Method for preparing coating on cutting blade

A technology for cutting blades and coatings, applied in coatings, metal material coating processes, gaseous chemical plating, etc., can solve problems such as coating delamination and loss of surface finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

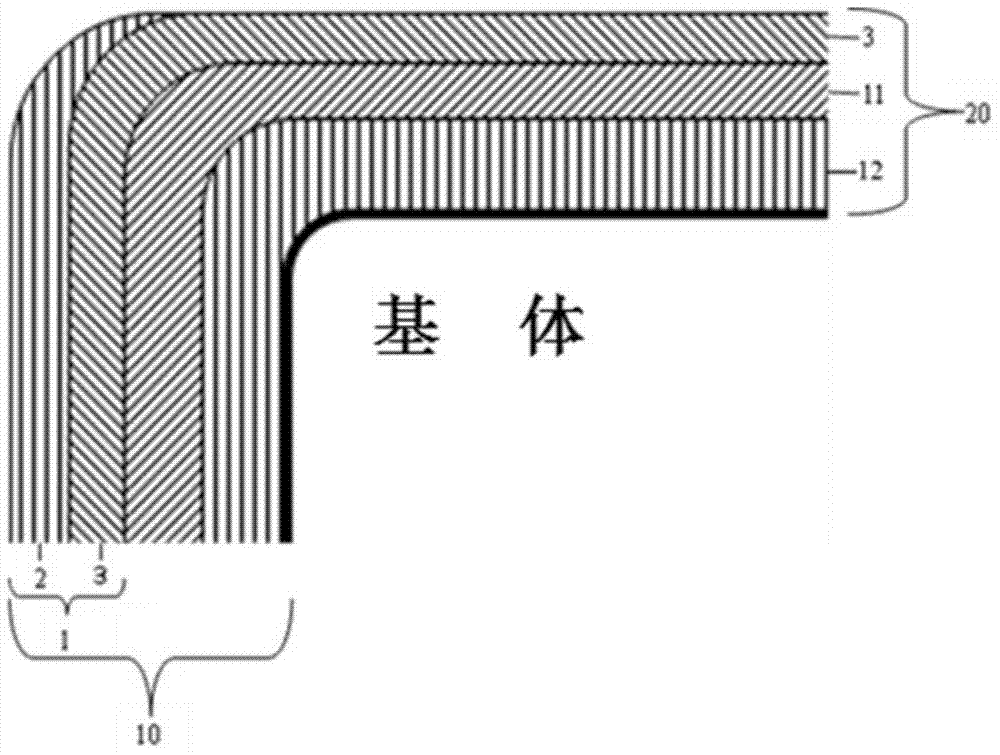

[0030] 1) Select the base of the cutting blade, which can be made of cemented carbide;

[0031] 2) Coating a TiN layer on the cutting blade substrate; the method of coating the TiN layer adopts a conventional CVD method, and the process gas of the method is TiCl 4 、H 2 and N 2 , by mass percent as TiCl 4 1.5%, N 2 38%, the balance is H 2 , the process conditions of the conventional CVD method are: pressure 100 mbar, temperature 940° C., time 60 min; the thickness of the TiN layer is 0.6 μm.

[0032] 3) Coating TiC x N y layer, where x≥0, y≥0, x+y=1; the coated TiC x N y The method of the layer adopts the MTCVD method, and the process gas of the method is TiCl 4 、H 2 , N 2 and CH 3 CN, TiCl by mass percentage 4 1.5%, CH 3 CN0.5%, N 2 5%, the balance is H 2 , the process conditions of the MTCVD method are: pressure 150mbar, temperature 900°C, time 300min; the TiC x N y The thickness of the layer is 10 μm.

[0033] 4) Deposition M 1 m 2 C x N y o z Transitio...

preparation Embodiment 2

[0038] 1) Select the base of the cutting blade, which can be made of cemented carbide;

[0039] 2) Coating a TiN layer on the cutting blade substrate; the method of coating the TiN layer adopts a conventional CVD method, and the process gas of the method is TiCl 4 、H 2 and N 2 , by mass percent as TiCl 4 1.0%, N 2 26%, the remainder is H 2 , the process conditions of the conventional CVD method are: pressure 60mbar, temperature 850°C, time 45min; the thickness of the TiN layer is 0.3μm.

[0040] 3) Coating TiC x N y layer, where x≥0, y≥0, x+y=1; the coated TiC x N y The method of the layer adopts the MTCVD method, and the process gas of the method is TiCl 4 、H 2 , N 2 and CH 3 CN, TiCl by mass percentage 4 1.0%, CH 3 CN0.2%, N 2 2%, the balance is H 2 , the process conditions of the MTCVD method are: pressure 100mbar, temperature 850°C, time 150min; the TiC x N y The thickness of the layer is 6 μm.

[0041] 4) Deposition M 1 m 2 C x N y o z Transition l...

preparation Embodiment 3

[0046] 1) Select the base of the cutting blade, which can be made of cemented carbide;

[0047] 2) Coating a TiN layer on the cutting blade substrate; the method of coating the TiN layer adopts a conventional CVD method, and the process gas of the method is TiCl 4 、H 2 and N 2 , by mass percent as TiCl 4 2.0%, N 2 38%, the balance is H 2 , the process conditions of the conventional CVD method are: pressure 150mbar, temperature 1000°C, time 70min; the thickness of the TiN layer is 0.9μm.

[0048] 3) Coating TiC x N y layer, where x≥0, y≥0, x+y=1; the coated TiC x N y The method of the layer adopts the MTCVD method, and the process gas of the method is TiCl 4 、H 2 , N 2 and CH3 CN, TiCl by mass percentage 4 3.0%, CH 3 CN1.0%, N 2 7%, the balance is H 2 , the process conditions of the MTCVD method are: pressure 200mbar, temperature 1000°C, time 350min; the TiC x N y The thickness of the layer was 14 μm.

[0049] 4) Deposition M 1 m 2 C x N y o z Transition ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com