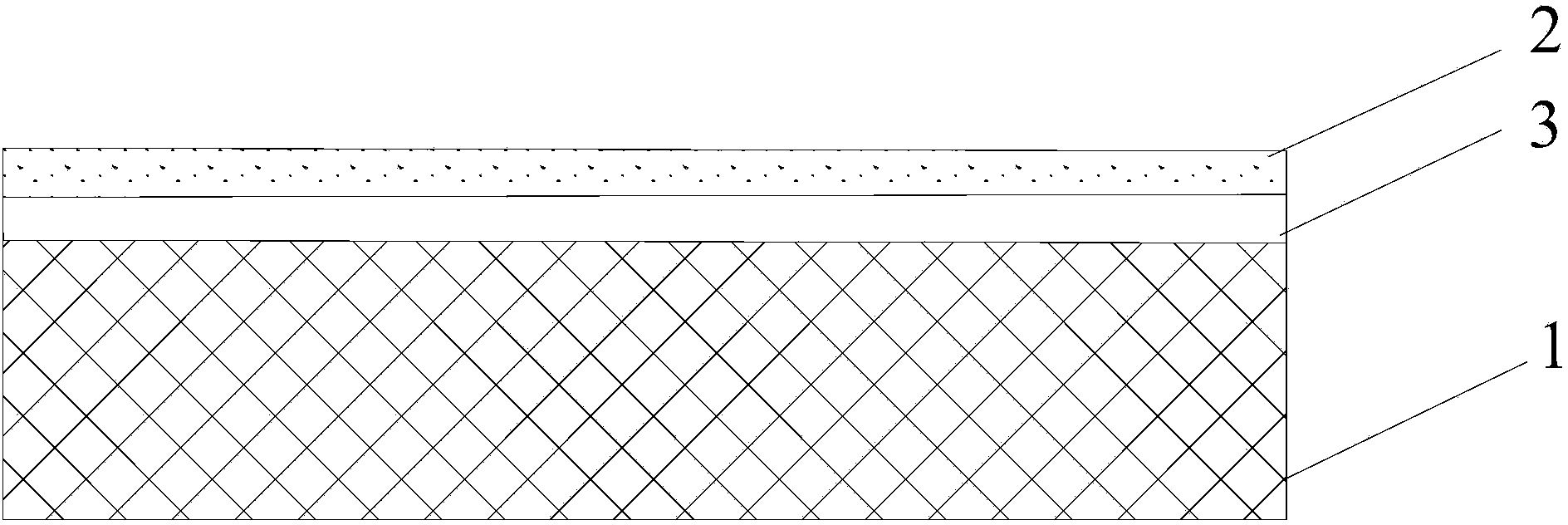

Soft stone compound insulation board

A composite thermal insulation and flexible technology, applied in the direction of synthetic resin layered products, hydraulic material layered products, layered products, etc., can solve the problems of complex preparation and difficult to meet the needs of beauty, and achieve stable quality and not easy to crack. , light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1) Using ordinary sand as raw material, after scrubbing and drying at 120°C for 5 hours, the sand contains no water at all, and the raw sand is screened to 20-200 mesh;

[0025] 2) 100 parts of raw sand, add 5 parts of binder phenolic resin (Shandong Shengquan Chemical Co., Ltd., coated sand phenolic resin) and 2 parts of iron oxide red pigment at a temperature of 120 ° C, and put it in a mortar mixer (model JJ -5) Stir evenly, cool and sieve to get the desired red colored sand;

[0026] 3) Mass parts of colored sand, polyurethane emulsion (PU), ultraviolet absorber UV-531, waterproofing agent (organic silicon waterproofing agent, purchased from Beijing Haiyan Xingye Concrete Additive Sales Co., Ltd.), flame retardant aluminum hydroxide Respectively 100 parts, 20 parts, 0.4 parts, 1.4 parts of waterproofing agent, 3 parts. Stir well. Put it in a mold frame of 0.4m×0.8m×0.002m and roll it into shape, and cure it after 24 hours at room temperature to obtain a flexible s...

Embodiment 2

[0030] 1) Using ordinary sand as raw material, after scrubbing and drying at 120°C for 5 hours, the sand contains no water at all, and the raw sand is screened to 20-200 mesh;

[0031] 2) 100 parts of raw sand, 5 parts of binder phenolic resin (Shandong Shengquan Chemical Co., Ltd., coated sand phenolic resin) and 0.5 part of iron oxide red pigment are added at a temperature of 120 ° C, and put in a mortar mixer (model JJ -5) Stir evenly, cool and sieve to get the desired red colored sand

[0032] 3) Mass parts of colored sand, polyurethane emulsion (PU), ultraviolet absorber UV-531, waterproofing agent (organic silicon waterproofing agent, purchased from Beijing Haiyan Xingye Concrete Additive Sales Co., Ltd.), flame retardant aluminum hydroxide Respectively 100 parts, 20 parts, 0.4 parts, 1.4 parts of waterproofing agent, 3 parts. Stir well. Put it in a mold frame of 0.4m×0.8m×0.0015m and roll it into shape, and cure it after 24 hours at room temperature to obtain a flexib...

Embodiment 3

[0036] According to the steps 1) to 3) of Example 2, the flexible surface material is prepared. During the interior decoration, the insulation board is laid first, and then a layer of epoxy resin adhesive is coated on the insulation board, and then the flexible surface material is laid, and it is left to stand for 24 hours. That's it.

[0037] The flexible stone composite thermal insulation board proposed by the present invention can be made into a product in a factory, and then used in a building, and can also be laid with a thermal insulation board when building decoration, and then the flexible surface material is bonded. Flexible application method

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com