Metal electrode plate suitable for electrolyzing water vapor by electrolyte membrane

A metal electrode and electrolyte membrane technology, applied in electrodes, electrode coatings, electrolytic components, etc., can solve the problems of full contact of reactants with difficult membrane electrodes, uneven internal potential distribution, easy occurrence of hot spots and dry spots, etc. Performance requirements, uniformity improvement, effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

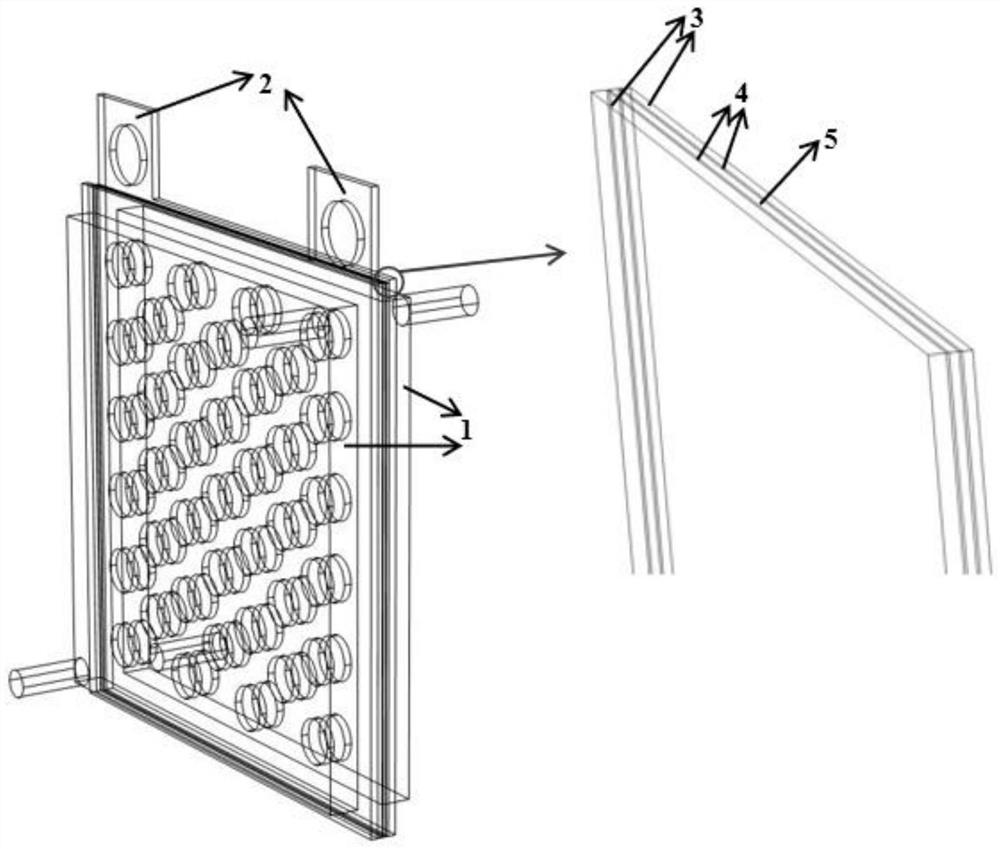

[0033] The present invention provides a metal electrode plate suitable for electrolysis of water vapor by an electrolyte membrane. The metal plate provides necessary reaction potential and mechanical properties for the electrolysis reaction, and the through hole provides a transmission channel for water (water vapor) to reach the surface of the catalytic layer, And to promote heat and mass transfer between the electrolyte membrane and water (water vapor), the metal electrode plate includes a metal plate 10 and a terminal 20, the terminal 20 is fixed on the metal plate 10; the metal plate 10 is provided with one or more The through hole 30 is used to form a fluid domain. The area of the fluid domain formed by the through hole 30 is 54% of the area of the metal plate. When opening a plurality of through holes, the through holes are evenly arranged on the metal plate or around the center point of the metal plate. Radiated distribution. The metal plate supports the through hol...

Embodiment 2

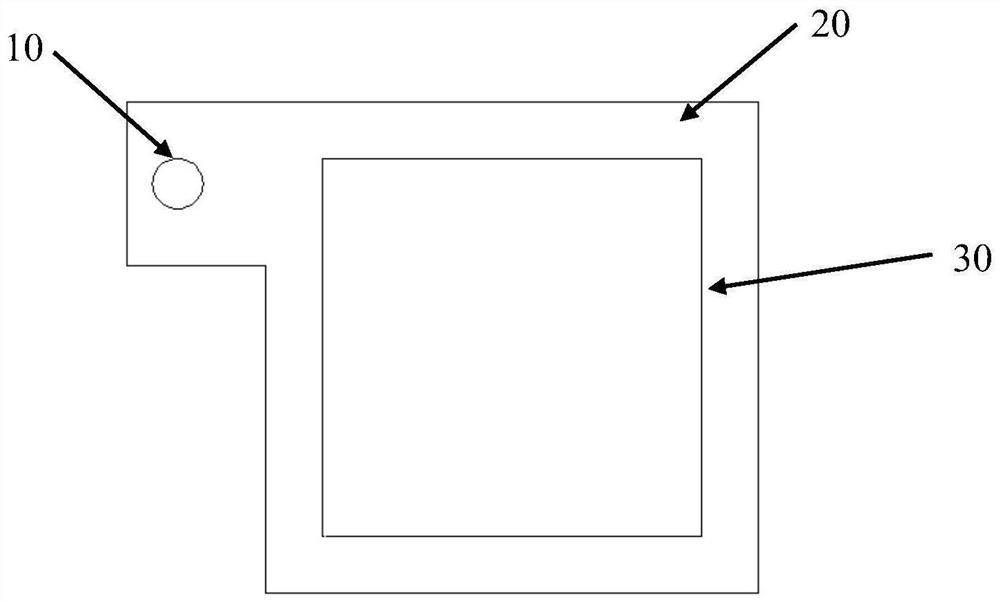

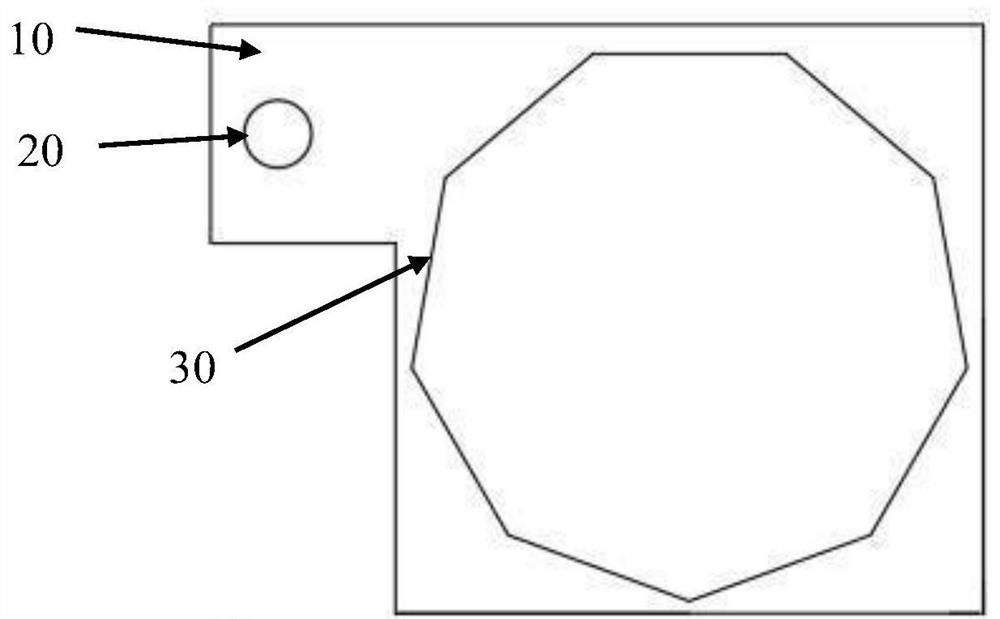

[0035] In order to optimize the system performance, the figure 2 and image 3 The new type of metal electrode plate structure, a through hole is opened in the center of the metal electrode plate to increase the fluid domain area of the metal electrode plate. in the center of the electrode plate with image 3Taking the new electrode plate structure shown as an example, a square through hole is opened in the center of the metal electrode plate. Figure 4 The through-holes opened on the metal electrode plate are polygonal. Compared with the original metal electrode plate structure, the new metal electrode plate structure increases the area of the fluid domain by 1 to 2.5 times, increases the air transport area for the reactant (water vapor) to reach the interface of the catalyst layer, and improves the heat transfer of the membrane electrode. Mass transfer improves system performance and improves the uniformity of temperature and humidity distribution inside the solid ele...

Embodiment 3

[0040] Since the new metal electrode plate structure makes the potential distribution inside the module uneven, further proposed such as Figure 4 and Figure 5 The shown metal electrode plate structure has a plurality of through holes radiating from the center point of the metal electrode plate. by Figure 5 Taking the metal electrode plate 2 suitable for the electrolysis of water vapor system as an example, the current density at the inner center and diagonal positions of the metal electrode plate is relatively low. Therefore, the metal electrode plate 2 of this embodiment retains the metal plate at the diagonal positions, and a plurality of through holes are arranged in an "X" shape on the metal electrode plate 2, which improves the potential distribution in the center and diagonal positions of the module. , the water electrolysis rate on the anode side is improved, and the system performance is optimized. The results are as follows:

[0041] It can be seen from Table 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com