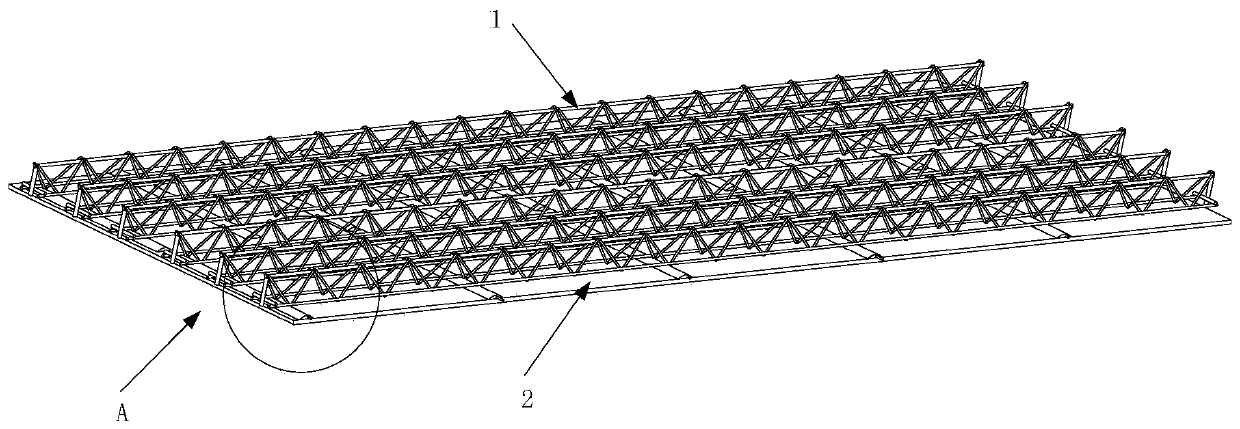

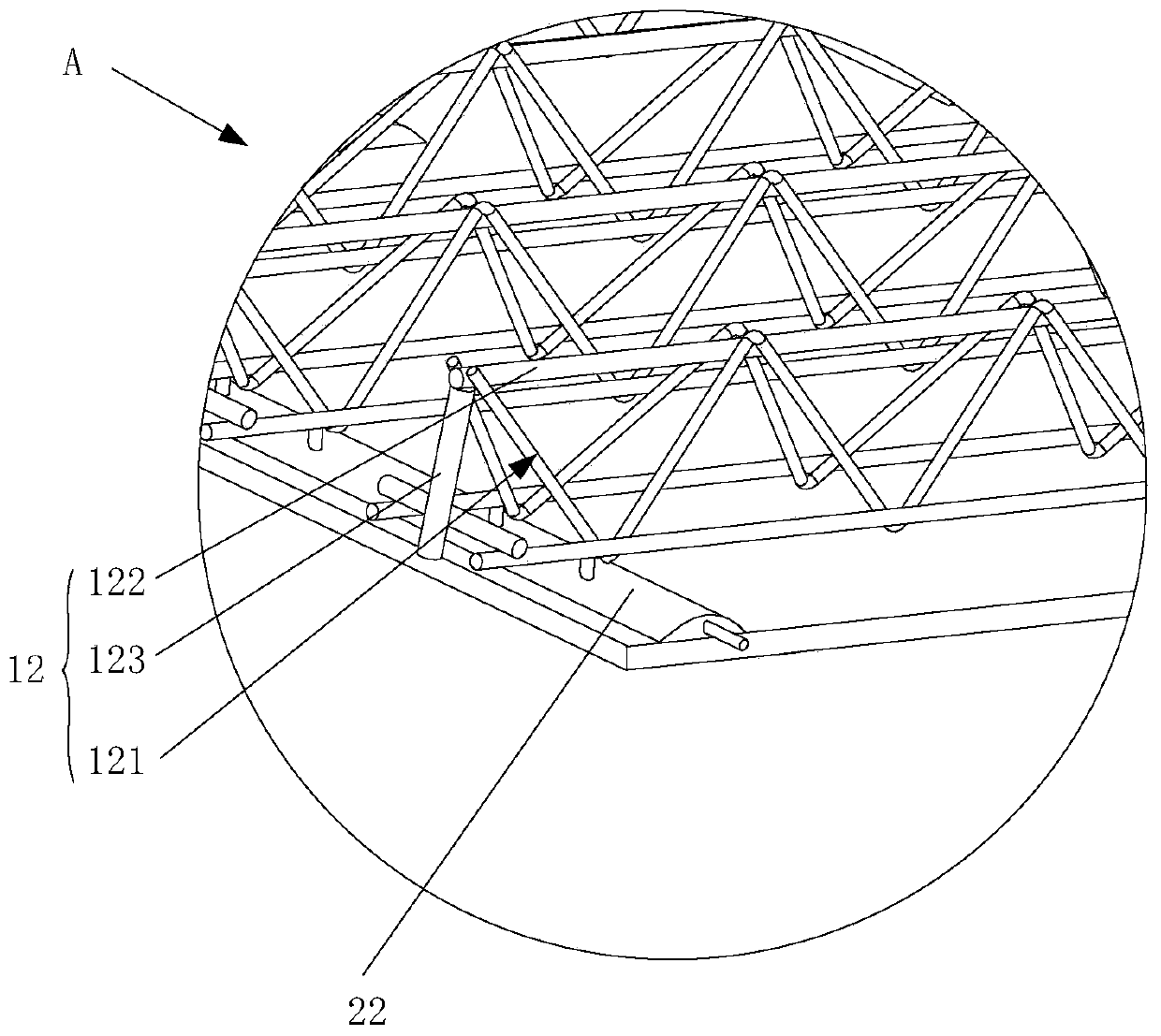

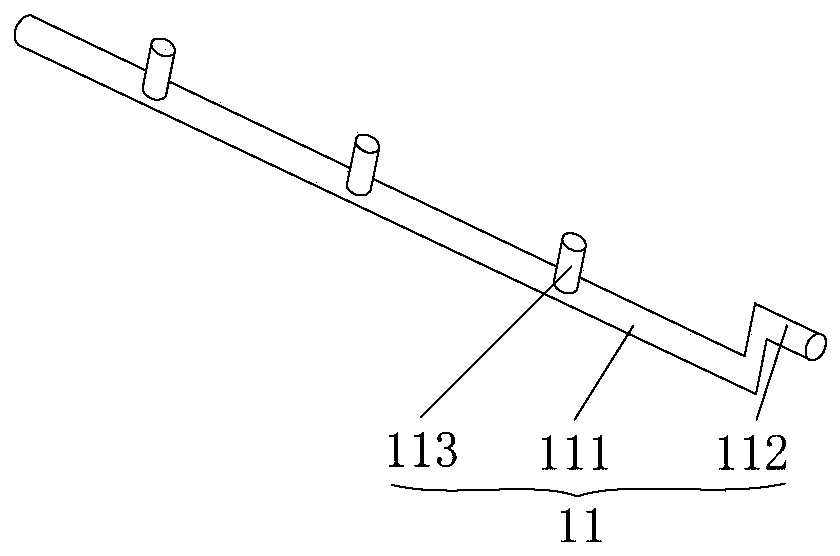

Floor supporting structure and manufacturing method thereof

A supporting structure and manufacturing method technology, applied in the direction of floors, building structures, building components, etc., can solve the problems of long production cycle and high cost, and achieve the effect of short production cycle, low cost and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0090] Such as Figure 9 As shown, a method for manufacturing a floor support structure according to the present invention includes:

[0091] Step S101, laying part of the formwork body, and one side of part of the formwork body is a decorative surface;

[0092] Step S102, placing the truss assembly on the side of the partial formwork body away from the decorative surface;

[0093] Step S103, laying the remaining formwork body, so as to pre-embed at least part of the truss components in the formwork body, and form a reserved space for pouring concrete between the truss components and the formwork body.

[0094] The specific operation process is as follows:

[0095] First proceed to step S101, laying part of the formwork body, and one side of the part of the formwork body is the decorative surface; then proceed to step S102, place the truss assembly on the side of the partial formwork body away from the decorative surface, to facilitate the next steps Pre-embed the truss com...

Embodiment 2

[0097] Such as Figure 10 As shown, a method for manufacturing a floor support structure according to the present invention includes:

[0098] First subunit laying step S201, laying felt soaked with gypsum slurry, spraying glass fibers with gypsum slurry to the felt, compacting the glass fibers with gypsum slurry with a compactor, laying mesh cloth on the glass fibers, Use compacting parts to compress the mesh cloth;

[0099] Step S202, repeating the first subunit laying step at least once.

[0100] Step S203, placing the truss assembly on the side of the partial formwork body away from the decorative surface;

[0101] The second subunit laying step S204, laying the felt soaked with gypsum slurry and compacting the felt soaked with gypsum slurry using a compactor, spraying glass fibers with gypsum slurry to the felt and compacting the felt with gypsum slurry using a compactor The glass fiber is laid on the glass fiber, and the mesh cloth is compacted with a compactor, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com