A pcb board welding device based on double board clamping technology

A PCB board and soldering device technology, applied in the PCB field, can solve the problems of long soldering time, difficult soldering, difficulty in meeting modern production needs, etc., and achieve the effects of improving processing efficiency, facilitating reverse processing, and improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

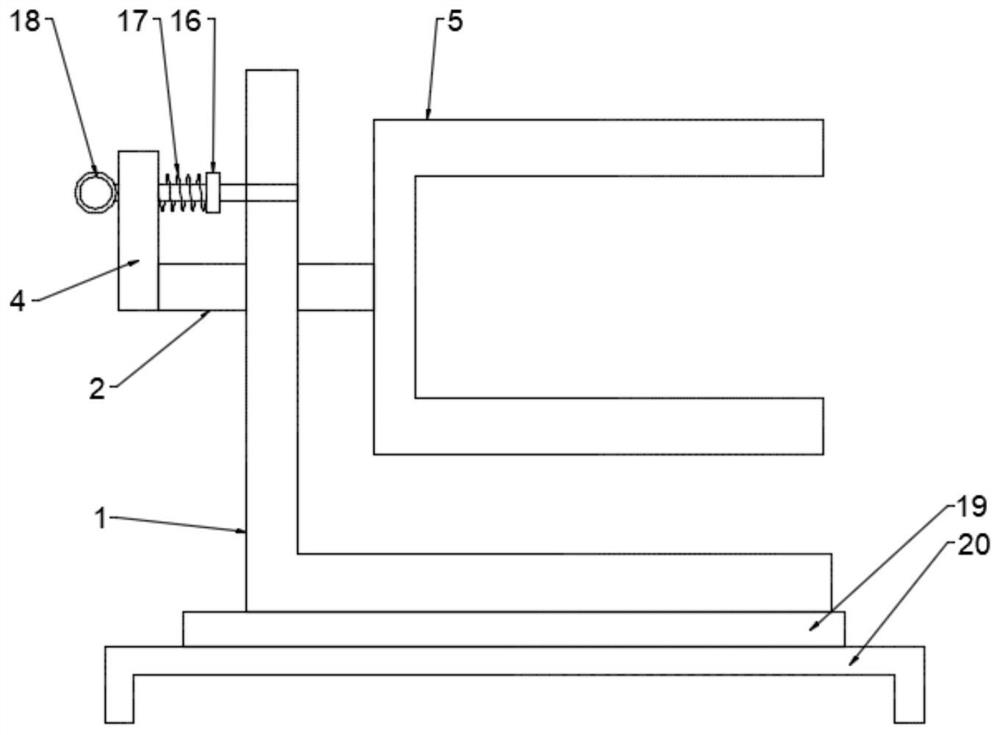

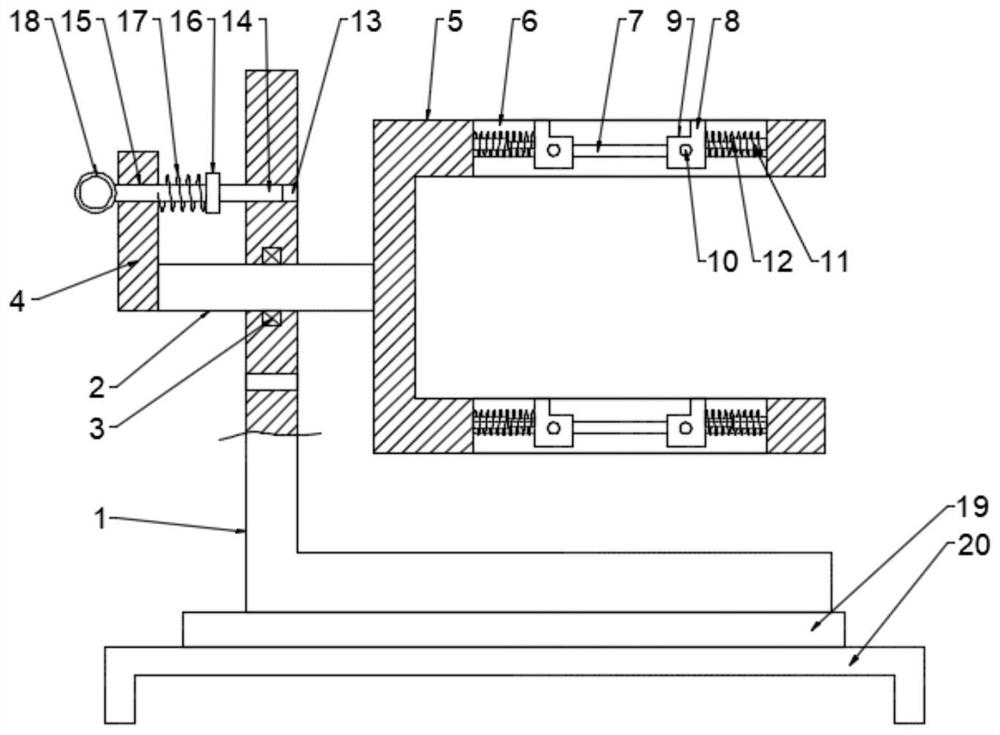

[0026] see Figure 1~3 , a PCB board welding device based on double-board clamping technology, including a bracket 1, the bracket 1 is an L-shaped structure, the side wall of the bracket 1 is embedded with a rotating shaft 2, and the rotating shaft 2 is rotatably connected to the bracket through a bearing 3 1, the left end of the rotating shaft 2 is fixedly connected to the toggle lever 4, the other end of the toggle lever 4 is provided with a positioning mechanism, and the right end of the rotating shaft 2 is fixedly connected to the support frame 5, and the support frame 5 is U-shaped structure, the side wall of the support frame 5 is provided with a clamping cavity 6, and a clamping mechanism is provided in the clamping cavity 6, and the PCB board is installed in the clamping cavity 6 through the clamping mechanism, and two PCB boards are clamped at a time, It can realize the synchronous operation of two PCB boards and improve the processing efficiency; loosen the positioni...

Embodiment 2

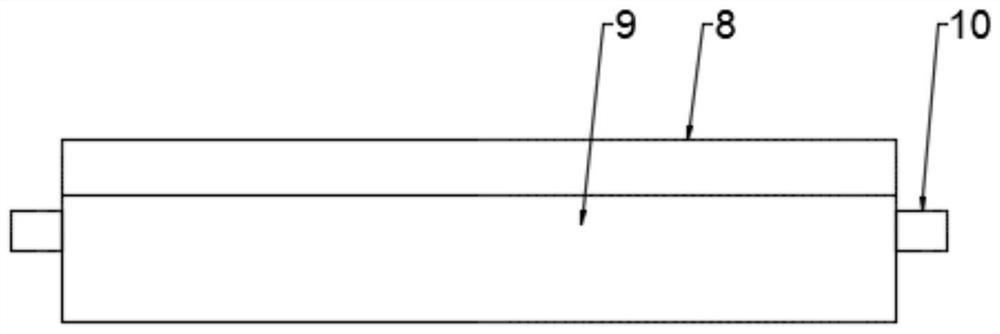

[0028] This embodiment is a further elaboration on the basis of Embodiment 1. The clamping mechanism includes a chute 7, a push clamp 8 and a telescopic rod 11. The front and rear walls of the cavity 6 are symmetrically provided with a chute 7, The left and right sides of the inner cavity of the card cavity 6 are symmetrically provided with push clips 8 matched with the chute 7, and there is a sliding connection between the card cavity 6 and the push clip 8, and the front and rear ends of the push clip 8 are symmetrically arranged with the chute. 7 is matched with the sliding pin 10, which is a sliding connection between the sliding pin 10 and the chute 7, and the push clip 8 can slide left and right along the chute 7 through the mutual cooperation of the sliding pin 10 and the chute 7.

[0029] The top adjacent side of the push clip 8 is provided with a clip groove 9, and one end of the push clip 8 opposite to the clip groove 9 is fixedly connected to the telescopic rod 11, an...

Embodiment 3

[0031] This embodiment is a further elaboration on the basis of Embodiment 1. The positioning mechanism includes a positioning rod 14 and two positioning holes 13, and the two positioning holes 13 are symmetrically arranged on the upper and lower sides of the side wall of the bracket 1. The rotating shaft 2 is arranged in the center between the two positioning holes 13, and the rotating angle of the rotating shaft 2 is positioned by using the positioning holes 13, which reduces the complexity of operation and improves the convenience of processing.

[0032] The overhanging end of the toggle rod 4 is provided with a jack 15, the jack 15 is provided with a positioning rod 14 matched with the positioning hole 13, and the positioning rod 14 is slidingly connected to the jack 15, The left side end of positioning rod 14 is fixedly connected with the finger ring 18 that cooperates with jack 15, and the outer circular surface right side of positioning rod 14 is provided with the baffle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com