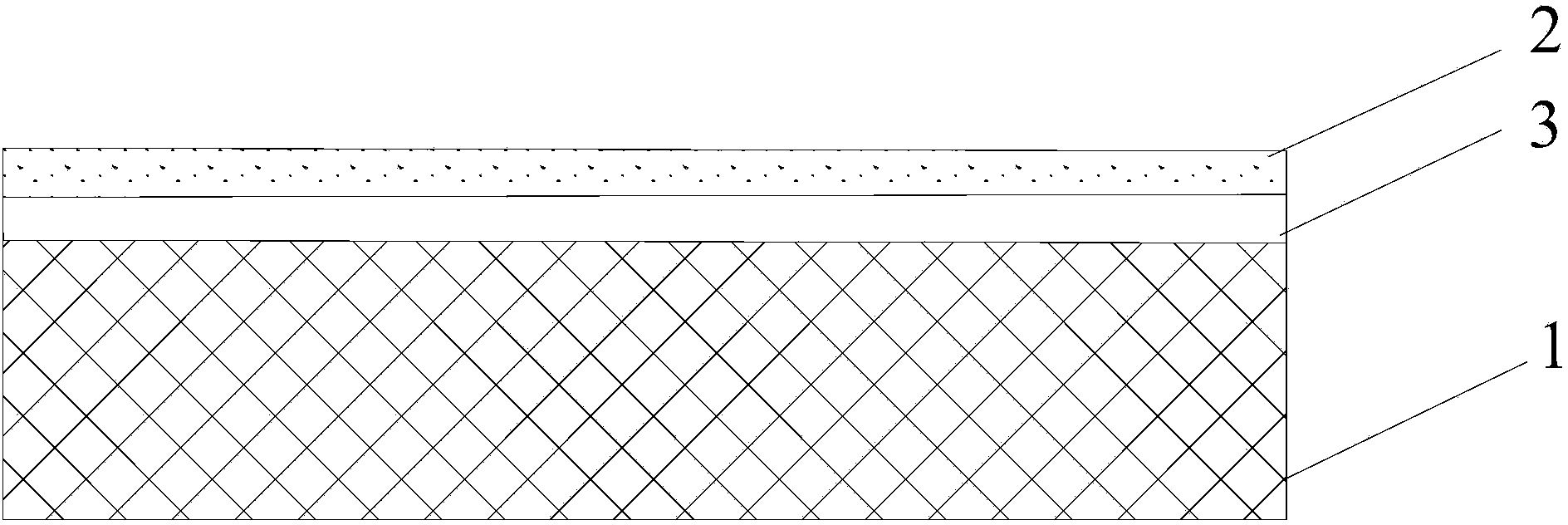

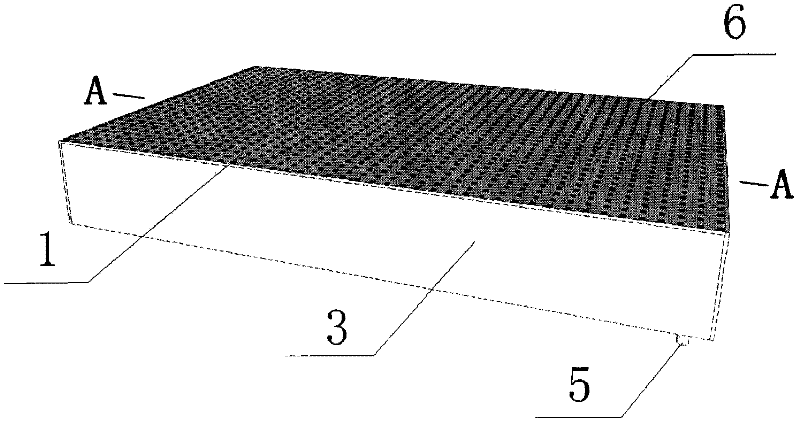

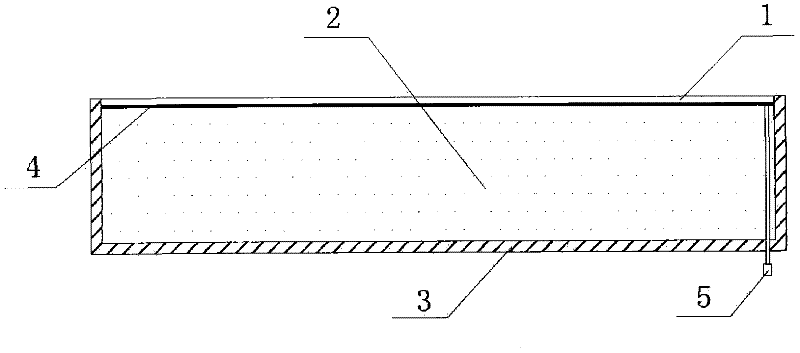

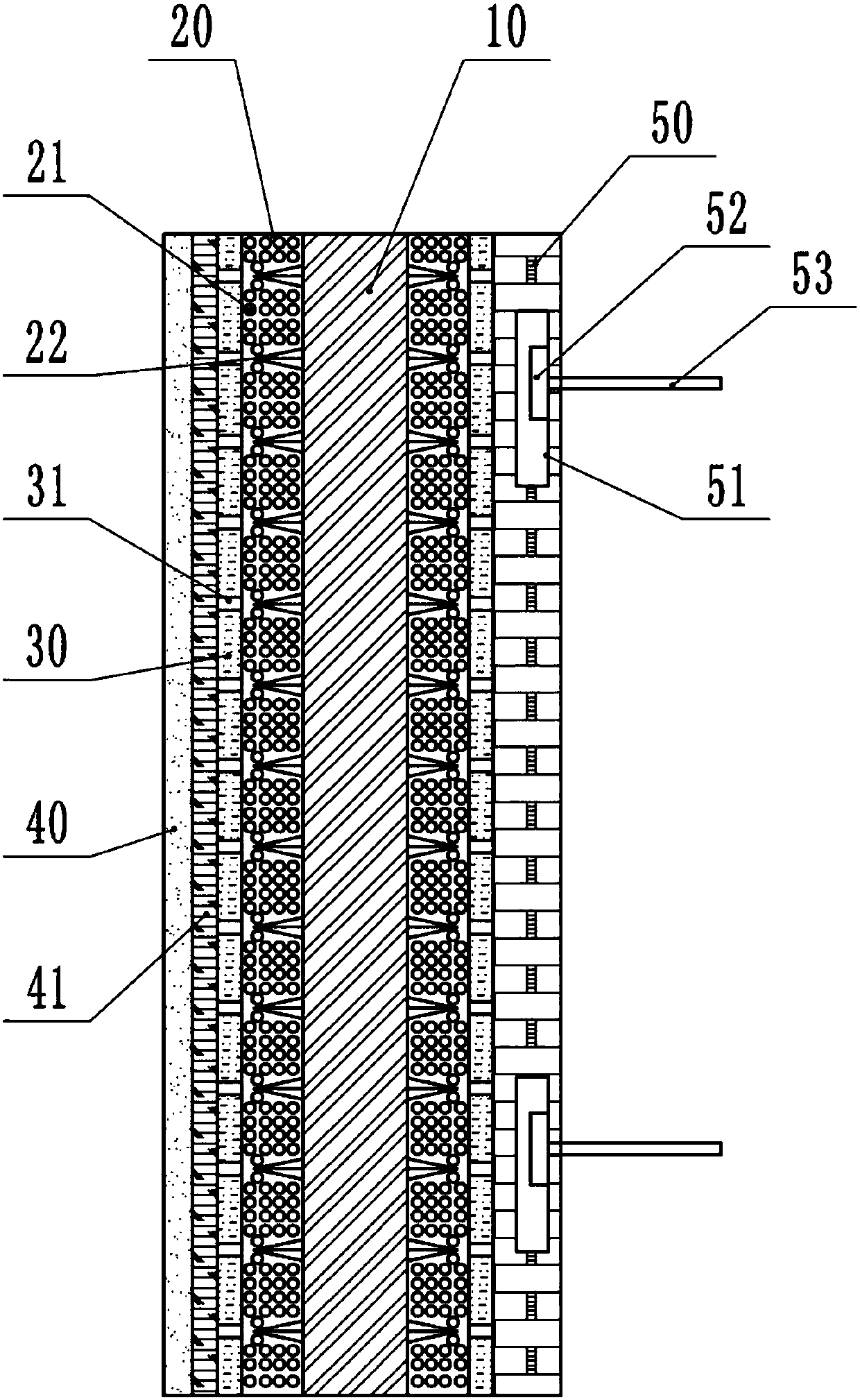

Soft stone compound insulation board

ActiveCN103526894AStable in natureReduce weightCovering/liningsSynthetic resin layered productsAdhesivePolystyrene

The invention belongs to the field of building materials and provides a soft stone compound insulation board. The soft stone compound insulation board is made of a double-layer material compounded by a soft surface material and an insulation base material. The soft surface material is obtained through the method that after adhesive is added to colored sand obtained by laminating color matching, solidification is conducted; the insulation base material is polystyrene foam plastic or expanded perlite or a polyurethane board. The compound material made of the soft decoration surface material and the insulation material in a compound mode has the advantages of being good in insulation, light, waterproof, breathable, diversified in color and texture, good in weather fastness, capable of being applied to an inner and outer wall insulation system and overcoming the shortage that an outer wall insulation material is prone to falling off and aging and the like.

Owner:内蒙古仁创沙产业有限公司

Coating structure for wall decoration

InactiveCN105239739AStrong crack resistanceImprove waterproof performanceCovering/liningsFilling pastesWeather resistanceSoil resistance

The invention discloses a coating structure for wall decoration. The coating structure is attached on a wall, and consists of anti-cracking putty layers, an anti-alkali sealing primer layer, a composite Taojingshi layer and a Taojingshi cover finish-coat paint layer from inside to outside in sequence, wherein two anti-cracking putty layers are provided. The coating structure is high in weather resistance, checking resistance, water repellency, color retaining performance and soiling resistance, low in cost, long in service life, economical, durable, excellent in heat insulating property, pollution resistance and ageing resistance, excellent in damp and mildew preventing property and excellent in permeability, and has decoration and protection functions.

Owner:广州绅琪节能材料有限公司

Method for preparing colored autoclaved brick from lake sludge

InactiveCN102431080AWith decorative functionImprove waterproof performanceCeramic shaping apparatusBrickSludge

The invention relates to a method for preparing a decorative colored autoclaved brick from lake sludge as a main raw material. The method is characterized by comprising the following steps: 1) preparation of base layer blank: mixing 40-50 wt% of lake sludge, 30-50 wt% of aggregate, 8-15 wt% of quicklime and 2-5 wt% of gypsum with water, and stirring to obtain the base layer blank for later use, wherein the weight ratio of water to solid is 0.10-0.18; 2) preparation of color layer blank: adding an inorganic pigment, which accounts for 5-10 wt% of the base layer blank, into the base layer blank, and evenly stirring to obtain the color layer blank for later use; 3) slaking; 4) rolling; 5) secondary cloth pressure molding; and 6) autoclaving, and curing to obtain the colored autoclaved brick.The colored autoclaved brick prepared by the method has the function of self decoration, and is environment-friendly.

Owner:WUHAN UNIV OF TECH +1

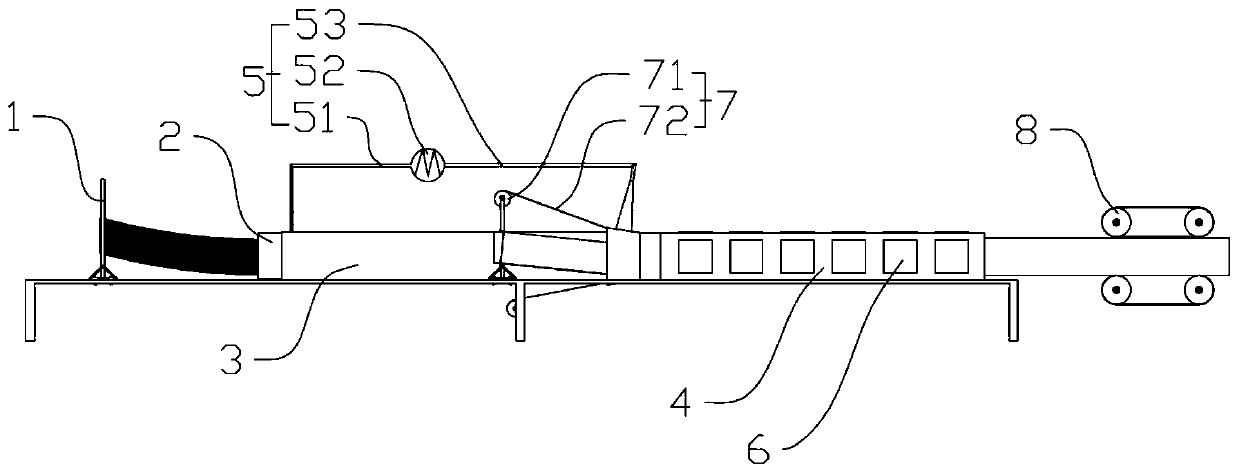

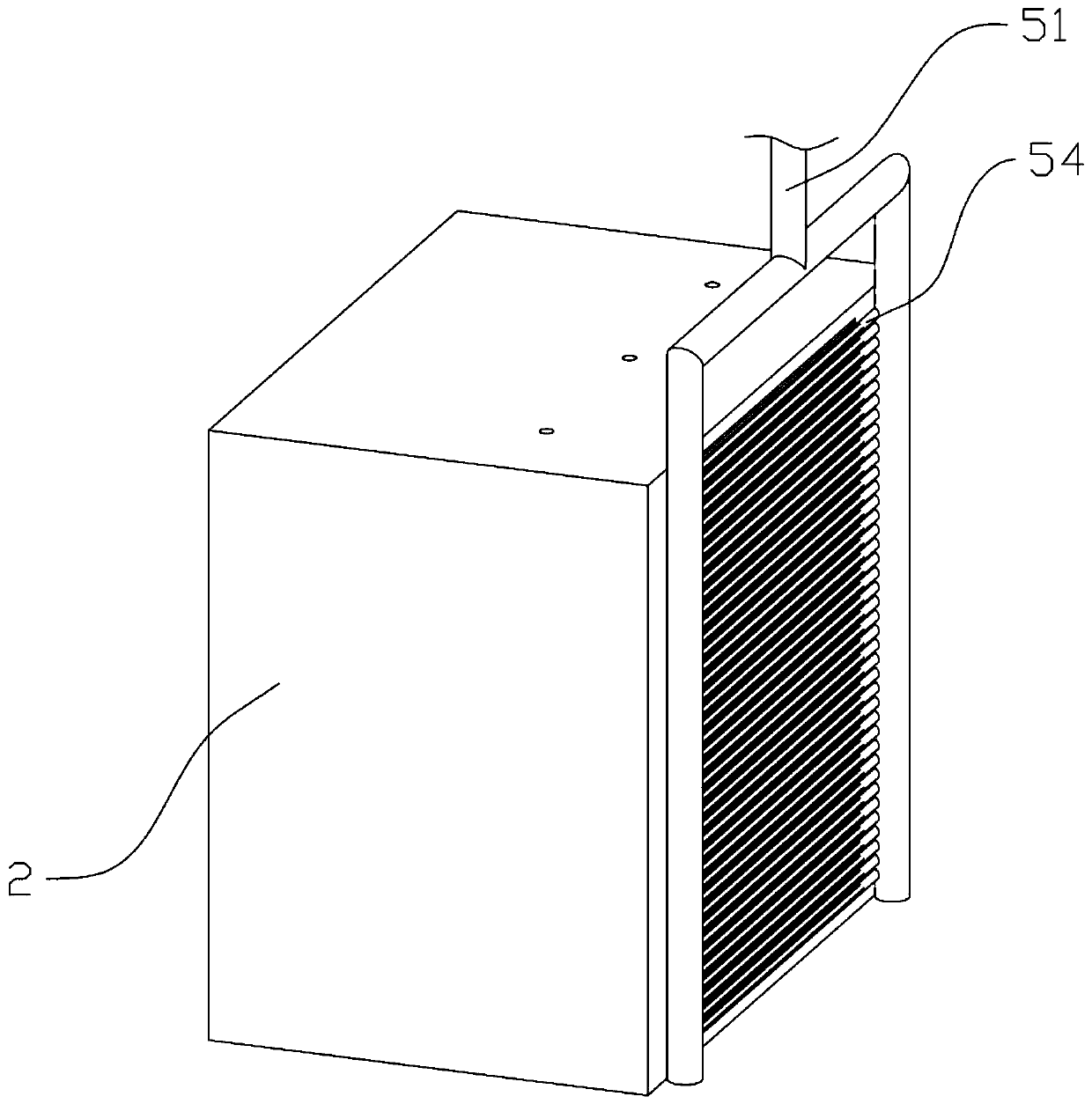

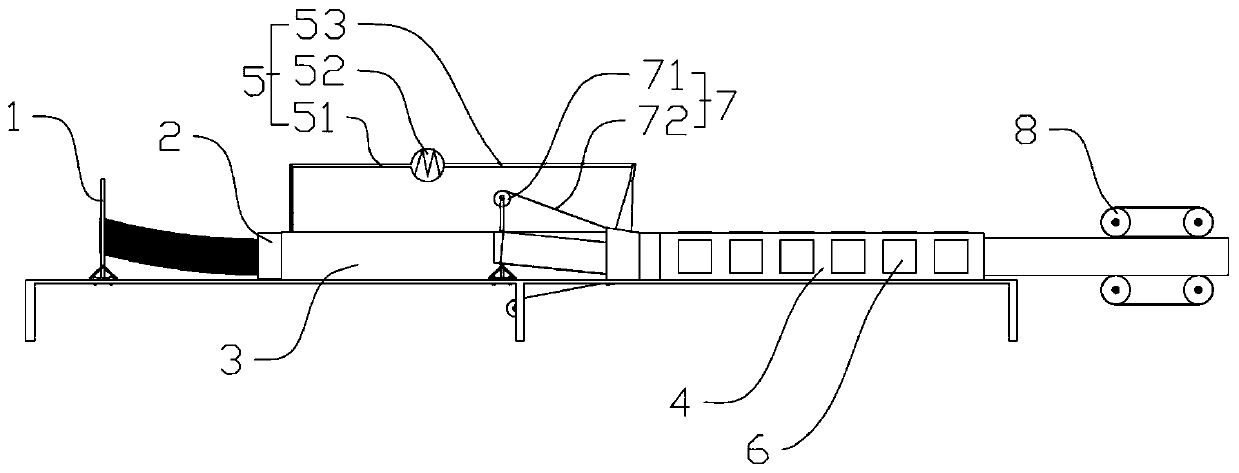

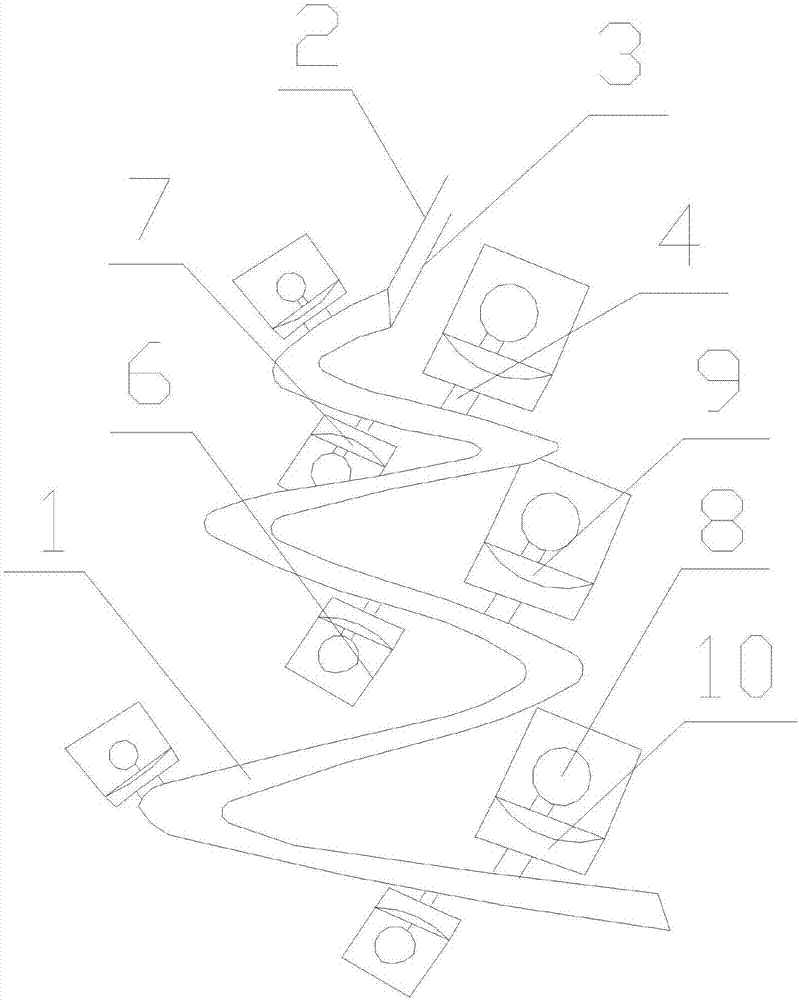

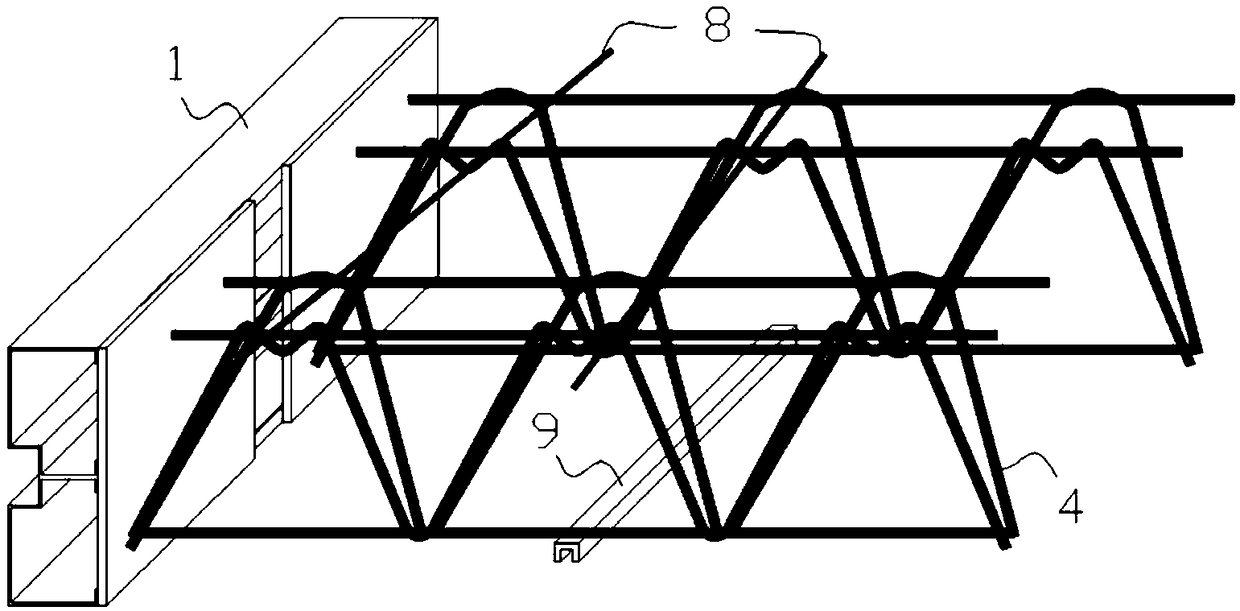

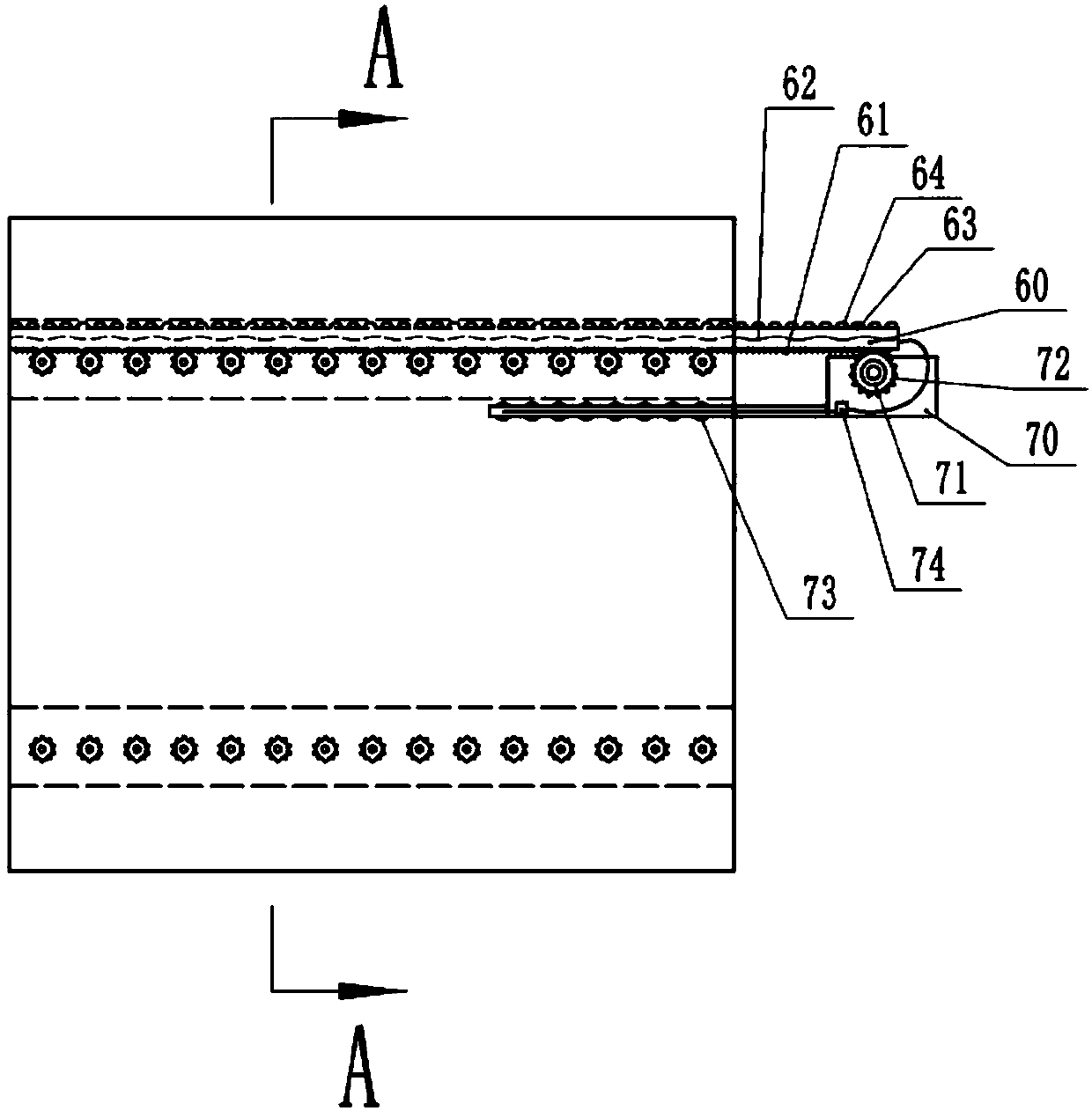

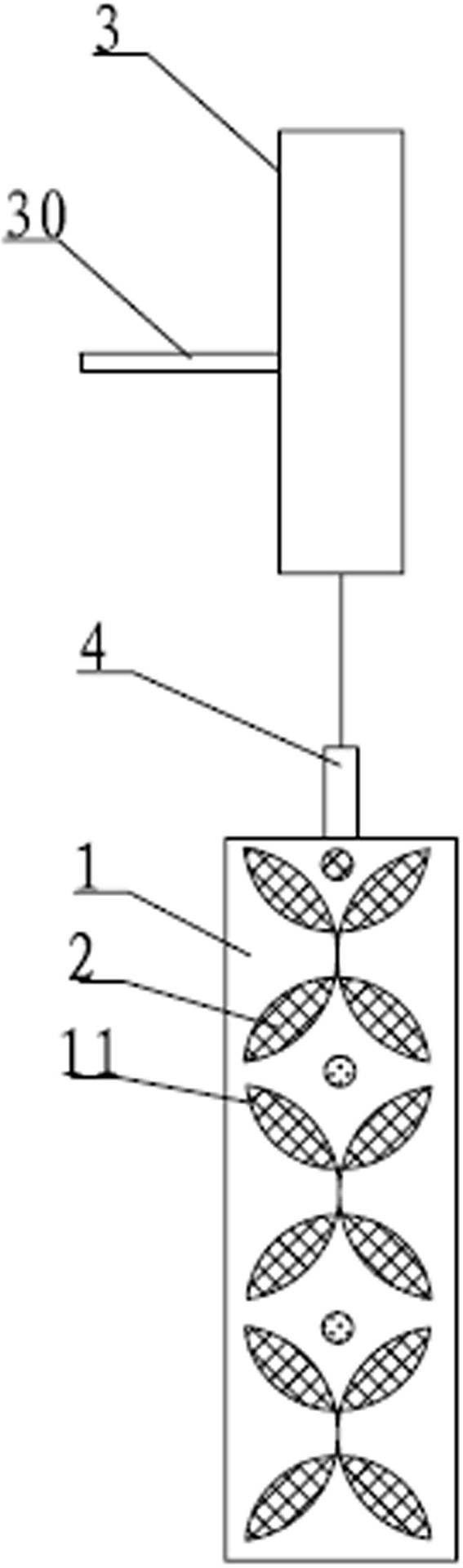

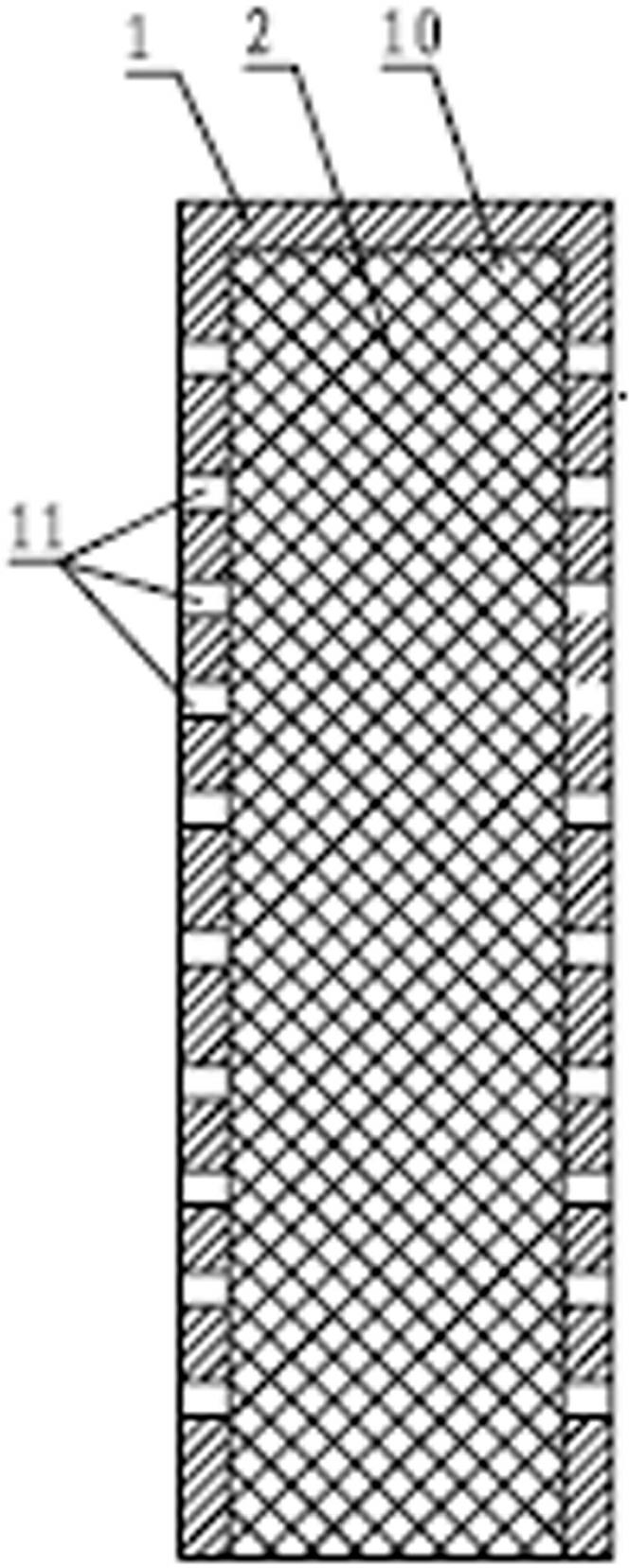

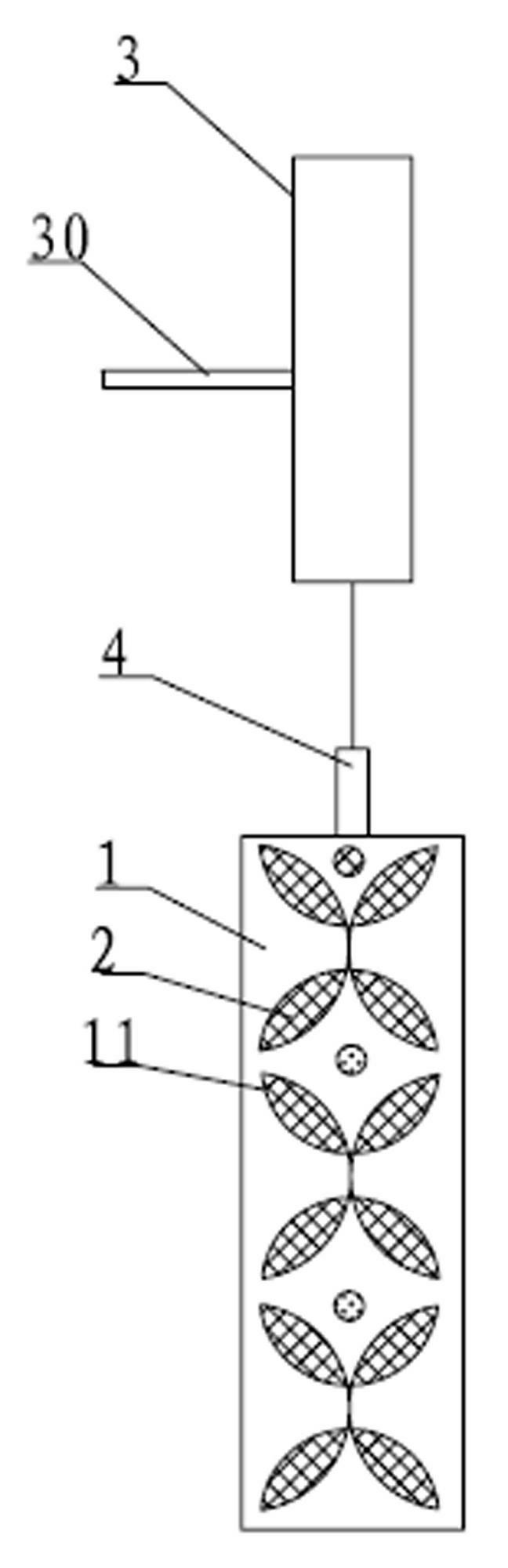

Foaming device and continuous production line and production method of fiber reinforced foaming composite material

The invention relates to a foaming device and continuous production line and production method of fiber reinforced foaming composite material. The continuous production line comprises a distribution frame, a glue injection box, a foaming device, a forming die and a traction device, wherein the distribution frame is used for enabling fiber material to be spatially distributed according to design requirements; the glue injection box comprises infiltration channels, glue injection channels and a discharging channel; a plurality of infiltration channels and glue injection channels are arranged onthe glue injection box; the foaming device is arranged in a tunnel structure; one end of the foaming device communicates with the glue injection box while the other end of the foaming device communicates with the forming die; an air supply device is arranged on the side, close to the foaming device, of the glue injection box; and a heating device is arranged on the forming die. The fiber materialis infiltrated by liquid base material injected into the infiltration channels through the glue injection channels while the fiber material passes through the infiltration channels to become a composite material precursor, after passing through the discharging channel the composite material precursor enters the foaming device for pre-foaming and then enters the forming die for complete foaming andcuring or setting so as to form the final composite material product. Different fibers and / or different liquid base materials can be infiltrated in different infiltration channels to form different composite material precursors, so that different parts of the finally formed composite material have different material compositions, different functions and different performances.

Owner:湖州守真新材料科技有限公司

Glue injection box and continuous production line and production method for fiber-reinforced foamed composite materials

PendingCN110154421APrevent defects such as voidsSimplify the air supply structureProduction lineDistribution frame

The invention provides a glue injection box and a continuous production line and production method for fiber-reinforced foamed composite materials. The continuous production line comprises a distribution frame, the glue injection box, a foaming device, a forming die and traction devices, wherein the distribution frame is used for enabling fiber materials to be spatially distributed according to design requirements. The glue injection box comprises infiltration channels, glue injection channels and a discharge channel, wherein the glue injection box is provided with multiple infiltration channels and glue injection channels. The foaming device is arranged to be of a tunnel-type structure, one end of foaming device communicates with the glue injection box, and the other end of the foaming device communicates with the foaming die. An air supply device is arranged on the side, close to the foaming device, of the glue injection box, and a heating device is arranged on the foaming die. The fiber materials pass through the infiltration channels and are infiltrated by liquid matrix materials which are injected into the infiltration channels through the glue injection channels to form composite material precursors, pre-foaming is conducted after the composite material precursors enter the foaming device through the discharge channel, and then the composite material precursors enter theforming die for complete foaming and solidifying or shaping; and different fibers and / or the liquid matrix materials can also be infiltrated in different infiltration channels to form different composite material precursors. Therefore, different parts of the manufactured composite material can be different in material composition, function and property.

Owner:湖州守真新材料科技有限公司

Construction method for inorganic dry powder stripe type exterior wall decoration mortar coating system

The invention discloses a construction method for an inorganic dry powder stripe type exterior wall decoration mortar coating system, comprising six steps of foundation treatment, snapping diving joint lines, scraping decoration mortar, painting building coating layer of exterior wall, aqueous pointing paint and touching up a seam and cleaning; wherein the foundation in the foundation treatment comprises an exterior wall foundation layer, an insulation layer and a plastering anti-crack layer; the exterior wall building coating layer in the painting building coating layer of exterior wall comprises an aqueous sealing primer layer, a first elastic emulsion varnish layer and a second elastic emulsion varnish layer. The construction method provided by the invention adopts inorganic dry powderstripe type decoration mortar and brushing the aqueous sealing primer and elastic emulsion varnish after removing textured paper; finally, the seam is touched up by aqueous pointing paint, so that thecoating of the whole construction surface is a whole without a gap; the rain and moisture in air cannot permeate into the foundation through the gap so as to stop the generation of whiskering, crack,water seepage, etc. The decoration effect, sense of beauty and life cycle of the exterior wall of the building are effectively improved.

Owner:安徽安兴装饰工程有限责任公司

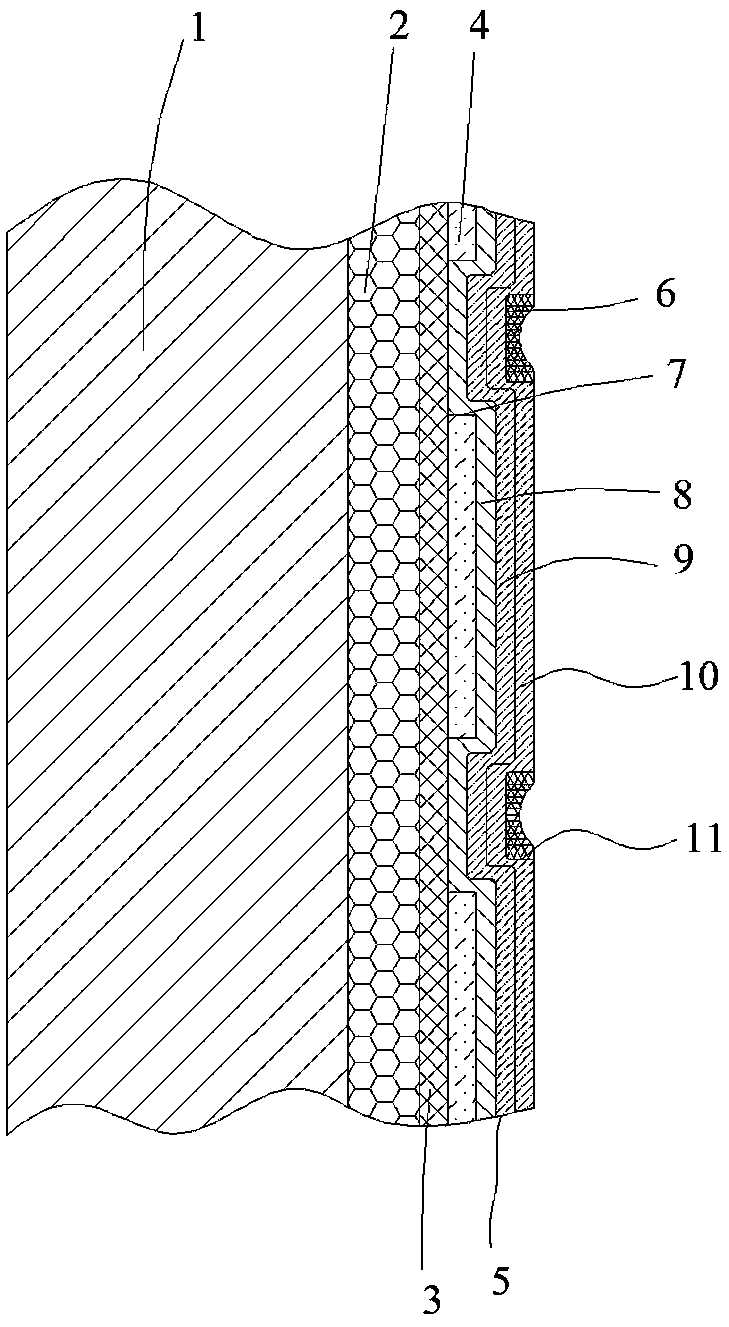

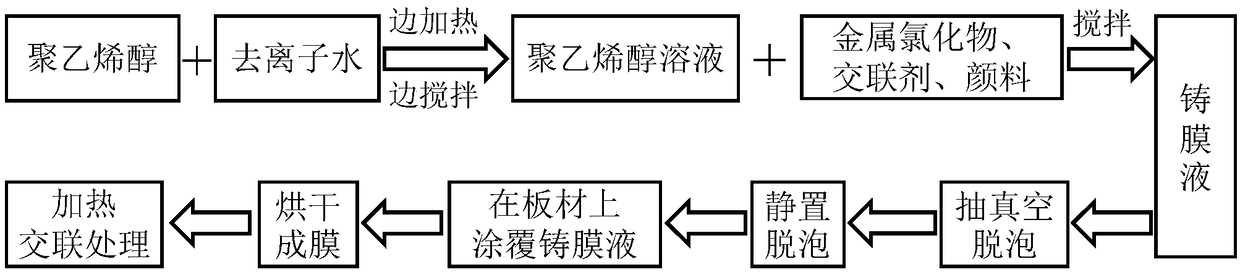

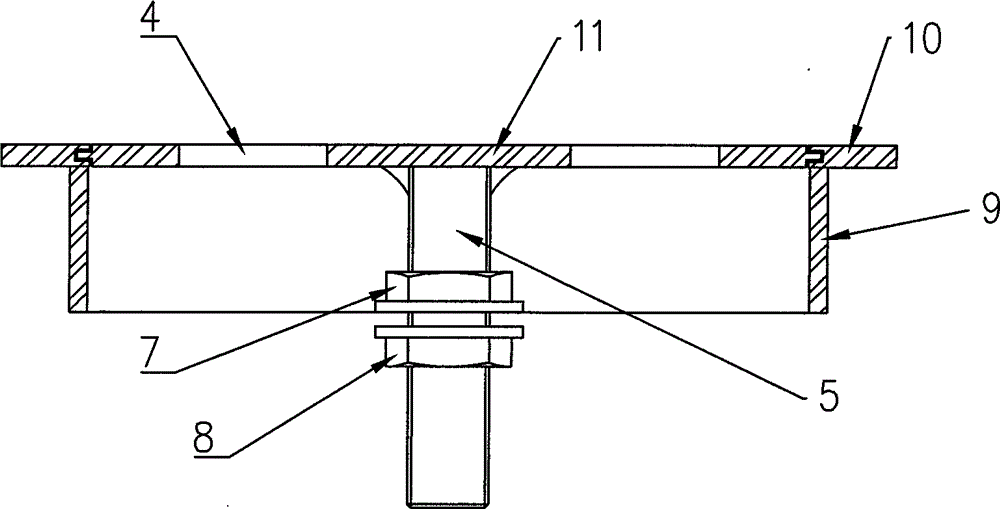

Passive humidity control organic-inorganic composite film and preparation method thereof

InactiveCN109012234AGood defoamingAccelerate evaporationSemi-permeable membranesDispersed particle separationCross-linkMetal chloride

The invention discloses a preparation method of a passive humidity control organic-inorganic composite film, and the method is as follows: dissolving polyvinyl alcohol, a metal chloride, a cross-linking agent and a pigment in deionized water to prepare a film casting liquid, defoaming the film casting liquid, applying the defoamed film casting liquid to a plate, and placing the plate in a constanttemperature and humidity box to promote evaporation of water in the film casting liquid to prepare an organic-inorganic composite film; and finally placing the composite film in an oven for heat treatment to promote cross-linking reaction between the polyvinyl alcohol and the cross-linking agent. The composite film is mainly based on the polyvinyl alcohol and the metal chloride to realize intelligent regulation of the humidity of a closed space, the cross-linking agent is used to enhance the water resistance of the film, and the pigment is used for regulating the color of the film to achievethe purpose of decoration. Compared with the prior art, the composite film can realize the intelligent adjustment of the humidity of the closed space, has a stable performance, can be used repeatedly,and has a decorative function.

Owner:CHANGZHOU UNIV

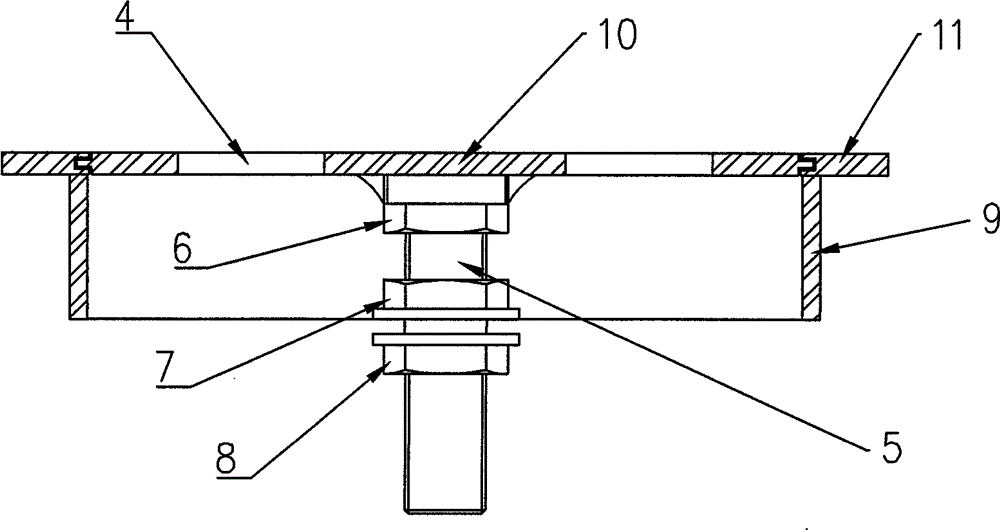

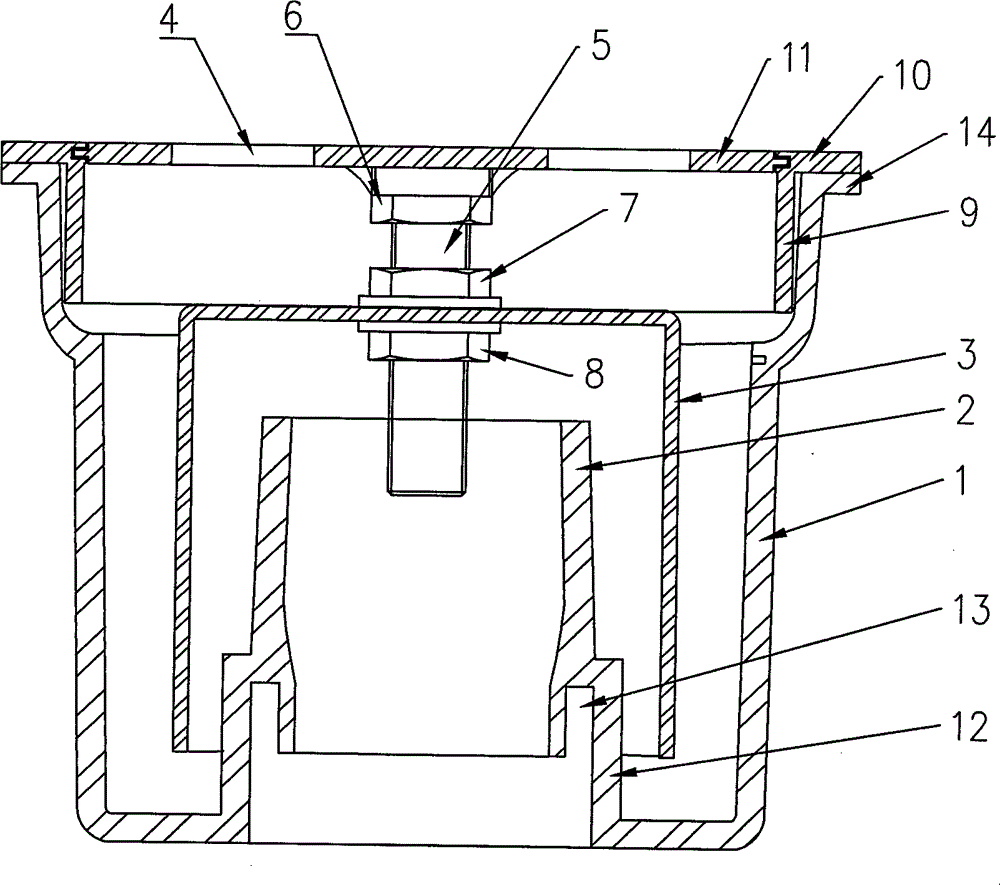

Water sealing deodorant decorative floor drain cover and water sealing deodorant decorative floor drain

InactiveCN104018572AApplicable engineering installationWith decorative functionSewerage structuresWater dischargeWater leakage

The invention discloses a water sealing deodorant decorative floor drain cover comprising a head cover, wherein a water leakage hole is formed in the head cover; the middle part of the lower end surface of the head cover is connected with the top end of a pull rod; the pull rod is connected with an inverse water bowl in an arrangement manner; the inverse water bowl can be moved up and down along the pull rod to regulate the fixed position. A water sealing deodorant decorative floor drain comprises a floor drain shell with an opened top end; the head cover is arranged above the floor drain shell; an overflow pipe is arranged in the floor drain shell; the inverse water bowl with an opened bottom end is arranged in the cavity of the floor drain shell; the water inlet of the overflow pipe is formed in the cavity of the inverse water bowl; the lower end surface of the head cover is connected with the top end of the pull rod; the pull rod is connected with the inverse water bowl; the inverse water bowl can be moved up and down along the pull rod so as to regulate the fixed position. The invention aims to provide the water sealing deodorant decorative floor drain cover and the water sealing deodorant decorative floor drain which are significant in deodorant effects, high in water discharge speed and less in blockage possibility, can be used for avoiding or reducing the diffusion and spreading of smelly gas such as virus and insects such as cockroaches by virtue of the floor drain, and can be used for ensuring the relative positions and sizes of the inverse water bowl and the floor drain shell.

Owner:张菁

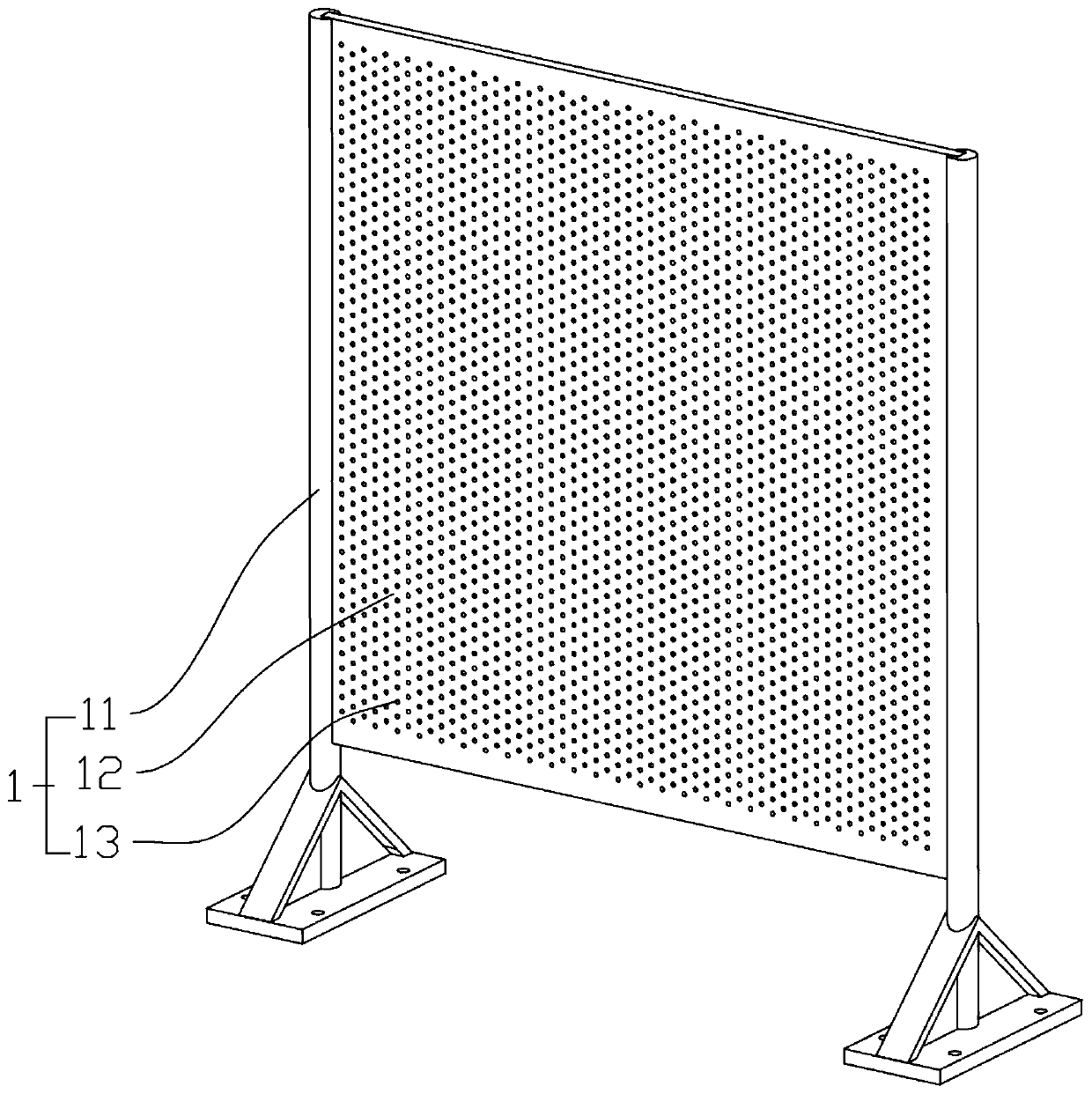

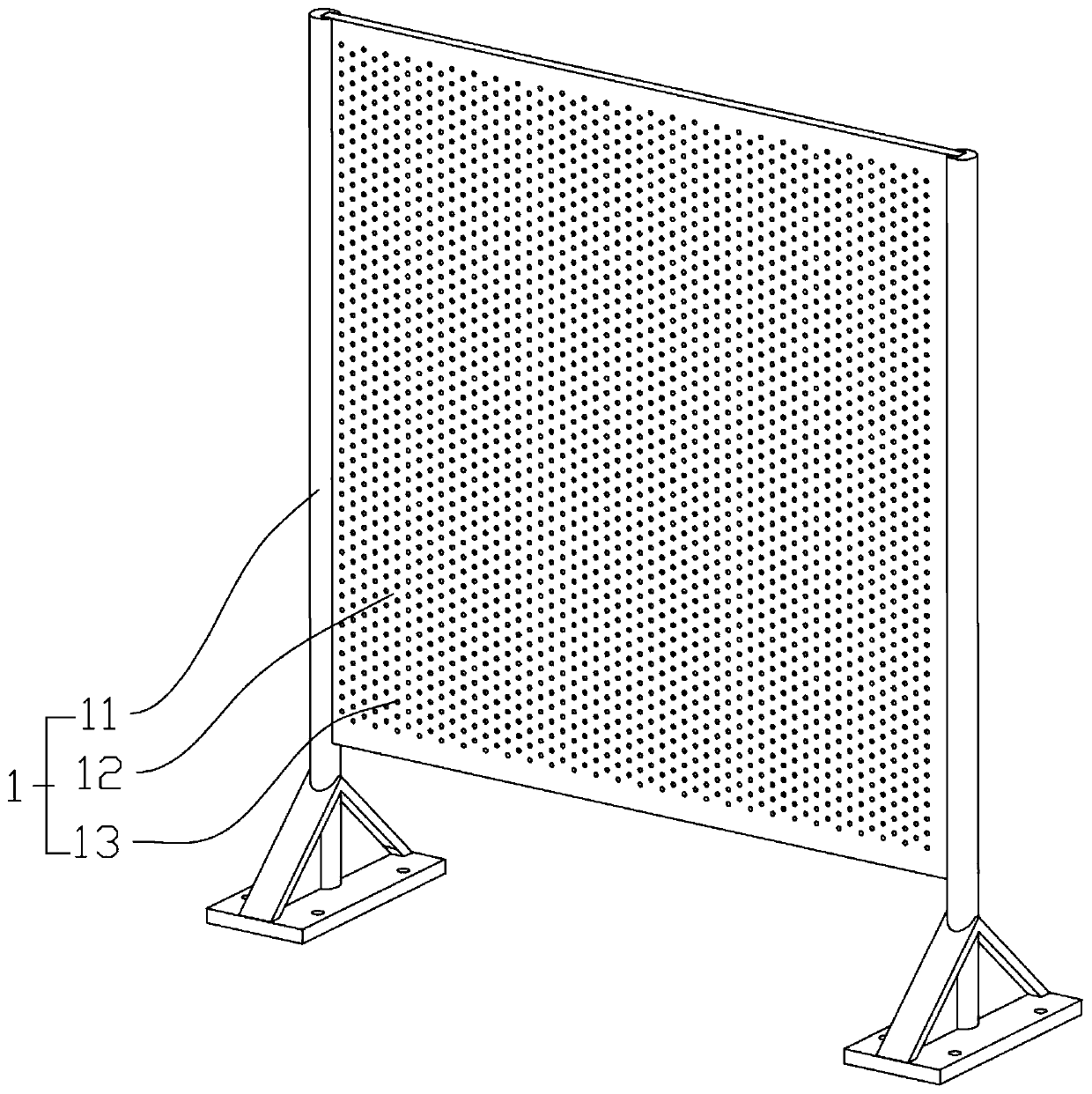

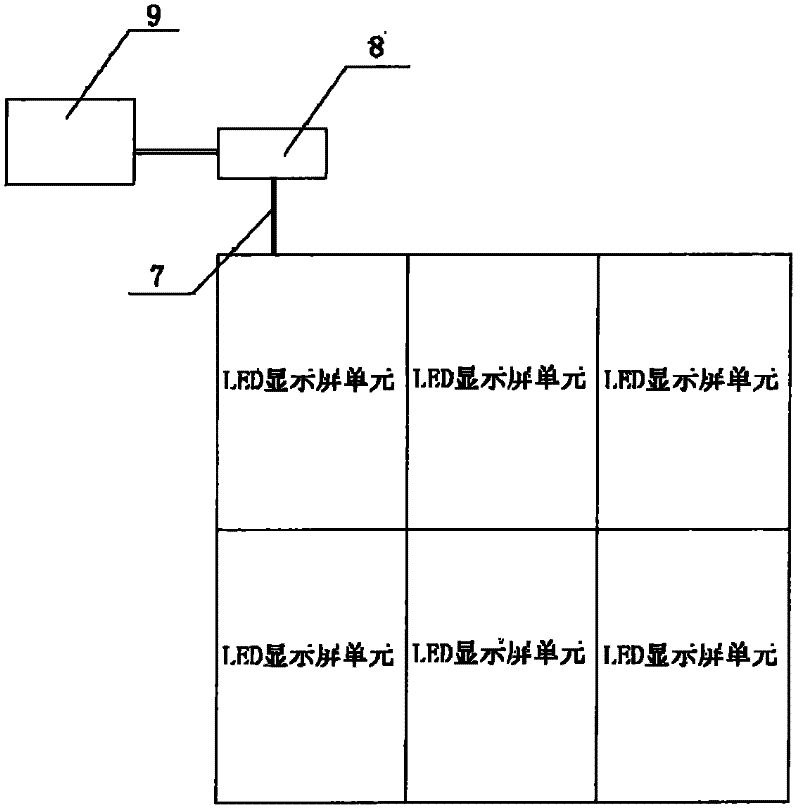

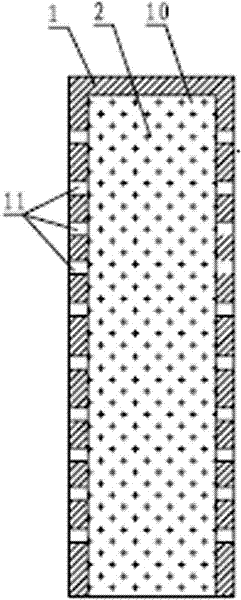

Sound absorption light emitting diode (LED) display screen

InactiveCN102306476ASimple structureReduce weightCovering/liningsIdentification meansLED displayControl system

The invention relates to a sound absorption light emitting diode (LED) display screen, which has functions of decoration, sound absorption and display. LED display screen units comprise rectangular LED screen bodies, perforated plates, porous sound absorption materials, LED panchromatic pixel substrates and connecting pieces, and control image information through a computer and a control system. The plurality of LED display screen units are connected by the connecting pieces to form the whole sound absorption LED display screen, and can realize independent display and also can be combined for display. The LED display screen can be used as wall facade decoration or ceiling decoration, sound absorption coefficient of each frequency range can be set according to requirements, and at the same time high-definition or standard-definition display precision is achieved.

Owner:SHENZHEN UNIV +2

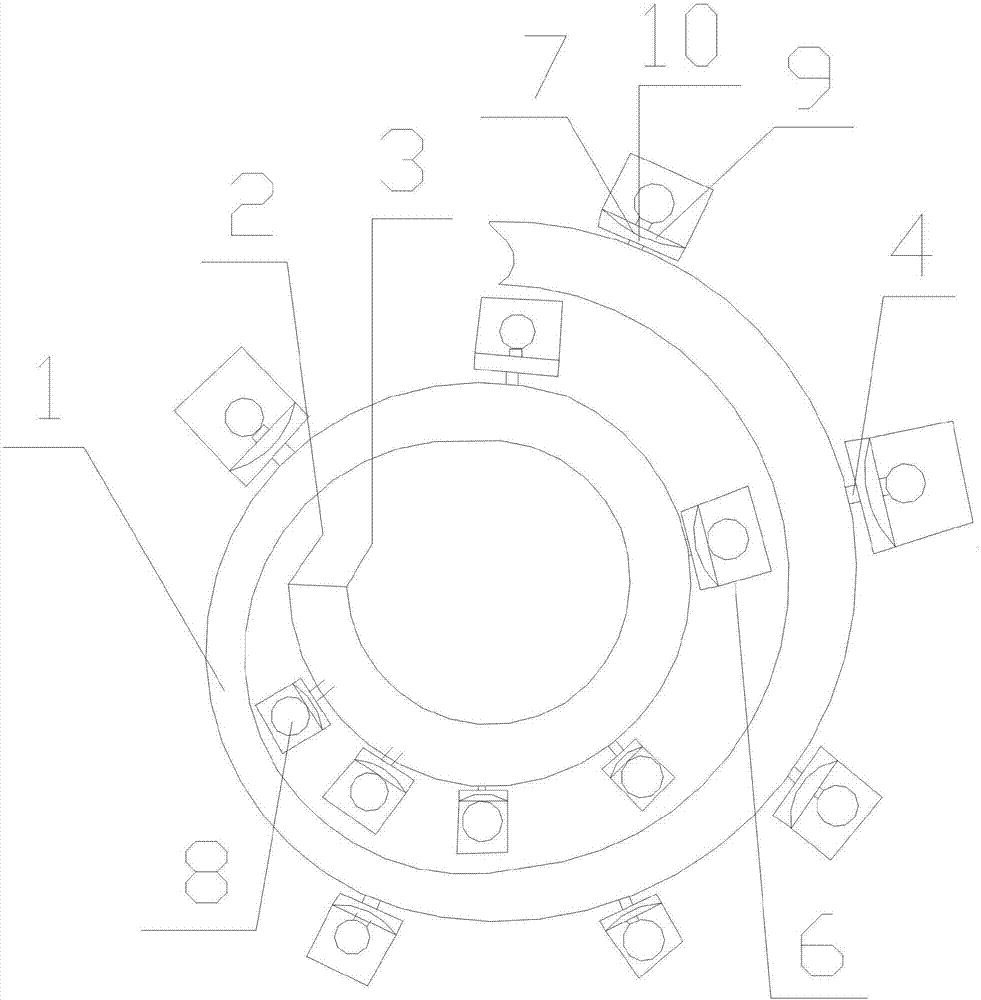

Park roadway lighting decorative lamp

InactiveCN106907616ASimple structureScientific and reasonable designMechanical apparatusElectric circuit arrangementsEffect lightEngineering

The invention discloses a lighting decoration lamp for park roads, which solves the problems of single function, high energy consumption and poor lighting effect in the prior art; it includes an LED lamp line, a positive power supply line and a negative power supply line fixed on the top of the LED light line, uniform The supporting block distributed on the outside of the LED light line, and the lighting device; the lighting device includes a lighting lamp connected to the supporting block through a reflective device, the reflective device includes a concave lens and a silver-plated layer, and the lighting lamp includes an LED lamp bead mounting plate, an LED lamp bead, The lamp housing and the lamp shade, the LED lamp beads are electrically connected to the positive and negative power lines at the same time, the lamp housing is cylindrical and the side facing the LED lamp beads is a linear Fresnel flat prism, and the linear Fresnel flat prism has Fresnel The side of the lampshade opposite to the linear Fresnel flat prism is a light-transmitting diffuser plate, and the inner side of the arc-shaped side of the lampshade is provided with a reflective layer. The invention has the advantages of simple structure, scientific and reasonable design, energy saving, environmental protection and good lighting effect.

Owner:CHENGDU CYLON ELECTRONICS TECH

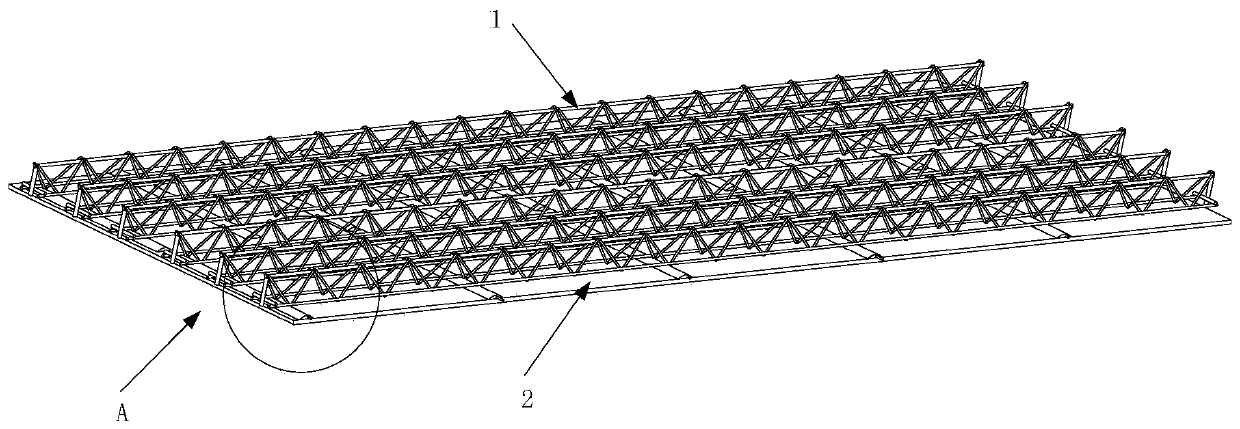

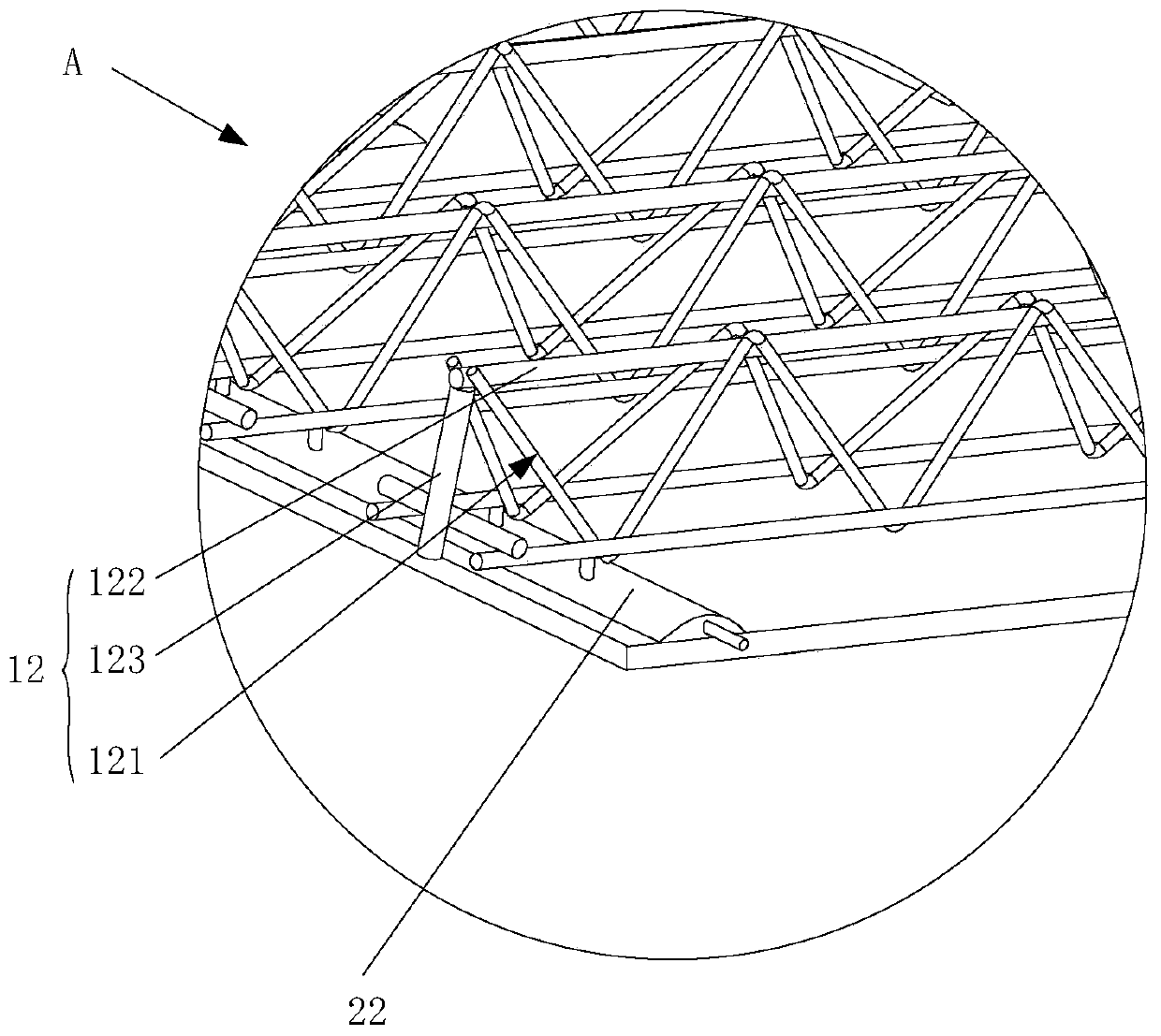

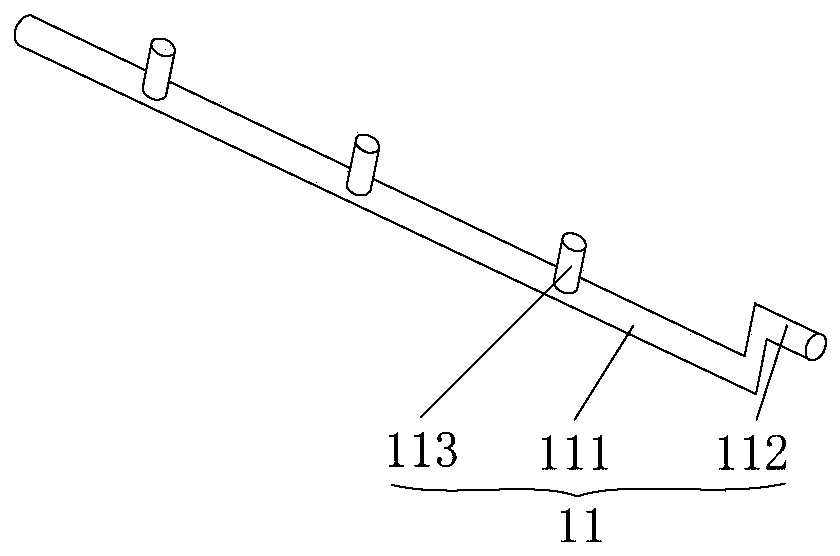

Floor supporting structure and manufacturing method thereof

PendingCN110374240AImplement synchronous jobsWith support functionFloorsPetroleum engineeringProduction cycle

The invention provides a floor supporting structure and a manufacturing method thereof, and relates to the technical field of building. The floor supporting structure provided by the invention comprises a truss component and a module shell body; the truss component at least partly pre-buried in the module shell body; a preserved space used for pouring concrete is provided between the truss component and the module shell body; and the side, which is back to the truss component, of the module shell body is a decorative surface. By adopting the floor supporting structure, decoration and the supporting structure can be performed synchronously; both a supporting function and a decoration function are realized; concrete pouring does not need to be performed before on-site decoration work; the production cycle is short; and cost is low.

Owner:盈创新材料(苏州)有限公司

Jewelry

InactiveCN102389186AWith decorative functionSimple structureEar-ringsPolymer scienceOrganic chemistry

Owner:张家港欧爱化妆品有限公司 +1

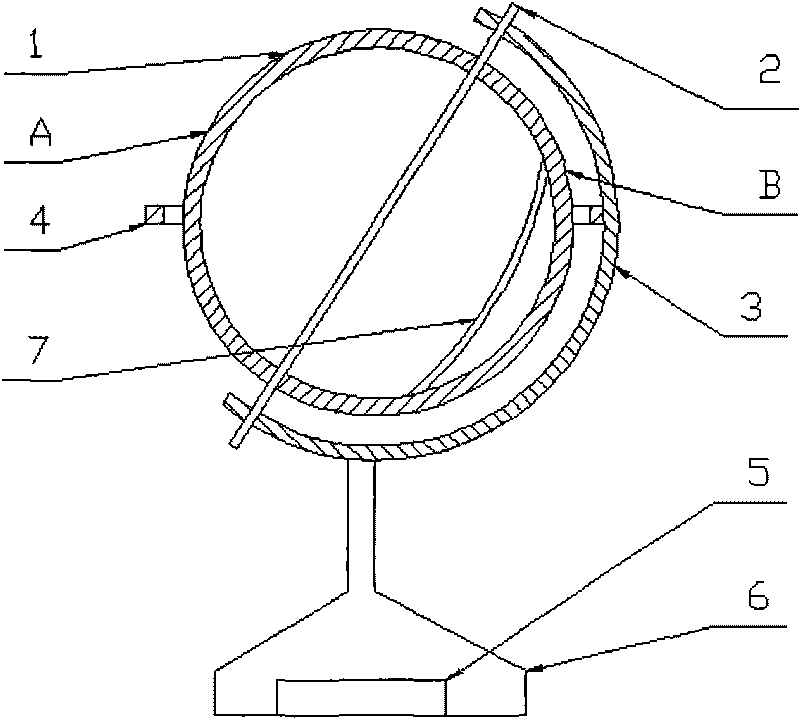

Diatom carving with air purification function and preparation method thereof

The invention discloses a diatom carving with air purification function and a preparation method thereof. The diatom carving with air purification function provided by the invention is composed of thefollowing raw materials by weight: 50-80 parts of diatomite, 15-20 parts of kaolin, 10-20 parts of titanium dioxide, 50-80 parts of shell powder, 10-20 parts of titanium dioxide, 10-20 parts of starch glue, 30-50 parts of carboxy styrene-butadiene latex, 5-10 parts of a colorant, and 100-150 parts of water. The diatom carving with air purification function prepared by the method provided by the invention has decorative function, and at the same time can purify air, lower the content of harmful substances like formaldehyde, benzene, xylene and the like in the air, also can remove peculiar smell in the air and adjust the indoor air humidity, has decorative function while paying close attention to the public health, and is a multifunctional environment-friendly product.

Owner:白山和一硅藻科技股份有限公司

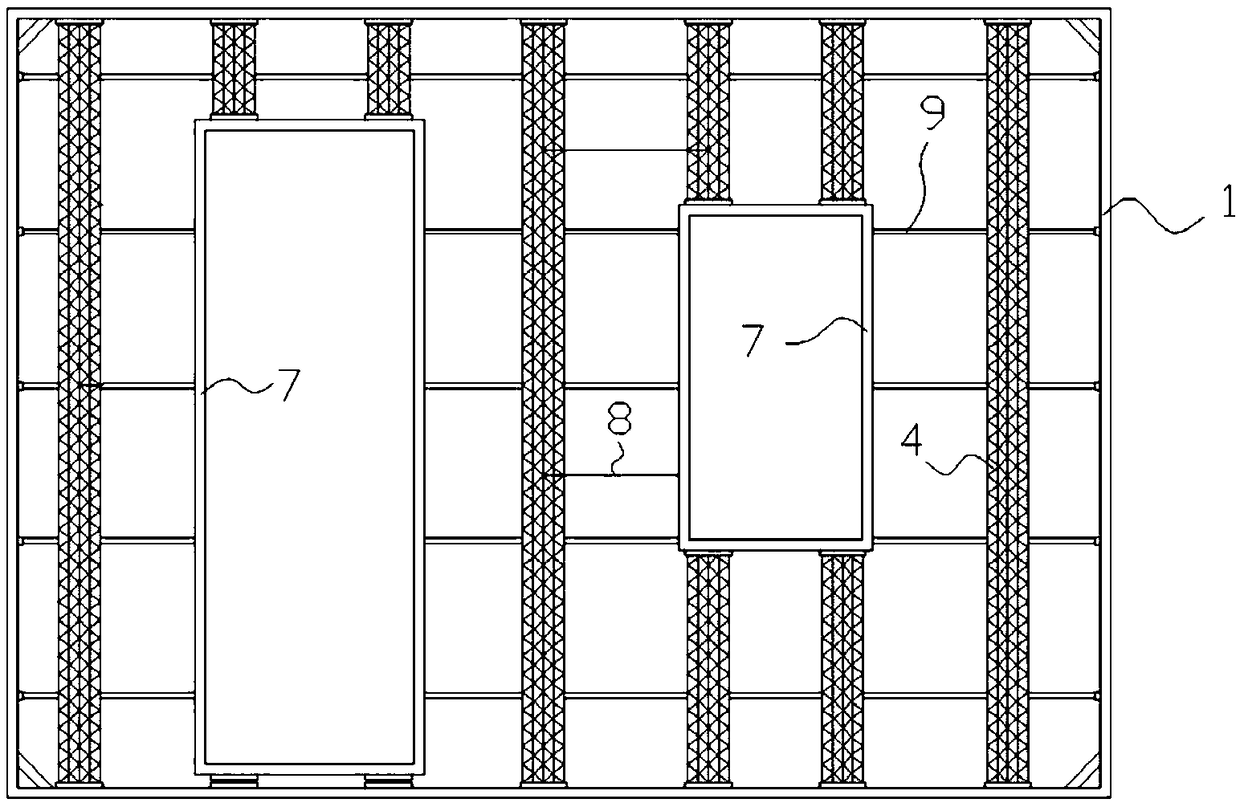

Insulation decorative structure integrated assembly type external wall hanging board

ActiveCN109505391AIncreased load-bearing capacityImprove insulation effectCovering/liningsInter layerKeel

The invention belongs to the field of building materials, and particularly relates to an insulation decorative structure integrated assembly type external wall hanging board which comprises a truss, an upper layer board, a lower layer board and an insulation filling layer, wherein longitudinal keels are uniformly arranged side by side in the truss, and reinforcing ribs are arranged between the longitudinal keels. The insulation filling layer is an inner middle layer of the truss, the upper and lower sides of the truss are connected to the upper layer board and the lower layer board, and the truss, the upper layer board and the lower layer board are connected by bonding or fixing. The hanging board is characterized in that the truss is composed of four sides defined by deformed C-shaped steel, wherein two pieces of C-shaped steel are connected side by side with a notch facing the inside to form one side with a bead or a groove. A door / window frame is arranged in the truss, and the upperand lower ends of the door / window frame are connected with the keel. The external wall hanging board designed can be integrally formed in a factory, reduces the construction process, and integrates the functions of structure, insulation and decoration.

Owner:新疆建筑科学研究院(有限责任公司) +1

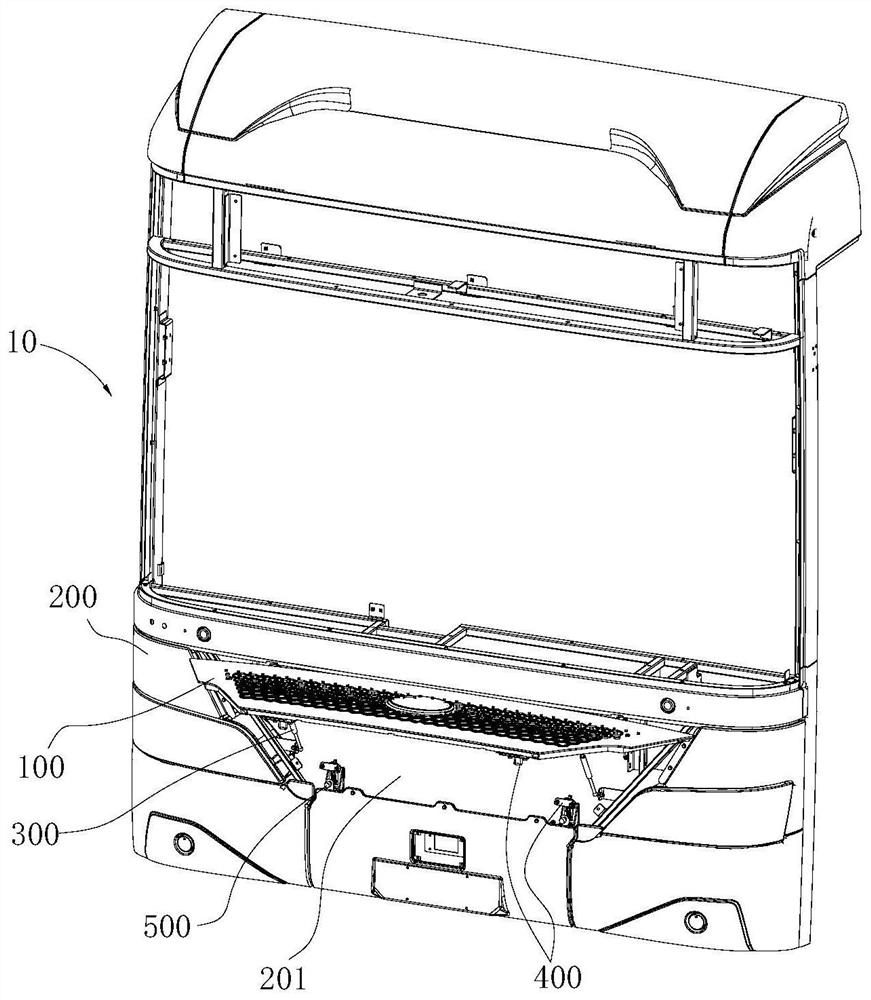

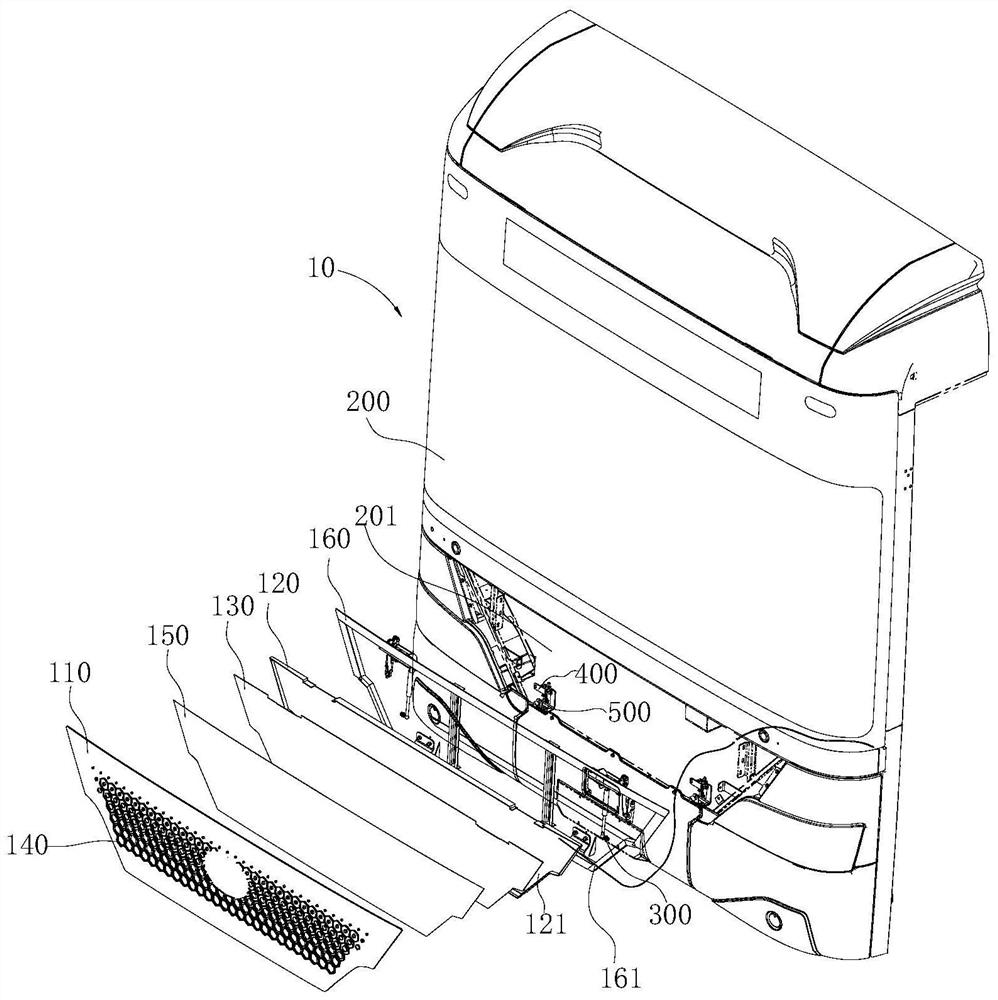

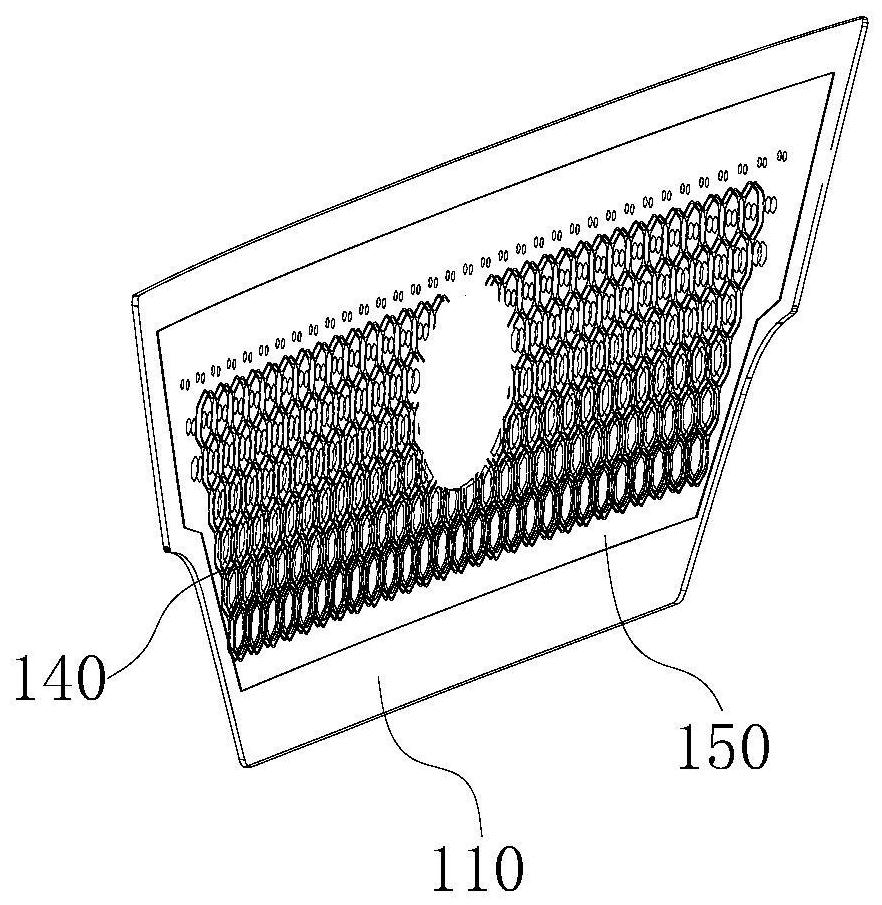

Cover plate and vehicle

PendingCN113619692AWith decorative functionImprove aestheticsLighting elementsSuperstructure subunitsStructural engineeringMechanical engineering

Owner:FAW JIEFANG AUTOMOTIVE CO

Decorative sound-absorbing wall surface

InactiveCN108049586AEffective noise reductionAvoid outgoingCovering/liningsFlooringInsulation layerAirbag

The invention discloses a decorative sound-absorbing wall surface. The decorative sound-absorbing wall surface comprises sound insulation layers and fixing bars. Silencing layers are glued to the twosides of the sound insulation layers. One sides of the silencing layers, far away from the sound insulation layers, are all glued to sound-guiding layers, wherein one of the sound-guiding layers is glued to a decorative layer, and another sound-guiding layer is glued to a fixing plate. A plurality of sound-guiding holes are formed in the sound insulation layers. A plurality of multiple pyramids are arranged in the silencing layers. The tips of the multiple pyramids face the sound-guiding hole. The silencing layers are provided with a plurality of silencing balls. A plurality of fixing groovesare formed in the fixing plate in a embedded mode. The fixing grooves are provided with a plurality of nail holes. The fixing grooves are provided with gear plates. Screw wall nails penetrating through nail holes are arranged on the gear plates. One side of the fixing rod is a rack, and the other side of the fixing rod is provided with an airbag bar. A bracket can be arranged on the wall surface in a detachable mode, and a stepping motor is arranged on the bracket. Compared with the prior art, the wall surface has better sound-absorbing performance and decorative effect; and the installation and the replacement are convenient.

Owner:重庆亭航装饰材料有限公司

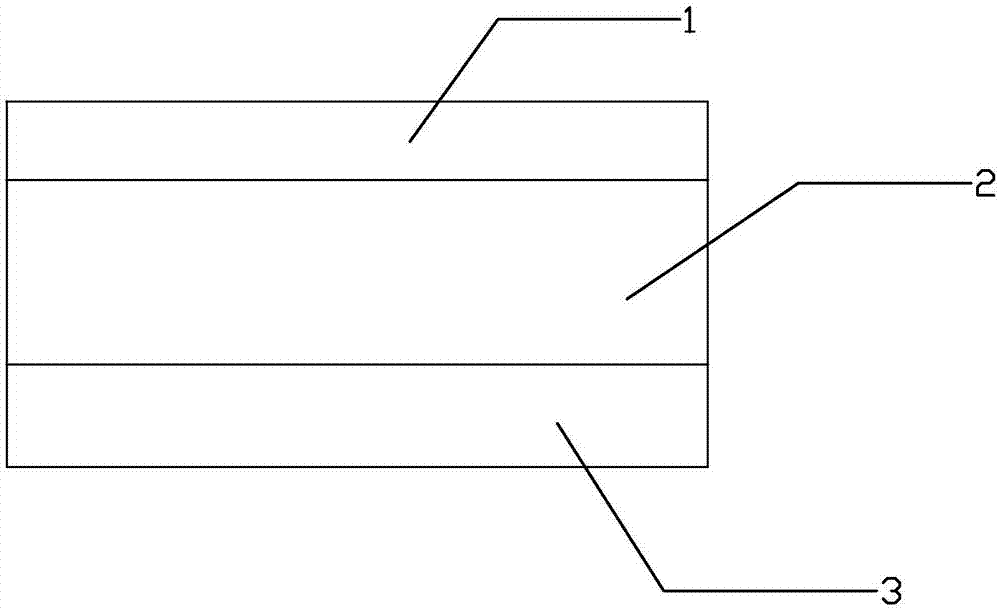

High strength carbon fiber stone composite board

The invention discloses a high strength carbon fiber stone composite board. The high strength carbon fiber stone composite board comprises a base plate layer, a decoration panel layer and a carbon fiber reinforcing layer. The carbon fiber reinforcing layer is located between the base plate layer and the decoration panel layer. All layers are fixed as an integrity through binder. The high strength carbon fiber stone composite board has the advantages that the decorative function is achieved, the high strength and the light weight are achieved, and transportation is convenient, and the high strength carbon fiber stone composite board can be used indoors and outdoors.

Owner:FOSHAN UNIVERSITY

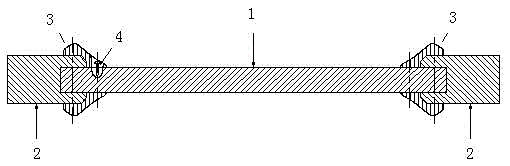

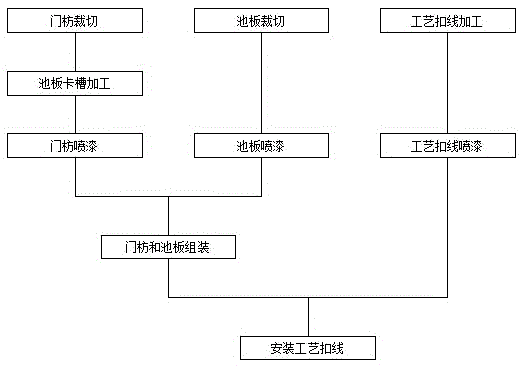

Anti-contraction wooden concave strip door leaf and manufacturing method thereof

InactiveCN105484632ASimple structureImprove applicabilityWood working apparatusGlass pane fixingMachining processIndustrial engineering

The invention discloses an anti-contraction wooden concave strip door leaf and a manufacturing method thereof. The door leaf comprises an internal plate, door frames and process convex strips. The door frames are provided with clamping grooves with the width corresponding to the thickness of the internal plate, and the edges of the internal plate are installed in the clamping grooves of the door frames. The process convex strips are fixed to the door frames and the internal plate through fasteners. By simplifying the connection structure between the internal plate and the door frames, adaptability of the internal plate and the door frames is improved, so that production and storage of the internal plate and the door frames can be independently carried out, production efficiency is improved, production cost is reduced, and the production period is shortened. Fastened connection between the door frames and the internal plate is enhanced through the process convex strips, and firmness and reliability of connection between the door frames and the internal plate are improved. Paint bottom layers are sprayed on the internal plate, the door frames and the process convex strips in advance so that the door leaf can be prevented from contracting or deforming in the use process due to thermal expansion and cold contraction. Moreover, gun nails are adopted for fastening the process convex strips, connection is reliable, the processing technology is simple, and installation efficiency is high.

Owner:GUANGZHOU SHENGSHANG WOODEN DOORS CO LTD

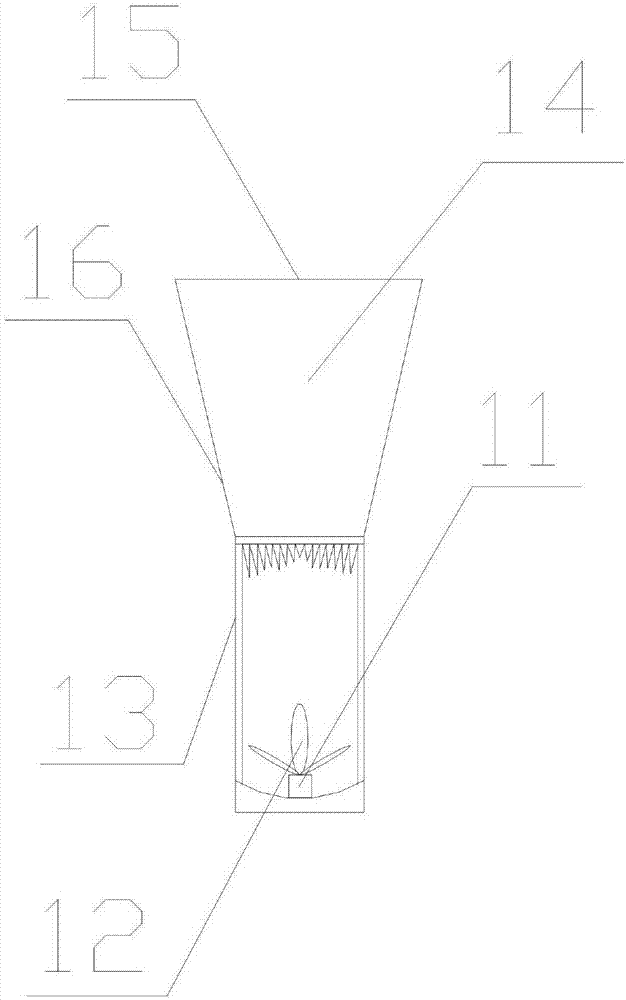

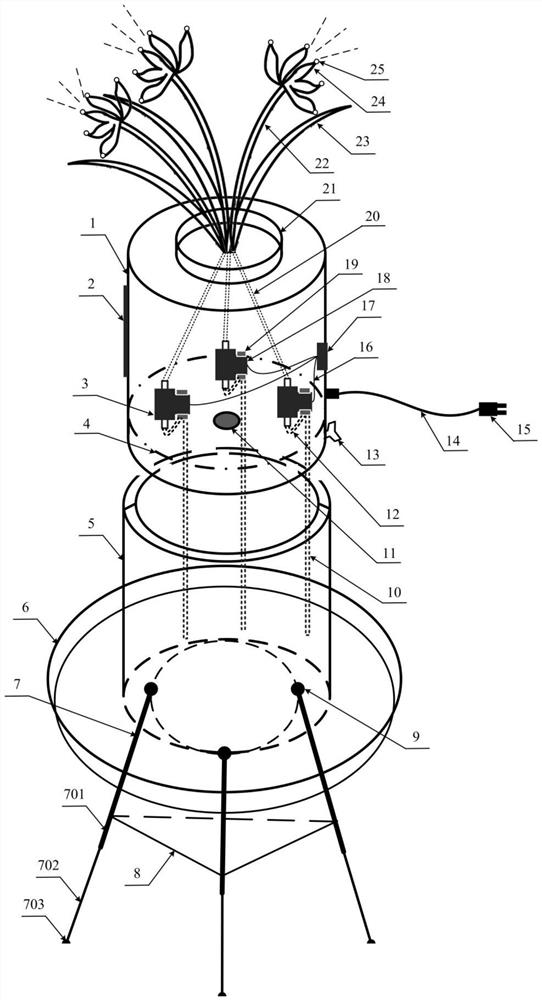

Indoor air humidifier

InactiveCN112833489ASolve drying problemsReduce energy consumptionMechanical apparatusLighting and heating apparatusMedicineTap water

Air humidity has an important influence on human health. In autumn, winter, early spring, indoor space is always very dry in northern China and other areas, people living and working indoors feel very uncomfortable, and therefore an air humidifier needs to be used for increasing the humidity of indoor air. The invention relates to an indoor air humidifier. Based on the principle of physical spray humidification, the indoor air humidifier can directly use tap water as a water source without generating calcium and magnesium white powder, has a two-stage storage function for water drops generated by water mist which is not absorbed by the air, prevents falling water drops from contaminating indoor floor tile surfaces or floor board surfaces, has the functions of height adjustment and sterilization, solves multiple problems of an existing humidifier, can humidify indoor air conveniently, safely and healthily, is attractive in appearance, artistic and aesthetic, meets both the humidification requirement and the indoor decoration requirement and has a very broad application prospect.

Owner:腾科技术(天津)有限公司

Jewelry capable of emitting fragrance

Owner:张家港欧爱化妆品有限公司 +1

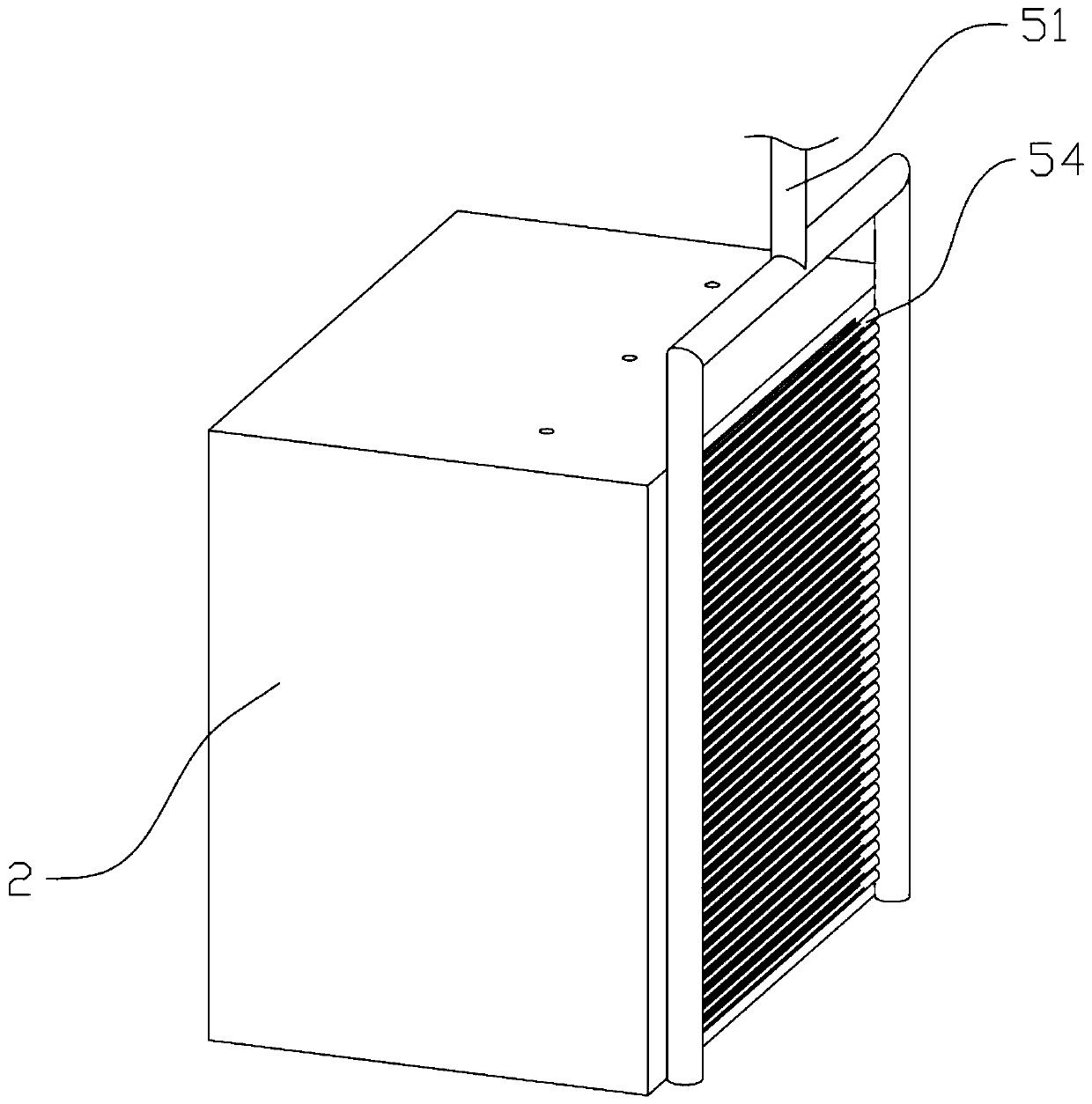

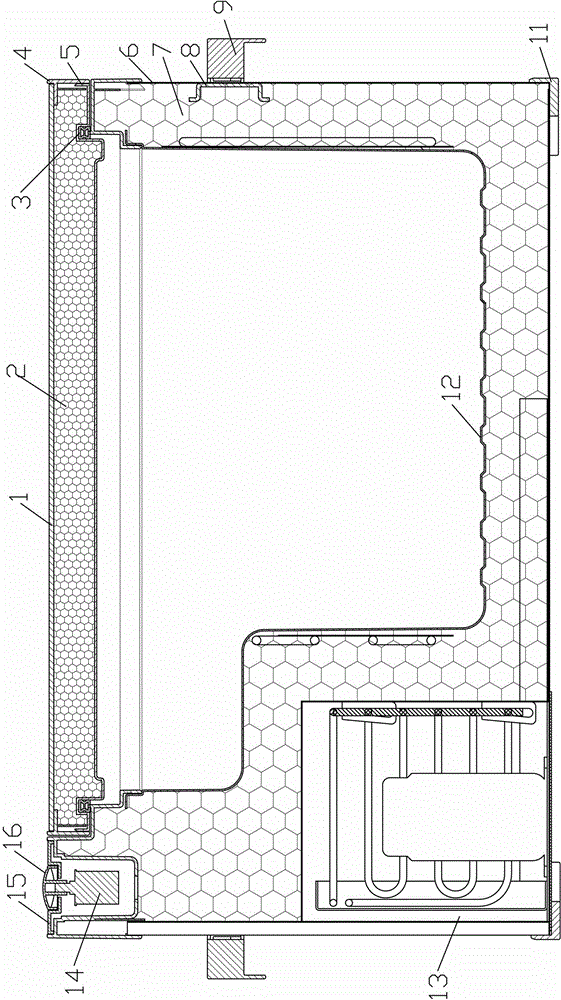

Vehicle-mounted glass panel foam door refrigerator

InactiveCN104654703ASolve the shortcomings of monotonous appearance and color listBeautiful appearanceWing handlesLighting and heating apparatusTemperature controlAssembly line

The invention discloses a vehicle-mounted glass panel foam door refrigerator, which comprises a door and a refrigerator body; the door is arranged on the refrigerator body, a refrigeration system and a temperature control system are arranged in the refrigerator body, the door comprises a glass panel, a foam layer, a door frame and a liner, the glass panel and the liner are arranged on the door frame, and the foam layer is arranged between the glass panel and the liner; the refrigerator body comprises a refrigerator body door frame, an external plate, a liner and a handle, the external plate and the corresponding liner are arranged on the refrigerator body door frame, a foam layer is arranged between the external plate and the corresponding liner, and the handle is arranged on the external plate. The vehicle-mounted glass panel foam door refrigerator has a good temperature-keeping effect and a good heat insulation effect, is convenient to operate, has an attractive appearance, and is suitable for production on an assembly line.

Owner:HENAN SNOWSEA HOME APPLIANCE TECH

Silicon ceramic sheet and preparation method thereof

InactiveCN106673702ALow water absorptionAdjustable water absorptionCeramicwareClaywaresLead zirconate titanateFiber

The invention discloses a silicon ceramic sheet and a preparation method thereof. The silicon ceramic sheet is prepared from the following components in parts by weight: 15-17 parts of feldspar, 6-10 parts of kieselguhr, 6-8 parts of aluminum nitride, 3-5 parts of clay, 4-8 parts of kaolin, 3-5 parts of nickel foam, 4-6 parts of boron nitride, 6-10 parts of wollastonite, 6-10 parts of limestone, 4-6 parts of lead zirconate titanate, 4-6 parts of zinc oxide, 6-10 parts of carbon fiber and 2-4 parts of an auxiliary tackifier. A substrate is formed by adopting an inorganic material foaming layer, so that the prepared silicon ceramic sheet has the characteristics of being light in weight and low in water absorption rate, and adjustable water absorption rate of a ceramic building sheet can be achieved by adjusting the foaming rate or different foaming sizes of the inorganic material foaming layer.

Owner:吴硕

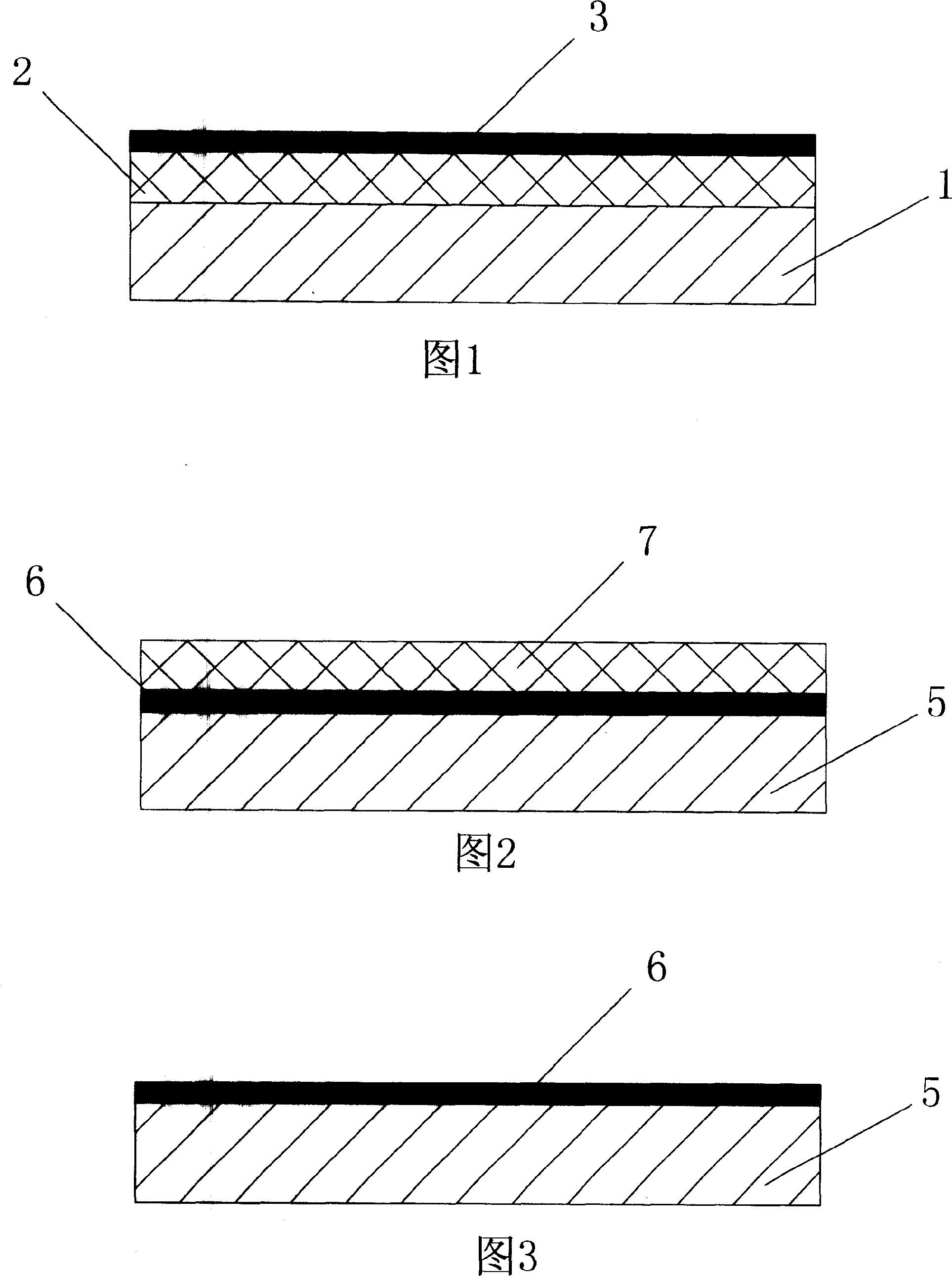

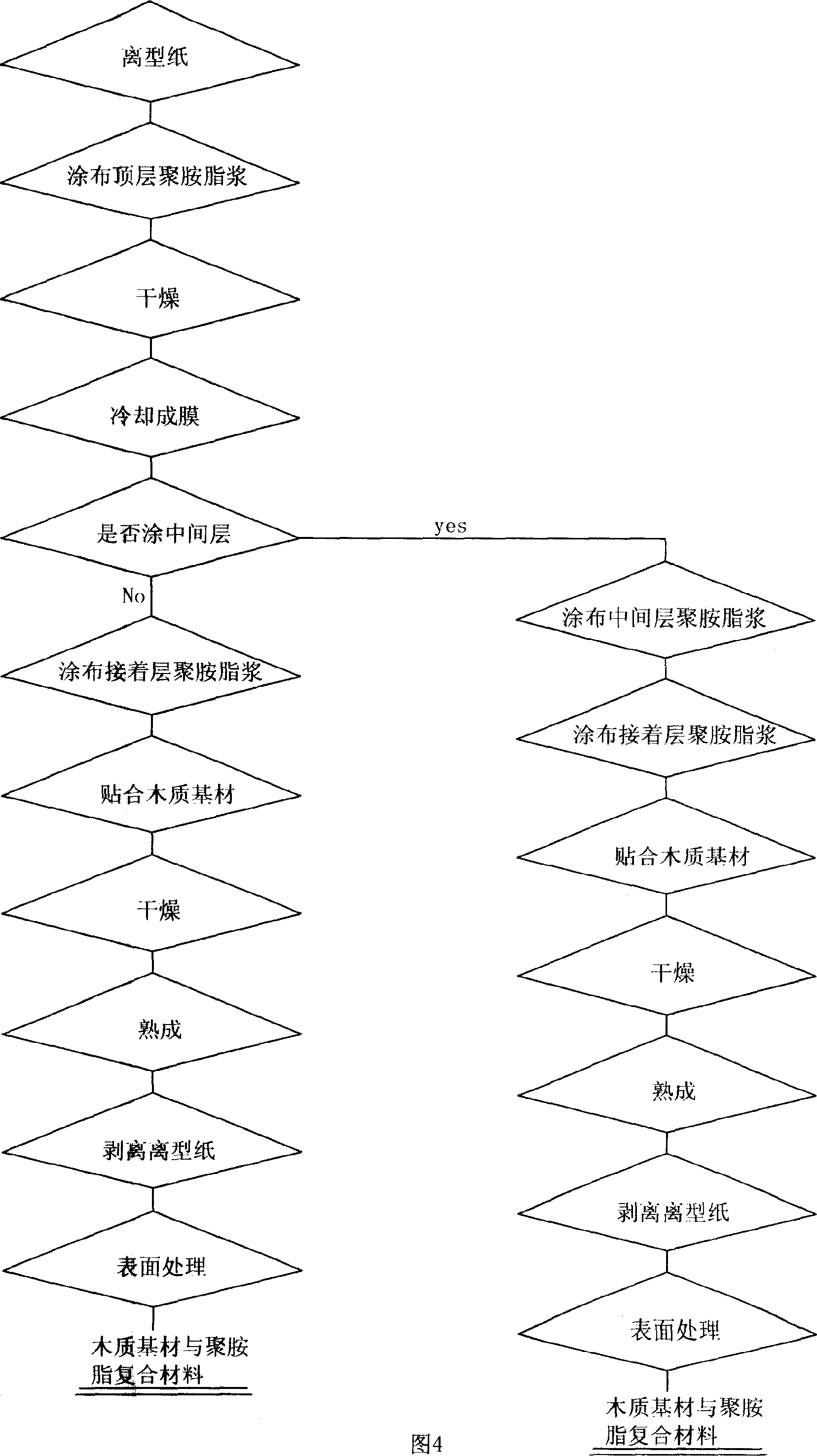

Composite material of wooden base material and manufacture method thereof

InactiveCN101015972AReduce thicknessMeet different needsLamination ancillary operationsDecorative surface effectsOrganic solventSlurry

The invention discloses a method for producing the composite material of wooden base and polyurethane, and relative production. The invention comprises a wooden base whose surface is disposed with at least layer of polyurethane slurry added with organic solvent, colorant, and agents. The invention coats polyurethane slurry on specific paper, adjusts the components of each coat, to produce the composite layer with different functions, to meet different demands. And since the specific paper is formed with paper or word, the specific paper can be removed after composing and shaping the composite layer and wooden base, to transfer pattern and word on the composite layer, with decorative function. The invention can be used to pattern paper, packing box, floor or the like.

Owner:吕东鸿

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com