Anti-contraction wooden concave strip door leaf and manufacturing method thereof

A production method and anti-shrinkage technology, applied in the direction of door leaves, manufacturing tools, wood processing equipment, etc., can solve the problem of not being able to realize the separate production and inventory of pool boards and door frames, limiting the production and application range of craft buckle lines, inventory, transportation and The difficulty of installation and other problems can shorten the production period, improve the firmness and reliability, and prevent the shrinkage of wood.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

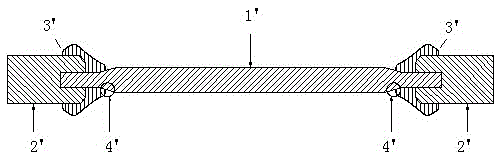

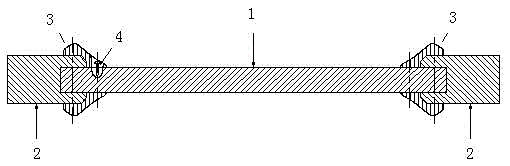

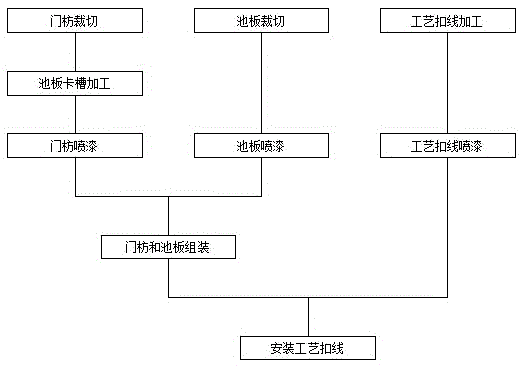

[0028] figure 2 For the anti-shrinkage wooden threaded door leaf disclosed in the preferred embodiment of the present invention, the height and width of the threaded door leaf are about 2m and 1m respectively. It can be seen from the figure that the anti-shrinkage wooden buckle door leaf includes a pool plate 1, a door frame 2 and a craft buckle 3. The door frame 2 is installed around the pool plate 1, and the process buckle wire 3 is fastened on the pool plate 1 and the door frame 2. There is a pool board slot on the door frame 2, the width of the pool board slot coincides with the thickness of the pool board 1, and the depth of the pool board slot is 1-50mm; the edge of the pool board 1 is clipped on the door frame 2 in the slot of the pool plate. The pool plate 1, the door frame 2 and the process buckle line 3 are equipped with gun nails 4 for fastening at the center line. The length of the gun nails is 20mm and the diameter is 2mm.

[0029] The process buckle 3 disclos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com