Insulation decorative structure integrated assembly type external wall hanging board

A decorative structure and prefabricated technology, which is applied in building construction, covering/lining, construction, etc., can solve the problems of not being able to meet large quantities, large-scale, modern production, cumbersome construction steps, and low installation efficiency, so as to reduce construction costs. The effect of simplifying the process, simplifying the construction steps, and improving the installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

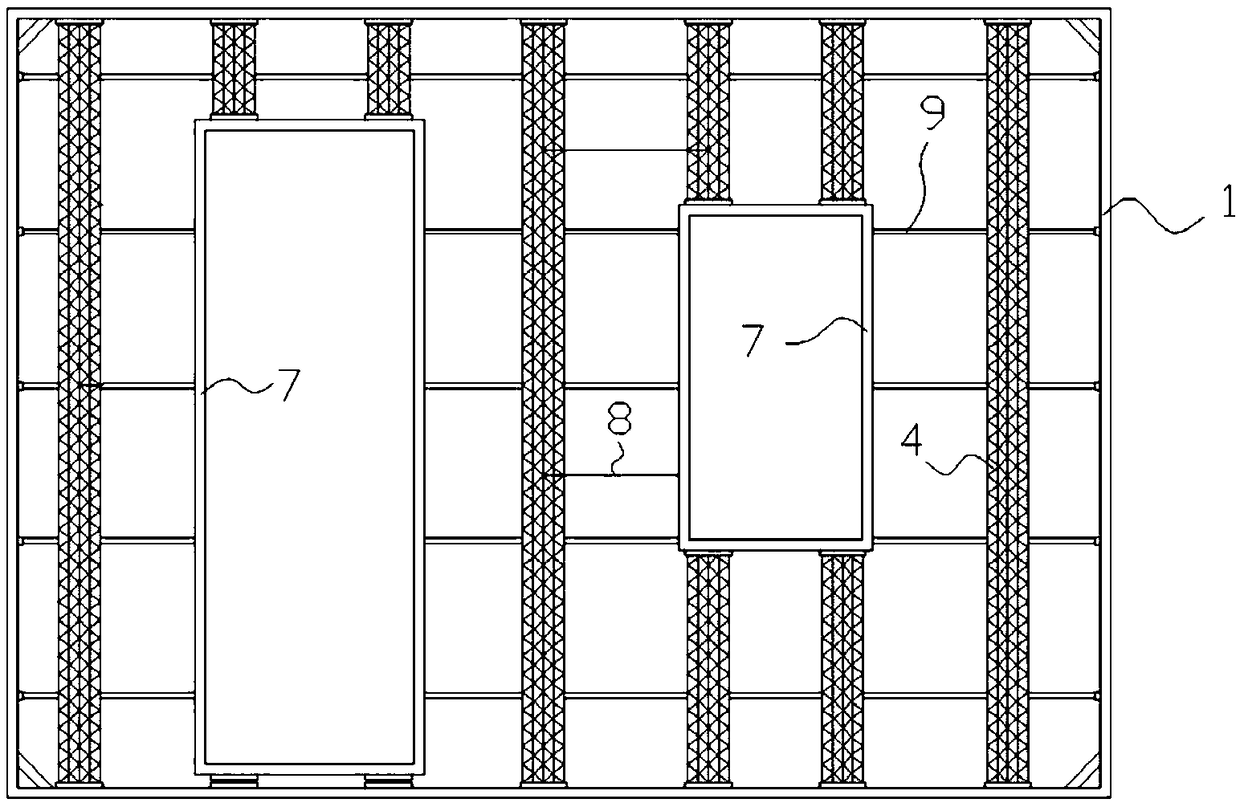

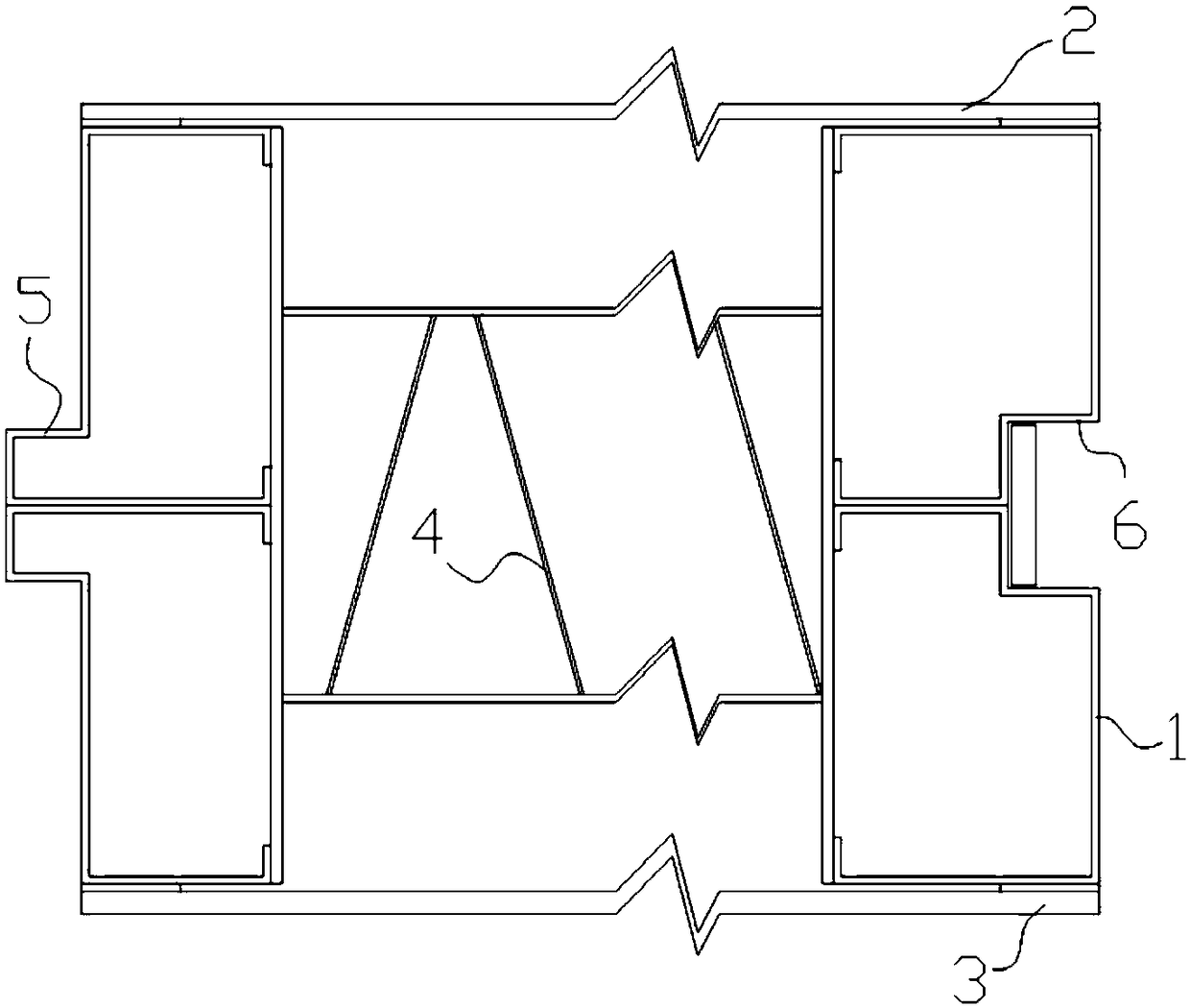

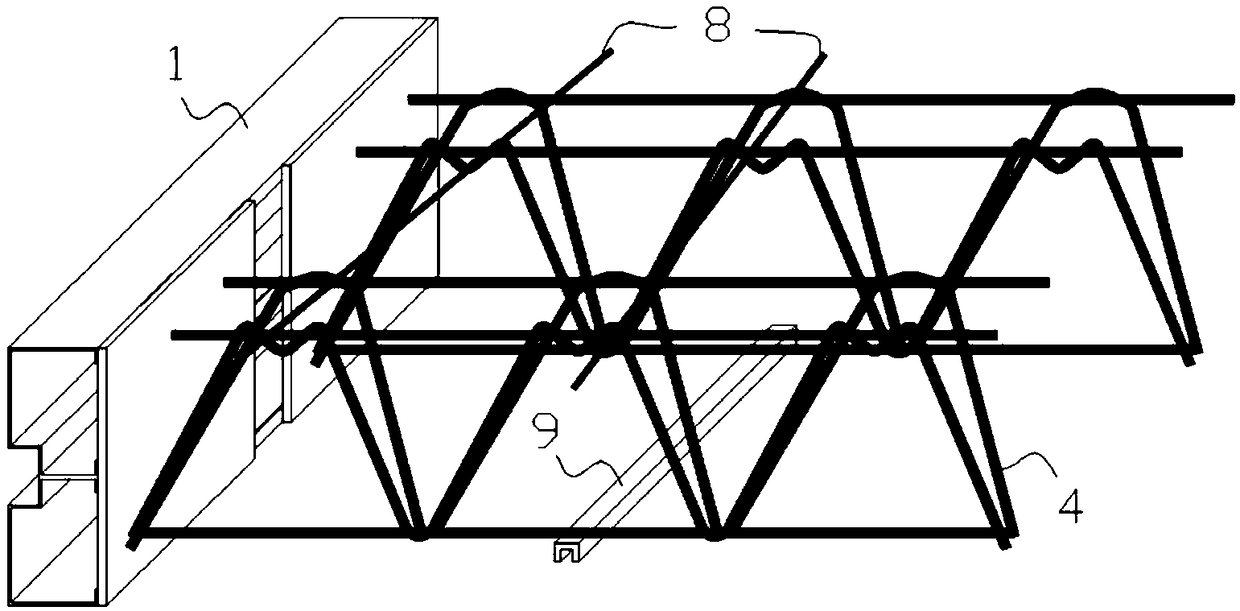

[0024] Such as figure 1 As shown, a thermal insulation and decorative structure integrated assembly type external wall hanging panel includes a truss 1, an upper plate 2, a lower plate 3, and a thermal insulation filling layer, wherein the longitudinal keel 4 is evenly arranged side by side in the truss, and the longitudinal keel 4 Reinforcing ribs 8 are arranged between the thermal insulation and filling layer, the upper and lower layers of the truss are connected to the upper and lower plates, and the three are connected by bonding or fixing. The characteristic is that the truss 1 is surrounded by a deformed C-shaped steel Composed of four side surfaces, two of the deformed C-shaped steel notches are connected side by side with a rib 5 or groove 6 facing inward. One side has a groove 6 and the other is opposite. The side surface has a convex rib 5 adapted to the groove 6; a door / window frame 7 is preset in the truss 1, and the upper and lower ends of the door / window frame 7 ar...

Embodiment 2

[0026] Such as Figure 4 As shown, one side of the thermal insulation and decorative structure integrated fabricated external wall hanging board is formed by connecting two deformed C-shaped steels side by side by connecting components 10, which are composed of fasteners 101 and self-tapping screws 102. The piece 101 is closely attached to the slot wing of the deformed C-shaped steel, and the two deformed C-shaped steels are connected side by side to form a side by a self-tapping screw 102. Due to the existence of the fastener 101, the impact of external stress on the truss can be buffered, and the deformation of the truss can be effectively prevented. The fastener 101 can be made of plate, steel, plastic steel, etc., and a plastic material is preferred here. At least one self-tapping screw 102 is used on each connecting assembly 10, which can be selected according to factors such as the size and strength of the self-tapping screw 102. Use more than one connecting assembly 10 ...

Embodiment 3

[0028] Such as Figure 5 As shown, at the convex and concave parts of the connecting ends of adjacent external wall hanging panels, that is, the bottom of the groove 6 on the side of the truss, the Ω sealing ring 11 is bonded. The Ω seal 11 is generally a tube body 111 with a side plate 112. The outer surface of the tube body 111 has two notches at the lowest end of the tube body 111, and the two notched ends of the outer surface of the tube body 111 respectively extend outwards. The width of the side plate 112 is adapted to the width of the groove 6. The bottom surface of the side plate 112 has viscous material. When needed, the viscous material on the bottom surface of the side plate 112 is exposed and pasted on the bottom of the groove 6. When the adjacent external wall hanging boards are installed, the rib 5 and the groove 6 are jointed with each other. The rib 5 first touches the tube body 111 of flexible material. As the jointing progresses, the tube body 111 of the Ω seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com