Foaming device and continuous production line and production method of fiber reinforced foaming composite material

A composite material and fiber-reinforced technology, which is applied in the field of foaming devices for fiber-reinforced foamed composite materials, can solve problems that affect the interface strength between matrix materials and fiber materials, are difficult, and restrict the performance of composite materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be described in further detail below in conjunction with the accompanying drawings.

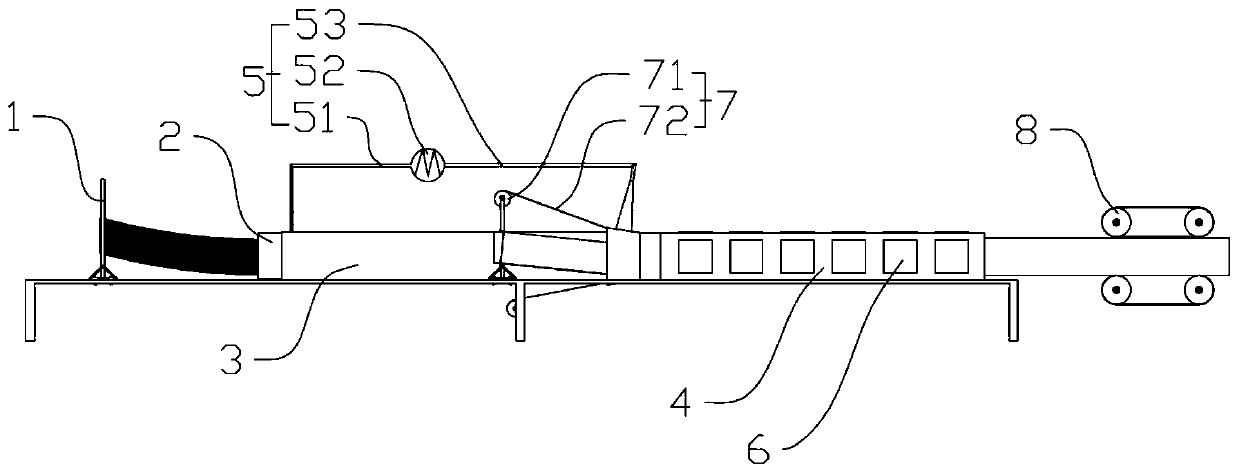

[0068] In order to realize the object of the present invention, can adopt following technical scheme, as figure 1 Shown, a continuous production line of fiber reinforced foam composites, including:

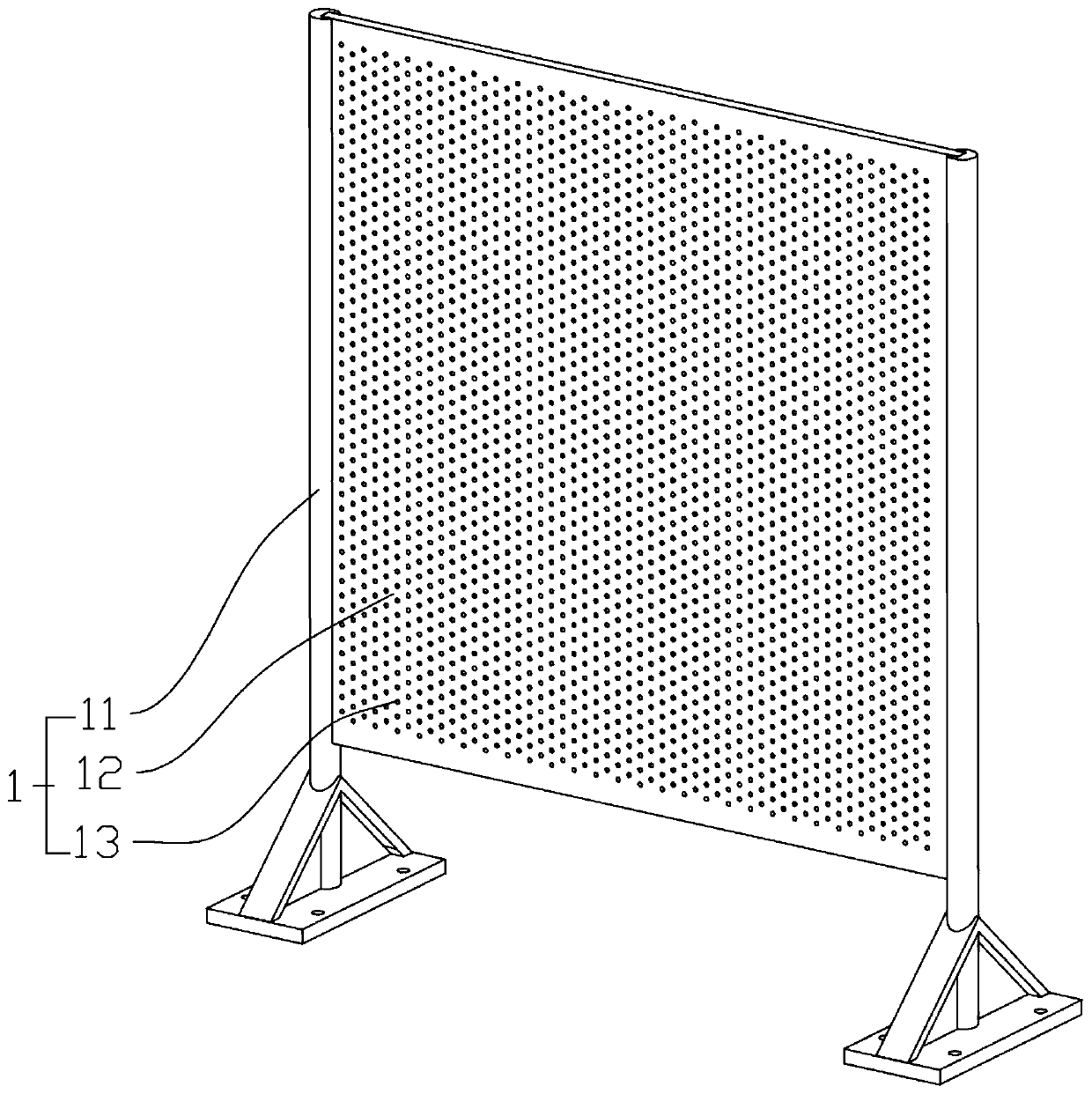

[0069] The distribution rack 1 is used for feeding the fiber material passing through the distribution rack 1 into the injection box in a distributed state.

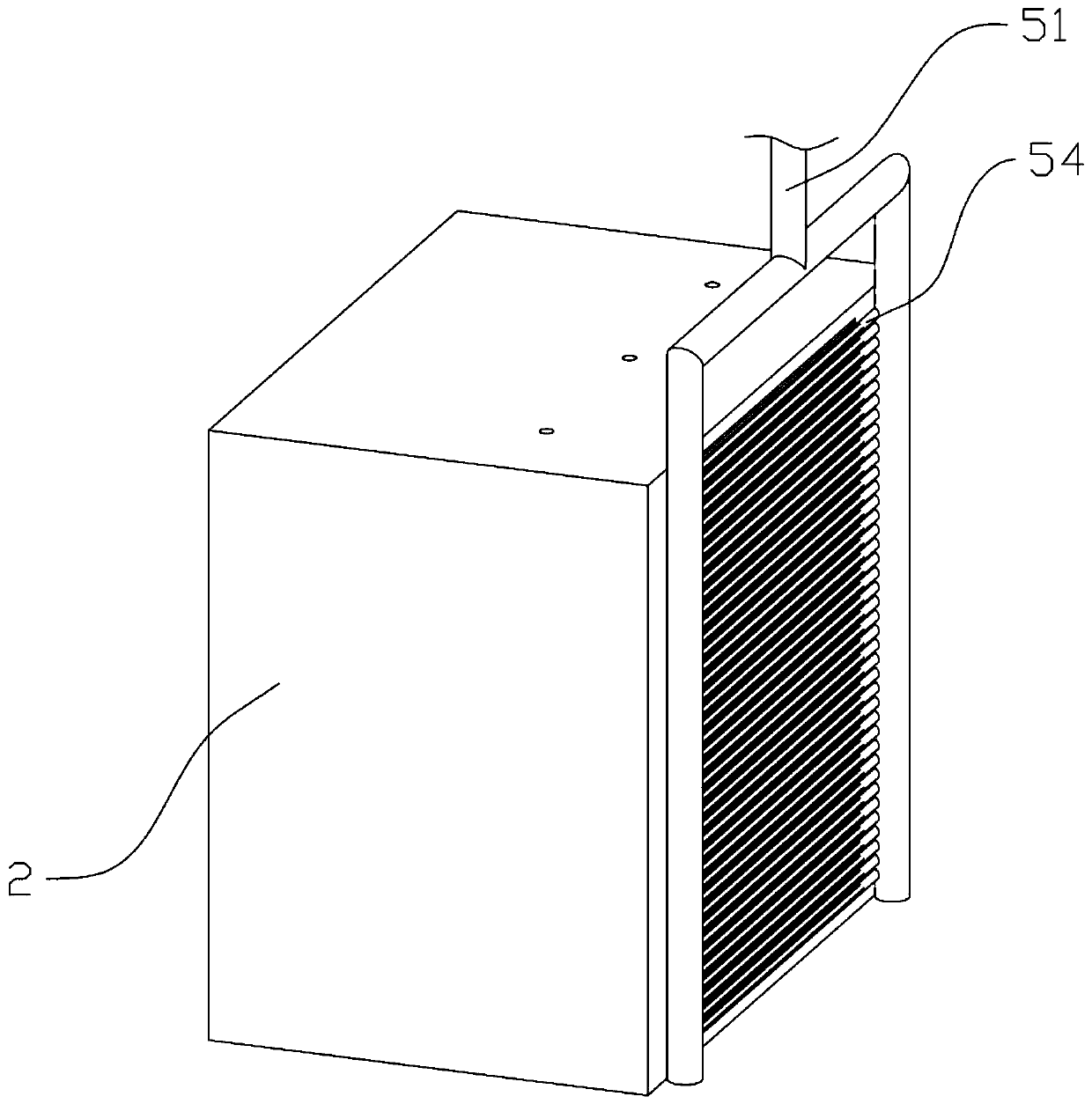

[0070]The glue injection box 2 includes a wetting channel 21 for impregnating the fiber material and a glue injection channel 22 for the liquid matrix material to enter the wetting channel 21, and the wetting channel 21 includes a feed port 211 for the fiber material to enter and a discharge port 212 for the composite material formed by impregnating the liquid matrix material with the fiber material to pass through, the area of the feed port 211 is greater than or equal to the area of the discharge por...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com