360-degree rotary iron frame welding equipment and technology allowing position of mold to be adjusted

一种焊接设备、旋转式的技术,应用在焊接设备、辅助焊接设备、焊接/切割辅助设备等方向,能够解决生产效率低、安装铁线以及焊接作业不方便、焊接和组装无法同步进行等问题,达到效率高、提高生产效率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to describe the technical content, achieved goals and effects of the present invention in detail, the following descriptions will be made in conjunction with the embodiments and accompanying drawings.

[0021] The most critical idea of the present invention is that the mold can be pushed and pulled to rotate, no matter when welding or installing iron wires, workers do not need to adjust the station position, and can adjust the position of the iron frame by moving the mold, which is more efficient.

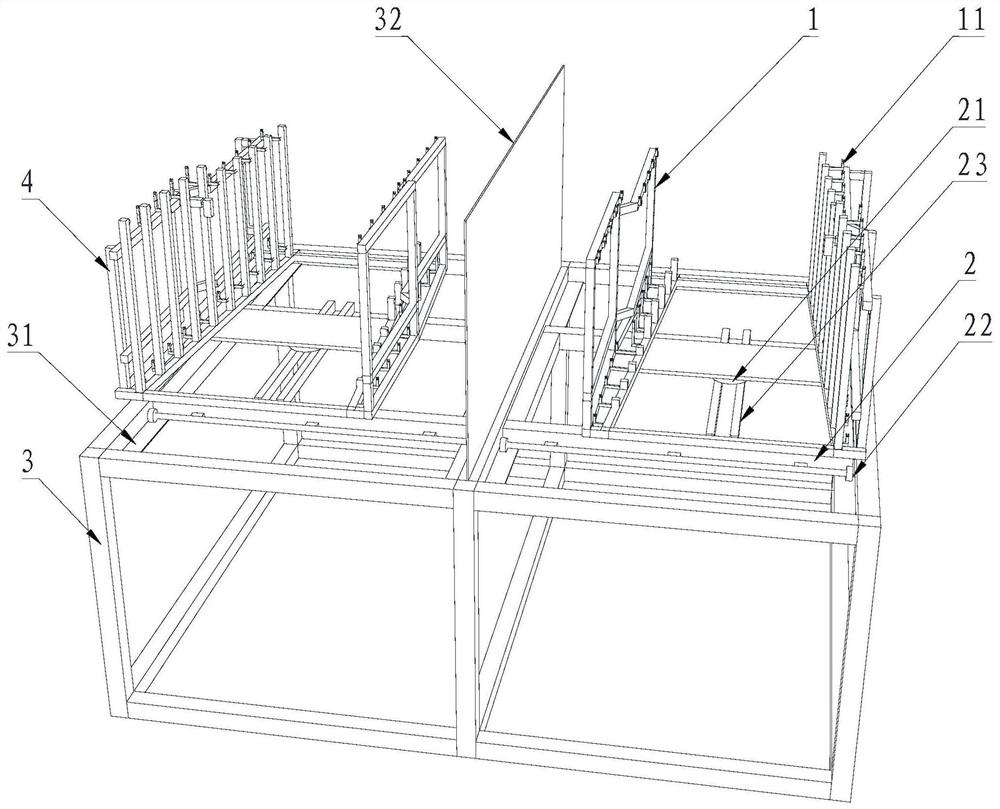

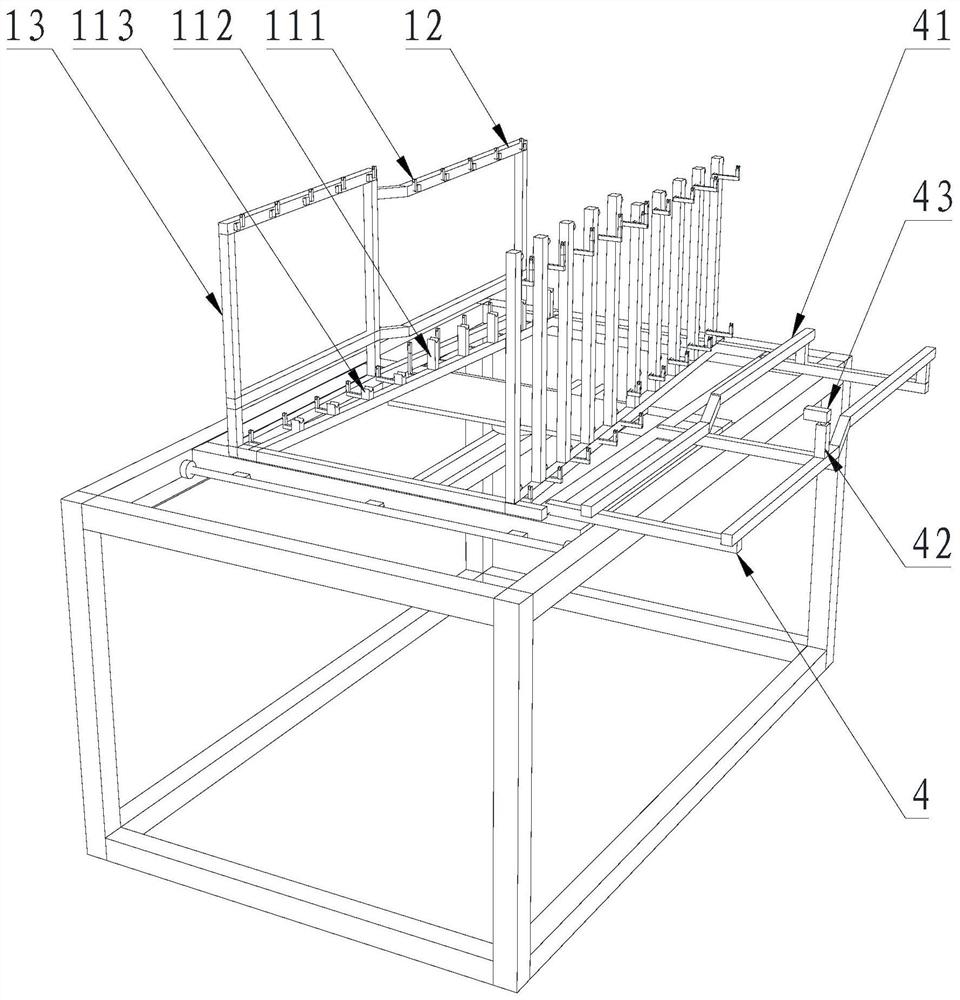

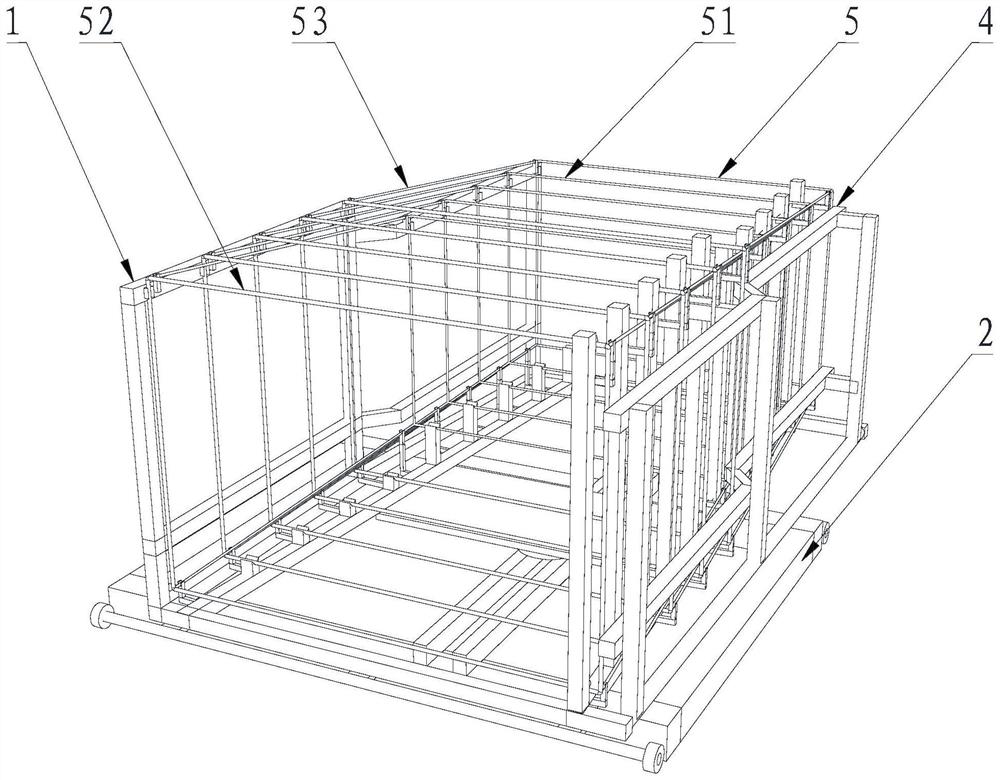

[0022] Please refer to Figure 1 to Figure 3 , a 360-degree rotating iron frame welding equipment, including an iron frame mounting frame, a movable frame and a fixed frame;

[0023] The top of the movable frame is provided with a turntable, and the bottom of the iron frame installation frame is erected on the turntable;

[0024] The top of the fixed frame is provided with a first slide rail, and the bottom of the movable frame is provided with a pulley matched w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com