Antibacterial mildew-proof high-strength whitewash mortar

An antibacterial, mildew-proof, high-strength technology, which is applied in the field of antibacterial, mildew-proof and high-strength plaster mortar, can solve the problems that the strength and water resistance cannot meet the specific construction requirements, and the lack of bottom-layer anti-mold products, etc., to achieve high flexural and compressive strength , good stability and strength, strong adhesive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

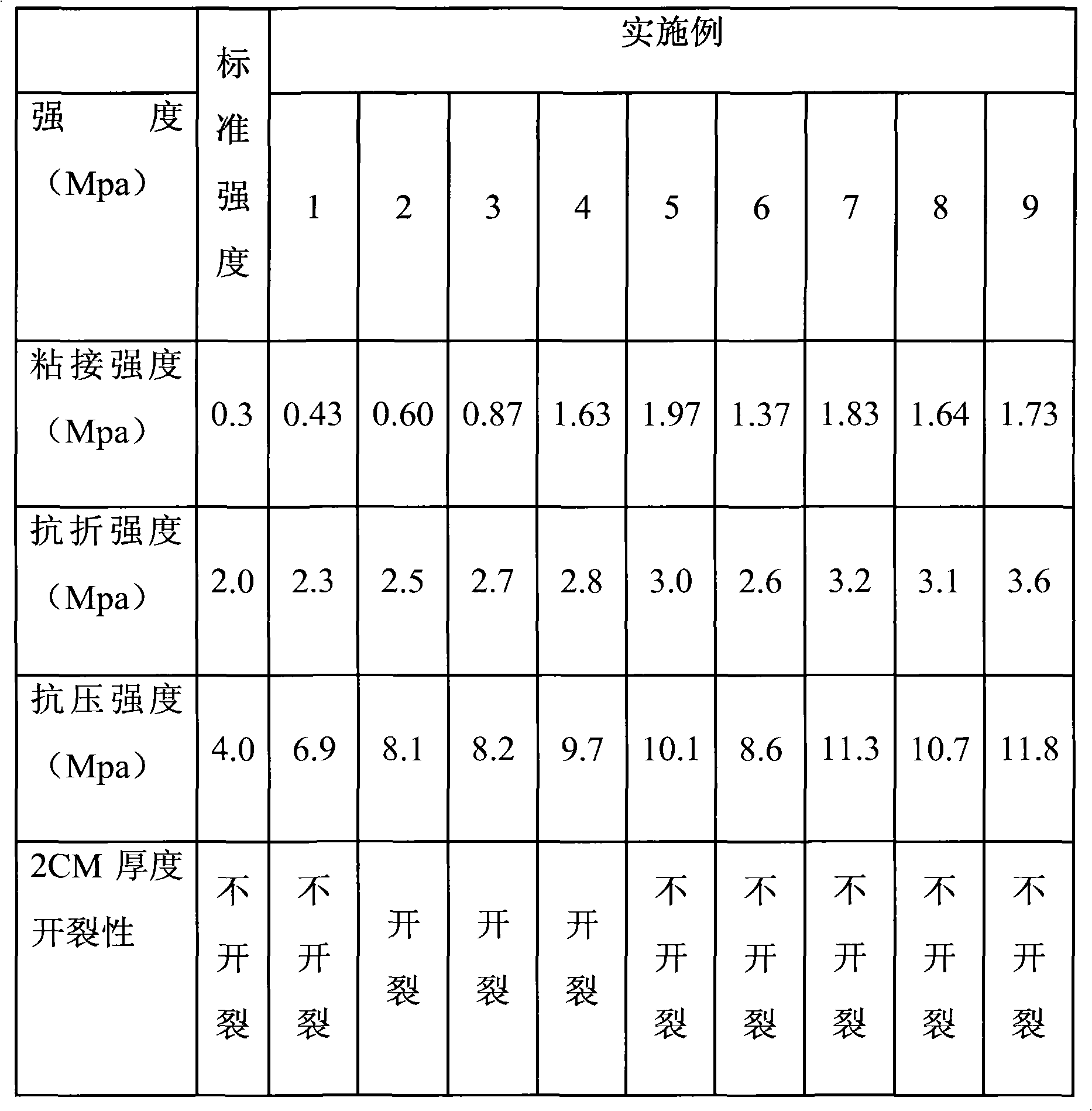

Examples

Embodiment 1

[0042] The weight ratio of each component:

[0043] Portland black cement 325 No. 50,

[0044] fly ash 50,

[0045] blast furnace slag 80,

[0046] α-type building plaster 230,

[0047] Quartz sand 500,

[0048] Nano antibacterial and antifungal agent 30,

[0049] Conditioner 3,

[0050] Inorganic gel 5,

[0051] retarder 3,

[0052] Anti-crack agent 2.

[0053] Mix with non-gravity double flying knife mixing equipment to prepare mildew-proof plaster mortar.

Embodiment 2

[0055] The weight ratio of each component:

[0056] Portland black cement No. 325 80,

[0057] fly ash 100,

[0058] Blast Furnace Slag 100,

[0059] α-type building plaster 80,

[0060] Quartz sand 550,

[0061] Nano antibacterial and antifungal agent 30,

[0062] Regulator 3,

[0063] Inorganic gel 5,

[0064] retarder 3,

[0065] anti-cracking agent 2,

[0066] Redispersible rubber powder 5.

[0067] Mix with non-gravity double flying knife mixing equipment to prepare mildew-proof plaster mortar.

Embodiment 3

[0069] The weight ratio of each component:

[0070] Portland black cement No. 325 100,

[0071] fly ash 50,

[0072] blast furnace slag 120,

[0073] α-type building plaster 100,

[0074] Quartz sand 630,

[0075] Nano antibacterial and antifungal agent 30,

[0076] Regulator 3,

[0077] Inorganic gel 5,

[0078] retarder 3,

[0079] anti-cracking agent 2,

[0080] Redispersible rubber powder 10.

[0081] Mix with non-gravity double flying knife mixing equipment to prepare mildew-proof plaster mortar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com