360-degree rotary iron frame welding device and process

A technology of welding equipment and welding process, which is applied in the field of 360-degree rotating iron frame welding equipment and technology, can solve the problems of low production efficiency, inconvenient installation of iron wires and welding operations, and inability to synchronize welding and assembly to achieve high efficiency. High, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to describe the technical content, achieved goals and effects of the present invention in detail, the following descriptions will be made in conjunction with the embodiments and accompanying drawings.

[0020] The most critical idea of the present invention is that the mold can be pushed and pulled to rotate, no matter when welding or installing iron wires, workers do not need to adjust the station position, and can adjust the position of the iron frame by moving the mold, which is more efficient.

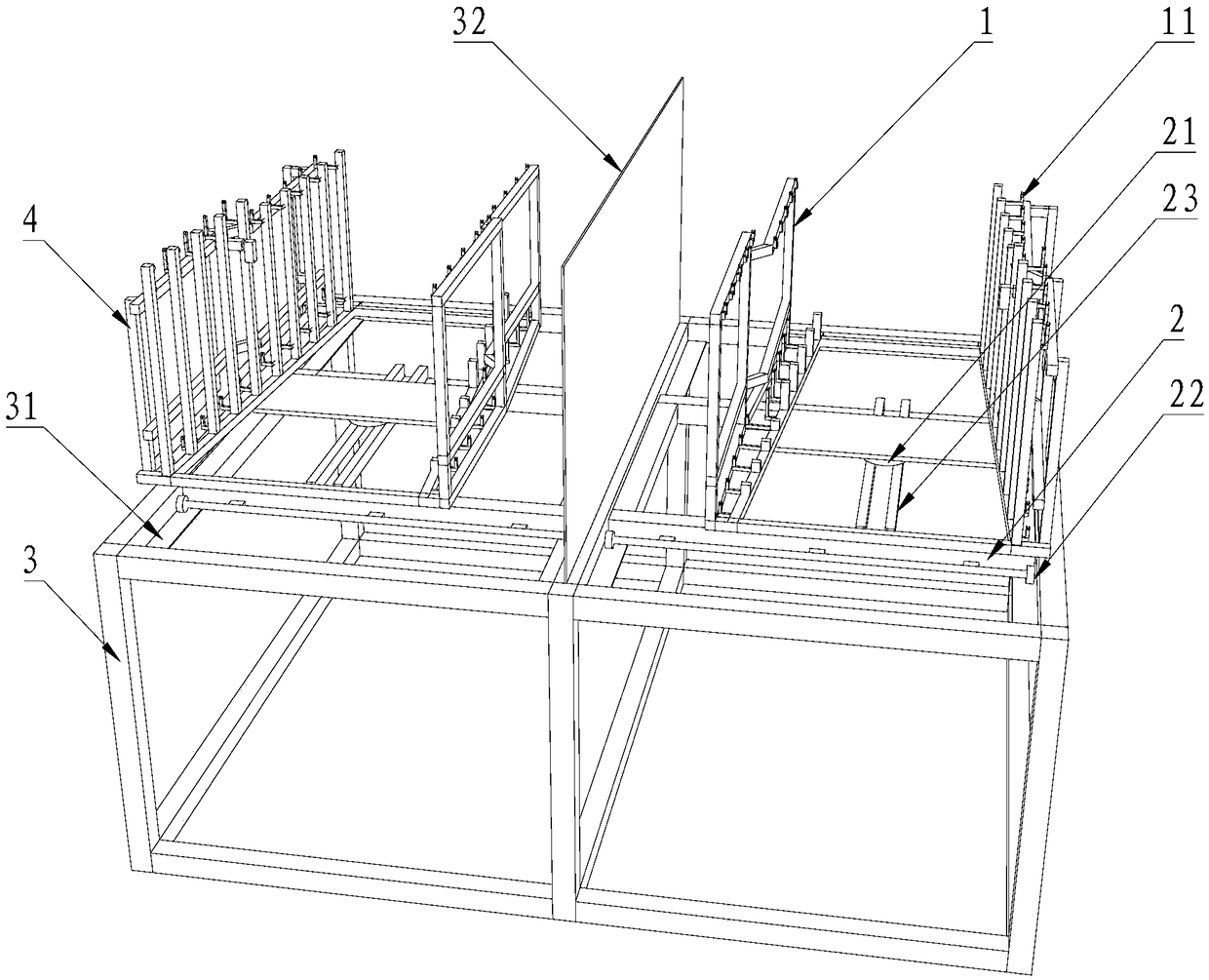

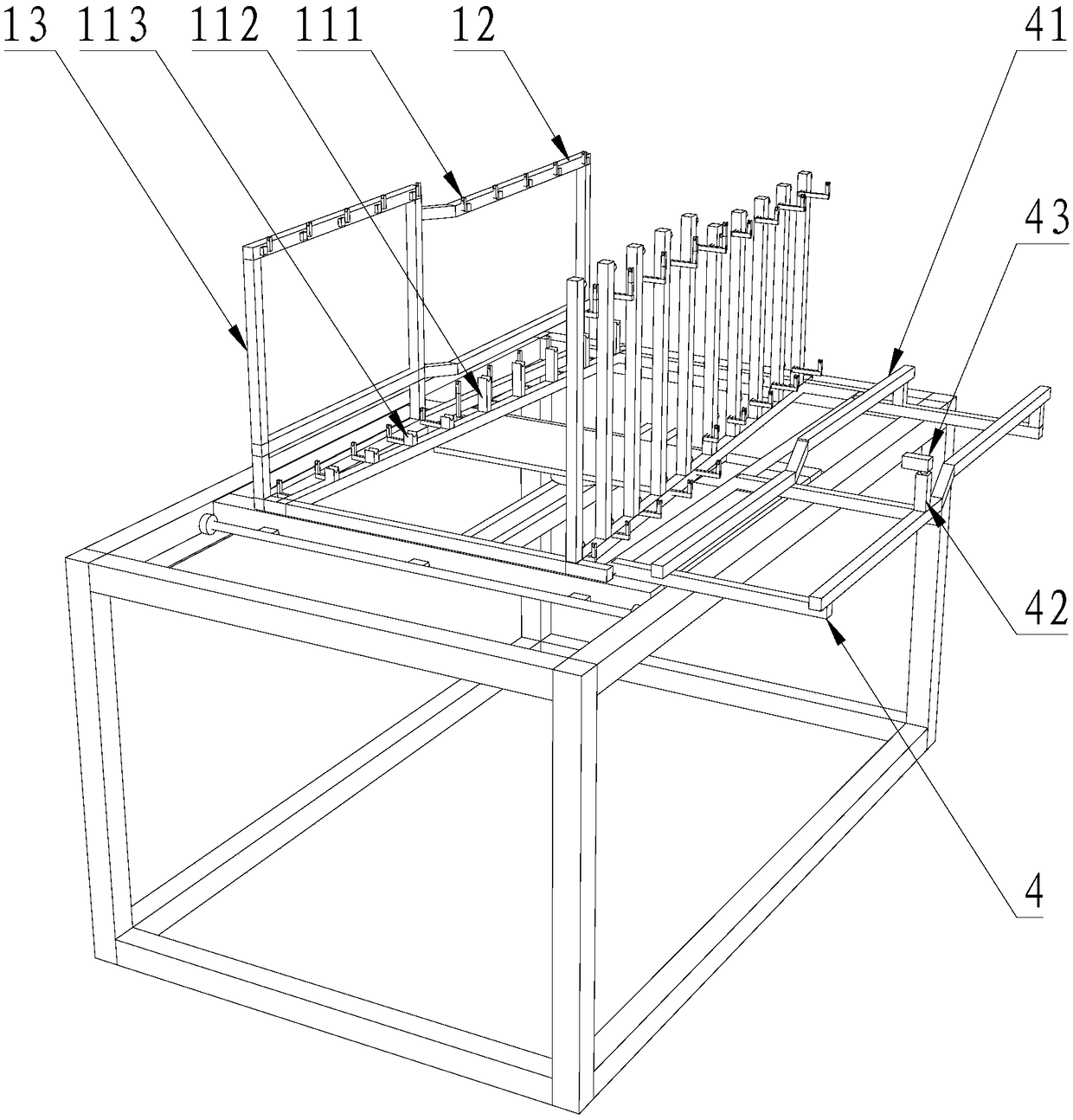

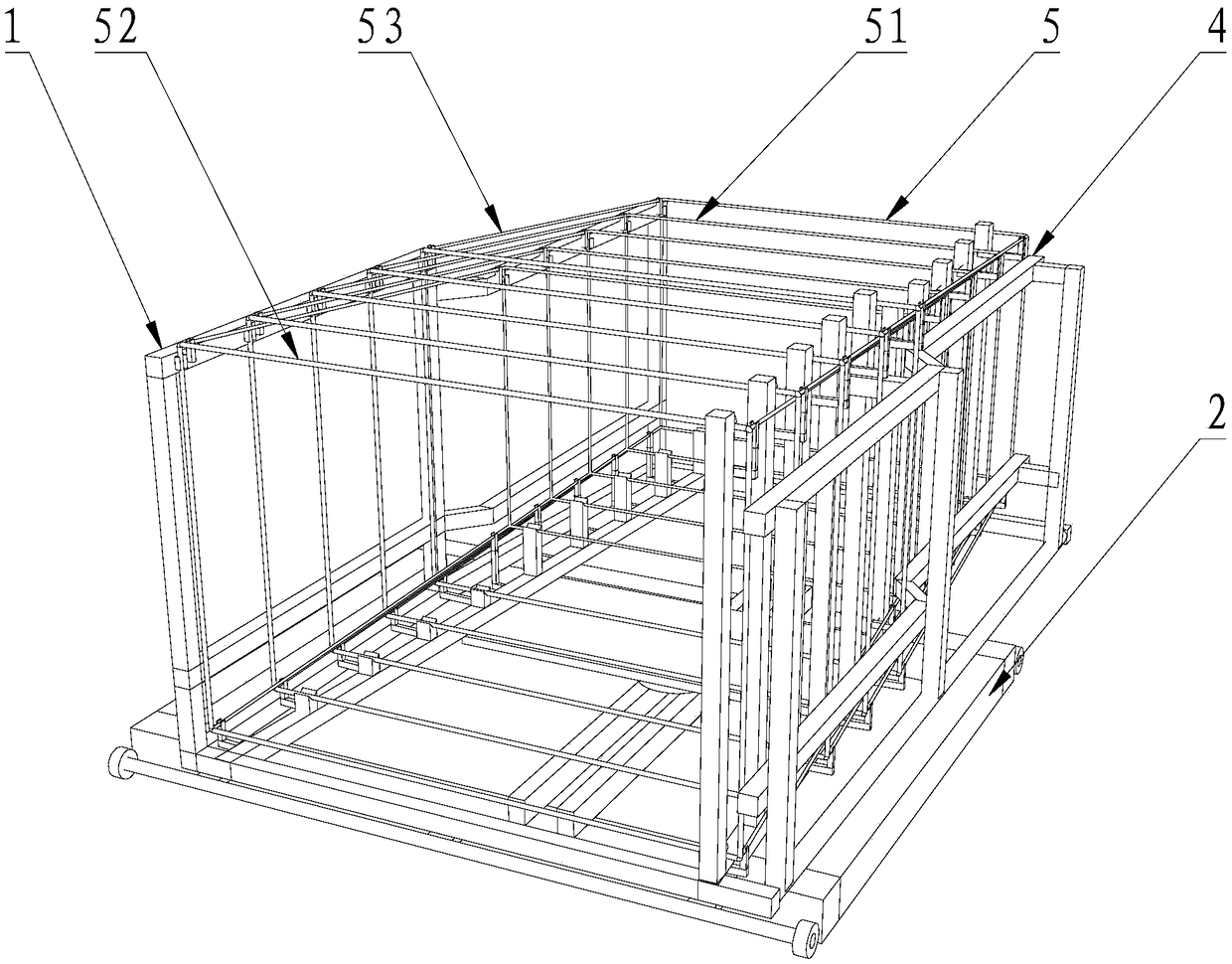

[0021] Please refer to Figure 1 to Figure 3 , a 360-degree rotating iron frame welding equipment, including an iron frame mounting frame, a movable frame and a fixed frame;

[0022] The top of the movable frame is provided with a turntable, and the bottom of the iron frame installation frame is erected on the turntable;

[0023] The top of the fixed frame is provided with a first slide rail, and the bottom of the movable frame is provided with a pulley matched w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com