Passive humidity control organic-inorganic composite film and preparation method thereof

An inorganic composite membrane, passive technology, applied in the field of air dehumidification, can solve problems such as energy consumption, and achieve the effect of improving quality, stable performance and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

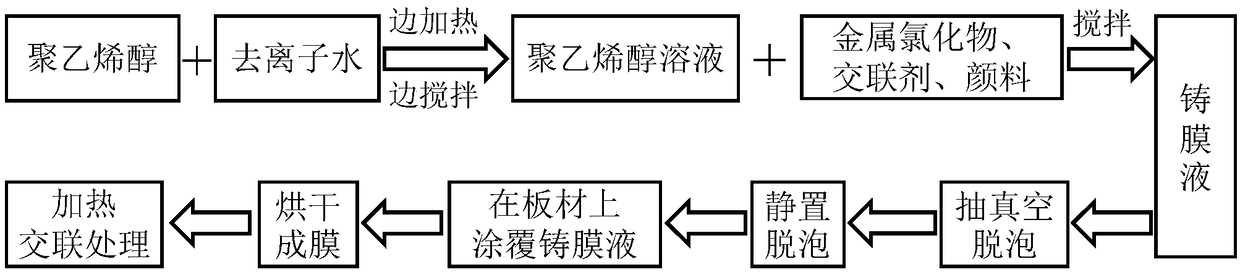

Method used

Image

Examples

Embodiment 1

[0025] Take 200ml of deionized water, and dissolve 10 parts of polyvinyl alcohol in deionized water at room temperature. After the polyvinyl alcohol is completely dispersed, the solution is heated while stirring, and the heating temperature is 90°C. After the polyvinyl alcohol is completely dissolved, the temperature drops to 30°C. Add 1 part of oxalic acid, 1 part of calcium chloride, and 1 part of chrome yellow into the polyvinyl alcohol solution, and stir while heating until the mixture is uniform. The casting solution was placed in a vacuum oven with a temperature of 30° C. and a vacuum of 50 Pa for 2 hours of vacuum degassing. Then put the casting solution after evacuation in a reagent bottle and place it under room temperature for 1 hour for defoaming for later use. Subsequently, the casting solution is manually coated on the metal plate, and then the metal plate coated with the casting solution is placed in a constant temperature and humidity box, the temperature is set...

Embodiment 2

[0028] Take 200ml of deionized water, and dissolve 15 parts of polyvinyl alcohol in deionized water at room temperature. After the polyvinyl alcohol is completely dispersed, the solution is heated while stirring, and the heating temperature is 93°C. After the polyvinyl alcohol is completely dissolved, the temperature drops to 42°C. Add 5 parts of boric acid, 5 parts of sodium chloride, and 5 parts of iron oxide yellow into the polyvinyl alcohol solution, and stir while heating until they are evenly mixed. The casting solution was placed in a vacuum oven with a temperature of 45° C. and a vacuum degree of 75 Pa for 1.25 hours of vacuum degassing. Then put the vacuumized casting solution in a reagent bottle and leave it at room temperature for 5.5 hours for degassing for later use. Then use a laboratory small-scale coating machine to coat the casting solution on the metal plate, and then place the metal plate coated with the casting solution in a constant temperature and humidit...

Embodiment 3

[0031] Take 200ml of deionized water, and dissolve 20 parts of polyvinyl alcohol in deionized water at room temperature. After the polyvinyl alcohol is completely dispersed, the solution is heated while stirring, and the heating temperature is 95°C. After the polyvinyl alcohol is completely dissolved, the temperature drops to 55°C. Add 10 parts of citric acid, 10 parts of lithium chloride, and 10 parts of iron oxide green into the polyvinyl alcohol solution, and stir while heating until they are evenly mixed. The casting solution was placed in a vacuum oven with a temperature of 60° C. and a vacuum of 100 Pa for 0.5 hours of vacuum degassing. Then put the vacuumized casting solution in a beaker and seal the mouth of the beaker with a plastic wrap and place it at room temperature for 10 hours for degassing for later use. Subsequently, the casting solution is manually coated on a glass plate, and then the glass plate coated with the casting solution is placed in a constant tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com