Composite material of wooden base material and manufacture method thereof

A technology for wood base material and composite material, which is applied to the manufacturing field of the wood base material and polyurethane composite material, can solve the problems of high production cost, unfavorable productivity, thick composite layer thickness and the like, achieves high productivity and reduces production cost , the effect of small thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following is the best embodiment of a wood substrate and polyurethane composite material and its manufacturing method described in the present invention, which does not limit the protection scope of the present invention.

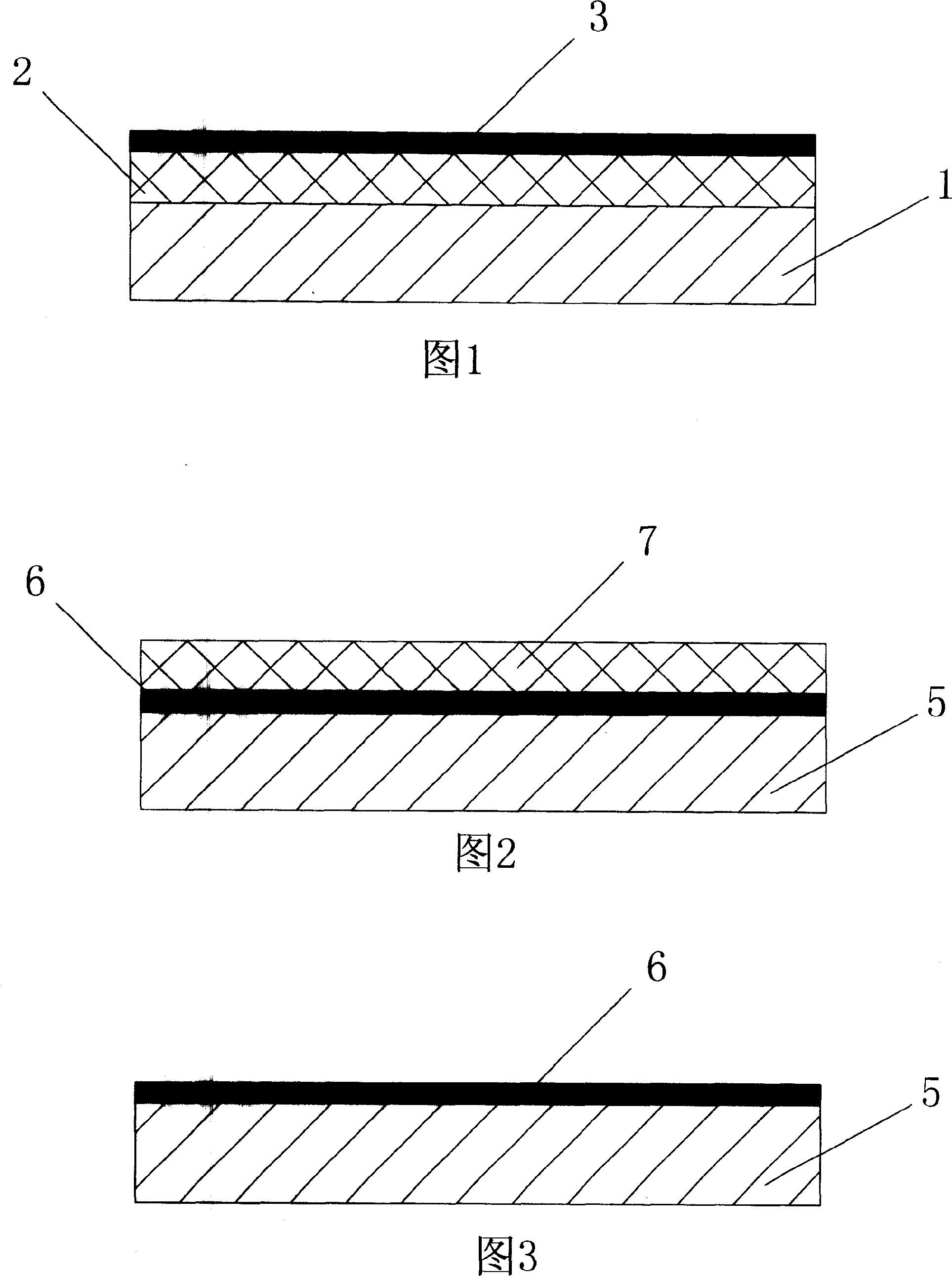

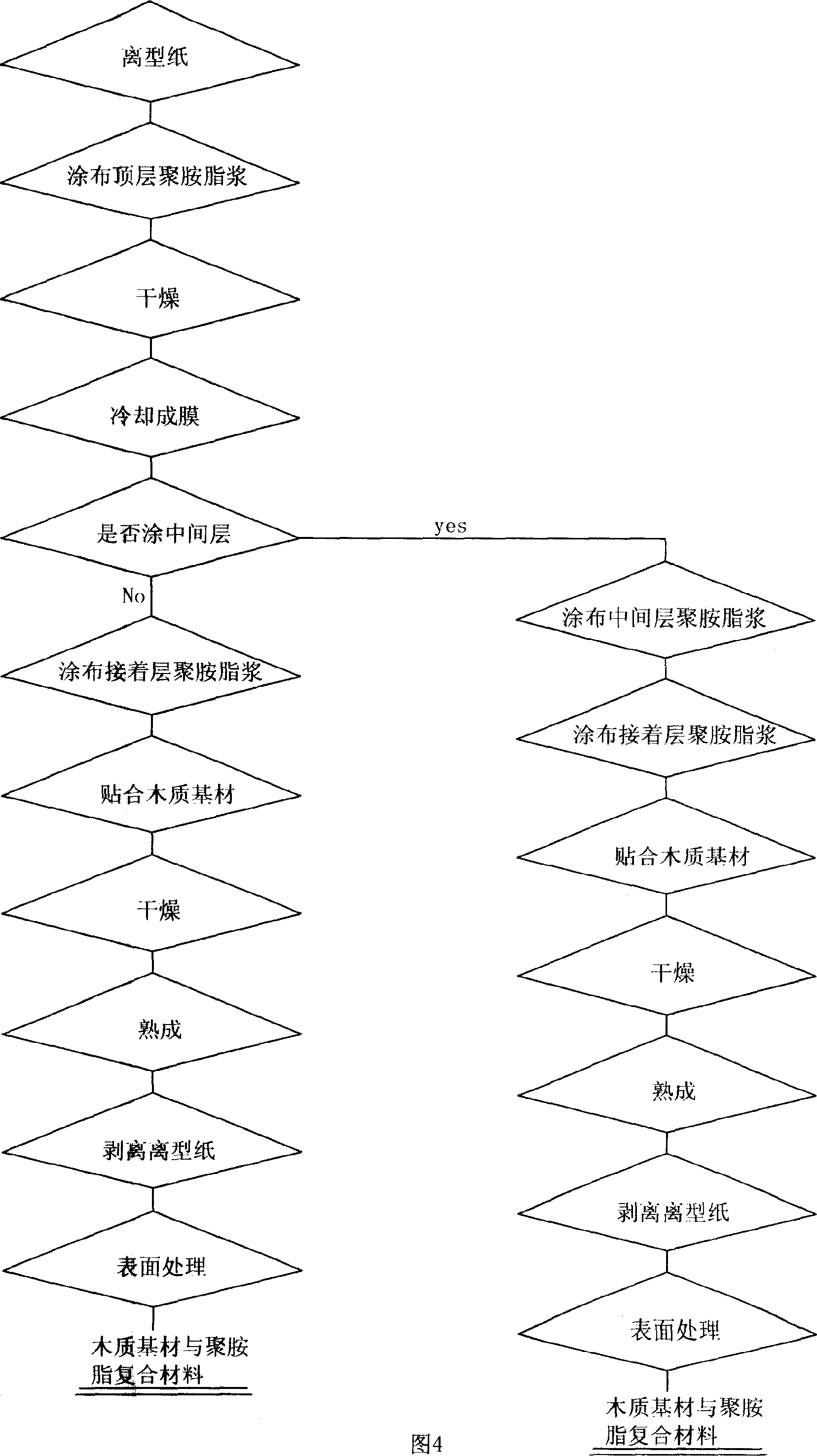

[0030] Implementation one, with reference to Fig. 2, Fig. 3, provide a kind of wooden base material and polyurethane composite material, comprise wooden base material 5, be provided with one layer at least on the surface of described wooden base material 5 by adding organic solvent, color Coating 6 is formed by coating polyurethane slurry with materials and additives. The coating 6 is formed by coating polyurethane slurry on the release paper 7 and pasting it on the wooden substrate 5, then drying and cooling, and peeling off the release paper 7 to form a coating on the surface of the wooden substrate 5. The composite layer of polyurethane is formed from the coating 6 described above.

[0031] Various patterns, patterns or characters are also tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com